Abstract

The conventional convexity assumptions frequently placed on piecewise linear frontiers of production technologies modeled using data envelopment analysis imply non-increasing marginal products. Assuming geometric convexity in the context of the exponential technology represents a more general alternative that imposes no underlying restrictions on the marginal products, while simultaneously reducing the impact of the outlying observations. In this paper, we propose an exponential by-production technology capable of generating the outputs deemed undesirable from the society’s point of view. We subsequently rely on this technology to measure environmental productivity. Our empirical illustration uses data from the Chinese industrial sector, which is both a major energy consumer and polluter. By comparing our findings with the results from a conventional production model we demonstrate that our proposed indicator mitigates the impact of outlying observations when gauging the contributions of inputs and outputs to green growth. Our results suggest that the Chinese industrial sector experienced the annual productivity growth rate of around 0.40% during 1999–2016 and that the green productivity was mostly driven by technological progress. We also demonstrate that technological progress has been a bigger contributor to the growth in industrial output in China’s east than its inland or western regions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The conventional non-parametric technology based on piecewise linear convex production sets relies on the data expressed in levels, whereby the quantities of inputs are assumed to produce certain levels of outputs. Such setup allows for outlying observations to distort the production technology and results in unreasonable estimates of inefficiency and measures of input and output substitution. In addition, conventional models of production cannot accommodate increasing marginal products of inputs. Briec and Ravelojaona [1] have recently proposed the so-called exponential distance function, defined with respect to a more general multiplicative production technology capable of modeling increasing marginal products, popularized by Banker and Maindiratta [2]. The exponential distance function, which is invariant to the units of measurement and is related to the generalized multiplicative directional distance function (DDF) introduced by Mehdiloozad et al. [3], was subsequently used by Abad and Ravelojaona [4] to measure productivity in the presence of undesirable outputs.

At the same time, no attempt has been made so far to use exponential distance functions to measure environmental performance using the so-called by-production approach of Murty et al. [5]. The by-production framework for modeling production in the presence of socially unintended outputs deserves a particular consideration among the existing specifications for assessing environmental productivity because it satisfies the materials balance principle, which requires the weight of all material outputs to equal that of the material inputs used to produce them, but also due to the fashion in which it allows to model the disposability of harmful by-products.

Our paper provides both methodological and empirical contributions. The main methodological contribution lies in our proposed novel approach for incorporating the multiplicative, exponential DDF into the by-production technology to develop the so-called exponential by-production framework for evaluating the environmental and economic performance. The exponential production technology accommodates convexity, linearity, and concavity within different regions of the production surface. We rely on the multiplicative DDF to define the exponential version of the Luenberger indicator [6] and use it to provide an empirical illustration using the Chinese industrial sector data. We subsequently compare our findings with the results corresponding to the conventional and linear productivity growth model and demonstrate that our specification helps mitigate the influence of outliers.

The continued growth in industrial output has been a major source of development in China over the past decades. Reliable measurement of productivity of the Chinese manufacturing industry is important for identifying performance gaps and can be accomplished at different levels of aggregation to provide reasonable directions for further development [7]. The Chinese industrial sector has experiences a truly miraculous expansion during the past four decades, with an average annual growth rate of value added reaching nearly 11% between 1978 and 2018 [8]. The Chinese industrial sector, and especially its manufacturing industry, has surpassed that of the USA becoming the largest in the world in terms of the gross value-added since 2011 when measured in purchasing power parity terms. However, such rapid industrial development caused a dramatic increase in energy consumption leading to a significant increase in the pollution levels [9]. For example, the industrial output accounted for around 40% of China’s gross domestic product (GDP) while consuming 68% of the total energy and contributing about 83% of carbon dioxide (CO2) emissions between 1980 and 2006 [10]. Indeed, China overtook the USA as the largest CO2 emitter in 2007, generating unprecedented pressure from the international community to reduce its CO2 emissions. More recently, China consumed approximately 24% of the world’s total energy and contributed around 28% to the global CO2 emissions in 2018 [11]. Consequently, a number of recent studies of the Chinese industry have opted to incorporate environmental performance during the measurement of efficiency and productivity [12, 13].

