Abstract

Oil palm dominates global oil production, trade, and consumption. Nigeria is one of the leading palm oil producers and consumers. A significant challenge of the palm oil industry is to reduce the environmental impacts (e.g. pollution and carbon footprint) and integrate a circular economy in operation. This study aims to comparatively quantify the environmental impacts of technologies used by different mills. We applied a life cycle assessment in the case of Nigeria. The study covers the reception and processing of fresh fruit bunch (FFB) to end-product palm oil. The inputs include generated empty fruit bunch (EFB), mesocarp fibre, palm kernel shell, palm oil mill effluent, diesel, water and all outputs to the environment for a functional unit of 1-tonne FFB. The results showed that large-scale mills perform worse (468 kg CO2-eq per t FFB) than the semi-mechanised and smallholder mills in effects on climate change but better in the other impact categories, including human toxicity, ecotoxicity, and fine particulate matter formation. In large-scale mills, the climate change impacts decrease by 75% when the raw palm oil mill effluent (POME) is used in composting EFB. Similarly, climate change impacts reduce by 44% when biogas from POME substitutes diesel in the semi-mechanised and smallholder mills. We conclude that regulatory measures are needed to ensure improved management practices in the production processes. Particular attention should be paid to the generation and reuse of biomass and POME. This study provides a handy reference to assist the sustainable energy transition in Nigeria’s and other parts of sub-Saharan Africa’s oil palm industry to mitigate climate change and form a cleaner bioeconomy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

There is a growing need for oil crops to meet worldwide food, feed, and fuel demands (Meijaard et al., 2020). Oil palm (Elaeis guineensis jacq.) contributed 34% of global vegetable oil in 2017 (Mayes, 2020); it is the most traded oil crop in monetary terms and most efficient in terms of productivity (Nurrochmat et al., 2020). The average yield per hectare of oil palm is eight times more than soybeans—the second most competitive oil crop (Schmidt & Weidema, 2008). Therefore, palm oil will continue to play a significant role in global vegetable oil production, trade/economy, and consumption. For instance, palm and palm kernel oil represent 70% of Nigeria’s total domestic vegetable oil supply (Nzeka, 2014). In 2018, Nigeria produced more palm oil (one million tonnes) than other countries globally, except for Columbia, Thailand, Malaysia, and Indonesia (FAOSTAT, 2021), which amounted to over 64 million tonnes in total. Until the 1960s, Nigeria took the lead among palm oil producers, contributing 43% of global production, which dropped progressively over time due to over-reliance on traditional producing methods (Thomas et al., 2011). Nowadays, Nigeria shares < 2% of global but > 50% of Africa’s total palm oil production (Anyaoha et al., 2018). The palm oil industry still and will continue playing an essential role in Nigeria’s agricultural sector covering production, consumption, rural livelihoods, and environmental impacts due to intense use of resources and energy, generation of waste, and cause of pollution.

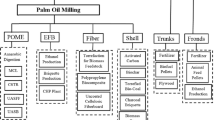

Oil palm produces fruits in bunches known as fresh fruit bunch (FFB). In Nigeria, processors of FFB can be classified into large-scale and small-scale mills. This classification is based on the levels of technology applied in palm oil production in Nigeria (Anyaoha & Zhang, 2021). Semi-mechanised and smallholder mills make up the small-scale mills, contributing over 80% of processed FFB. Palm kernel shell (PKS), mesocarp fibre (MF), and empty fruit bunch (EFB) are the primary solid biomass residues produced in the industry after FFB is processed; palm oil mill effluent (POME) is the liquid waste. Large-scale mills use PKS and MF to heat the boiler for steam production. To use EFB as fuel, large-scale mills usually install additional infrastructures to extract oil/dewater and reduce the size of EFB. But this will lead to an extra cost and only meaningful during the period of low FFB yields. Disposal is a more cost-effective means to treat EFB, mostly in heaps; however, it leads to methane emissions. The FFBs are manually quartered in small-scale mills and left for two or more days, enabling an easy detachment of the fruits from FFB spikelets. Unlike large-scale mills, small-scale mills commonly use diesel to power processing machines; semi-mechanised mills use different amounts of PKS, MF and EFB to generate steam, while smallholder mills use EFB and MF to boil/cook the fruits. Both large- and small-scale mills in Nigeria predominately follow a typical “linear economy” (take-make-dispose) and have well-known negative environmental impacts, such as water, soil and air pollution, biodiversity loss, and greenhouse gas (GHG) emissions (Meijaard et al., 2020). Therefore, a recognised significant challenge is to reduce environmental impacts and enhance the sustainability of the palm oil industry by integrating the concept of circular economy in operation.

Studies of life cycle assessment (LCA) have been conducted on crude palm oil (CPO) production, FFB processing, biogas production from POME, and EFB composting. Aziz and Hanafiah (2020) and Harsono et al. (2014) emphasised the importance of biogas from POME anaerobic digestion as a sustainable energy source and a proper waste management approach. Schmidt and De Rosa (2019) highlighted that POME contributes significantly to methane emission in the palm oil mill stage. Composting EFB with POME is an efficient way of reducing greenhouse gases (GHG) emissions in the oil palm industry (Baron et al., 2019 and Norhasmillah et al., 2013). Stichnothe and Schuchardt (2011) reported that emissions from EFB and POME in open ponds contribute 77% of the total global warming potential (GWP) in a worst-case scenario of life cycle assessment compared to that of plantation, palm oil mill, and transportation stages. Similarly, Chanlongphitak et al. (2015) carried out a life cycle assessment of EFB utilisation for power plants; EFB utilisation contributed over 60% of total GWP compared to oil palm plantation, CPO extraction and transportation. Rasid et al. (2013) reported that bio-oil production and utilisation for power generation contribute approximately 80% of CO2 in tonne per ha/year compared to oil palm plantation stage, palm oil mill, and transportation in a life cycle assessment, in which EFB and PKS were used in pyrolysis, but POME treatment was not included.

Schmidt and Rosa (2020) reported that the Roundtable on Sustainable Palm Oil certification (RSPO) of bleached and deodorised palm oil could lead to multiple benefits, including less land-use change, GHG emissions reduction, peat soil conservation, and more biogas captured from POME. Nasution et al. (2018) compared different EFB and POME treatment technologies. The technologies are POME in open ponds with EFB dumping, composting EFB with raw POME, composting EFB with POME digestate, while biogas from POME anaerobic digestion is captured. Others include applying POME anaerobic digestate, dumping EFB on land and biogas capture from POME while using membrane technology to recover and recycle water from POME. The use of digestate in EFB composting resulted in less GWP than other technologies.

