Abstract

Technological accidents triggered by natural hazards, which are commonly referred to as Natech events, are rare occurrences yet carry the potential for significant damage. Specifically, the release of hazardous chemicals into the aquatic environment and community water systems poses a grave threat to human health and society. Accordingly, we must conduct assessments that consider the potential consequences of these accidents. In this study, we examined the criteria for implementing spill protection measures to mitigate river spills of chemical substances using information on the amount of chemical substances and their toxicity. The countermeasure options readily available to employees at industrial plants and chemical storage sites where a chemical spill might originate included emergency shut-off valves, bunds and related spill containment structures, and other spill prevention measures. In this case study, a combination of countermeasure options was evaluated to examine the effectiveness of spill mitigation in the Yodo River located in the Kyoto Prefecture of Japan. Results of the case study showed that bunds were emerged as the most useful countermeasure option, reducing the probability of accidents occurring and impact of accidents. We also defined a methodology for calculating the chemical storage volumes appropriate for different countermeasures to ensure that the concentration of chemicals that could reach the water intake does not exceed the standard values. We believe that these methodologies can help chemical-handling companies make decisions when countermeasure options for responding to a chemical spill into a river. Chemical-handling companies can estimate the risk to downstream water treatment plants in the chemical spill, which can also help them consider mitigation measures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Background

When large earthquakes strike, they pose a risk of not only physical damage from seismic motion but also secondary damage, such as chemical spills that are released into the surrounding environment from damaged industrial facilities. Industrial accidents triggered by natural disasters are termed natural-hazard triggered technological accidents, or Natech events, are rare occurrences that carry the potential for significant damage. During the 1995 Southern Hyogo Prefecture Earthquake, a valve attached to a chemical storage tank ruptured, resulting in the spillage of 40 kL of heavy oil C into a bund and approximately 600 L of oil released to the environment through a crack in the containment (Amagasaki City, Amagasaki Future Association 1998). In addition, the sloshing of an oil tank during the 2003 Tokachi-oki Earthquake caused damage to the floating roof of the tank, and a fire ignited by the spilled oil ensued, resulting in extensive damage. In light of potential chemical spills during such disasters, various methods have been proposed to estimate the frequency of accidents and assess the damage effects (Fabbrocino et al. 2005; Antonioni et al. 2007; Meng et al. 2015).

These studies have assessed the effects of spilled chemicals on industrial facilities and the surrounding population, considering risks such as fire hazards or inhalation exposure. However, if a chemical spills from facilities into a river, then the hazard could be widespread, potentially contaminating drinking water supplies. In 2014, a spill of 4-methylcyclohexane methanol occurred at a plant along the Elk River in Kanawha County, West Virginia. This incident resulted in nearly 600 hospital visits and 13 hospitalizations by local residents complaining of poor health and symptoms related to the spill (Manuel 2014). Meanwhile, an incident occurred in Japan in 2012 where untreated hexamethylenetetramine was discharged in the Tone River basin, and formaldehyde exceeding water quality standards was detected at certain water treatment plants. Accordingly, several water treatment plants were compelled to halt water intake, resulting in water supply disruptions in five cities in Chiba Prefecture (360,000 households and 870,000 people) (Study Group on Response Strategies for Disinfection Byproduct Precursors in Water Sources 2013). Thus, the discharge of hazardous chemicals into water systems has the potential to cause serious damage to human health and society, and a risk assessment that considers the possibility of sudden releases during disasters should be conducted.

In Japan, the Water Pollution Control Law was partially amended in 2010 to prevent groundwater pollution caused by hazardous substances. The Ministry of the Environment (2010) has established new regulations that require installers of facilities using and storing hazardous substances to comply with the prescribed standards concerning structure, equipment, and specification methods to prevent underground seepage, conduct periodic inspections, and record and store the results of these inspections. Furthermore, in 2022, a partial revision of the Guidelines Concerning Measures to be taken by Business Operators Handling Designated Chemical Substances, etc. for the Management of Class I and II Designated Chemical Substances stipulated the consideration of measures to prevent the release of certain chemical substances during disasters. The guidance further stipulated countermeasures to be taken. In addition, the Ministry of Economy, Trade, and Industry (2024a, b) has compiled several case studies showcasing collaboration with local governments and initiatives undertaken to mitigate damage resulting from chemical substance leaks to assist in formulating specific measures. In terms of corporate business continuity during disasters, Business Policy Forum, Japan (2013), conducted a survey and compiled information on the status of corporate initiatives. This resource can serve as a valuable reference.

However, facilities must consider their own countermeasures to prevent chemical substance spills, considering the wide variety of chemical substances handled and stored by businesses, and the necessary measures differ depending on the disaster situation, location, and other pertinent factors. The Fire Service Law establishes detailed standards for each type of hazardous material storage facility. Outdoor storage tanks are required to install oil bunds, while those exceeding a certain storage volume must install emergency shut-off valves. Meanwhile, business operators handling designated chemical substances must establish standards for implementing countermeasure options based on the size of each industrial facility and the substances handled.

The Ministry of the Environment (2022) created a manual outlining the procedures for local governments to follow in the event of a chemical disaster or accident. This manual describes the procedures that environmental departments within local governments should establish to address a leak or spill of chemical substances from facilities handling chemical substances, as well as the actions that should be taken during and after such accidents.

Local governments and chemical substance handling businesses must establish a system for responding to chemical substance spill events in the event of a disaster from a normal time. However, the conditions of chemical substance handling businesses significantly vary from one business to another, making it challenging to establish clear regulations. In this study, we examined the criteria for implementing spill protection measures to mitigate river spills of chemical substances using information on the amount of hazardous chemical substances stored at business establishments and in river basins and their toxicity. Specifically, this study investigated chemical spill prevention measures by comparing the extent to which the risk of a river spill can be reduced by using a combination of countermeasure options implemented by business sites when chemical substances spill from business sites into rivers as a result of earthquakes. We highlight our findings by examining the effectiveness of countermeasures to mitigate a chemical spill in the Yodo River located in the Kyoto Prefecture of Japan.

2 Method

2.1 Outline

This study examines the effectiveness of a combination of countermeasure options using a risk assessment approach, assuming that a storage tank or piping is damaged during an earthquake at a chemical facility that handles chemical substances, and a large amount of chemical substances flow out into a river. Chemical substances were assumed to be stored in outdoor storage tanks. Outdoor storage tanks are one of the classifications of storage facilities under the Fire Service Law and are considered to be suitable for storing large quantities of chemical substances due to the lack of storage volume restrictions. Given the assumption of discharge into rivers, this study considers chemical substances stored in liquid form. Therefore, the storage tank is assumed to be a cylindrical tank, which is commonly used for liquid storage.