For our empirical illustration, we rely on our proposed exponential by-production framework to measure the economic and environmental performance of the Chinese industry. We estimate the green productivity growth in the Chinese industrial sector using data from 30 provinces for the period 1999–2016. We use the Luenberger productivity indicator (LPI) to measure the so-called environmental productivity that accounts for harmful emissions and decompose it into components representing the change in efficiency (EC) and technological progress (TP). Our results suggest that productivity gains in the Chinese industrial sector have been mainly driven by technological progress, providing possible policy implications for the sustainable development of the Chinese industry at the regional level.

The remainder of the paper is organized as follows. The next section reviews the literature on the exponential production technology and productivity measurement in the presence of undesirable outputs. Section 3 introduces the exponential by-production framework for the nonlinear multiplicative production technology and outlines our approach for measuring green productivity. Section 4 describes the data and summarizes our empirical results. The final section offers policy implications and concludes our study.

2 Literature Review

Three major approaches for treating socially undesirable outputs in production can be identified in the literature. The first approach assumes that unintended by-products are inputs to a production process satisfying free disposability [14, 15]. This method violates the materials balance principle [16,17,18] and is likely to yield misleading results due to its underlying assumption of unbounded undesirable by-products. The second approach treats undesirable outputs as by-products generated jointly with intended outputs and assumes the so-called weak disposability between them. The environmental production model based on the weak disposability axiom was proposed by Färe et al. [19], and Chung et al. [20] were the first to define an activity analysis model for a DDF satisfying weak disposability. Although this approach has been widely applied in the environmental performance literature [21], the weak disposability assumption has been shown to violate the laws of conservation of mass and energy.

The third strand of the literature on polluting technologies is based on the by-production (BP) model developed by [5], which replaces the postulate of weak disposability with that of costly disposability. The BP technology is the intersection of two independent sub-technologies, such as (i) the intended-production technology, which assumes free disposability of inputs and intended outputs and does not consider by-products and (ii) the residue-generating technology, which models the costly disposability of pollution. The BP approach, which represents the latest development in the literature on modeling the production of undesirable externalities, has recently been extended to a dynamic performance framework [22].

The above three approaches can be implemented using measures of efficiency in production such as distance functions. An appealing feature of distance functions is that they are defined with respect to the input and output quantities and thus do not require price information. In addition to approximating inefficiency in production, distance functions can be used to assess temporal changes in total factor productivity (TFP) and measure technological change.

A number of indices and indicators possessing different properties have been proposed in the literature to measure productivity. For example, Färe et al. [23] demonstrated that the Malmquist productivity index can be defined using the Shephard [24] distance function. Later on, the ratio-based Hicks-Moorsteen TFP index was suggested by Bjurek [25]. Chambers [6] proposed the difference-based LPI, defined with respect to the DDF that accommodates a simultaneous input contraction and output expansion during the efficiency measurement. Briec and Kerstens [26] subsequently described the Luenberger-Hicks-Moorsteen TFP indicator and Abad [27] introduced the environmental generalized Hicks-Moorsteen productivity index and the environmental generalized Luenberger-Hicks-Moorsteen productivity indicator. More recently, Abad and Ravelojaona [4] proposed the exponential version of the environmental Luenberger-Hicks-Moorsteen productivity indicator. Rather than relying on the radial measures of technical efficiency [28], Abad and Ravelojaona [4] use the non-radial exponential distance function [1], which can be used to rank the environmental performance of the decision-making units (DMUs).

Hence, we attempt to fill the gaps in the environmental productivity literature by using the newly proposed exponential distance functions in the context of the relatively recent by-production technology. More specifically, we formulate a by-production model in a nonlinear technology setting and estimate productivity growth using the measures defined with respect to this multiplicative by-production technology.

3 Methods

This section summarizes the by-production technology models, defines the distance functions, and describes the productivity measures used in our analysis. The proposed approach accommodates the undesirable outputs, and data envelopment analysis (DEA) is used to estimate the by-production technology.

3.1 Production Technology with Undesirable Outputs

Koopmans [29] and Farrell [30] were among the first to define a production technology using the activity analysis framework. A purely nonparametric extension to this framework, referred to as the DEA, was subsequently popularized by Charnes et al. [31]. The DEA methodology, which has been used extensively in the environmental performance literature, can be used to operationalize the by-production models of polluting technologies.