Other life cycle assessment studies investigated FFB production from continued land use (Zulkifli et al., 2010), refined palm oil production and fractionation (Tan et al., 2010), oil palm seedling production (Muhammad et al., 2010), and production of oil palm seeds (Muhamad et al., 2014). Anyaoha and Zhang (2021) reported a first-kind-of life cycle inventory of different levels of technologies in the oil palm industry, giving more insight into the influence of technology application on emissions. This is particularly important as existing studies have not reported the impact of technologies (applied by large- and small-scale mills) on environmental emissions using life cycle assessment, covering traditional and industrial processing methods in palm oil production. Some studies reported technological differences, underling the importance of producing capacity and waste generation and utilisation in the oil palm industry (Anyaoha et al., 2018; Izah & Ohimain, 2015; Ohimain & Izah, 2014, 2015). Technology-based comparative life cycle assessments like this work have not been done yet to the best of our knowledge. Specifically, this work aims to further investigate the “hotspots” of environmental impacts in palm oil production based on Anyaoha and Zhang (2021), assuming that different levels of technologies are applied in other countries. This study's results are expected to provide a handy reference to assist the sustainable energy transition in Nigeria’s and other parts of sub-Saharan Africa’s oil palm industry to mitigate climate change, enhance sustainability, and form a cleaner bioeconomy.

2 Materials and method

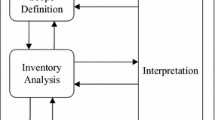

Life cycle assessment is widely used to assess the environmental burdens of products, processes, and services following standards, specifically ISO 14040 and 14,044 (ISO, 2006a and 2006b), thus an essential tool to provide evidence for supporting decision-making. The phases of LCA include (i) definition of the goal, scope, functional unit, and boundary conditions; (ii) life cycle inventory analysis (LCI); (iii) life cycle impact assessment (LCIA); and (iv) life cycle interpretation, and reporting. In the following sections, the study’s goal, functional unit, and boundary conditions are specified in Sect. 2.1; life cycle inventory in Sect. 2.2 covers the design of flow diagrams, data collection, allocation and final calculations; life cycle assessment in Sect. 2.3 refers to the modelling work using inventory data under different impact categories, followed by sensitivity analyses in Sect. 2.4 and specification of limitations in Sect. 2.5.

2.1 Scope and goal definition

We use a gate-to-gate approach in this study, which includes reception of the FFB, sterilisation and threshing of bunches, digestion of fruits, oil extraction, palm nut/fibre separation, cracking of palm nut, palm kernel shell/palm kernel separation, oil clarification, and the fate of solid and liquid wastes. In small-scale mills, the bunches are quartered before threshing; fruits are sterilised in semi-mechanised mills but cooked/boiled in smallholder mills. Alternative solid and liquid waste management scenarios were analysed for both large-scale and small-scale mills. The study goal is to compare the environmental impacts of different techniques applied in Nigeria’s oil palm industry in a gate-to-gate life cycle assessment. The functional unit describes the product or service to be used in the life cycle assessment. Therefore, the system boundary covers the processing of fresh fruit bunch, from the reception of a functional unit of one tonne (1t) fresh fruit bunch to processed palm oil product. All inputs and outputs data were allocated to the functional unit according to ISO 14040 and 14,044 specifications.

Two scenarios were considered for large-scale mills: using raw POME in EFB composting (Scenario L.1) and generating biogas using POME, while the digestate provides moisture for EFB composting (Scenario L.2). In the second scenario (L.2), part of the captured biogas substitutes diesel in the boiler start-up. In small-scale mills, replacing diesel with biogas (Scenario S.3) was proposed. The intervention related to the utilisation of the remaining biogas was not included. Figure 1 shows a representative process flow with boundary conditions for the three types of mills.

2.2 Life cycle inventory

This study is a continuation of the work of Anyaoha and Zhang (2021), which documented life inventories of FFB processing by the large-scale, semi-mechanised, and smallholder mills in Nigeria. In addition to the inventories of large-scale, semi-mechanised, and smallholder mills calculated in Anyaoha and Zhang (2021), inventories of the proposed three scenarios have been calculated as explained below with the sources of data referenced. Table 1 shows the input energy and material mass balance for a tonne of FFB as reported by Anyaoha and Zhang (2021). A proposed 10 tonnes of FFB per day mill for the small-scale processors will substitute all fossil fuel (diesel) with biogas from POME anaerobic digestion and increase stakeholders’ capacity through a cluster system where they can share the same facilities for processing FFB. The proposed cluster system for small-scale mills (scenario S.3) includes the mill unit (stripper, digester, clarifier, boiler, and cracker), POME anaerobic digester, and biogas engine for electricity generation, while the extra biomass sold to independent power producers, which will substitute either natural gas or diesel used in electricity generation in Nigeria. However, this displaced electricity and the emissions saved were not accounted for in the analysis. A gas engine to generate electricity was considered because it is less expensive than a steam turbine at a smaller capacity.

In anaerobic digestion, POME is first transferred into a cooling and mixing pond and afterwards into the anaerobic tank. The generated gas can be stored for use when needed or directly fired for heat or electricity production. Schmidt (2007) provided a detailed report on the emissions related to POME, which was adopted in this study. The same methane of 6.54 kg emitted in the aerobic pond in Anyaoha and Zhang (2021) was assumed to be available in the POME digester. However, 7.8% of the 6.54 kg CH4 would be emitted (Schmidt, 2007); the remaining 92.2% was assumed to be captured. Methane emission from incomplete flaring was estimated as 0.45 kg (15% of 6.03 kg) with a flaring efficiency of 50% (UNFCCC, 2006, p. 30). The emission from the gas engine was 1.5% of 5.13 kg (0.077 kg). The gas engine efficiency and energy content of methane were taken as 40% and 50.4 MJ/kg (Schmidt, 2007) or 13.9 kWh/kg as lower heating value. The emissions of SO2 and NOx from the combustion of 5.13 kg methane were estimated using 0.018 g and 0.2 g per energy input at 100% efficiency. The emission of N2O at 0.0015 kg per t FFB remains unchanged (Schmidt, 2007).