Figure 1 shows a flowchart of the evaluation of the countermeasure options in this study. The flowchart is structured based on the concept of risk assessment in the Disaster Prevention Assessment Guidelines for Petroleum Complexes (Fire and Disaster Management Agency 2013). The authors have made modifications to evaluate specific combinations of countermeasure options.

First, we set up countermeasure cases based on a combination of scenarios with and without countermeasure options. An event tree (ET) is created for each countermeasure case. We developed scenarios to simulate a chemical spill at a chemical facility. The event that causes a mass release of chemical substances is a leakage of chemical substances from a storage tank or pipe. In the chemical spill scenarios, ETs were developed for the cases where the countermeasure options worked and those where they did not work for the leaked chemicals. Thereafter, the occurrence risk and impact of a mass chemical spill in each scenario are estimated. The occurrence risk is the probability of a disaster occurring, and the impact is the amount of chemicals spilled into the river. Finally, the overall risk of a disaster is evaluated based on the occurrence hazard and the impact. Here, we examined combinations of countermeasure options that result in acceptable risk levels.

2.2 Setting the countermeasure cases

The countermeasure cases shown in Table 1 were created based on whether or not the assumed countermeasure options were installed. In Table 1, “None” indicates that no countermeasure option was implemented. Bold “Yes” indicates that the target countermeasure options are installed in each case. In this study, bunds/catch basins (bunds), emergency shut-off valves (shut-off valves), and spill prevention measures by employees (employees) were evaluated as countermeasure options that are required by the Fire Defense Law, Water Pollution Control Law, and prefectural ordinances for business establishments handling chemical substances that meet certain conditions. Since it is difficult to completely recover chemical substances once they have been released into a river, it is important to prevent chemical substances from leaking out of the premises of a business establishment. Therefore, we included in our assessment the feasible countermeasure options on the chemical-handling establishments. Bunds include physical structures installed around chemical storage tanks, such as dikes, cisterns, and ditches, to temporarily contain leaks. Emergency shut-off valves are installed at the joints between tanks and pipe and are remotely operated to close the valves in the event of pipe failure, thereby preventing leakage from the tank itself. The Water Pollution Control Law and the Fire Defense Law require prompt recovery of leaked materials in the event of a spill. Accordingly, we assumed that the business unit would recover the leaked material and prevent its spread within the safety parameters once an accidental spill is confirmed and set up measures to prevent spills by employees as a countermeasure option. The measures to be taken by employees to prevent chemical substances from leaking outside of the facility are assumed to include specific measures, such as collecting spilled chemical substances by surrounding them with absorbents and closing drains that lead to the exterior of the facility.

2.3 Development of ET

ETs were created by adhering to the following steps in accordance with the methodology of the Disaster Prevention Assessment Guidelines for Petroleum Complexes (2013): (1) establishment of initiating events, (2) establishment of event branches, and (3) development of an ET (Fire and Disaster Management Agency 2013).

2.3.1 Initiating event settings

In this study, two initiating events of chemical spillage were assumed: tank or pipe catastrophic failure. In past earthquakes, damage to outdoor storage tanks has been broadly classified into buckling, uplift, and sloshing damage to floating roofs or top plates (Hamdan 2000; Sugatsuke et al. 2014). Buckling and uplift caused damage to the lower part of the tank, resulting in the total loss of the contents. During the 1995 Southern Hyogo Prefecture Earthquake, buckling occurred in the water tank at the lowest position of the side plate, causing all the stored water to flow out through the fracture opening (Yamada and Kamei 1995). Meanwhile, chemical spillage due to sloshing was limited in volume compared with damage at the bottom and side plates. In this study, the chemical discharge into the river was targeted, and the overflow due to sloshing, where the amount of discharge was small, was not treated, and the initiating event was presumed to be a catastrophic failure in the chemical storage tank and pipe. It was assumed that the entire volume in the tank would be released within a short period of time, specifically within 10 min (Haag 1999). The tank and pipe ruptures were assumed to occur independently of each other. An event where the tank and pipe simultaneously ruptured was not considered because of its extremely low probability of occurrence.

2.3.2 Event branching settings

After a spill incident (initiating event) occurred at a chemical-handling facility due to an earthquake, the event was divided based on countermeasure options for each case. The assumed countermeasure options were emergency shut-off valves, bunds, and spill prevention measures by employees, in that order.

2.3.3 Deployment of ET

The ETs were deployed by event branching according to whether the countermeasure option was installed or not. In each ET of a tank and pipe catastrophic failure, the event bifurcation was determined by the number of countermeasures, the number of possible scenarios in case \(i\), and the number of scenarios assumed in case \({v}_{i}\). The number of scenarios assumed in the case is expressed in Eq. (1). Figures 2a and b show an example of an ET deployment diagram (Cases 2 and 8).

2.4 Estimation of risk

2.4.1 Setting the probability of earthquake ground motions

In this study, we set the probability of occurrence for seismic tremors to intensity 5 or lower and higher based on the seismic intensity classes defined by the Japan Meteorological Agency (JMA). The seismic hazard station releases information regarding the probability of tremors with intensities ranging from lower than 5 to 7 occurring within the next 30 years for a 250 m mesh (National Research Institute for Earth Science and Disaster Resilience (2023)). On this basis, this study estimated the probability of scenarios occurring across four seismic intensity classes. The probability of earthquake motion exceeding these seismic intensity classes was determined according to Eq. (2).

This study utilized the peak ground acceleration (\(PGA\)) of the earthquake as the parameter of seismic motion. The seismic intensity classes were replaced with measured seismic intensity (Table 2) according to the method of calculating measured seismic intensity specified by the JMA, the median value of the measured seismic intensity in seismic intensity class \(l\), and the median value of the measured seismic intensity in seismic intensity class \({I}_{l}\). The median value of the measured seismic intensity for each seismic intensity class is shown as measured seismic intensity \({I}_{l}\). The equation of Tong and Yamazaki (1996) was used to calculate the seismic intensity from the measured seismic intensity (Eq. 3), \({PGA}_{l}\). The median value of the measured seismic intensity in the seismic intensity class was used as the measured seismic intensity.

2.4.2 Estimation of the probability of initiating event occurrence

Damage probabilities of tanks and pipes were calculated using a fragility curve, with PGA serving as the intensity index (Salzano et al. 2003). The mean values and standard deviations of the fragility curves used in Eq. (4) are shown in Table 3. We used the mean and standard deviation values of the fragility curves for each component of the oil pipeline system established by Federal Emergency Management Agency (FEMA) (2022) based on the work of G&E Engineering Systems (G&E) (1994).