We begin by assuming that DMUs produce G desirable outputs and generate B undesirable by-products by using all their inputs. Two types of inputs are used in the environmental production technology, namely M non-polluting inputs and N pollution-generating inputs. Both types of inputs can produce the desirable outputs, while only the pollution-generating inputs contribute to the production of the undesirable outputs.

The by-production technology (TBP) of Murty et al. [5] consists of two interrelated processes. The sub-technology T1 models a traditional production process whereby the desirable outputs are produced by all inputs. The sub-technology T2 approximates the manner in which the undesirable outputs are generated by polluting inputs. Let xm,t \(\in {R}_{+}^{M}\) and xn,t \(\in {R}_{+}^{N}\) be the vectors of non-polluting and pollution-generating input quantities, and let yt \(\in {R}_{+}^{G}\) and zt \(\in {R}_{+}^{B}\) be the quantities of desirable and undesirable outputs, respectively. The conventional by-production technology is defined as:

Here, f(.) and g(.) are continuously differentiable functions. Free disposability is assumed in T1 with respect to all inputs and desirable outputs, whereas costly disposability is maintained in T2 as regards the pollution-generating inputs and undesirable outputs. In addition, T1 and T2 satisfy a set of standard axioms frequently assumed in the literature, such as convexity and closedness. The reduced form of the by-production technology in a non-parametric framework under variable returns to scale (VRS) can be defined as follows [32]:

where λk and δk are the activity variables associated with the sub-technologies T1 and T2, which implies that their corresponding frontiers can be defined using different benchmarks. The constraints \(\sum_{k\in K}\lambda_k=1\) and \(\sum_{k\in K}\delta_k=1\) are added to impose VRS for T1 and T2, respectively.

In this paper, we extend the conventional by-production model to the case of the multiplicative technology. Following Mehdiloozad et al. [3] and Abad and Ravelojaona [4], we define the logarithm form of the by-production model as:

where \(\log x^m=(\log x_1,\dots,\log x_M)\), \(\log x^n=(\log x_{M+1},\dots,\log x_{M+N})\), \(\log y^g=(\log y_1,\dots,\log y_g)\), and \(\log z^b=(\log z_1,\dots,\log z_b)\). Compared to the traditional DEA specifications used to model piece-wise linear production frontiers, the multiplicative technology defined above corresponds to a piece-wise log-linear frontier satisfying geometric convexity, closedness, and boundedness [2, 3]. Thus, the non-parametric exponential by-production technology can be defined as follows:

The technology defined in Eq. (4) can be linearized by taking the logs of the input and output quantities. The resulting piece-wise log-linear technology satisfies geometric convexity that accommodates increasing, constant, and diminishing marginal products. It is therefore sufficiently flexible to satisfy convexity, linearity, and concavity simultaneously [3]. Finally, the linearized by-production model is given by:

3.2 The Output-Oriented Multiplicative DDF

The conventional DDF was proposed by Chambers et al. [33] and has since gained popularity in empirical analysis due to its ability to fully describe the underlying production technology. In this paper, we rely on the output-oriented multiplicative DDF that assumes an increase in the desirable outputs and a simultaneous reduction in the undesirable ones required to map the DMUs onto the frontier of the exponential by-production technology in a pre-assigned direction. This multiplicative DDF can be written as:

where \(\left({d}_{y},{d}_{z}\right)=\left({y}_{k}^{g},{z}_{k}^{b}\right)\) is the vector defining the direction in which the frontier is approached, which we set equal to the observed values of outputs. The inefficiency scores θy and θz approximate respectively the maximum feasible increase in the desirable outputs and a simultaneous reduction in the undesirable ones. The multiplicative DDF can be estimated using the following linear program:

The inefficiency scores can then be retrieved by means of exponentiation and by taking the reciprocal value of the distance function, i.e.:

3.3 Decomposition of the Exponential LPI

Abad and Ravelojaona [4] have recently demonstrated that the output-oriented multiplicative DDF can be used to extend the original difference-based productivity indicator proposed by Chambers [6] to an exponential technology. They argued that the productivity indicator specified in this way, referred to as the exponential LPI, can overcome the potential problem of undefined values of the indicator that can occur when estimating productivity. More specifically, the output-oriented exponential LPI measures the productivity growth between time periods t and t + 1 and can be defined as:

This green productivity indicator can be decomposed into the efficiency change (EC) and technological progress (TP) terms. EC measures the change in the distance to the production frontiers over time, i.e. it approximates the observation-specific improvements in efficiency related to, for example, more efficient use of resources due to their reallocation. TP assesses the productivity gains attributable to improvements in technology among the DMUs defining the best-practice frontier, i.e. it measures the frontier shifts occurring over time. The components of the exponential LPI are defined as follows:

4 Data and Results

4.1 Data

Our empirical illustration relies on the balanced panel of the Chinese industrial sector data representing 30 mainland provinces over the period 1999–2016, which we categorized into three groups. The first category includes eleven economically developed eastern provinces, such as Beijing, Tianjin, Hebei, Liaoning, Shanghai, Jiangsu, Zhejiang, Fujian, Shandong, Guangdong, and Hainan. The second category consists of the eight inland provinces of Shanxi, Jilin, Heilongjiang, Anhui, Jiangxi, Henan, Hubei, and Hunan. Finally, the third group comprises the economically underdeveloped regions located primarily in China’s west and includes Inner Mongolia, Guangxi, Sichuan, Chongqing, Guizhou, Yunnan, Tibet, Shannxi, Gansu, Qinghai, Ningxia, and Xinjiang.

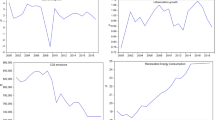

Our application uses annual data for the period 1999–2016 taken from the China Industrial Economics Statistical Yearbook and China Energy Statistics Yearbook. The technology modeled in this study consists of one desirable output, representing the total output produced by the industrial sector, one undesirable output, as well as three inputs, including labor force, capital, and energy consumption. Table 1 reports the annual growth rates corresponding to these variables with the notes to the table providing details on the variable definitions and their associated units of measurement.

As shown in Table 1, the Chinese industrial sector has dramatically expanded in size during 1999–2016. For example, the capital stock and total industrial output grew by about 19% and 13.7% respectively at the national level annually, which far exceed the growth rates of approximately 7.4% in the CO2 emissions, 2.9% in labor force, and 7.3% in the energy consumption. At the regional level, the eastern provinces have experienced the highest annual growth in labor force (3.2%) and energy consumption (7.5%) but the smallest increase in capital stock and total output among the three geographical regions, suggesting the inland and western provinces may be catching up to the more industrialized east. Also, while the eastern regions have experienced the highest growth in energy consumption, their corresponding increase in CO2 emissions has been comparable to that of the other two groups. In other words, the inland and western provinces might have generated more CO2 per unit of energy consumed compared to the regions located in China’s east and are therefore more likely to be facing relatively serious environmental issues.

4.2 Empirical Results

We first used the linear program specified in (7) and the transformation in (8) to calculate the inefficiency scores for each geographical category across time and summarized them in Fig. 1.Footnote 1 These scores measure potential gains in the industrial output and simultaneous reductions in the CO2 emissions from using resources more efficiently i.e. they approximate the possible improvements in both the economic and environmental performance of the Chinese industrial sector. Looking at the plot, we can see that the western and inland regions consistently outperform the eastern provinces and that the inefficiency levels are steadily increasing over time across all three economic zones.Footnote 2 Also, the western and inland regions report almost identical inefficiency estimates, suggesting similarities in the industry structure between these zones compared to the relatively industrialized East.

In Fig. 2, we plot the components of the green productivity indicator defined in (9), which we obtained using the decomposition given in (10) at the country level. We can see that the observed growth in green productivity has been mostly driven by technological progress, possibly due to the positive effects of the policies targeting technological improvements implemented by the Chinese government. This result appears to be in line with the findings of Li and Lin [34], who demonstrate that green productivity grew between 1998 and 2011 in China and suggest that improvements in the environmental production technology might have contributed to the development of the Chinese industrial sector.Footnote 3