The composting operation includes size reduction of EFB using a cutting mill, forming longitudinal heaps, turning the heaps for aeration and mixing, applying POME to balance moisture content and C:N ratio, and screening the finished compost. The shredder, pump, screening device can be operated using electricity from the mill, while the turning device is powered using a diesel engine. Baron et al. (2019) reported the following ranges: composting processes (28 to 120 days), turning frequency (every two days to every 40 days), and POME/EFB ratio (0.25 to 0.65 m3 per t), while Stichnothe and Schuchardt (2010) reported that up to 3.5 m3 of POME could be used for EFB composting.

Yoshizaki et al. (2012) reported diesel consumption of 2.8985 L per t EFB or 0.667 L of diesel per t FFB used to operate tractor, turner, wheel loader and forklift. There was no specific mention of how much diesel was consumed by each machinery. The applied values for diesel consumption are shown in Table 2.

Electricity consumptions for the scenarios were taken from Nasution (2018), as shown in Table 2. Baron et al. (2019) reported that 51% of EFB resulted in compost. We assumed the effects of POME sludge on the mass of compost to be negligible. The emissions from diesel combustion for composting were estimated based on the method explained in Anyaoha and Zhang (2021).

Methane, formed in the anaerobic section, is usually oxidised in the aerobic section of the composting. N2O emissions range from 0.5 to 5 per cent of initial nitrogen content (IPCC, 2006). We apply the values estimated by Hellebrand (1998) in this study. They (Table 3) were used for both EFB composting with raw POME and POME digestate.

Table 4 and 5 summarise the input and output parameters and their diesel consumptions of three scenarios.

2.3 Life cycle impact assessment

Gabi Education software (Sphera, Germany) was used to analyse inventory data with Ecoinvent 2.0 and GaBi 9.2.1.68 Education databases providing background data. The impact category indicators were calculated using ReCiPe 2016 method. The evaluated ReCiPe 2016 impact categories at the midpoint level include climate change (CC), fine particulate matter formation (PMF), freshwater ecotoxicity (FWE), human carcinogenic toxicity (HTC), human non-carcinogenic toxicity (HTNC), marine ecotoxicity (ME), photochemical ozone formation, ecosystems (POF, E), photochemical ozone formation, human health (POF, H), stratospheric (ozone) depletion (OD), terrestrial acidification (TA), terrestrial ecotoxicity (TE), and marine eutrophication (MEP).

2.4 Sensitivity analysis

With the same functional unit of 1-tonne FFB, we used sensitivity analysis to determine the significance of the assumptions by varying inputs. The results of the input and output ranges are comprehensively presented in Anyaoha and Zhang (2021). We also used sensitivity analysis to assess input parameters such as diesel, biomass, and POME on impact categories using Gabi software. The minimum electricity requirement per t FFB was considered in terms of biomass use. The minimum water requirement was also considered since POME is dependent on water use.

Diesel consumptions for the large-scale, semi-mechanised, and smallholder mills were increased by 50 and 75%. For the large-scale mills’ biomass use, in the first case (Large-70), 50% of PKS, 70% of MF, and 75% of EFB (same as average values from Chavalparit et al. (2006), Schmidt (2007), and Yoshizaki et al. (2012)) were used. In the second case (Large-50), 50% PKS, and 50% MF and the same 75% EFB were used. The value of water decreased by 30% and with 64.5% as POME. The second case was a further reduction of POME by 50% only.

In semi-mechanised mills, EFB was reduced by 50% (Semi-50) for steam generation according to Ohimain and Izah (2015) and open-incineration of the excessive biomass. Another scenario was the sale of excessive biomass (Semi-50 N) and using 50% of EFB as fuel. A 30% water reduction with 64.5% of water as POME and a 50% reduction in POME only were considered.

For smallholder mills, 17% of EFB, 29% of MF, and 4% of PKS, as reported by Ohimain and Izah (2014), were used with open-incineration of the remaining biomass (Small-25) and without open-incineration (Small-25 N). As Anyaoha and Zhang (2021) explained, water requirement was considered regarding POME, which was reduced by 50 and 75%.

2.5 Assumptions and limitations/constraints

-

The life cycle assessment is a gate-to-gate approach and does not reflect the total emissions of palm oil production (from planting to distribution).

-

We assumed that within the functional unit, all generated POME was used in composting EFB. There might be variations, especially the peaks of dry and wet seasons, when evaporation is at its highest and lowest rate, respectively.

-

The return of compost to plantation, building, machinery, and transportation was excluded.

-

The composting sites are located close to the palm oil mills

The Gabi software used in this study is developed in Europe. However, where possible, we adapt the input data using the actual situation in Nigeria. Where not possible, we referred to the available generic data.

3 Results

3.1 Life cycle inventory

The material inputs and outputs for the large-scale, semi-mechanised, and smallholder mills have already been presented in Anyaoha and Zhang (2021). Other inventories, including the scenarios, are in Tables 3, 4, and 5.

3.2 Life cycle impact assessment

The environmental impacts of the large-scale, semi-mechanised and smallholder systems are presented below, followed by the three scenarios. Figure 2 shows the relative contributions of the mills to different impact categories. In contrast, Figs. 3, 4, and 5 show the contributions of various units (milling, biomass treatment, and POME treatment) to the impact categories in the life gate-to-gate analysis.

Relative contributions of large-scale, semi-mechanised, and smallholder mills to the different impact categories. CC–climate change, PMF–fine particulate matter formation, FWE—freshwater ecotoxicity, HTC— human carcinogenic toxicity, HTNC—human non-carcinogenic toxicity, ME—marine ecotoxicity, POFE—photochemical ozone formation, ecosystems, POFH—photochemical ozone formation, human health, SD—stratospheric depletion, TA—terrestrial acidification, TE—terrestrial ecotoxicity, ME—marine eutrophication, and MEP—marine eutrophication

3.2.1 Climate change

The climate change effect is expressed in kg CO2-eq; it quantifies the impact of GHG, including CO2, methane, and nitrogen oxide, on global temperature change (Huijbregts et al., 2017). The large-scale mills emit 468 kg CO2-eq per t FFB to the atmosphere, while semi-mechanised and smallholder mills emit 162 and 158 kg CO2-eq per t FFB, respectively (Fig. 3a). The results imply that large-scale mills contribute 65% more than semi-mechanised and smallholder mills. POME makes up 48% of the impact in large-scale mills, while 40% is from EFB dumping. Emissions from the biomass open-burning in semi-mechanised and smallholder mills contribute 64% and 66% of the total emission amount. Though the emissions may not be avoidable when the biomass is used in power plants, their combustion can substitute fossil fuel consumption. The proposed two scenarios in large-scale mills considerably decreased the global warming impact. Scenario L.1 lowers the emissions from large-scale mills to 128 kg CO2-eq per t FFB, while scenario L.2 reduces it to 158 kg CO2-eq per t FFB. On the other hand, scenario S.3 decreased small-scale mills’ emission to 89 kg CO2-eq per t FFB.