2.4.3 Setting event branching probabilities

2.4.3.1 Failure probabilities of emergency shut-off valve

The results of the investigation in the Great East Japan Earthquake indicated that the leakage of contents from pipes despite having emergency shut-off valves was due to the loss of normal and emergency power sources (Fire and Disaster Management Agency 2014). Accordingly, the failure probability of the emergency shut-off valve in this study was defined as the product of the probability of power failure and the probability of non-start of the emergency power supply. Equation (5) shows the probability of a power failure in an area with a measured seismic intensity (Nojima et al. 2003). The Nippon Engine Generator Association (2012) conducted a survey of 4811 private power generators for disaster prevention installed in areas where the seismic intensity was six or higher during the Great East Japan Earthquake. The association reported that 84 of these generators failed to normally operate due to non-starting or abnormal shutdown. The results demonstrated that the probability of failure of emergency shut-off valve operation was calculated by multiplying the probability of power failure by the probability of loss of emergency power supply of 1.75%.

2.4.3.2 Failure probabilities of bunds

We used the failure probability of bunds (1.0 × 10−3) set by the Miyagi Prefecture Oil Complex Disaster Prevention Assessment Study (2014). The regulations for outdoor tank storage facilities under the Fire Defense Law require that the capacity of the oil bunds be at least 110% of the capacity of the stored material inside the bunds. The Water Pollution Control Law also requires that bunds be installed around specified facilities that use hazardous substances or storage facilities for hazardous substances. Although the Water Pollution Control Law does not state the capacity of bunds, it provides that “the capacity must be sufficient to prevent the discharge of water containing hazardous substances equivalent to the anticipated amount of discharge.” Accordingly, the bunds around tanks that store hazardous chemicals can adequately contain the volume of water in the tanks. Therefore, this study assumed that the levees can temporarily store the entire tank capacity even in the event of a spill, and no external spill will occur unless the levees are damaged.

2.4.3.3 Failure probabilities of measures to prevent spills by employees

Employees on duty manually close valves and drains in the event of a spill and collect the spill with adsorbent to prevent it from spreading offsite. In the Miyagi Prefecture Disaster Prevention Assessment Study for Petroleum Complexes, etc. (2014), a failure probability of 1.0 × 10−1 was set for temporary measures to prevent the spread and recovery of spilled oil in the event of a small spill. Given that similar measures are assumed in this study, the failure probability of spill prevention measures by employees was set to 1.0 × 10−1.

2.4.4 Estimation of the probability of scenario occurrence

According to the ET, the probability of occurrence (return period) of each scenario was calculated as in Eq. (6) based on the method of Antonioni et al. (2007) \({{p}_{s}}_{ij}\) is calculated by summing the number of divisions, which assumes the product of the probability of occurrence of each event. The bifurcation probabilities of success and failure are determined by the failure probability of each countermeasure option (Table 4).

2.5 Estimation of impact

2.5.1 Setting the chemical spill volume in the initiating event

The damage to the tank and pipe was assumed to be a total spill due to a major rupture. Therefore, the amount of spillage due to the initiating event of a tank or pipe catastrophic failure was assumed to be equal to the storage volume.

2.5.2 Setting the release ratio by event bifurcation

Two spill ratios were set for success and failure: the spill ratio when the countermeasure option normally functions is used for success; the spill ratio when the function is partially lost is used for failure. The emergency shut-off valve is assumed to prevent the contents from leaking out of the tank body through its operation, limiting the leakage to the inside of the pipe only. In the success case, a spill ratio of 0.01 is set, as adopted by Nakakubo et al. (2016), based on the estimates by Osaka Prefecture (2013). The spill ratio at the time of success was set to zero because the dike and other facilities have sufficient capacity to accommodate the tank’s contents. The spill ratio was also set to zero for spill prevention and recovery by employees. The ratio of spills in the event of failure was set based on a case of a heavy oil spill during the Miyagi-oki Earthquake in 1978. In this incident, two heavy oil tanks (31,500 kL) and one reduced-pressure light oil tank (23,700 kL) in the Sendai area ruptured near the joint between the side and the bottom plates, resulting in the spillage of approximately 70,000 kL of heavy oil (Miyagi Prefecture Oil Complex Disaster Prevention Assessment Study 2014). The expansion of the oil spill on land was prevented by a breakwater. However, the oil spilled into the bunds (6000 kL capacity) through a drainage ditch. The emergency shut-off gate of the drainage opening leading to the port was immediately closed, but it could not be completely closed due to the accumulation of sludge. Several thousand kL of oil were spilled into the sea by the time the sealing was completed with sandbags and dump trucks bringing in sand (Miyagi Prefecture Oil Complex Disaster Prevention Assessment Study 2014). In this case, we assumed that the amount that could not be prevented by dikes, etc. was 6000 kL. Meanwhile, the amount of spillage that could not be prevented by closing the drainage ditch was 1000 kL out of the 70,000 kL that spilled from the tank. The spill ratio was set to 0.1 when dikes, etc. and employees failed to prevent and collect the spill.

2.5.3 Estimation of the outflow volume from the facility

The amount of chemicals discharged into the river in the event of a spill incident is estimated to assess the impact. Meanwhile, the amount of chemicals discharged outside the site for each scenario was calculated using Eq. (7), where \({RR}_{k}\) represents the release ratio, and the countermeasure option \(k\) in each scenario. The ratio of the amount of chemicals flowing into the next countermeasure option or outside the facility is shown in Table 5. The values of the two options are also provided in Table 5.

2.5.4 Estimation of the concentration reaching the intake

The behavior of chemicals discharged into the river until they reach the water treatment plant intake was estimated using the advection–diffusion equation and assuming a 1D river model Eq. (8). Assuming a constant river flow velocity and a cross-sectional area, the maximum concentration of chemical substances downstream was estimated using Eq. (9). All the chemical substances were assumed to be discharged into the river at once by a hypothetical waterway after being discharged outside of the project site. The cross-sectional area of the river was calculated from the average flow and velocity of the river Eq. (10).

The diffusion coefficient was calculated using Elder’s longitudinal dispersion coefficient equation as in Eq. (11), and the friction velocity was calculated using Eq. (12). The cross-section of the river was assumed to be triangular in shape (Fig. 3), and the wetting perimeter was calculated from the cross-sectional area and water depth. The hydrodynamic gradient was calculated based on the distance of flow from the office to the water treatment plant and the difference in elevation. We calculated the average depth \(H\) using Eq. (13), the flow-duration curve. We calculated the coefficients \(a\) and \(b\) using one year of flow and depth data in the target river.

2.6 Aggregation scenario

The probability that the maximum concentration of a chemical at the intake of the water treatment plant exceeds the standard value \(Ca\) was determined by summing the probabilities of occurrence of the scenarios Eq. (14).

Reference values \(Ca\) were used for the water quality and subacute reference values for the targeted chemicals. The subacute reference value is a concept proposed by the National Institute of Health Sciences (2020) as an indicator to be used as a reference when continuing water supply with intake restrictions in the event of water quality abnormalities. Equation (15) shows the subacute reference value, and Eq. (16) presents how to calculate the subacute reference dose (National Institute of Health Sciences 2020).