Table 2 describes the annual rates of the green productivity growth in the Chinese industrial sector at the provincial, regional, and country levels. Our results suggest that despite an increase in inefficiency of about 0.03% per year, overall productivity improved by approximately 0.4% annually between 1999 and 2016, driven by technological progress occurring at the rate of roughly 0.55% per year. We can also see that the productivity gains have not been uniform, declining in the provinces of Hainan (− 0.47%), Ningxia (− 0.41%), and Gansu (− 0.04%). We believe this could be due to a relatively fast development of the energy-intensive sectors in these provinces, often accompanied by equally rapid growth in the demand for energy, which might have undermined the green productivity growth [35]. Except for the provinces of Yunnan and Ningxia, environmental efficiency stayed either constant or declined over time, implying that most provinces have failed to converge to the benchmarks defining the best-practice production frontier over time. Hence, the growth in the Chinese industrial sector’s green productivity appears to have been highly dependent on, and indeed exclusively driven by, the technical improvements occurring between 1999 and 2016.Footnote 4

We next turn to the change in green productivity at the regional level, displayed in Fig. 3. The average annual productivity growth rate of 0.54% in China’s east led the overall gains observed at the country level, while the inland and western provinces experienced lower annual growth rates of 0.46% and 0.17%, respectively. Furthermore, while the cumulative green productivity shows an increasing trend in the eastern and inland regions during the entire period considered, in China’s west, it first stagnates beginning in 2005 and subsequently declines during 2011–2015, emphasizing the pressing need for improvements in green productivity in the country’s relatively underdeveloped areas.

Figure 4 illustrates the average cumulative change in environmental efficiency, which appears to have followed a similar pattern across the three geographical zones. These results are closely related to the inefficiency scores reported in Fig. 1 and suggest noticeable declines in environmental efficiency beginning in 2003 before its recovery after 2005. In general, this component of the LPI appears to fluctuate around zero contributing relatively little to the overall change in green productivity.Footnote 5

Looking next at the regional-level technological change component of the LPI shown in Fig. 5, we note robust technological progress taking place in the eastern and inland regions. According to the fourth column of Table 2, annual technical improvements in the eastern and inland zone averaged to 0.62% and 0.59%, respectively. These provinces have greatly benefited from the national strategies aimed at boosting innovation and implementing better managerial practices, with particularly the economically developed east having ample opportunities to introduce relatively advanced technologies. By contrast, the pattern of technical change in China’s west does not follow a clear trend, experiencing periods of decline after 2005 and then again after 2012.

Finally, in Fig. 6, we compare the components of the environmental LPI with their purely economic counterparts that do not account for pollution. We can see that the specification ignoring undesirable outputs consistently overestimates productivity growth. Moreover, the original model that considers CO2 emissions during estimation yields higher estimates of technological progress, indicating that reducing pollution levels can help achieve larger shifts in the environmental production frontier over time. Hence, the environmental regulation implemented by the government agencies represents an important incentive for accelerating technical change in China’s industrial sector, while energy conservation and lower emission levels can act as critical drivers of green productivity [36].

4.3 Comparison Between the Exponential and Non-exponential Model

Compared to the conventional piece-wise linear frontiers of technology, the exponential technology and its corresponding log-linear frontier possesses a different curvature while simultaneously mitigating the impact of outliers present in the data. In Table 3, we summarize the differences in the estimates of inefficiency and productivity change rendered by the different models. Looking at the bottom row, we can see that the exponential model yields much lower inefficiency estimates along with lower productivity growth rates. For example, the average inefficiency associated with the exponential specification equals approximately 5.6%, while its counterpart corresponding to the conventional, linear model is much higher at nearly 25%. The exponential technology estimates annual productivity growth of 0.4%, compared to more than 2% per year for the non-exponential technology, suggesting the results are quite sensitive to the assumed shape of the production frontier. Generally speaking, the exponential model does not extrapolate the data as much as the linear model does, thereby reducing the impact of the outlying DMUs. As a result, the difference between the inefficiency scores corresponding to these models is larger than the difference between their associated estimates of productivity change.

In Table 4, we provide the summary statistics describing the evolution in green productivity under the different assumptions regarding the technology, which confirm the results outlined above. We also report the number of cases of divergent directions in the productivity change estimates between the two models. For instance, our last period corresponds to seven such outcomes and also shows mean productivity change values possessing different signs, confirming that the choice of the mathematical framework for the underlying non-parametric production technology may have a substantial impact on the productivity growth estimates.

