Abstract

Ozonated water dip technique was evaluated for the detoxification of six pesticides, i.e., chlorpyrifos, cypermethrin, azoxystrobin, hexaconazole, methyl parathion, and chlorothalonil from apple fruits. Results revealed that ozonation was better than washing alone. Ozonation for 15 min decreased residues of the test pesticides in the range of from 26.91 to 73.58%, while ozonation for 30 min could remove the pesticide residues by 39.39–95.14 % compared to 19.05–72.80 % by washing. Cypermethrin was the least removed pesticide by washing as well as by ozonation. Chlorothalonil, chlorpyrifos, and azoxystrobin were removed up to 71.45–95.14 % in a 30-min ozonation period. In case of methyl parathion removal, no extra advantage could be obtained by ozonation. The HPLC analysis indicated that ozonation also affected adversely the ascorbic acid and cyanidin-3-glucoside content of apples. However, 11 polyphenols studied showed a mixed trend. Gallic acid, 3,4-dihydroxybenzoic acid, catechin, epicatechin, p-coumaric acid, quercetin-3-O-glucoside, quercetin, and kaempferol were found to decrease while syringic acid, rutin, and resveratrol were found to increase in 30-min ozonation.

Similar content being viewed by others

Introduction

Apple (Malus domestica) is an important temperate fruit of commercial value. It is fourth among the most widely produced fruits in the world following banana, orange, and grape. Apple is well known for its nutritional and health benefits. It is a good source of dietary fibers, minerals, vitamin C, and many other antioxidants. Apple peel is rich in many health-promoting factors such as anticarcinogenic, anti-inflammatory, vasoprotective, antidiabetes, and antiobesity (Yehudah et al., 2005). To combat various pests and diseases of apple, farmers use a number of pesticides. However, the use of non-recommended pesticides and dosages many a time lead to pesticide residues in fruits. Additionally, sometimes due to the lack of storage facilities or perishable nature, harvested produce are rushed to the market, leaving large amounts of pesticide residues on the fruits. Although humans are exposed to small amounts of pesticide residues after pesticides are metabolized by plants or decomposed by environmental agents, trace amounts of pesticide persisting in the human body for long periods can also cause chronic diseases such as cancer (Carrozza et al., 2009). As a result, food commodities are often found with unsafe levels of pesticides and present unforeseen situations for consumers. Due to injudicious use and non-adherence to postharvest intervals, residues of pesticides such as chlorpyrifos, cypermethrin, and azoxystrobin have occasionally been detected in apple at levels crossing the maximum residue limits (MRLs) (MPRNL, 2015). There are increasing concerns and awareness among consumers regarding possible adverse effects of unsafe levels of pesticide residues in fruits and vegetables. Therefore, a variety of postharvest treatments such as washing with tap water, alkali wash, washing with surfactant, electrolyzed water, etc. are being used so that pesticide residues in the produce can be reduced to safer levels (Lu et al., 2013). One of the newer approaches for detoxification of pesticide residues is use of ozonated water dips for postharvest treatment of fruits and vegetables.

