Abstract

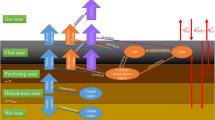

This paper reports on two experiments conducted in a fire resistance furnace to study the differences in the boundary conditions, the fire dynamics and the fuel required to run the furnace when a combustible timber specimen as opposed to a non-combustible concrete specimen is tested. In both experiments measurements were taken in the furnace to evaluate the difference in the environments of the furnace and the response of the elements being tested. These include non-control plate thermometers distributed throughout the furnace; O2, CO2 and CO gas measurements taken at different distances from the specimen surface and in the furnace exhaust; instrumentation of one of the bricks comprising the furnace lining with thermocouples at different depths from the exposed surface; and mass loss of the combustible timber specimen. Thermal exposure of elements in a furnace is discussed, as well as the impact of the different materials on the similarity of thermal exposure. This is done through analysis and discussion of the different measurements taken and the apparent influence of the specimen being tested on the boundary condition of the heat diffusion equation. We conclude that; (1) the fire dynamics in a furnace are dependent on the specimen being tested; (2) that the test with the combustible specimen requires less fuel flow to the burners such that the control plate thermometers follow the ISO 834 temperature–time curve compared to the non-combustible specimen, however that this is not only a result of the combustibility of the specimen but is also a consequence of the different thermal inertia of the two materials; (3) that the boundary condition for heat transfer to a test object in furnace tests is dependent on the properties of the specimen being tested; and (4) that the timber when placed on the furnace experiences smouldering combustion after the char layer has formed. A fire resistance test of combustible construction of a given period represents a significantly less onerous test in terms of energy absorbed or fuel made available than one of a non-combustible construction, implying that the existing fire resistance framework may not be appropriate for timber structures and that an alternative approach may be required.

Similar content being viewed by others

References

Brock Commons Tallwood House. https://www.naturallywood.com/emerging-trends/tall-wood/brock-commons-tallwood-house. Accessed 21 March 2018

Australia’s tallest engineered timber office building opens. https://architectureau.com/articles/australias-tallest-engineered-timber-office-building-opens/. Accessed 13 June 2019

Mjøstårnet. https://www.moelven.com/mjostarnet/. Accessed 13 June 2019

Shoparc 475 West 18th. http://www.shoparc.com/projects/475-west-18th/. Accessed 21 March 2018

Lever architecture, framework. https://leverarchitecture.com/projects/framework. Accessed 21 March 2018

SHoP architects’ wooden skyscraper for New York gets the chop. https://www.dezeen.com/2017/03/15/shop-architects-wooden-skyscraper-chelsea-new-york-gets-the-chop/. Accessed 13 June 2019

Framework tall wood tower in Portland gets the chop. https://www.treehugger.com/green-architecture/framework-tall-wood-tower-portland-gets-chop.html. Accessed 13 June 2019

Carbon 12. https://carbon12pdx.com/. Accessed 13 June 2019

Møller CF (2013) Wooden skyscraper. http://www.cfmoller.com/r/Wooden-Skyscraper-i13265.html. Accessed 21 March 2018

PLP architecture, Oakwood timber tower. https://www.plparchitecture.com/oakwood-timber-tower.html. Accessed 21 March 2018

ISO—The International Organisation for Standardisation (1999) ISO 834-1:1999, fire-resistance tests—elements of building construction—part 1: general requirements

Thomas PH (1970) The fire resistance required to survive burnout—Fire Research Note No. 901, Borehamwood

Robertson AF, Gross D (1970) Fire load, fire severity, and fire endurance; fire test performance. In: ASTM STP 464. American society for testing and materials, pp 3–29

Bergman TL, Lavine AS, Incropera FP., Dewitt DP (2016) Fundamentals of heat and mass transfer, (8th edn). ISBN: 9781118989173

Torero J, Law A, Maluk C (2017) Defining the thermal boundary condition for protective structures in fire engineering structures. https://doi.org/10.1016/j.engstruct.2016.11.015

Wickström U (1994) The plate thermometer—a simple instrument for reaching harmonized fire resistance tests. Fire Technol 30:195. https://doi.org/10.1007/BF01040002

Emmons HW (1967) Fire research abroad. Fire Technol 3:225–231

Olsson S (1993) Calibration of fire resistance furnaces with plate thermometers. Commission of the European Communities, BCR Information, Report EUR 14555 EN, Luxembourg

Ingason H, Wickström U (2007) Measuring incident radiant heat flux using the plate thermometer. Fire Saf J 42(2):161–166

Wickstrom U, Anderson J, Sjostrom J (2018) Measuring incident heat flux and adiabatic surface temperature with plate thermometers in ambient and high temperatures. Fire Mater. https://doi.org/10.1002/fam.2667

Häggkvist A, Sjöström J, Wickström U (2013) Using plate thermometer measurements to calculate incident heat radiation. J Fire Sci 31(2):166–177

Hidalgo J, Maluk C, Cowlard A, Abecassis-Empis C, Krajcovic M, Torero J (2017) A thin skin calorimeter (TSC) for quantifying irradiation during large-scale fire testing. Int J Therm Sci 112:383–394. https://doi.org/10.1016/j.ijthermalsci.2016.10.013

Schmid J, Brandon D, Werther N, Klippel M (2018) Thermal exposure of wood in standard fire resistance tests. Fire Saf J. https://doi.org/10.1016/j.firesaf.2018.02.002

Law A, Hadden R (2017) Burnout means burnout. SFPE Europe Q1 2017 (5)

Bartlett A, McNamee R, Robert F, Bisby L (2019) Comparative energy analysis from fire resistance tests on combustible versus non-combustible slabs. Fire Mater (in press)

Epernon fire tests programme. http://www.epernon-fire-tests.eu/. Accessed 16 Aug 2018

Węgrzyński W, Turkowski P, Roszkowski P (2019) The discrepancies in energy balance in furnace testing, a bug or a feature? Fire Mater. https://doi.org/10.1002/fam.2735

Lange D, Sjöström J, Brandon D, Schmid J (2018) Timber and the fire resistance furnace—a comparative study of the conditions in a fire resistance furnace when testing combustible and non-combustible construction. In: 10th international conference on structures in fire, SiF 2018, Belfast, 6–8 June 2018

EN 1363-1. Fire resistance tests. General requirements

Harmathy TZ (1969) Design of fire test furnaces. Fire Technol 5(2):140–150

European Committee for Standardisation. EN 1995-1-2: design of timber structures—part 1–2: general—structural fire design

European Committee for Standardisation. EN 1992-1-2: design of concrete structures—part 1–2: general—structural fire design

Drysdale D (2011) An introduction to fire dynamics, 3rd ed. Wiley, Hoboken

Emberley R, Do T, Yim J, Torero JL (2017) Critical heat flux and mass loss rate for extinction of flaming combustion of timber. Fire Saf J 91:252–258. https://doi.org/10.1016/j.firesaf.2017.03.008

Acknowledgements

The authors gratefully acknowledge the financial support from J. Gust Richert foundation, Svenskt Trä for supplying the timber used in the test, as well as the participants and members of COST action FP1404 for the informed debate and discussion that led to this work being carried out.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1: Plate Thermometer Positions

Appendix 1: Plate Thermometer Positions

Detailed positions of the plate thermometers used in these tests is provided in the Table 1.

Rights and permissions

About this article

Cite this article

Lange, D., Sjöström, J., Schmid, J. et al. A Comparison of the Conditions in a Fire Resistance Furnace When Testing Combustible and Non-combustible Construction. Fire Technol 56, 1621–1654 (2020). https://doi.org/10.1007/s10694-020-00946-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-020-00946-6