5 Conclusions and Policy Implications

This paper introduces an exponential environmental Luenberger productivity indicator (LPI) based on the output-oriented exponential by-production technology. The proposed indicator is exhaustively decomposable; it can thus be used to analyze the dynamics of green productivity growth across regions and time. It incorporates the most recent developments in the modeling of the so-called polluting technologies and therefore allows for a robust analysis of green productivity.

Annual data on China’s industrial sector covering 1999–2016 were used to calculate and decompose the exponential LPI using non-parametric estimation techniques. Our results suggest that the sector’s green productivity grew by about 0.4% annually, accompanied by technological progress occurring at the mean annual rate of 0.55% and a simultaneous decrease in the average efficiency levels of around -0.03% per year. Improvements in green productivity follow a steady trend before slowing down during the later years included in our study.

At the regional level, the industrially developed eastern provinces show the largest gains in green productivity compared to the inland and western regions, with provinces located in China’s west experiencing productivity declines after 2006. While the efficiency performance has been relatively lackluster, technological progress proved to be a robust contributor to the growth in green productivity particularly in the eastern and inland regions, establishing technological innovation as the most important factor driving industrial productivity in China. We also demonstrate that the traditional production models that ignore undesirable outputs can overestimate the growth in productivity, while underestimating technological progress.

In its continued pursuit of ever bigger industrial productivity growth, China has been experimenting with its economic policies for decades, targeting technological progress via substantial investments in new equipment while attempting to improve efficiency by implementing market reforms. Given the relative importance of technical change revealed by our results, we believe it is necessary to continuously promote technological innovations to boost green productivity in the industrial sector. We think this can be achieved by further pursuing the transition towards more environmentally friendly production methods while simultaneously phasing out any remaining outdated production capacity.

Due to their relatively large labor force, substantial capital intensity, and high output levels, the eastern provinces offer particularly suitable opportunities for promoting growth in the green industrial productivity. At the same time, productivity in China’s west lags behind the country-level trends due to its underdeveloped industrial infrastructure and relatively scarce capital, suggesting the western provinces should continue promoting technological improvements so as to reduce the gap with the more industrialized east. This can be achieved by accelerating the shift away from relying on higher input quantities towards targeting environmental performance, with increased investments in the green technology that can help promote balanced growth. While the government should help cut pollution levels by designing effective emission reduction strategies such as investment in specialized equipment, the relatively developed regions should take full advantage of their position to accelerate investment in green production technologies and spread them to other regions.

Despite ample evidence of the importance of technological progress in securing growth in green industrial productivity, the evolution in efficiency appears to have played a rather mitigated role. Given the considerable room for improvement in the energy efficiency in China, we believe the government should promote investment in the energy-saving technologies. Leveraging the endowment advantages of western regions, the government should encourage the use of clean energy, such as hydraulic power, wind power, solar energy, and other environmentally sustainable forms of energy.

As far as future research using the exponential by-production technology framework is concerned, possible extensions may include empirical applications that rely on disaggregated data or using methods other than data envelopment analysis to assess green productivity. Since our proposed indicator is deterministic in nature, future studies could also concentrate on defining robust measures of efficiency and productivity growth using partial frontiers and resampling, or directly incorporating statistical noise by estimating the productivity growth components using econometric techniques. Finally, although the sample used for the empirical illustration does not extend beyond 2016, the trends in the environmental industrial productivity growth we identified appear to be rather stable, reducing the likelihood of any substantial short- or medium-run shocks. However, it could be interesting to estimate the change in efficiency and productivity using more recent data to see if these trends might have changed more recently, as well as assess the impact of the coronavirus pandemic on the performance of the Chinese industrial sector.

Availability of Data and Material

Data will be made available by the corresponding author on request.

Code Availability

Code will be made available by the corresponding author on request.

Notes

All calculations were carried out using the Visual Basic programming language and the Excel Solver add-in. The data can be obtained from the corresponding author.

Zhu et al. [13] report similar results using the example of China’s iron and steel industry.

References

Briec, W., & Ravelojaona, P. (2015). Multiplicative duality theory in production economics. Social science research network (SSRN). http://ssrn.com/abstract=2644581. Accessed 30 July 2022.