3.2.2 Fine particulate matter formation

Fine particulate matter formation is expressed in kg PM2.5-eq. It describes the change in ambient concentrations of components consisting of NH3, NOx, SO2, organic chemicals, metals, and soil or dust particles. The large-scale, semi-mechanised, and smallholder mills yield 0.9, 2.8 and 3.1 kg PM2.5-eq. to PMF, respectively (Fig. 3b). This represents 70 and 72% more outputs of PMF from semi-mechanised and smallholder mills than the large-scale mills, respectively. Substituting diesel with biogas in small-scale mills (scenario S.3) decreased the output to 0.8 kg PM2.5-eq. There were no changes in PMF because of scenarios L.1 and L.2.

3.2.3 Ecotoxicity

The ecotoxicity, which includes terrestrial, freshwater, and marine ecotoxicity, describes the effects of toxic substances on diverse ecosystems (Acero et al., 2017). The impact categories are measured in 1,4-dichlorobenzene equivalent (kg 1,4-DCB eq.). The semi-mechanised and small-scale mills contribute comparably 43 kg 1,4-DCB eq. to freshwater ecotoxicity, while the large-scale mills contribute less than 1 kg 1,4-DCB eq. (Fig. 3c). The effects on marine and terrestrial ecotoxicity are shown in Figs. 3d and 4a. Almost all the ecotoxicity impacts are from biomass open-incineration in the small-scale mills. Scenario S.3 decreased the contributions to terrestrial, freshwater, and marine ecotoxicity to 457, 0.015, and 0.36 kg 1,4-DCB eq., respectively. These represent significant reductions compared to the values from semi-mechanised and smallholder mills, as shown in Figs. 3c, 3d, and 4a, because of the avoided emissions from biomass open-incineration. There were no notable changes in the contributions to terrestrial ecotoxicity between large-scale mills and scenarios L.1 and L.2.

3.2.4 Human toxicity

Human toxicity (cancer and non-cancer) relates to the potential harm of a unit of chemical released into the environment (Acero et al., 2017). It is measured in kg 1,4-DCB eq. The semi-mechanised and smallholder mills lead to 243 kg 1,4-DCB eq. more to human toxicity (cancer) and 95,200 kg 1,4-DCB eq. more to human toxicity (non-cancer) than large-scale mills (Figs. 4b and c). The contribution to human toxicity (cancer) decreased to 0.012 kg 1,4-DCB eq. in scenario S.3, while that of human toxicity (non-cancer) dropped to 29.2 kg 1,4-DCB eq. There were no changes in the values of the large-scale mills and scenarios L.1 and L.2.

3.2.5 Stratospheric (ozone) depletion

The stratospheric ozone depletion, expressed in kg CFC-11 eq., quantifies the effects of substances like chlorofluorocarbon, halons, and hydrochlorofluorocarbons on stratospheric ozone concentration, which leads to a higher amount of ultraviolet (UV) light entering the earth’s atmosphere (Acero et al., 2017; Huijbregts et al., 2017). The semi-mechanised and smallholder mills lead to 72% more ozone harmful substances than the large-scale mills (Fig. 4d). Effects of Scenario S.3 on stratospheric depletion decreased by 74%, while Scenario L.1 increased stratospheric ozone depletion by 19%.

3.2.6 Photochemical ozone formation

Human health ozone formation and ecosystem ozone formation are quantified in kg NOx-eq. They describe the changes in ambient concentration of ozone due to emissions of precursor substances such as nitrogen oxides (NOx) and volatile organic compounds. The reaction can be aided by the presence of carbon monoxide (CO), sulphur dioxide (SO2), nitrogen oxide (NO), ammonium and non-methane volatile organic compounds (Acero et al., 2017; Frischknecht et al., 2007; Huijbregts et al., 2017). The large-scale, semi-mechanised, and smallholder mills lead to 0.88, 2.21, and 2.19 kg NOx-eq. to ecosystem ozone formation, respectively (Fig. 5a). In terms of POF, H, large-scale, semi-mechanised, and smallholder mills lead to 0.71, 2.01 and 2.0 kg NOx-eq., respectively (Fig. 5b). Scenario S.3 contributes 0.86 and 0.71 kg NOx-eq. to POF, E and POF, H, respectively. Scenarios L.1 and L.2 have almost the same ecosystem ozone formation and human health ozone formation (0.88 and 0.72 kg NOx-eq.).

3.2.7 Terrestrial acidification

Terrestrial acidification is expressed in kg SO2-eq. It describes the changes in acid deposition due to emissions of NOx and SO2. An example is the formation of acid rain when SO2 reacts with water. The semi-mechanised and smallholder mills contribute about 58% more to terrestrial acidification than the large-scale mills (Fig. 5c). The open-incineration of biomass contributes more than 70% of the total value in small-scale mills. With the proposed scenario S.3 for small-scale mills, the TA decreased to about 0.2 kg SO2-eq, representing a 68% decrease. TA decreased by less than 16% in both scenarios L.1 and L.2.

3.2.8 Marine eutrophication

Marine eutrophication, measured in kg N eq., relates to the response of the marine ecosystem to increased emissions of nutrients (e.g. nitrogen) to oceanic waters (Cosme et al., 2017). The contributions of semi-mechanised and smallholder mills to MEP are shown in Fig. 5d. Large-scale mills have zero contribution. We assumed that POME in large-scale mills stays in the pond; the effects of disposal later in farm fields was not considered in this work. However, in small-scale mills, POME disposal in agricultural land contains high nitrogen and phosphorus, leading to high MEP, as shown in Fig. 5d. No MEP was recorded in all proposed scenarios, which did not account for the disposal of POME in the agricultural land.