Ozone (O3) is a natural substance present in the atmosphere. It is one of the most potent sanitizers against a wide spectrum of microorganisms. Ozone is generated by passing air or oxygen gas through a high voltage electrical discharge or by UV irradiation. It is used for sterilization, virus inactivation, deodorization, bleaching (decoloration), decomposition of organic matter, and mycotoxin degradation etc. (Balawejder et al., 2012). Ozone changes to oxygen by autolysis and does not affect the flavor of vegetables and fruits. Previous studies conducted on the decontamination of pesticides, i.e., mancozeb, chlorpyrifos, permethrin, chlorfluazuron, chlorothalonil, and imidacloprid in fruits and vegetables such as citrus, lychee, Chinese white cabbage, green-stem bokchoy, tomato, etc., have shown 40 to 99 % reduction of initial pesticide concentration by ozonation (Whangchai et al., 2011; Kusvuran et al., 2012; Chen et al., 2013; Upadhyay et al., 2014). Claims have also been made that ozone, besides decreasing or dislodging the surface residues, also removes various systemic pesticide residues. Pesticides are organic molecules which are supposed to be degraded by ozone. Recent studies have shown that ozone treatment may affect other useful organic molecules such as flavonoids, ascorbic acid, lycopene, and phenols present in the fruits and vegetables. Different types of reports are available in this regard. Few studies reported that ozone treatment decreased the ascorbic acid content in strawberry while total phenol content and flavonoids were increased in banana and pineapple (Yeoh et al., 2014; Karaca and Velioglu, 2014; Tiwari et al., 2009; Alothman et al., 2010). Aguayo et al. (2006) reported that ozonation had no effect on ascorbic acid content, total phenols, and antioxidant activity of fruits. Nutraceutical value of the fruits should not be affected or altered during the various processes used to get rid of pesticide residues. Therefore, the present study was undertaken to assess the ozonation technique for the removal of six commonly used pesticides from apple fruits along with its effect on ascorbic acid (vitamin C), cyanidin-3-glucoside, and polyphenols in apple.

Materials and methods

Materials

Apple fruits used in this study were purchased from the local Mother Dairy Fruit & Vegetable Pvt. Ltd, New Delhi. Analytical grade standards of chemicals were supplied by various pesticide manufacturing companies based in India. Chlorpyrifos (O,O-diethyl O-3,5,6-trichloropyridin-2-yl phosphorothioate; 98.6 %), cypermethrin ((RS)-alpha-cyano-3-phenoxybenzyl(1RS)-cis-trans-3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropane carboxylate; 99.5 %), hexaconazole (2-(2,4-dichlorophenyl)-1-(1H-1,2,4-triazol-1-yl)hexan-2-ol; 98.8%), azoxystrobin (methyl(2E)-2-(2-{[6-(2-cyanophenoxy)pyrimidin-4-yl]oxy}phenyl)-3-methoxyacrylate; 99.2 %), and chlorothalonil (2,4,5,6-tetrachloroisophthalonitrile; 99.7 %) were supplied by Rallis India Ltd. Methyl parathion (O,O-dimethyl O-4-nitrophenylphosphorothioate; 80 %) was procured from Bayer India Ltd. Analytical grade ascorbic acid (99 %), was purchased from Merck India Ltd. Polyphenols-gallic acid (97.5 %), 3,4-dihydroxybenzoic acid (97 %), catechin (99 %), epicatechin (98 %), syringic acid (98 %), p-coumaric acid (98 %), rutin hydrate (94 %), quercetin-3-O-glucoside (85 %), quercetin (95 %), resveratrol (99 %), kaempferol (97 %), cyanidin-3-glucoside (95 %), β carotene (95 %), and lycopene (90 %) were purchased from Sigma-Aldrich Corporation.

A commercial ozonizer having ozone output of 200 mg h−1 and pressure 0.15 kg cm−2 from Kent RO systems Pvt. Ltd was used for all ozonation experiments. Analytical grade solvents were glass distilled before use. The glassware was rinsed with acetone and dried in oven at around 250 °C prior to use. Neutral alumina was procured from Merck India Ltd. and activated by heating at 450 °C for 4 h. Anhydrous sodium sulfate was of analytical reagent grade (Merck India Ltd.). It was washed with acetone and activated by heating at 450 °C for 4 h. high performance liquid chromatography (HPLC) grade solvents methanol and water (Merck India Ltd.) were filtered through 0.25 and 0.45-μm membranes, respectively.

Preparation of standard

Ten milligrams of individual analytical grade pesticide (chlorpyrifos, cypermethrin, hexaconazole, azoxystrobin, chlorothalonil; methyl parathion was taken 12.5 mg on a.i. basis) was taken in a 10 mL volumetric flask and dissolved in acetone to obtain a stock solution of 1000 μg mL−1. Working standards of 100, 10, 1, and 0.1 μg mL−1 concentrations of each pesticide were prepared by serial dilution with hexane. Standard solution (100 μg mL−1) of ascorbic acid was prepared in double-distilled water. It was serially diluted with double-distilled water to obtain a standard of 10 μg mL−1 concentration. Stock solutions (100 μg mL−1) of 11 polyphenols were prepared in methanol. These were serially diluted with methanol to obtain working standards of 10 and 1 μg mL−1 concentration. Cyanidin-3-glucoside standard solution was also prepared in methanol and diluted appropriately.