Banker, R., & Maindiratta, A. (1986). Piecewise loglinear estimation of efficient production surfaces. Management Science, 32(1), 126–135.

Mehdiloozad, M., Sahoo, B. K., & Roshdi, I. (2014). A generalized multiplicative directional distance function for efficiency measurement in DEA. European Journal of Operational Research, 232(3), 679–688.

Abad, A., & Ravelojaona, P. (2017). Exponential environmental productivity index and indicators. Journal of Productivity Analysis, 48(2), 147–166.

Murty, S., Russell, R., & Levkoff, S. B. (2012). On modeling pollution-generating technologies. Journal of Environmental Economics and Management, 64, 117–135.

Chambers, R. (1996). A new look at the exact input, output, productivity, and technical change measurement. Department of Agricultural and Resource Economics, University of Maryland, Working Paper 197840.

Zhang, Z. M., Zhao, H., & Wang, X. D. (2021). Financial decentralization, financing constraints, and total-factor productivity: Evidence from China. Transformations in Business & Economics, 20(3C-54C), 483–504.

National Bureau of Statistics of China. (2019). Accessed from http://www.stats.gov.cn/english/. Accessed 30 July 2022.

Teng, X., Liang, C., & Chiu, Y. H. (2019). Energy and emission reduction efficiency of China’s industry sector: A non-radial directional distance function analysis. Carbon Management, 10(4), 333–347.

Chen, J., Gao, M., Ma, K., & Song, M. (2019). Different effects of technological progress on China’s carbon emissions based on sustainable development. Business Strategy and the Environment. https://doi.org/10.1002/bse.2381

Baležentis, T., Blancard, S., Shen, Z., & Štreimikienė, D. (2019). Analysis of environmental total factor productivity evolution in European agricultural sector. Decision Sciences. https://doi.org/10.1111/deci.12421

Zhu, X. H., Chen, Y., & Feng, C. (2018). Green total factor productivity of China’s mining and quarrying industry: A global data envelopment analysis. Resources Policy, 57, 1–9.

Zhu, X. H., Li, H. L., Chen, J. Y., & Jiang, F. T. (2019). Pollution control efficiency of China’s iron and steel industry: Evidence from different manufacturing processes. Journal of Cleaner Production, 240, 118184.

Mohtadi, H. (1996). Environment, growth and optimal policy design. Journal of Public Economics, 63, 119–140.

Hailu, A., & Veeman, T. S. (2001). Non-parametric productivity analysis with undesirable outputs: An application to the Canadian pulp and paper industry. American Journal of Agricultural Economics, 83, 605–616.

Murty, S., & Russell, R. (2002). On modeling pollution generating technologies. University of California-Riverside, Working Paper Series, No. 2002–14.

Du, K., Lu, H., & Yu, K. (2014). Sources of the potential CO2 emission reduction in China: A nonparametric metafrontier approach. Applied Energy, 115, 491–501.

Dakpo, K. H., Jeanneaux, P., & Latruffe, L. (2016). Modelling pollution-generating technologies in performance benchmarking: Recent developments, limits and future prospects in the nonparametric framework. European Journal of Operational Research, 250(2), 347–359.

Färe, R., Grosskopf, S., Lovell, C. A. K., & Pasurka, C. (1989). Multilateral productivity comparisons when some outputs are undesirable: A nonparametric approach. The Review of Economics and Statistics, 71, 90–98.

Chung, Y. H., Färe, R., & Grosskopf, S. (1997). Productivity and undesirable outputs: A directional distance function approach. Journal of Environmental Management, 51, 229–240.

Färe, R., Grosskopf, S., & Pasurka, C. A. (2001). Accounting for air pollution emissions in measures of state manufacturing productivity growth. Journal of Regional Science, 41(3), 381–409.

Dakpo, K. H., & Oude Lansink, A. (2019). Dynamic pollution-adjusted inefficiency under the by-production of bad outputs. European Journal of Operational Research, 276(1), 202–211.

Färe, R., Grosskopf, S., Lindgren, B., & Roos, P. (1995). Productivity developments in swedish hospitals: A malmquist output index approach. In A. Charnes, W. W. Cooper, A. Y. Lewin, & L. M. Seiford (Eds.), Data envelopment analysis: Theory, methodology and applications (pp. 253–272). Kluwer.