3.3 Sensitivity analysis

Figure 6 presents the line charts of the sensitivity analyses. In large-scale mills, a higher diesel consumption by 50 and 75% would increase impacts of all categories by < 2%. In the case of Large-70, climate change and other impact categories will lower by 14% and 37%, while FEW and CC will decline to 50% and 16% in the case of Large-50. With a 30% reduction in water and 64.5% POME, CC will reduce by 26% and other impact categories by < 8%. Further decrease in POME by 50% will lead to a 32% decrease in CC and < 13% in PMF, OD and TA (Fig. 6a). There is no change in other impact categories.

Line chart for different options of biomass utilisation in a sensitivity analysis. a Large-70–50% palm kernel shell, 70% mesocarp fibre, and 75% empty fruit bunch; Large-50–50% palm kernel shell, 50% mesocarp fibre, and 75% empty fruit bunch. b Semi-50–50% empty fruit bunch with open-incineration, Semi-50 N–50% empty fruit bunch without open-incinerations. c Small-25–17% empty fruit bunch, 29% mesocarp fibre, and 4% palm kernel shell with open-incineration, Small-25 N–17% empty fruit bunch, 29% mesocarp fibre, and 4% palm kernel shell without open-incineration

Like large-scale mills, an increase in diesel consumption by 50 and 75% in semi-mechanised mills increases all impact categories by < 10% (Fig. 6b). With the Semi-50 scenario, a 31% increase in FWE, HTC, HTPNC, MEP, and TE is recorded, while others increase by < 14% (Fig. 6b). The Semi-50 N results in > 78% reduction in all impact categories. In the case of a 30% reduction in water with 64.5% as POME, or only a 50% reduction in POME, the analyses indicate increases of FWE, HTC, ME and HTPNC by < 1%, while others decrease by 10% in both cases, except for MEP (30 and 50%).

Small-25 results in an increase in all impact categories ranging between 4 and 37% except PMF, which decrease by 8% (Fig. 6c). Small-25 N results in > 83% reduction in all impact categories. The decrease of POME by 50% reduces MEP and PMF by 30% and 16%; other impact categories decrease by < 6%. (Fig. 6c). POME reduction by 75% decreases MEP, PMF and the others by 50, 16 and < 10%, respectively. The increase in diesel consumption by 50 and 75% results in a < 6% increase in all impact categories except PMF, which decreases by 16%.

4 Discussion

Technology plays an essential role in reducing environmental impacts resulting from industrial activities like palm oil production. The low level of applied technology and little investment in the small-scale palm oil industry characterise a higher diesel consumption and biomass open-incineration in Nigeria. These practices lead to various harmful emissions, including GHG. Factors of technology and capacity need to be considered in reducing environmental impacts. The use of biogas to substitute diesel (Scenario S.3) showed reductions in most impact categories because emissions were avoided from diesel consumption, open-incineration and POME disposal. In large-scale mills, storing POME in ponds buys time, enabling water evaporation, solid sludge formation, and emissions of GHG, hydrogen sulphide, and ammonia.

The main contributors to CC in the large-scale mills are EFB dumping and POME in the pond. As shown in Fig. 3, EFB dumping and POME in the pond contribute 185 and 223 kg CO2-eq per t FFB, respectively. Our results are of a similar magnitude to previous studies. Nasution et al. (2018) reported 230 and 140.84 kg CO2-eq per t FFB, while Stichnothe and Schuchardt (2011) reported 220 and 120 kg CO2-eq per t FFB for EFB dumping and POME in the pond, respectively.

The main contributing factor to PMF is particulates during biomass combustion in the boiler or open-incineration. The higher values recorded in semi-mechanised and smallholder mills than large-scale mills demonstrate the influence of biomass open-incineration, which decreased considerably in Scenario S.3 without biomass open-incineration. The contribution from biomass open-incineration is more than 50% of total PMF in both semi-mechanised and smallholder processors. Schmidt and Rosa (2020) reported that particulates emitted from the palm oil mill boilers contribute to PMF.

Specifically, open-incineration of biomass in semi-mechanised and smallholder mills contributes more to climate change, fine particulate matter formation, freshwater ecotoxicity, human carcinogenic toxicity, human non-carcinogenic toxicity, marine ecotoxicity, photochemical ozone formation, ecosystems, photochemical ozone formation, human health, stratospheric depletion, terrestrial acidification, terrestrial ecotoxicity, except marine eutrophication. This is demonstrated by the increases in all impact categories with semi-50 and Small-25 except PMF, which decreases by 8% in smallholder mills. Open-incineration of biomass has no economic benefit to processors and contributes more to the impact categories. Compared to large-scale mills, small-scale mills are more sensitive to changes in diesel consumption. This is particularly true because of their dependence on diesel. In terms of POME reduction, smallholder and semi-mechanised processors are more sensitive to MEP (an increase of at least 30%). However, the values of MEP in both systems are < 1 kg N eq. It should be noted that water use cannot be reduced below the minimum requirement. Additionally, scenario S.3 demonstrates that all impact categories except CC decreased by 60% with semi-mechanised and smallholder mills. In general, substituting diesel with biogas reduces all impact categories by at least 40%. Therefore, there is a need for an economic assessment of this option.

The impacts of large-scale mills appear to be less sensitive to an increase in diesel use. This is particularly true with CC since EFB dumping and POME in the pond contribute 88% of the total impact. A similar result is recorded with a reduction in biomass, which demonstrates that CC is less sensitive to both options in the sensitivity analysis when compared to other impact categories. However, CC was more sensitive to changes in POME than other impact categories, in line with the high share of POME in total CC. Therefore, biogas generation using POME or direct composting with EFB in Scenarios L.1 and L.2 appears good options for reducing environmental impacts of the large-scale mills, particularly to mitigate CC. Scenarios L.1 and L.2 demonstrate the positive effects of composting EFB with either raw POME or digestate. The valuable methane collected during anaerobic digestion reduces the carbon footprint by substituting fossil fuel. Therefore, economic assessment between the different options to manage EFB and POME becomes vital. Replacing part of the biomass with biogas produced from POME offers another opportunity to improve the industry’s circularity and sustainability that needs to be further investigated in economic terms. Moreover, the challenges of managing POME and EFB are somewhat connected since the sterilisation of EFB contributes > 28% of the total POME generated.