Subacute reference values were calculated by point of departure (\(POD\)) using NOAEL (National Institute of Health 2020). The NOAEL was set based on the method of the National Institute of Health Sciences (2020). Although the National Institute of Health (2020) calculated the subacute reference values for adults and children, this study conducted comparisons for adults (\(BW\) = 50 kg/person, \(DI\) = 2 L/day/person).

3 Case study

3.1 Target location

As a case study of the methodology developed in Chapter 2, we estimated the probability of a spill incident and the volume of spilled water for a chemical-handling facility located in the Yodo River watershed in Japan. The Yodo River has a flow path length of 75 km, a basin area of 8240 km2, and a large city with a population of approximately 1.5 million located upstream of the intake point, making it more susceptible to human activities than other large cities in Japan; thus, the potential contamination risk of water supply sources is higher than those of other major rivers (Ministry of Land, Infrastructure, Transport and Tourism, Yodo River Office 2024). The water treatment plant intake for the concentration risk assessment was the Kunijima water intake, which is located approximately 10 km from the mouth of the Yodo River and supplies water for domestic use in Osaka Prefecture.

We took the average of the available flow data from 1970 to 2021 at the Hirakata station of the Ministry of Land, Infrastructure, Transport, and Tourism’s Water Information System (Ministry of Land, Infrastructure, Transport and Tourism 2024) and used 293.7 m3/s for the river flow. The cross-sectional area was calculated based on the assumption that the river velocity is 1 m/s, considering a slow-flowing plain area. We used data from 2002, when annual depth and flow measurements were available at the Hirakata station, and calculated a = 3.8 × 10–3 and b = 1.8 × 10–6.

3.2 Target business establishment

Table 6 shows information regarding the business sites that are the subject of case studies in this work. The amount of chemical substances stored at the site was estimated based on the emissions and transfers reported in the Pollutant Release and Transfer Register in 2021 (Ministry of Economy, Trade and Industry (2024a, b)), according to the method of Hamamoto et al. (2021) The site is located in Ukyo-ku, Kyoto City, Kyoto Prefecture and handles tetrachloroethylene. Tetrachloroethylene is used in the manufacture of Freon gas and as a metal cleaner and is considered highly toxic and carcinogenic to laboratory animals. Tetrachloroethylene is also designated as a hazardous substance under the Water Pollution Control Law, and effluent and water quality standards (0.01 mg/L) have been established. The chemical concentration was evaluated at the water intake of Kunijima water treatment plant, which is located approximately 40 km downstream from the subject site. The hydraulic gradient \({I}_{e}\) was set to 4.0 × 10–4 based on the difference in height above sea level between the target business establishment and the water intake.

The NOAEL was 14 mg/kg/day in drinking water, and \(UFs\) of 1000 (100 for species and individual differences and 10 for carcinogenicity) were applied based on a 90-day study in rats by Hayes et al. (1986) and a 6 week oral study in mice by Buben and O’Flanherty (1985). We calculated a subacute reference value of 0.35 mg/L for tetrachloroethylene from these values.

3.3 Criteria for implementing countermeasure options

3.3.1 Calculation of hazard ratios and storage targets

The maximum amount of chemical storage that can be stored at the site \({S}_{max}\) (kg), the drought flow rate of the target river \({Q}_{min}\) (m3/s), and the potential attainable concentration at the downstream water treatment plant intake \({C}_{p}\) (mg/L) were determined using Eqs. (17–20).

The reference concentrations, such as subacute or water quality reference values for the chemical substance to be evaluated, are \({C}_{st}\) mg/L, the hazard ratio was calculated using Eq. (21).

The measures that should be introduced at the facility can be divided into cases, as shown in Table 7, considering only the influence on the intake of the water treatment plant.

When combined with storage volume reduction, the storage volume target is calculated as in Eq. (22). If the site has installed bunds and employee spill prevention measures as countermeasure options, then the spill rate in case of failure is 0.10 (Table 4). Both \(RR\) would be 0.01.

3.3.2 Risk state 1 (\({HQ}_{c}<1\))

The risk of chemical concentrations at downstream intakes exceeding the standard values due to chemical spills from the project site is estimated to be small even under worst conditions. Therefore, the introduction of the countermeasure option is considered to be a low priority.

3.3.3 Risk state 2 (1 \(\leqq {HQ}_{c}<10\))

If no measures are taken under worst conditions, then the chemical concentrations at downstream intakes may exceed the standard values due to chemical spills from the site. If the amount of chemicals spilled from the facility is reduced by less than one-tenth, then the concentration of chemicals at the intake is estimated to be below the standard, thus requiring the installation of at least one bund or an equivalent countermeasure option.

The chemical storage volume under normal conditions at a value that \({HQ}_{c}\) is maintained at a value less than one. Accordingly, the risk of chemical concentration exceedances at downstream intakes can be mitigated in the event of a spill.

3.3.4 Risk state 3 (\(10\leqq {HQ}_{c}<100\))

If no measures are taken, even under worst-case conditions, the chemical concentration at the downstream intake may exceed the standard value due to chemicals spilled from the site. If the amount of chemicals spilled from the site is reduced to less than one-hundredth of the standard, then the concentration of chemicals at the intake is estimated to be below the standard. Therefore, a combination of bunds and employee spill prevention measures or equivalent options should be implemented at a minimum.

Alternatively, the normal chemical storage volume \({HQ}_{c}\) is maintained at a value less than one, thereby reducing the risk of chemical concentration exceedances at downstream intakes in the event of a spill.

3.3.5 Risk state 4 (\(100\leqq {HQ}_{c}\))

Even with all the countermeasure options assumed in this study, the chemical concentrations at the downstream intake may exceed the standard values under worst conditions, requiring additional countermeasure options, such as employing multiple bunds and reducing the chemical storage under normal conditions.

3.4 Sensitivity analysis

A sensitivity analysis was conducted to test the usefulness of the method with respect to the criteria for introducing the countermeasure option. In this section, we estimated the extent to which the maximum concentration achieved at the intake varies when the target sites and flow conditions change in the targeted Yodo River watershed and to identify the parameters that contribute the maximum concentration at intake. Table 8 shows the conditions of the sensitivity analysis. The variables for the sensitivity analysis were set to the probability of seismic intensity exceedance within 30 years, storage amount of chemical substance, average river flow, and distance to the water treatment plant intake. Moreover, the concentration at the water treatment plant intake was calculated. Values of Low, Base, and High were set for the sensitivity analysis. Base is the value set for the case study sites shown in Table 5. In terms of the probability of seismic intensity exceedance, Low was set to a value half of Base, and High was set to a value of 50% for a seismic intensity of 6 or higher. Accordingly, the probability of occurrence of earthquakes with intensity levels of 5 to 6 would be equal. With regard to chemical storage, the value in the case study was set as Base, with one-tenth of the storage value as Low and 10 times the storage value as High. In terms of the average river flow, the value of 62.8 m3/s, which is the minimum value for which data are available among the flow data from 1970 to 2021 at the Hirakata station of Water Information System, was set as Low, and twice the average flow was set as High. The average depth of water at the river flow Low is 1 m, and High is 3 m. The average depth of water at the river flow Low is 1 m, and High is 3 m. The distance to the water treatment plant intake was set to Low for 1 km as the closest case and High for 80 km as the farthest case, according to the Base distance of 40 km.