Instrumental detection limit

Standard solutions of pesticides were injected ten times consecutively in gas chromatograph (GC) or HPLC and instrumental detection limit (IDL) was calculated using the following formula:

where S.D = standard deviation; St95 = 2.262 (Student’s t test at 95 % confidence level)

The calculated concentrations were finally verified by actually injecting the standard solution of same concentration of each pesticide/compound into GC/HPLC.

Preparation of fortified samples

For fortification of apples, aqueous solution of each pesticide was prepared separately. Ten milliliters of 1000 μg mL−1 stock solution of each individual pesticide was taken in a 1 L volumetric flask, and acetone (10 mL) was added. This was diluted with water and the final volume made with water to obtain a clear solution of 10 μg mL−1 concentration. This solution was taken in a beaker. Fresh apple fruits of uniform size were dipped in this solution for 15 min, taken out, and then left overnight for air drying.

Ozonation

Fortified apples (3–4 in number) were placed in the beaker and distilled water (1 L) was added to immerse the fruits. Ozone gas was passed into the water in beaker for 15 min using Kent ozonizer at room temperature. In a separate set of fortified apples in beakers, ozone gas was passed for 30 min. A set of water-washed samples were also prepared by dipping the apples in distilled water for 30 min. After a stipulated time period, the fruits were taken out and allowed to dry before further processing. Non-washed treated samples without imposing ozonation were also processed simultaneously. A set of untreated control samples was also kept for analysis. Each experiment was replicated thrice.

Extraction of pesticides

From each treatment—control, non-washed (treated sample), washed, ozonated for 15 min (Oz15), and ozonated for 30 min (Oz30)—apples were chopped. A precisely weighed representative apple samples (25 g) was taken in a conical flask and acetone (50 mL) was added and put on a horizontal shaker. The extract was filtered by suction filtration using a Buchner funnel and Whatman filter paper No.1. The extraction process was repeated twice more using acetone (50 + 40 mL). Combined filtrate was concentrated (2 mL) on vacuum rotary evaporator at 40−45 °C. The residual solution was diluted with 10 % NaCl solution (aqueous, 150 mL) and partitioned thrice with dichloromethane (100 + 70 + 50 mL). Aqueous phase was discarded. Organic phase was dried by passing through anhydrous Na2SO4 (10 g) and then evaporated to dryness using vacuum rotary evaporator at 35–40 °C. The contents were redissolved in 5 mL of acetone/hexane (1:1) and loaded on a prewashed (hexane) glass column packed with neutral alumina (5 g) sandwiched between anhydrous Na2SO4 (2 g). The column was eluted using 150 mL of acetone/hexane (1:9). The collected eluate was concentrated and finally dried under vacuum on a rotary evaporator. The residue was reconstituted in 10 mL of acetone/hexane (1:9) for GC analysis.

Extraction of ascorbic acid

Apple fruits were extracted using the method described by Watada (1982). Ozonized chopped apple fruits were crushed properly in a pestle and mortar and representative sample (20 g) was taken in a centrifuge tube for extraction. Aqueous meta-phosphoric acid (MPA; 3 %, 25 mL) was added and the contents were shaken for 5 min. The contents were centrifuged for 10 min at 9000 rpm. The aqueous portion was decanted carefully in an amber-colored volumetric flask and the volume made to 25 mL with MPA solution. The sample was filtered through a 0.45-μm filtration membrane prior to the HPLC analysis for ascorbic acid. Non-ozonized apple fruits processed in similar way served as control samples.