There have been discussions on the use of microwave to sterilise EFB. The successful deployment of the technology will reduce the amount of generated POME and improve the characteristics of EFB as fuel, which might bring added benefits to the processors. Cheng et al. (2011) demonstrated that microwave pretreatment of palm fruits resulted in a very low FFA content (0.26%) and moisture (0.05%). Nokkaew and Punsuvon (2014) reported products with 84.14% oil content, 8.49% moisture, 2.36 Deterioration of Bleachability Index, 882.55 ppm carotene content, and 3.40% FFA. Although 3.40% FFA is high, it is still below the threshold (5%). Both studies used at least 800 W of power and microwave-treated palm fruits. The challenge remains the feasibility of microwave pretreatment in terms of power requirement. This is important because steam sterilisation of FFB enables the detachment of palm fruit from the FFB spikelets in addition to cooking the fruits.

While PKS, MF, and EFB can be used as fuel in small-scale mills, it is crucial to mention the low-quality oil produced by small-scale processors due to the delay in processing the fruits. However, local consumers have reported a preference for oil taste with high FFA. The challenge remains the choice between taste and health. Most importantly, any effort to improve the technology and capacity of small-scale mills should consider balancing biomass use as fuel and quality of oil products, especially when using EFB as fuel. The challenge remains to sterilise fruits from FFB with little or no steam. In terms of environment, Wiloso et al. (2014) ranked the use of EFB as mulch better than conversion to either compost, ethanol, treatment in an incinerator, or direct sell as co-products. Other options reported include the generation of electricity through EFB gasification (Siregar et al., 2020), EFB pyrolysis (Rasid et al., 2013), and EFB combustion (Chanlongphitak et al., 2015).

Another disadvantage of small-scale mills in Nigeria is their lower yield of CPO per t FFB. Schmidt and Rosa (2020) reported that higher yields of CPO per t FFB and share of biogas capture in POME treatment facilities benefit RSPO certified production. For the large-scale mills, improved biogas capture technology will lead to decreased CH4 emissions. Small-scale mills have a lower yield of CPO per t FFB than large-scale mills due to the processing method. FFB yield is an outcome of inputs in oil palm plantation, while CPO is associated with FFB processing at the mill. A lower FFB yield negatively affects the share of palm oil products from these mills in the market, and more hectares of land are needed per t FFB. Conversion of regional rain forests to oil palm plantations will substantially affect biodiversity, food security, climate change, land degradation, and livelihoods. Additionally, lower CPO yield fails to cover the demand–supply gap in Nigeria’s palm oil market, which leads to palm oil imports from Malaysia and Indonesia. Palm oil production on peatlands in Indonesia and Malaysia causes a massive, unsustainable land-use change (Dohong et al., 2018; Hashim et al., 2018), thus contributing considerably to GWP.

It is worth noting that quartered EFB needs to be stored and dried in small-scale mills due to low production capacity. The scalability of this system may come with disproportionate costs to the processors. It is thus vital to compare the environmental impacts of EFB as either fuel or manure. Circular economy application in the palm oil industry should not focus on finding a use for every by-product or residue; it is more meaningful to eliminate/reduce the environmental effects of the products and identify the opportunity to close energy and resource loop where technically feasible and economically profitable. This is only possible through redefining and optimising the production processes and related technology. For example, integrating less water consumption, reuse/recycle of EFB and POME processes as demonstrated in the scenarios.

Table 6 presents previous studies on life cycle assessments of FFB processing. Stichnothe and Schuchardt (2011) considered returning compost to oil palm plantations to replace fertiliser. While this study considers technologies of palm oil mills and the fate of POME and EFB, Stichnothe and Schuchardt (2011) and Nasution et al. (2018) included oil palm plantation and composting, respectively.

5 Conclusion

This study uniquely compares technologies applied by different palm oil mills in Nigeria and their environmental impacts, including stratospheric depletion, photochemical ozone formation, human toxicity, ecotoxicity, fine particulate matter formation, and terrestrial acidification, marine eutrophication, and GHG emission on global warming. The results indicate that large-scale mills perform worse on global warming but better in other investigated impact categories than small-scale mills, including human toxicity, ecotoxicity, and fine particulate matter formation. It is evident from the assessments that biomass utilisation and POME generation are the critical hotspots of environmental impacts in palm oil processing. In large-scale mills, composting EFB with raw POME and biogas generation from POME could decrease their contribution to global warming by 75% and 66%, respectively. Substituting diesel and avoiding biomass open-incineration could reduce the global warming impact of small-scale mills by 44%. The positive effects and associated changes in technologies and mill operation require concerted efforts by regulation to improve industrial stakeholders’ management practices. Any efforts to reduce water consumption and waste disposal will lead to less environmental pollution and less footprint of the palm oil industry. Notably, this work provides insight into the need for re-designing and upgrading technology at the level of small-scale mills. It should consider integrating “circular economy aspects” like recycling and reusing by-products to reduce environmental impacts and increase sustainability. More work is needed to explore, for example, the effects of low CPO yield on GHG emissions along the West Africa palm oil belt to develop adaptive climate change mitigation measures and sustainable transformation of the palm oil industry for a greener economy.

References

Acero, A. P., Rodriguez, C., & Ciroth, A. (2017). LCIA methods: Impact assessment methods in life cycle assessment and their impact categories. Green Delta, 23, 1–23.

Anyaoha, K. E., & Zhang, L. (2021). Renewable energy for environmental protection: Life cycle inventory of Nigeria’s palm oil production. Resources, Conservation & Recycling, 174(July), 105797. https://doi.org/10.1016/j.resconrec.2021.105797

Anyaoha, K. E., Sakrabani, R., Patchigolla, K., & Mouazen, A. M. (2020). Co-gasification of oil palm biomass in a pilot scale downdraft gasifier. Energy Reports, 6, 1888–1896. https://doi.org/10.1016/j.egyr.2020.07.009

Anyaoha, K. E., Sakrabani, R., Patchigolla, K., & Mouazen, A. M. (2018). Evaluating oil palm fresh fruit bunch processing in Nigeria. Waste Management & Research, 00, 1–11. https://doi.org/10.1177/0734242X17751848

Aziz, N. I. H. A., & Hanafiah, M. M. (2020). Life cycle analysis of biogas production from anaerobic digestion of palm oil mill effluent. Renewable Energy, 145, 847–857. https://doi.org/10.1016/j.renene.2019.06.084

Baron, V., Saoud, M., Jupesta, J., Rezky Praptantyo, I., Tirto Admojo, H., Bessou, C., & Caliman, J. P. (2019). Critical parameters in the life cycle inventory of palm oil mill residues composting. IJoLCAS, 3, 1.