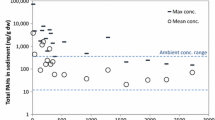

Figure 4 shows the results of the sensitivity analysis of the probability of seismic intensity exceedance, chemical storage, river flow, and distance to the water treatment plant intake to the chemical concentration reaching the intake in Case 1. The chemical concentration in Fig. 4b is more sensitive than the other variables because it is proportional to the amount of substance stored. Thereafter, the sensitivity of river flow rate is high, indicating that, during drought conditions, the concentration reaching the intake is about 10 times higher than that during normal conditions, even if the amount of runoff is the same. Given that the frequency of earthquakes affects the probability of accidents, the maximum concentration reaching the intake remains the same even if it fluctuates. When the distance to the intake is closest, the concentration is about 3 times higher than when it is farther away. Nevertheless, the fluctuation is small when compared with the storage volume and river flow rate.

Maximum concentration at the intake (Case 1) of sensitivity analysis. This is the result of the sensitivity analysis of the probability of seismic intensity exceedance, chemical storage, river flow, and distance to the water treatment plant intake to the chemical concentration reaching the intake in Case 1. a Sensitivity analysis of probability of seismic intensity exceeds the constant value (30 years). b Sensitivity analysis of storage amount of the chemical substance. c Sensitivity analysis of average river flow. d Sensitivity analysis of distance to water treatment plant intake

3.5 Results of the estimation of the maximum concentration at the water intake

Table 9 shows the comparison results for each countermeasure case. The maximum concentration at the intake represents the maximum concentration of a chemical substance that reaches the intake in each case under the scenario with the largest amount of runoff outside the facility. Case 1 shows the case with no countermeasure options, so the maximum concentration at the intake and probability of exceedance are the largest. Cases 2 through 4 represent the cases with only one countermeasure option: bunds, shut-off valve, and employees, respectively. Since it is assumed that the shut-off valve releases the entire amount in the event of loss of function, the maximum concentration at the intake in Case 3 is the largest among all cases, as in Case 1. The difference in probability of exceedance for Cases 2, 3, and 4 depends on the failure probability of each countermeasure option. Case 5 to Case 7 represent the cases with two countermeasure options introduced, Case 5 represents bunds and shut-off valve, Case 6 represents shut-off valve and employees, Case 7 represents bunds and employees. Among the three cases (mi = 2), the maximum concentration at the intake in Case 7 is the smallest and below the subacute reference concentration. The probability of exceedance is smaller in the order of the combination of countermeasure options with the smaller failure probability. Case 8 represents case in which all three countermeasure options were introduced and maximum concentration at the intake and probability of exceedance are the smallest. In the following sections, the effects of improvement from Case 1 for each case are compared by the number of countermeasure options installed. The number of countermeasure options \({m}_{i}\) is increased, while the maximum concentration at the intake and probability of exceedance gradually decrease.

3.5.1 Number of countermeasure options installed \({m}_{i}\) = 1 (Cases 2, 3, and 4)

In Cases 2 and 4, the maximum concentration at the intake was one-tenth of that in Case 1 without countermeasures. Meanwhile, Case 3 did not change the maximum concentration at the intake because the emergency shut-off valve would have resulted in the total storage volume spilling out if it did not work. The probability of exceedance was smallest for the bund (Case 2), which had the smallest probability of failure, followed by the spill prevention measures taken by employees (Case 4) and the emergency shut-off valve (Case 3).

3.5.2 Number of countermeasure options installed \({m}_{i}\) = 2 (Cases 5, 6, and 7)

In Case 7, where a bund and employees were installed, the maximum concentration at the water intake was less than the water quality standard even in the highest spill scenario. Accordingly, the exceedance probability was 0. Similar to the case with only one countermeasure option, the probability of exceedance is low in Cases 5 and 7, which include a bund as a countermeasure option. Case 6, which includes two countermeasures other than bunds, has a higher probability of exceedance than Case 2, which includes only bunds. This notion indicates that the bund should be implemented in preference to the other two countermeasure options.

Inoue (1980) proposed a value of 10−6/year for the frequency of occurrence as a socially acceptable safety level and showed that events below this value have a considerably small chance of occurring. In this case study, Case 7 has a probability of exceedance of 10−6/year below the reference value for all concentrations. Therefore, in the case of the site in this case study, the probability of the occurrence of an event that releases stored material into a river during an earthquake can be reduced to a socially acceptable level if bunds and spill prevention measures by employees are introduced at a minimum.

3.5.3 Number of countermeasure options installed \({m}_{i}\) = 3 (Case 8)

The probability of exceedance was about 10−5 compared with Case 1 with no measures, and the maximum concentration at the intake was 1 in 100. Meanwhile, the probability of exceeding the standard was 3.8 × 10−8/year, which is the smallest value. Case 8 has a probability of concentration exceedance below 10−6/year, similar to Case 7. This notion indicates that the probability of occurrence is at a socially acceptable level.

3.5.4 Assessment of criteria for implementing countermeasure options

We determined \({HQ}_{c}\) at the target establishments and evaluated the criteria for the implementation of the countermeasure options. The maximum storage \({S}_{max}\) was set at 5.7 × 106 kg and the drought flow rate \({Q}_{s}\) was set at 62.8 m3/s.

If the water quality standard value of 0.01 mg/L for tetrachloroethylene is used as the standard value for chemical concentration, \({HQ}_{c}\)=1.6 × 104, which is the level that requires risk reduction measures combining the introduction of countermeasure options and storage volume reduction at Risk state 4. Figure 5 shows the relationship between \({HQ}_{c}\) and storage volume. The maximum value in the graph represents \({HQ}_{c}\) at \({S}_{max}\), and the value of \({HQ}_{c}\) can determine the risk state at each storage volume. Figure 5 shows that the target establishment is in Risk state 4 when the maximum storage volume \({S}_{max}\) is assumed, which is a desirable level to reduce the risk by introducing multiple countermeasure options. It can be seen that to reduce the Risk state to 3, the storage volume needs to be reduced to less than 3.7 × 104 kg, for Risk state 2 to less than 3.7 × 103 kg and for Risk state 1 to less than 3.7 × 102 kg. Thus, it is possible to determine the Risk state according to the amount of chemical substances stored at a business establishment, and to understand the combination of recommended countermeasure options.

