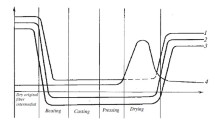

The change in relaxation state of polymer components of wood during its high-temperature biorefining and extrusion briquetting and subsequent heating at 380-450°C, i.e., above the thermal decomposition temperature of wood, is analyzed. It is demonstrated that the system can be translated into brittle state by changing the moisture content of the wood and treatment temperature and into forced plastic state by subsequent moistening, heating, and compression-shearing. Carbonization and activation of charcoal briquettes can be combined by subsequent low-temperature pyrolysis in controlled vaporgas environment conditions.

Similar content being viewed by others

References

E. L. Akim, Investigation of the Process of Synthesis of Fibre-forming Cellulose Acetates [in Russian], Doctor’s dissertation, LITLP, Leningrad (1971).

E. L. Akim, Khim. Volokna, No. 3, 4-13 (2016).

E. L. Akim and A. S. Smolin, Khim. Volokna, No. 4, 81-88 (2018).

E. L. Akim, Paper Processing [in Russian], Lesnaya Promyshlennost, Moscow (1979), p. 229.

E. L. Akim, Synthetic Polymers in Paper Industry [in Russian], Lesnaya Promyshlennost, Moscow (1985), p. 248.

E. L. Akim, Scientific Foundations of Chemical Technology of Carbohydrates [in Russian], LKI, Moscow (2008), p. 528.

A. A. Pekarets, “Innovative production of wood-charcoal briquettes,” Biofuel Congress, St. Petersburg, 20.03.2018.

A. A. Pekarets, Patent RU No. 2596683, A Complex for Continuous Thermal Treatment of Fine Solid Particles, Primarily Disperse Wood Materials and Methods of Thermal Treatment in This Complex [in Russian].

A. A. Pekarets, Russian Federation Patent No. 2628602, A Device for Producing Wood Charcoal [in Russian].

A. A. Pekarets, Patent RU No. 2653513, High-calorie Fuel Briquettes from Wood Waste Based Composites [in Russian].

A. Pekarets, Patent RU No. 2678089, An Industrial Complex for Waste-free Wood Charcoal Production by Lowtemperature Pyrolysis from Briquetted Wood Wastes [in Russian].

E. Hansen, R. Panwar, and R. Vlosky, The Global Forest Sector: Changes, Practices, and Prospects, Taylor and Francis Group, NY (2017), p. 462, ISBN: 978-1-4398-7927-6.

Forest Products Annual Market Review 2017-2018, Forestry and Timber, UNECE, p. 137.

J. -L. Wertz, M. Deleu, et al., Hemicelluloses and Lignin in Biorefineries, Taylor and Francis Group, NY (2018), p. 308, ISBN: 13:978-1-1387-2098-5.

D. A. I. Goring, Lignins, edited by K. Sarkanen and C. H. Ludwig, Lesnaya Promyshlennost, Moscow (1975), p. 629.

N. I. Neimark, Vysokomol. Soedin., XX B, No. 1, 3-7 (1978).

A. A. Kosobutskaya, N. I. Neimark, and E. V. Ignat’eva, Vysokomol. Soedin., XXII B, No. 11, 827-830 (1980).

A. A. Kosobutskaya, N. I. Neimark, and O. G. Tarakanov, Vysokomol. Soedin., XXV B, No. 1, 18 -22 (1983).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskie Volokna, No. 3, pp. 14-18, May-June, 2019

Rights and permissions

About this article

Cite this article

Akim, E.L., Mandre, Y.G. & Pekarets, A.A. Change in Relaxation State of Polymer Components of Wood During its High-Temperature Biorefining. Fibre Chem 51, 164–169 (2019). https://doi.org/10.1007/s10692-019-10067-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10692-019-10067-8