Extraction of cyanidin-3-glucoside

Apple fruit samples were peeled uniformly and peels were homogenized in a grinder mixer for 2 min. The representative sample (30 g) was transferred to a 100-mL centrifuge tube and 70 mL of extraction solvent (methanol acidified with 0.1 % HCl) was added. The mixture was sonicated (30 min) and then centrifuged (10 min) at 9000 rpm. The extract was filtered by suction filtration and filtrate evaporated using a vacuum rotary evaporator. The residue, thus obtained, was redissolved in methanol for HPLC analysis. Non-ozonized apple fruits processed in similar way served as control samples.

Extraction of polyphenols

Ozone-treated and control apple samples were homogenized in a mixer-grinder. The contents were transferred to a wide-mouth amber-colored bottle. Representative sample (10 g) of fruit was taken in a centrifuge tube. Methanol acidified with 1 % formic acid (20 mL) was added to it. The sample was vortexed for 2 min for mixing the contents uniformly and then centrifuged at 5000 rpm for 5 min. Supernatant (2 mL) was taken out carefully in an Eppendorf tube and centrifuged at 10,000 rpm for 5 min. Supernatant was removed carefully and taken in vial for HPLC analysis.

Instrumentation and analysis

Gas chromatography

Schimadzu 17A, gas chromatograph (GC) equipped with an electron capture detector (ECD-Ni63) and a megabore column (OV-1, 25-m length × 0.53 mm i.d. × 0.25-μm film thickness) was used throughout the study under specific isothermal temperature conditions. For methyl parathion, chlorpyrifos, and chlorothalonil, temperatures of injector/oven/detector were kept at 280/220/300 °C. Cypermethrin and hexaconazole were analyzed using 270 °C oven temperature while for azoxystrobin 295 °C was used. The carrier gas was high purity nitrogen with a flow rate of 5 mL min−1. Two microliters of aliquot of standard of these pesticides and samples were injected into the GC with a split ratio 1:10, and the retention time along with the peak area of other pesticide was recorded.

High performance liquid chromatography

For high performance liquid chromatography (HPLC) Hewlett Packard HPLC instrument (series1100) equipped with a degasser, a quaternary pump, and a diode array detector coupled with a Rheodyne injection system and a computer (model Vectra) was used. The stationary phase consisted of Lichrosphere on RP-18 packed stainless steel column (250 mm × 4 mm i.d.). Chromatogram was recorded on a Window NT-based HP Chemstation program. All the samples were filtered through a 0.45-μm membrane (Millipore) using a Millipore filtration syringe system and 20 μL (loop capacity) volume was injected in HPLC. Ascorbic acid was analyzed using orthophosphoric acid (0.1 % aqueous) as mobile phase with a flow rate of 1 mL min−1, and absorbance was recorded on 245-nm wavelength. Cyanidin-3-glucoside was analyzed using a mobile phase comprised of solvents A [0.1 % aqueous trifluoroacetic acid] and B [acetonitrile, water, and trifluoroacetic acid in the ratio 53:46:1]. The elution gradient programming used 80 % of solvent A initially—decreased to 40 % at 20 min—increased 80 % at 40 min with a flow rate of 1 mL min−1. The absorbance of cyanidin-3-glucoside measured at 520 nm.