3.5.5 Assessment of the probability of occurrence for large-scale disasters

Although a threshold of 10−6/year has been proposed for the probability of occurrence of disasters, the Disaster Prevention Assessment Guidelines for Petroleum Complexes (2013) consider only disasters with a frequency of occurrence of less than 10−6/year and with a particularly high impact as “large-scale disaster scenarios” without considering the probability of occurrence. The guideline uses distance as an indicator of disaster impact and considers a disaster to be large-scale if it has the potential to affect areas more than 200 m away from the chemical facility. In the case of a discharge into a river, as in this study, if highly concentrated chemical substances are supplied as drinking water without being fully treated at the water treatment plant, then numerous people in the water supply area may be affected. Accordingly, the release of chemicals into rivers should be treated as a high-impact event. In certain cases, such as Cases 7 and 8, where the probability of chemical concentrations exceeding the standard values at the water intake is low, the risk reduction of spillage accidents should be considered regardless of the probability of occurrence.

The introduction of two or more bunds is an effective means of further reduce the chemical spill volume. In fact, the Ministerial Ordinance on Specified Disaster Prevention Facilities and Disaster Prevention Organizations in Petroleum Industrial Complexes requires facilities with outdoor storage tanks that store 10,000 kL or more of flammable liquids covered by the Fire Service Law to install bunds surrounding all individual bunds of outdoor tank storage facilities on the site and to provide double spill protection measures. The law requires that the facility install a double spill containment measure.

The results of the case study suggest that measures should be taken in advance to prevent the failure of the private generator to start to increase the effectiveness of the emergency shut-off valve countermeasures. Equation (6) indicates that the probability of power failure is high, reaching 98% for an earthquake intensity of 6 or higher and 13% for an earthquake intensity 5 or lower. Consequently, the probability of emergency shut-off valve failure is also high. Therefore, the probability of failure of private generators must be reduced to minimize the probability of emergency shut-off valve failure, and being prepared at all times, including conducting regular maintenance, is crucial.

4 Conclusion

In this study, countermeasure options that should be implemented by chemical facilities for chemical spill events in rivers in the event of a large-scale earthquake were examined, with the influence on water intake at downstream water treatment plant intakes as the target of evaluation. Specifically, the countermeasure options for the plant side were assumed to be emergency shut-off valves, bunds, and spill prevention measures by employees. A set of case scenarios, each representing a set of countermeasure options accident scenarios were created based on the success or failure of the countermeasure options, assuming a spill from the tank itself and from the tank pipe. In each of these scenarios, the probability of occurrence and the amount of spillage outside the facility were calculated to compare the effectiveness of the countermeasure cases. The probability of occurrence of each scenario was estimated using the probability of a spill from the storage container and the success/failure probability of the countermeasure options. The amount of chemical substances spilled outside the facility was estimated using the ratio of the reduction of the amount of chemical substances spilled by the countermeasure options based on the amount of chemical substances stored. The concentration of chemical substances at the intake of the water treatment plant was estimated from the estimated amount of outflow using the advection–diffusion equation of the river. The probability of the concentration of chemical substances at the intake exceeding the standard value was calculated to evaluate the combination of countermeasure options, considering the probability of occurrence and influence of the accident.

The results of the case study in the Yodo River system showed that the bund was the most useful countermeasure option of the three countermeasure options, reducing the probability of accidents occurring and the impact of accidents. The spill prevention measures by employees and emergency shut-off valves were found to be less effective than the bund but important nonetheless for reducing accident risk. We proposed enhancing countermeasure options to further reduce the risk of accidents by introduction of two or more bunds and periodic maintenance of emergency power generators. A sensitivity analysis performed for chemical concentrations at the water intake using the probability of an earthquake, chemical storage volume, river flow rate, and distance from the water treatment plant to the water intake as variables showed that the storage volume and river flow rate were two factors that had the greatest influence on the concentration at the intake. We analyzed the worst-case scenario in which the river flow rate is the lowest, and the chemical storage volume is the highest at the plant based on these results. Furthermore, we proposed to use the value of the hazard ratio to define the criteria for the introduction of countermeasure options. We also defined a methodology for calculating the target storage volume to ensure that the concentration of chemicals at the intake does not exceed the standard value using the hazard ratio and the ratio of outflows when the implemented countermeasure options fail. We believe that chemical-handling companies will be able to understand the countermeasure options and the guideline for the amount of chemical storage for a chemical spill event into a river by using these methodologies. Moreover, these companies will be able well equipped to use this information to implement appropriate spill protection measures.

Given that this study dealt with a chemical spill into a river, an event that could have an influence on the surrounding community in the event of a large spill, several assumptions were made in the risk assessment to make it a worst-case scenario. The storage type was not considered for the spill from a chemical storage container, and only the catastrophic event of a cylindrical outdoor tank storage facility was considered. Considering that the entire amount assumed to spill outside the facility would be discharged into a river at once, the time lapse after the spill accident could not be considered.

Although this study evaluated the concentration of chemical substances at the water treatment plant intake and assumed human health as the endpoint, the influence of a chemical spill on aquatic organisms also must be considered if the outflow of chemical substances into a river is substantial. If a standard value for concentration is set based on the acute toxicity value for riverine aquatic organisms, then the probability of exceeding the standard value for concentration can be calculated from the amount of chemical substances discharged outside the facility. The framework of this study can also be applied to the risk assessment for riverine aquatic organisms.

Data availability

The data on the probability of tremors with intensities ranging from lower than 5 to 7 occurring within the next 30 years are available at https://www.j-shis.bosai.go.jp/. The data on the emissions and transfers reported in the Pollutant Release and Transfer Register system in 2021 are available at https://www.meti.go.jp/policy/chemical_management/law/prtr/6a.html. The data on the available flow data from 1970 to 2021 at the Hirakata station are available at http://www1.river.go.jp/.

Abbreviations

- \(i\) :

-

Countermeasure cases (1–8)

- \(j\) :

-

Accident scenarios

- \(k\) :

-

Countermeasure options (1–3)

- \(l\) :

-

Assumed earthquake classification (1–5)

- \(m\) :

-

Number of options for countermeasures

- \(n\) :

-

Number of seismic intensity categories

- \(f\) :

-

Probability of seismic intensity exceedance in 30 years (/year)

- \(F\) :

-

Probability of earthquake occurrence (/year)

- \(I\) :

-

Seismic intensity

- \(PGA\) :

-

Peak ground acceleration (m/s2)

- \({p}_{initiating event} ({p}_{ie})\) :

-

Probability of initiating event (/year)

- \({p}_{outage} ({p}_{o})\) :

-

Probability of power outage (/year)

- \({p}_{scenario}\)(\({p}_{s})\) :

-

Probability of scenario occurrence (/year)

- \({p}_{countermeasure}\)(\({p}_{c})\) :

-

Probability of countermeasure (/year)

- \(P({C}_{st})\) :