Chavalparit, O., Rulkens, W. H., Mol, A. P. J., & Khaodhair, S. (2006). Options for environmental sustainability of the crude palm oil industry in Thailand through enhancement of industrial ecosystems. Environment, Development and Sustainability, 8(2), 271–287. https://doi.org/10.1007/s10668-005-9018-z

Chanlongphitak, S., Papong, S., Malakul, P., Mungcharoen, T. 2015. Life Cycle Assessment of Palm Empty Fruit Bunch Utilization for Power Plants in Thailand. International Conference on Biological, Environment and Food Engineering (BEFE-2015) May 15–16, 2015 Singapore, 1–6.

Cheng, S. F., Nor, L. M., & Chuah, C. H. (2011). Microwave pretreatment: A clean and dry method for palm oil production. Industrial Crops and Products, 34(1), 967–971. https://doi.org/10.1016/j.indcrop.2011.03.002

Cosme, N., Jones, M. C., Cheung, W. W. L., & Larsen, H. F. (2017). Spatial differentiation of marine eutrophication damage indicators based on species density. Ecological Indicators, 73, 676–685. https://doi.org/10.1016/j.ecolind.2016.10.026

Dohong, A., Aziz, A. A., & Dargusch, P. (2018). Carbon emissions from oil palm development on deep peat soil in central kalimantan indonesia. Anthropocene, 22, 31–39. https://doi.org/10.1016/j.ancene.2018.04.004

FAOSTAT. 2021. Crops Processed. http://www.fao.org/faostat/en/#data/QD, Retrieved 14/01/2021.

Frischknecht, R., Jungbluth, N., Althaus, H., Doka, G., Dones, R., Heck, T., Hellweg, S., Hischier, R., Nemecek, T., Rebitzer, G., Spielmann, M., Wernet, G. 2007. Overview and Methodology Data v2.0 (2007). In ecoinvent report No. 1 (Issue 1). http://www.ecoinvent.org/fileadmin/documents/en/01_OverviewAndMethodology.pdf.

Harsono, S. S., Grundmann, P., & Soebronto, S. (2014). Anaerobic treatment of palm oil mill effluents: Potential contribution to net energy yield and reduction of greenhouse gas emissions from biodiesel production. Journal of Cleaner Production, 64, 619–627. https://doi.org/10.1016/j.jclepro.2013.07.056

Hashim, Z., Subramaniam, V., Harun, M. H., & Kamarudin, N. (2018). Carbon footprint of oil palm planted on peat in Malaysia. International Journal of Life Cycle Assessment, 23, 1201–1217. https://doi.org/10.1007/s11367-017-1367-y

Hellebrand, H. J. (1998). Emission of nitrous oxide and other trace gases during composting of grass and green waste. Journal of Agricultural and Engineering Research, 69(4), 365–375. https://doi.org/10.1006/jaer.1997.0257

Huijbregts, M. A. J., Steinmann, Z. J. N., Elshout, P. M. F., Stam, G., Verones, F., Vieira, M., Zijp, M., Hollander, A., & van Zelm, R. (2017). ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. International Journal of Life Cycle Assessment, 22(2), 138–147. https://doi.org/10.1007/s11367-016-1246-y

IPCC 2006, 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Prepared by the National Greenhouse Gas Inventories Programme, Eggleston H.S., Buendia L., Miwa K., Ngara T. and Tanabe K. (eds). Published: IGES, Japan.

ISO (International Organization for Standardisation). 2006a. International Organization for Standardisation (ISO) (2006a) Environmental management - Life cycle assessment - Principles and framework. ISO 14040:2006a; Second Edition 2006a–06, Geneva.

ISO (International Organization for Standardisation). 2006b. International Organization for Standardisation (ISO) (2006b) Environmental management - Life cycle assessment - requirements and guidelines. ISO 14044:2006b; First edition 2006b–07–01, Geneva.

Izah, S. C., & Ohimain, E. I. (2015). Comparison of traditional and semi-mechanised palm oil processing approaches in nigeria; implications on biodiesel production. Journal of Environmental Treatment Techniques, 3(2), 82–87.

Mayes, S. (2020). The history and economic importance of the oil palm. In M. Ithnin & A. Kushairi (Eds.), The oil palm genome. Compendium of plant genomes. Springer.

Meijaard, E., Brooks, T. M., Carlson, K. M., Slade, E. M., Garcia-Ulloa, J., Gaveau, D. L., Lee, J. S. H., Santika, T., Juffe-Bignoli, D., Struebig, M. J., & Wich, S. A. (2020). The environmental impacts of palm oil in context. Nature Plants, 6(12), 1418–1426.

Muhamad, H., Ai, T. Y., Khairuddin, N. S. K., Amiruddin, M. D., & May, C. Y. (2014). Life cycle assessment for the production of oil palm seeds. Tropical Life Sciences Research, 25(2), 41–51.

Muhammad, H., Hashim, Z., Subramaniam, V., Tan, Y. A., Wei, P. C., Let, C. C., & May, C. Y. (2010). Life cycle assessment of oil palm seedling production (part 1). Journal of Oil Palm Research, 22(DECEMBER), 878–886.