Shephard, R. W. (1970). Theory of cost and production functions. Princeton University Press.

Bjurek, H. (1996). The Malmquist total factor productivity index. Scandinavian Journal of Economics, 98, 303–313.

Briec, W., & Kerstens, K. (2004). A Luenberger-Hicks-Moorsteen productivity indicator: Its relation to the Hicks-Moorsteen productivity index and the Luenberger productivity indicator. Economic Theory, 23(4), 925–939.

Abad, A. (2015). An environmental generalised Luenberger-Hicks-Moorsteen productivity indicator and an environmental generalised Hicks-Moorsteen productivity index. Journal of Environmental Management, 161, 325–334.

Peyrache, A., & Coelli, T. J. (2009). Multiplicative directional distance function. CEPA working paper: School of Economics, University of Queensland, Australia.

Koopmans, T. C. (1951). Analysis of production as an efficient combination of activities. In T. C. Koopmans (Ed.), Activity analysis of production and allocation (pp. 33–97). Wiley.

Farrell, M. J. (1957). The measurement of technical efficiency. Journal of the Royal Statistical Society, 120(3), 253–290.

Charnes, A., Cooper, W. W., & Rhodes, E. (1978). Measuring the efficiency of decision making units. European Journal of Operational Research, 2, 429–444.

Shen, Z., Baležentis, T., Chen, X., & Valdmanis, V. (2018). Green growth and structural change in Chinese agricultural sector during 1997–2014. China Economic Review, 51, 83–96.

Chambers, R., Chung, Y., & Färe, R. (1996). Benefit and distance functions. Journal of Economic Theory, 70(2), 407–419.

Li, K., & Lin, B. Q. (2015). Measuring green productivity growth of Chinese industrial sectors during 1998–2011. China Economic Review, 36, 279–295.

Li, K., & Lin, B. Q. (2014). The nonlinear impacts of industrial structure on China’s energy intensity. Energy, 69, 258–265.

Liu, G. T., Wang, B., Cheng, Z. X., & Zhang, N. (2020). The drivers of China’s regional green productivity, 1999–2013. Resources, Conservation and Recycling, 153, 104561.

Sun, J. C., Du, T., Sun, W. Q., Na, H. M., He, J. F., Qiu, Z. Y., Yuan, Y. X., & Li, Y. N. (2019). An evaluation of greenhouse gas emission efficiency in China’s industry based on SFA. Science of The Total Environment, 690, 1190–1202.

Feng, C., Huang, J. B., & Wang, M. (2018). Analysis of green total-factor productivity in China’s regional metal industry: A meta-frontier approach. Resources Policy, 58, 219–229.

Zhou, Z. X., Xu, G. C., Wang, C., & Wu, J. (2019). Modeling undesirable output with a DEA approach based on an exponential transformation: An application to measure the energy efficiency of Chinese industry. Journal of Cleaner Production, 236, 117717.

Funding

This study received funding from the National Natural Science Foundation of China (72104028) and financial support from the Beijing Institute of Technology Research Fund Program for Young Scholars.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Zhiyang Shen: methodology, data collection, computations, and formal analysis. Tomas Baležentis: methodology, formal analysis, revision preparation, reviewing, and editing. Michael Vardanyan: methodology, formal analysis, revision preparation, reviewing, and editing. The draft of the manuscript was written by Zhiyang Shen, Tomas Baležentis, and Michael Vardanyan and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• This paper analyzes Chinese industry productivity gains across provinces.

• An exponential by-production approach is proposed to estimate green productivity.

• Green productivity growth is mainly driven by technological progress.

• Policy implication is derived from the disparity of regional industrial performance.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shen, Z., Baležentis, T. & Vardanyan, M. Evaluating Green Productivity Gains with the Exponential By-Production Technology: an Analysis of the Chinese Industrial Sector. Environ Model Assess 27, 759–770 (2022). https://doi.org/10.1007/s10666-022-09849-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10666-022-09849-y

Keywords

- Multiplicative directional distance function

- Environmental performance

- By-production technology

- Chinese industry

- Exponential productivity indicator