Liquid chromatography-mass spectroscopy

Polyphenols (gallic acid, 3,4-dihydroxybenzoic acid, catechin, epicatechin, syringic acid, p-coumaric acid, rutin, quercetin-3-O-glucoside, quercetin, resveratrol and kaempferol) were analyzed by UPLC-HRMS (ultra performance liquid chromatography-high resolution mass spectroscopy). The samples were eluted with a gradient programming with solvents A [methanol/water (10:90) + 0.1 % formic acid] and B [methanol/water (90:10) + 0.1 % formic acid]. The elution gradient programming used 90 % of solvent A initially held at 90 % for 1 min, decreased to 50 % at 5 min, decreased to 2 % at 8 min, held at 2 % for 15 min, and finally increased to 90 % at 20 min. Flow rate was 0.4 mL min−1 throughout the programming. The Thermo UHPLC system was coupled to a Q Exactive orbitrap (Thermo Scientific, Bremen, Germany) via heated electrospray ionization (HESI), and controlled by Thermo Xcalibur 2.2. SP1.48 was used. UHPLC separation was performed on a 2-μm, 2.1 × 100 mm Hiber HS Purospher STAR RP18 from Merck, Dermstat, Germany) at 40°C. The injection volume was 5 μL and the samples were kept at 10 °C throughout the analysis. Spectra were collected in positive ESI mode over a mass range of 100–1500 amu in full scan with ddMS2 mode at a resolving power of 35,000. The ddMS2 mode was used with normalized collision energy of 35 V (40 % Stepped NCE). The source parameters were set as follows: capillary 4.5 kV, heater temperature 300 °C, capillary temperature 500 °C, sheath gas flow 50 psi, and aux gas flow rate 40 psi.

Quantification of residues

After extraction and cleanup, the samples were analyzed by GC for quantification of different pesticides. Standard solutions of individual pesticides were injected in GC under the standardized condition. Residue of each pesticide was calculated by using calibration curve. Similarly, ascorbic acid, cyanidin-3-glucoside, and polyphenols were analyzed by HPLC and the concentration in the samples was calculated using standard curve.

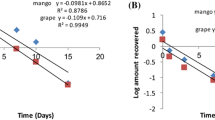

Recovery experiment

For the recovery of pesticides (chlorpyrifos, cypermethrin, methyl parathion, hexaconazole, azoxystrobin, chlorothalonil), chopped control apple sample (25 g) was fortified at a level of 0.1, and 1.0 μg g−1 and kept at room temperature for 4 h. Samples were extracted with acetone and then cleaned up with activated neutral alumina as described in the above section. All the experiments were carried out in triplicate along with unfortified control. Analysis was done using specific GC conditions for each pesticide and residues were calculated by using calibration curve.

Estimated method detection limit

Estimated method detection limit (EMDL) is defined as the appropriate minimum concentration of pesticide that can be determined from a particular matrix by a particular method, depending upon the IDL of the instrument, recovery of a pesticide by the described method, and it can differ from matrix to matrix. After checking the IDL and recovery, EMDL for each pesticide for the apple matrix was calculated as follows:

where

For each pesticide, apples were fortified at EMDL level and recoveries were checked to confirm the limit of detection (LOD) and limit of quantification (LOQ).

Results

Calibration curve, IDL, recovery and EMDL

All the pesticides gave a sharp peak under the described condition of GC. Their retention time and IDL are given in Table 1. Calibration curve was drawn by taking the concentration versus peak area of each pesticide. Calibration curve for chlorpyrifos, methyl parathion, and chlorothalonil was linear from 0.001 to 10 μg mL−1 while for cypermethrin, azoxystrobin, and hexaconazole, it was linear from 0.005 to 10 μg mL−1. The calculated IDL values ranged within 0.007–0.07 μg mL−1. Recoveries at EMDL level gave signal to noise ratio of 3:1 and were considered to be the LOD while 5:1 was taken as LOQ. Recovery of chlorpyrifos, cypermethrin, methyl parathion, hexaconazole, azoxystrobin, and chlorothalonil from fortified apple samples ranged between 78.8 and 94.4 %. Recovery of chlorothalonil, azoxystrobin, and hexaconazole were found to be 90.4, 85.7, and 86.4 %, respectively. Recovery of methyl parathion, chlorpyrifos, and cypermethrin were 79.0, 80.35, and 78.8 %. LOD of pesticides for apple ranged between 0.002 and 0.02 μg g−1. LOD of pesticides ranged between 0.006 and 0.06 μg g−1. Ascorbic acid eluted at retention time of 5.45 min as a sharp peak under the described conditions of HPLC. The calibration curve was found to be linear from 0.01 to 100 μg mL−1. Cyanidin-3-glucoside gave a sharp peak at retention time of 21.72 min and the calibration curve was found to be linear from 0.001 to 100 μg mL−1.