Nasution, M. A., Wibawa, D. S., Ahamed, T., & Noguchi, R. (2018). Comparative environmental impact evaluation of palm oil mill effluent treatment using a life cycle assessment approach: A case study based on composting and a combination for biogas technologies in North Sumatera of Indonesia. Journal of Cleaner Production, 184, 1028–1040. https://doi.org/10.1016/j.jclepro.2018.02.299

Nokkaew, R., & Punsuvon, V. (2014). Sterilisation of oil palm fruits by microwave heating for replacing steam treatment in palm oil mill process. Advanced Materials Research, 1025–1026(2014), 470–475. https://doi.org/10.4028/www.scientific.net/AMR.1025-1026.470

Norhasmillah, A. H., Puah, C. W., Ibrahim, N. A., Baharuddin, A. S., & Choo, Y. M. (2013). Life cycle inventory of the commercial production of compost from oil palm biomass: A case study. Environment, Development and Sustainability, 15(6), 1663–1670. https://doi.org/10.1007/s10668-013-9457-x

Nurrochmat, D. R., Boer, R., Ardiansyah, M., Immanuel, G., & Purwawangsa, H. (2020). Policy forum: Reconciling palm oil targets and reduced deforestation: Landswap and agrarian reform in Indonesia. Forest Policy and Economics, 119, 102291. https://doi.org/10.1016/j.forpol.2020.102291

Nzeka, U.M. 2014. Nigeria Provides Export Market for Oilseeds and Products. In GAIN Report, USDA Foreign Agricultural Service. https://apps.fas.usda.gov/newgainapi/api/report/downloadreportbyfilename?filename=NigeriaProvidesExportMarketforOilseedsandProducts_Lagos_Nigeria_6–2–2014.pdf.

Ohimain, E. I., & Izah, S. C. (2015). Energy self-sufficiency of semi-mechanized oil palm processing: A case study of Bayelsa palm mill, Elebele, Nigeria. Energy Economics Letters, 2(3), 35–45. https://doi.org/10.18488/journal.82/2015.2.3/82.3.35.45

Ohimain, E. I., & Izah, S. C. (2014). Energy self-sufficiency of smallholder oil palm processing in Nigeria. Renewable Energy, 63, 426–431. https://doi.org/10.1016/j.renene.2013.10.007

Rasid, N. S. A., Syed-Hassan, S. S. A., Kadir, S. A. S. A., & Asadullah, M. (2013). Life cycle assessment to evaluate the green house gas emission from oil palm bio-oil based power plant. Korean Journal of Chemical Engineering, 30(6), 1277–1283. https://doi.org/10.1007/s11814-013-0022-y

Schmidt, J., & De Rosa, M. (2020). Certified palm oil reduces greenhouse gas emissions compared to non-certified. Journal of Cleaner Production, 277(124045), 1–12. https://doi.org/10.1016/j.jclepro.2020.124045

Schmidt, J., De ROsa, M. 2019. Life Cycle Assessment of Palm Oil at United Plantions Berhad 2019.

Schmidt, J., & Weidema, B. P. (2008). Shift in the marginal supply of vegetable oil. International Journal of Life Cycle Assessment, 13(3), 235–239. https://doi.org/10.1065/lca2007.07.351

Schmidt, J. 2007. Life cycle assessment of rapeseed oil and palm oil: Ph.D. thesis, Part 3: Life cycle inventory of rapeseed oil and palm oil. Department of Planning and Development, Aalborg University.

Siregar, K., Luthfi Machsun, A., Sholihati, S., Alamsyah, R., Ichwana, I., Christian Siregar, N., Syafriandi, S., Sofiah, I., Miharza, T., Muhammad Nur, S., Anne, O., Hendroko Setyobudi, R. 2020. Life Cycle Impact Assessment on Electricity Production from Biomass Power Plant System through Life Cycle Assessment (LCA) Method using Biomass from Palm Oil Mill in Indonesia. E3S Web of Conferences, 188. https://doi.org/10.1051/e3sconf/202018800018.

Stichnothe, H., & Schuchardt, F. (2011). Life cycle assessment of two palm oil production systems. Biomass and Bioenergy, 35(9), 3976–3984. https://doi.org/10.1016/j.biombioe.2011.06.001

Stichnothe, H., & Schuchardt, F. (2010). Comparison of different treatment options for palm oil production waste on a life cycle basis. The International Journal of Life Cycle Assessment, 15(9), 907–915. https://doi.org/10.1007/s11367-010-0223-0

Tan, Y. A., Muhammad, H., Hashim, Z., Subramaniam, V., Wei, P. C., Let, C. C., Ngan, M. A., & May, C. Y. (2010). Life cycle assessment of refined palm oil production and fractionation (part 4). Journal of Oil Palm Research, 22(DECEMBER), 913–926.

Thomas, B., Emeh, C., Fadare, S.O., Abayomi, F., & Canedo, T. (2011) Palm Oil Value Chain Analysis in the Niger Delta. Abuja. Available at: www.pindfoundation.org/.

UNFCCC 2006. Methane recovery and utilisation project at United Plantations Berhad, Jendarata Palm Oil Mill, Malaysia. Clean Development Mechanism Project Design Document Form (CDM-PDD), version 03 – in effect as of: 28 July 2006. UNFCCC. In Schmidt (2007). Life cycle assessment of rapeseed oil and palm oil: Ph.D. thesis, Part 3: Life cycle inventory of rapeseed oil and palm oil. Department of Planning and Development, Aalborg University.

Wiloso, E. I., Bessou, C., & Heijungs, R. (2014). Methodological issues in comparative life cycle assessment: Treatment options for empty fruit bunches in a palm oil system. The International Journal of Life Cycle Assessment, 20(2), 204–216. https://doi.org/10.1007/s11367-014-0815-1

Yoshizaki, T., Shirai, Y., Hassan, M. A., Baharuddin, A. S., Raja Abdullah, N. M., Sulaiman, A., & Busu, Z. (2013). Improved economic viability of integrated biogas energy and compost production for sustainable palm oil mill management. Journal of Cleaner Production, 44, 1–7. https://doi.org/10.1016/j.jclepro.2012.12.007

Yoshizaki, T., Shirai, Y., Hassan, M. A., Baharuddin, A. S., Abdullah, N. M. R., Sulaiman, A., & Busu, Z. (2012). Economic analysis of biogas and compost projects in a palm oil mill with clean development mechanism in Malaysia. Environment, Development and Sustainability, 14(6), 1065–1079. https://doi.org/10.1007/s10668-012-9371-7

Zulkifli, H., Halimah, M., Chan, K. W., Choo, Y. M., & Mohd Basri, W. (2010). Life cycle assessment for oil palm fresh fruit bunch production from continued land use for oil palm planted on mineral soil (part 2). Journal of Oil Palm Research, 22, 887–894.

Acknowledgements

This work was financially supported by the Alexander von Humboldt Foundation International Climate Protection Fellowship.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Anyaoha, K.E., Zhang, L. Technology-based comparative life cycle assessment for palm oil industry: the case of Nigeria. Environ Dev Sustain 25, 4575–4595 (2023). https://doi.org/10.1007/s10668-022-02215-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-022-02215-8