-

Probability of chemical concentrations at water treatment plant Intakes \({C}_{st}\) exceedance (/year)

- \({RR}_{c}\) :

-

Release ratio of outflows to countermeasure

- \({RR}_{w}\) :

-

Release ratio of the outflow if all countermeasure options fail

- \(M\) :

-

Amount of chemical substances discharged outside the plant (kg)

- \(\rho\) :

-

Density of chemical (g/L)

- \(S\) :

-

Chemical storage (kg)

- \({S}_{target} ({S}_{t})\) :

-

Target for chemical storage (kg)

- \({S}_{max}\) :

-

Maximum amount of chemical storage (kg)

- \(C\) :

-

Maximum chemical concentration at the water treatment plant intake (g/L)

- \({C}_{standard} ({C}_{st})\) :

-

Standard value of the chemical concentration (mg/L)

- \({C}_{potential} ({C}_{p})\) :

-

Potential concentrations of the chemicals at the water intake (mg/L)

- \({C}_{sa}\) :

-

Subacute reference concentration (mg/L)

- \(saRfD\) :

-

Subacute reference dose (µg/kg/day)

- \(BW\) :

-

Body weight (kg/person)

- \(DI\) :

-

Daily intake of drinking water (L/day/person)

- \(POD\) :

-

Point of departure level (µg/kg/day)

- \(UFs\) :

-

Product of uncertainty factors (–)

- \(D\) :

-

Diffusion coefficient (m2/s)

- \({A}_{r}\) :

-

River cross-sectional area (m2)

- \(u\) :

-

River flow velocity (m/s)

- \(L\) :

-

Distance downstream from river discharge point to water treatment plant intake (m)

- \(H\) :

-

Average depth (m)

- \({u}^{*}\) :

-

Friction velocity (m/s)

- \(g\) :

-

Gravitational acceleration (m/s2) (9.8 m/s2)

- \(a\) :

-

Coefficient of flow-duration curve

- \(b\) :

-

Coefficient of flow-duration curve

- \(R\) :

-

Wetting perimeter (m)

- \({I}_{e}\) :

-

Hydraulic gradient (–)

- \({HQ}_{c}\) :

-

Hazard ratio of the chemical concentrations at water intake (–)

References

Amagasaki City, Amagasaki Future Association (1998) Amagasakishi No Kiroku: Hanshin Awaji Dai Shinsai [Amagasaki City Report: the 1995 Southern Hyogo Prefecture Earthquake] https://da.lib.kobe-u.ac.jp/da/eqb/0100055388/ (Accessed 16 April 2024) (in Japanese)

Antonioni G, Spadoni G, Cozzani V (2007) A methodology for the quantitative risk assessment of major accidents triggered by seismic events. J Hazard Mater 147:48–59. https://doi.org/10.1016/j.jhazmat.2006.12.043

Buben JA, O’Flanherty EJ (1985) Delineation of the role of metabolism in the hepatotoxicity of trichloroethylene and perchloroethylene: a dose-effect study. Toxicol Appl Pharmacol 78(1):105–122. https://doi.org/10.1016/0041-008X(85)90310-2

Business Policy Forum, Japan (2013) Higashi Nihon Dai Shinsai Wo Fumaeta Kigyou No Jigyou Keizoku No Jikkousei Koujou Ni Kansuru Chousa Kenkyuu [Research Report on Improving the Effectiveness of Corporate Business Continuity in Light of the Great East Japan Earthquake—Aiming to Improve Risk-Response Capability and Ensure Competitiveness of Manufacturing in a Global Competitive Environment -] https://www.bpfj.jp/report/manufacturing_h24/ (Accessed 16 April 2024) (in Japanese)

Fabbrocino G, Iervolino I, Orlando F, Salzano E (2005) Quantitative risk analysis of oil storage facilities in seismic areas. J Hazard Mater 123:61–69. https://doi.org/10.1016/j.jhazmat.2005.04.015

Federal Emergency Management Agency (2022) Hazus Earthquake Model Technical Manual Hazus 5.1 <https://www.fema.gov/sites/default/files/documents/fema_hazus-earthquake-model-technical-manual-5-1.pdf> (Accessed 16 April 2024)

Fire and Disaster Management Agency (2013) Sekiyu Konbinaato No Bousai Asesumento Shisin [Disaster Prevention Assessment Guidelines for Petroleum Complexes]. https://www.fdma.go.jp/singi_kento/kento/items/kento100_44_houkokusho_assessment.pdf (Accessed 16 April 2024) (in Japanese)

Fire and Disaster Management Agency (2014) Kikenbutsu Shisetsu No Shisai Nado Taisaku GaidoRain [Okugai Tanku Chozoujo Hen] [Guidelines for Earthquake Disaster Countermeasures for Hazardous Materials Facilities [Outdoor Tank Storage Facilities]] https://www.fdma.go.jp/publication/guideline/items/guideline_3.pdf (Accessed 16 April 2024) (in Japanese)

G&E Engineering Systems (G&E), (1994), NIBS earthquake loss estimation methods, technical manual, fuel line systems, communication systems, waste water systems

Haag PAMU, Ale BJM (1999) Guidelines for quantitative risk assessment (Purple Book), Committee for the Prevention of Disasters, The Hague (NL)

Hamamoto S, Ito L, Yoneyama N, Tokai A (2021) Case study for the predictive environmental risk assessment of hexamethylenetetramine release to the Yodo River during a massive tsunami attack. Water 13(4):549. https://doi.org/10.3390/w13040549

Hamdan FH (2000) Seismic behaviour of cylindrical steel liquid storage tanks. J Constr Steel Res 53:307–333. https://doi.org/10.1016/S0143-974X(99)00039-5

Hayes JR, Conder LW Jr, Borzelleca JF (1986) The subchronic toxicity of tetrachloroethylene (perchloroethylene) administered in the drinking water of rats. Fundam Appl Toxicol 7(1):119–125. https://doi.org/10.1016/0272-0590(86)90204-6

Inoue T (1980) Societal acceptance. J High Press Gas Saf Inst Jpn 17(5):252–261

Manuel J (2014) Crisis and emergency risk communication: lessons from the Elk River spill. Environ Health Perspect 122(8):A214–A219. https://doi.org/10.1289/ehp.122-A214

Meng Y, Lu C, Yan Y, Shi L, Liu J (2015) Method to analyze the regional life loss risk by airborne chemicals released after devastating earthquakes: a simulation approach. Process Saf Environ Prot 94:366–379. https://doi.org/10.1016/j.psep.2014.09.001

Ministry of Economy, Trade and Industry (2024) PRTR Seido Ni Motozuku Todokede De-ta No Kouhyou Ni Tsuite [Public Release of the Reported Data Based on the PRTR] https://www.meti.go.jp/policy/chemical_management/law/prtr/6a.html (Accessed 16 April 2024) (in Japanese)

Ministry of Economy, Trade and Industry (2024) Kagakubusshitsu Kanri Shishin: Saigai Niyoru Kagakubusshitsu Nado Niyoru Higai No Mizen Boushi Ni Muketa Koujireishuu [Chemicals Management Guidelines: Good Practices for Preventing Damage Caused by Chemicals and Other Substances from Disasters] https://www.meti.go.jp/policy/chemical_management/law/information/pdf/shishin_jireishuu.pdf (Accessed 16 April 2024) (in Japanese)

Ministry of Land, Infrastructure, Transport and Tourism (2024) Water Information System. <http://www1.river.go.jp/> (Accessed 16 April 2024) (in Japanese).