Effect on pesticide removal

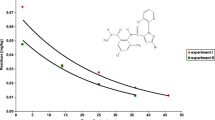

The concentration of six different pesticides on apple before and after imposing washing and ozonation techniques is presented in Table 2. Initial deposit of each pesticide on apple (on laboratory fortification by immersing fruits in pesticide aqueous solution) as calculated by the analysis of non-washed fortified samples was found to be varying between 0.037 and 1.18 μg g−1. Results revealed that washing as well as ozonation decreased the residues of all the pesticides in apple. In the 15-min ozonation period, the initial residues of 0.60, 1.18, 0.52, 0.122, 0.037, and 0.049 μg g−1 for methyl parathion, chlorpyrifos, chlorothalonil, cypermethrin, azoxystrobin, and hexaconazole were reduced to 0.345, 0.362, 0.137, 0.089, 0.013, and 0.023 μg g−1, respectively. Chlorothalonil, chlorpyrifos, and azoxystrobin showed better elimination (65.13–73.58 %) in the 15-min ozonation period, while residues of methyl parathion and hexaconazole were removed only up to 42.71 and 54.01 %, respectively. Reduction in cypermethrin residues was only 26.91 %. Increased removal of pesticide residues was noted by increase in ozonation time. Ozonation for 30 min was effective in decreasing the residues of methyl parathion, chlorpyrifos, chlorothalonil, cypermethrin, azoxystrobin, and hexaconazole to 0.336, 0.0572, 0.050, 0.074, 0.010, and 0.018 μg g−1, respectively, indicating 44.26, 95.14, 90.30, 39.39, 71.45 and 63.73 % removal. Maximum reduction of more than 90 % was observed in the case of chlorpyrifos and chlorothalonil while cypermethrin was the least removed.

Washing could remove the residues of methyl parathion, chlorpyrifos, chlorothalonil, cypermethrin, azoxystrobin, and hexaconazole by 44.22, 72.80, 68.20, 19.05, 45.12, and 36.28 % respectively (Fig. 1). In the case of methyl parathion, washing was found to be better from the 15-min ozonation. Even 30 min of ozonation was just at par with washing technique. The percent residue removal by washing was better than the 15-min ozonation in the case of chlorpyrifos as well, but 30 min of ozonation was significantly higher than the washing method. In the rest of the four pesticides, i.e., chlorothalonil, cypermethrin, azoxystrobin, and hexaconazole, ozonation for 15 and 30 min were better than washing.

Effect on ascorbic acid

Ascorbic acid (vitamin C) is the main antioxidant in fruits and vegetables. Under the described HPLC conditions, cyanidin-3-glucoside gave a sharp peak at 3.7 min. The concentration of ascorbic acid in apple before and after imposing ozonation is presented in Table 3. The initial concentration of ascorbic acid in non-ozonized apple samples was found to be 4.72 μg g−1. Ozonation of apples for 15 min resulted in decrease of ascorbic acid to 1.80 μg g−1 indicating 61.86 % reduction. Increase in ozonation time to 30 min further decreased the ascorbic acid content by 83.66 %.

Effect on cyanidin-3-glucoside

Anthocyanins form the main nutritive value of the fruits. These are mostly the colored compounds present in fruits in the form of glucosides or secondary conjugates of these glucosides with other organic molecules such as coumaric acids, etc. Out of a number of anthocyanins found in apple, the major one is the cyanidin-3-glucoside. This anthocyanin is present in the peel of the apple fruit. That is why the apple with peel is considered more nutritive for health. Under the described HPLC conditions, cyanidin-3-glucoside gave a sharp peak at 21.8 min. The concentration of cyanidin-3-glucoside in apple peel before and after different ozonation periods is presented in Table 3. The initial concentration of cyanidin-3-glucoside in non-ozonized apple samples was found to be 125.95 μg g−1. Ozonation of apples for 15 min decreased cyanidin-3-glucoside in peels to 89.42 μg g−1 indicating 29 % reduction. Increase in ozonation time to 30 min further decreased its content to 70.43 μg g−1 resulting in 44.08 % reduction.

