Abstract

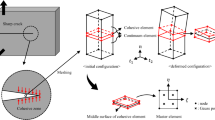

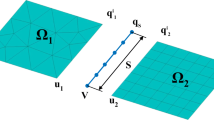

An semi-analytical formulation based on the cohesive crack model is proposed to describe the phenomenon of fatigue crack growth along an interface. Since the process of material separation under cyclic loading is physically governed by cumulative damage, the material deterioration due to fatigue is taken into account in terms of interfacial cohesive properties degradation. More specifically, the damage increment is determined by the current separation and a history variable. The damage variable is introduced into the constitutive cohesive crack law in order to capture the history-dependent property of fatigue. Parametric studies are presented to understand the influences of the two parameters entering the damage evolution law. An application to a pre-cracked double-cantilever beam is discussed. The model is validated by experimental data. Finally, the effect of using different shapes of the cohesive crack law is illustrated

Similar content being viewed by others

References

ASTM G 168 (2000) Standard practice for making and using precracked double beam stress corrosion specimens. ASTM Annual Book of ASTM Standards, vol 03.02

Bouvard JL, Chaboche JL, Feyel F, Gallerneau F (2009) A cohesive zone model for fatigue and creep-fatigue crack growth in single crystal superalloys. Int J Fatigue 31: 868–879

Carpinteri A (1985) Interpretation of the Griffith instability as a bifurcation of the global equilibrium. In: Shah S (ed) Application of fracture mechanics to cementitious composites (Proceedings of NATO advanced research workshop, Evanston, USA). Martinus Nijhoff, Dordrecht, pp 287–316

Carpinteri A, Di Tommaso A, Fanelli M (1985) Influence of material parameters and geometry on cohesive crack propagation. In: Wittmann FH (ed) Fracture toughness and fracture energy of concrete. Elsevier, Amsterdam, pp 117–135

Carpinteri A, Paggi M, Zavarise G (2008) The effect of contact on the decohesion of laminated beams with multiple microcracks. Int J Solids Struct 45: 129–143

Chaboche JL, Lesne PM (1988) A non-linear continuous fatigue damage model. Fatigue Fract Eng Mater Struct 11: 1–7

Chaboche JL (1988) Continuum damage mechanics: part I-general concepts. J Appl Mech 55: 59–64

Chaboche JL (1988) Continuum damage mechanics: part II-Damage growth, crack initiation, and crack growth. J Appl Mech 55: 65–72

Cornetti P, Pugno N, Carpinteri A, Taylor D (2006) Finite fracture mechanics: a coupled stress and energy failure criterion. Eng Fract Mech 73: 2021–2033

de-Andrés A, Pérez JL, Ortiz M (1999) Elastoplastic finite element analysis of three-dimensional fatigue crack growth in aluminum shafts subjected to axial loading. Int J Solids Struct 36: 2231–2258

Dowling NE, Begley JA (1976) Fatigue crack growth during gross plasticity and the J-integral. ASTM STP 590: 82–103

Elices M, Planas J, Guinea GV (2000) Fracture mechanics applied to concrete. In: Freutes M, Elices M, Martin-Meizoso A, Martmez-Esnaola JM (eds) Fracture mechanics: applications and challenges. ESIS publication 26. Elsevier, Amsterdam

Hertzberg RW (1995) Deformation and fracture mechanics of engineering materials. Wiley, New York

Kachanov LM (1958) On the time to failure under creep conditions. Izvestia Akademii Nauk SSSR, Otdelenie tekhnicheskich nauk 8: 26–31

Krajcinovich D (1984) Continuum damage mechanics. Appl Mech Rev 37: 1–6

Lemaitre J, Plumtree A (1979) Application of damage concept to predict creep-fatigue failures. ASME J Eng Mater Technol 101(3): 284–292

Lemaitre J (1996) A course on damage mechanics. Springer, Berlin

Leguillon D (2002) Strength or toughness? A criterion for crack onset at a notch. Eur J Mech A/Solids 21: 61–72

Maiti S, Geubelle PH (2005) A cohesive model for fatigue failure of polymers. Eng Fract Mech 72: 691–708

Maiti S, Geubelle PH (2006) Cohesive modelling of fatigue crack retardation in polymers: crack closure effect. Eng Fract Mech 73: 22–41

Mostovoy S, Ripling EJ (1975) Flaw tolerance of a number of commercial and experimental adhesives. Plenum Press, New York

Neumann P (1974) The geometry of slip processes at a propagating fatigue crack-II. Acta Metal 22: 1167–1178

Needleman A (1990) An analysis of tensile decohesion along an interface. J Mech Phys Solids 38: 289–324

Needleman A (1990) An analysis of decohesion along an imperfect interface. Int J Fract 42: 21–40

Nguyen O, Repetto EA, Ortiz M, Radovitzky RA (2001) A cohesive model of fatigue crack growth. Int J Fract 110: 351–369

Paris PC, Gomez MP, Anderson WP (1961) A rational analytic theory of fatigue. Trend Eng 13: 9–14

Pirondi A, Nicoletto G (2004) Fatigue crack growth in bonded DCB specimens. Eng Fract Mech 71: 859–871

Roe KL, Siegmund T (2003) An irreversible cohesive zone model for interface fatigue crack growth simulation. Eng Fract Mech 70: 209–232

Suo Z, Bao G, Fan B (1992) Delamination R-curve phenomena due to damage. J Mech Phys Solids 40: 1–16

Skibo MD, Hertzberg RW, Manson JA, Kim SL (1977) On the generality of discontinuous fatigue crack growth in glassy polymers. J Mater Sci 12: 531–542

Taylor D, Cornetti P, Pugno N (2005) The fracture mechanics of finite crack extension. Eng Fract Mech 72: 1021–1038

Wang J (1992) A continuum damage mechanic model for low-cycle fatigue failure of metals. Eng Fract Mech 41: 437–441

Wang T, Lou Z (1990) A continuum damage model for weld heat affected lone under low cycle fatigue loading. Eng Fract Mech 37: 825–829

Williams J, Hadavinia H (2002) Analytical solutions for cohesive zone models. J Mech Phys Solids 50: 809–825

Xu XP, Needleman A (1993) Void nucleation by inclusion debonding in a crystal matrix. Model Simul Mater Sci Eng 1: 111–132

Yang B, Mall S, Ravi-Chandar K (2001) A cohesive zone model for fatigue crack growth in quasibrittle materials. Int J Solids Struct 38: 3927–3944

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gong, B., Paggi, M. & Carpinteri, A. A cohesive crack model coupled with damage for interface fatigue problems. Int J Fract 173, 91–104 (2012). https://doi.org/10.1007/s10704-011-9666-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-011-9666-y