Ministry of Land, Infrastructure, Transport and Tourism, Yodo River Office (2024) Biwako Yodogawa Suikei No Shuhaisui No Shikumi [The Lake Biwa-Yodogawa River System Intake and Drainage Mechanism] https://www.kkr.mlit.go.jp/yodogawa/know/summary/problem/problem-shikumi.html (Accessed 16 April 2024) (in Japanese)

Ministry of the Environment (2010) Chikasui Osen No Mizen Boushi No Tameno Kouzou To tenken, Kanri Ni Kansuru Manyuaru (Dai 1.1ban) [Manual on Structure, Inspection and Management for Prevention of Groundwater Pollution (Version 1.1)] https://www.env.go.jp/water/chikasui/brief2012/manual.html (Accessed 16 April 2024) (in Japanese)

Ministry of the Environment (2022) Chihou Koukyou Dantai Kankyoubukyoku Niokeru Kagakubusshitsu Ni Kakawaru Saigai, Jiko Taiou Manyuaru Sakutei No Tebiki [Guidance for the Formulation of Disaster and Accident Response Manuals Related to Chemical Substances for Environmental Departments of Local Governments] https://www.env.go.jp/content/900518774.pdf (Accessed 16 April 2024) (in Japanese)

Miyagi Prefecture Oil Complex Disaster Prevention Assessment Study (2014) Miyagi Ken Sekiyu Konbinato tou Bousai Asesumento Chousa [Miyagi Prefecture Disaster Prevention Assessment Study for Petroleum Complexes, etc.] https://www.pref.miyagi.jp/soshiki/syoubou/miyagi-bousaikeikaku.html (Accessed 16 April 2024) (in Japanese)

Nakakubo T, Tada Y, Tokai A (2016) Assessment and measure-effectiveness of the effect to water supply function by release of chemical substances caused by earthquake. Japan J Risk Anal 26(3):131–140. https://doi.org/10.11447/sraj.26.131

National Institute of Health Sciences (2020) Reiwa 2nendo Dai 1kai Suishitsu Kijun Chikuji Kaisei Kentoukai Shiryou 2 Akyuusei Sanshouchi Ni Tsuite [FY2020 1st Study Meeting for Sequential Revision of Water Quality Standards Reference Material 2: Subacute Reference Values] https://www.mhlw.go.jp/content/10901000/000730285.pdf (Accessed 16 April 2024) (in Japanese)

National Research Institute for Earth Science and Disaster Resilience (2023) Japan Seismic Hazard Information Station. https://www.j-shis.bosai.go.jp/ (Accessed 16 April 2024) (in Japanese)

Nippon Engine Generator Association (2012) Higashi Nihon Daishinsai ni okeru Jika Hatsuden Setsubi no Kadou Hisai Joukyou [Operation and Damage of Private Power Generation Facilities in the Great East Japan Earthquake] https://nega.or.jp/publication/press/2012/pdf/2012_03_15.pdf (Accessed 16 April 2024) (in Japanese)

Nojima N, Sugito M, Suzuki Y, Ishikawa Y, Okumura T (2003) Development of a two-step risk evaluation model for post earthquake serviceability of utility lifelines based on seismic intensity distribution. J JSCE 724:225–238. https://doi.org/10.2208/jscej.2003.724_225

Osaka Prefecture (2013) Saigaiji Ni Okeru Kagaku Busshitsu No Risuku Teigen Kentou Gyoumu Houkokusho [Report on the Study of Reducing the Risk of Chemical Substances in Disasters] https://www.pref.osaka.lg.jp/attach/4460/00138828/houkokusho.pdf (Accessed 16 April 2024) (in Japanese)

Salzano E, Iervolino I, Fabbrocino G (2003) Seismic risk of atmospheric storage tanks in the framework of quantitative risk analysis. J Loss Prev Process Ind 16(2003):403–409. https://doi.org/10.1016/S0950-4230(03)00052-4

Study Group on Response Strategies for Disinfection Byproduct Precursors in Water Sources (2013) Suidou Suigen Ni Okeru Shoudoku Fukuseiseibutsu Zenku Busshitsu, Osen Taiou Housaku Nitsuite, Torimatome [Summary of Response Strategies for Disinfection Byproduct Precursors in Tap Water Sources] https://www.mlit.go.jp/common/830001678.pdf (Accessed 16 April 2024) (in Japanese)

Sugatsuke K, Harada T, Nonaka T (2014) Determination method of earthquake and tsunami damage to storage tank. Jpn Soc Civil Eng (Ocean Eng). https://doi.org/10.2208/jscejoe.70.I_822

Tong H, Yamazaki F (1996) Relationship between ground motion indices and new JMA seismic intensity. Monthly J Inst Ind Sci 48(11):547–550

Yamada M, Kamei A (1995) Hanshin Awaji Daishinsai ni okeru Okugai Tanku Chozoujo no Higai Joukyou [Damage to outdoor tank storage facilities in the 1995 Southern Hyogo prefecture earthquake]. J Jpn Soc Saf Eng 34(6):459–465

Acknowledgements

Akihiro Tokai serves as a member of the editorial board of Environment Systems and Decisions and recused himself from the peer review of this manuscript.

Funding

Open Access funding provided by Osaka University. This study was conducted by the Japan Environmental Restoration and Conservation Agency (JPMEERF18S11702, JPMEERF20231M03).

Author information

Authors and Affiliations

Contributions

S.H., A.T., T.N, and L.I. contributed to determining the conceptual and methodological framework of the study. S.H. developed the methodology and performed the analyses. S.H. and A.T. contributed to the discussion of the results. S.H. wrote the main manuscript text. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

This study was conducted by the Japan Environmental Restoration and Conservation Agency (JPMEERF18S11702, JPMEERF20231M03).

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hamamoto, S., Tokai, A., Nakakubo, T. et al. Effectiveness of countermeasure options for chemical facilities against the discharge of chemical substances into rivers caused by a large earthquake: case study of the Yodo river system in Osaka prefecture, Japan. Environ Syst Decis (2024). https://doi.org/10.1007/s10669-024-09982-x

Accepted:

Published:

DOI: https://doi.org/10.1007/s10669-024-09982-x