Effect on polyphenols

The ozonated water dip treatment of apple samples showed different trends for different polyphenols. The concentration of 11 polyphenols in apple before and after imposing ozonation is presented in Table 4. After 15 min of ozonation, 3,4-dihydroxybenzoic acid, syringic acid, rutin, quercetin-3-O-glucoside, quercetin, resveratrol, and kaempferol showed 8.89 to 278.16 % increase than their initial concentrations. Maximum increase was observed for syringic acid which increased from 0.038 to 0.144 μg g−1 in the 15-min ozonation (Fig. 2). Gallic acid, catechin, epicatechin, and p-coumaric acid showed 17.50 to 70.29 % decrease in the first 15 min. In the 30-min ozonation, the concentration of syringic acid decreased from 0.144 to 0.111 μg g−1; however, a net increase of 190.44 % was observed in 30 min. The similar trend was observed with all the polyphenols. Concentration of most of the polyphenols increased with the 15-min ozonation but decreased when ozonation continued for 30 min. Apart from syringic acid, only rutin and resveratrol showed net increase, though it was only 5.41 and 4.37 %, respectively. Other polyphenols, i.e., gallic acid, 3,4-dihydroxybenzoic acid, catechin, epicatechin, p-coumaric acid, quercetin-3-O-glucoside, quercetin, and kaempferol, all showed a net decrease of 6.72 to 54.38 % in 30 min. The maximum decrease of 54.38 % was observed in the case of p-coumaric acid.

Discussion

Effect on pesticide removal

Washing of fruits and vegetables before consumption is a conventional habit. It helps in cleaning the surface by eliminating the residues (dirt particles, microorganism, and pesticides) adhered to the surface. In the present study, also washing alone could remove the pesticide residues from apple between 19 and 70 %. Among the six pesticides studied, cypermethrin has least water solubility (9 × 10−3 mg L−1). This may be one of the reasons that it was comparatively less (19.05 %) removed by washing. However, chlorpyrifos and chlorothalonil in spite of their less water solubility (0.6 mg L−1) were better (68.2–72.8 %) removed by washing. Removal in case of hexaconazole, methyl parathion, and azoxystrobin ranged between 36.28 and 45.12 %. Ozonation increased the removal of pesticides except in methyl parathion where washing was at par with 30-min ozonation. In the case of the remaining five pesticides, the ozonation gave better removal (26.91–73.58 %) in 15 min. Further increase in time to 30 min showed still better removal (39.39–95.14 %) in all the cases. Less removal of hexaconazole and azoxystrobin than chlorothalonil in spite of their better solubility in water may be because of their systemic nature. A part of pesticides could have penetrated in the inner parts of the fruits and might not be available for decontamination easily. Chlorothalonil and chlorpyrifos might have adhered to the surface only during fortification. In 30-min ozonation time, chlorothalonil was best removed while cypermethrin was the least removed pesticide. Methyl parathion in spite of its high solubility could be removed only up to 44.2 % and no added advantage of ozonation could be observed. Wu et al., 2007 also reported the removal of methyl parathion up to 28.6–47.9 % from vegetable Brassica rapa by ozonation for 30 min but in his report, cypermethrin removal was up to 60 % by ozonation. It could be due to a large surface area available in Brassica leaves. Better removal of cypermethrin (73–74 %) from cabbage was also reported by Cengiz and Certel (2012) using 10 % acetic acid or 10 % sodium chloride. In the present study, the less removal of cypermethrin may be due to poor water solubility and less surface area of apple in comparison to Brassica leaves and cabbage.

Effect on ascorbic acid

Earlier workers have also reported the reduction in ascorbic acid content when gaseous ozone was used as fumigation for preservation. When ozone was applied at the rate of 9.2 μL L−1 to freshly cut papaya for 20 min, the total phenolic content increased by 10.3 % while ascorbic acid content decreased by 2.3 % (Yeoh et al., 2014). Similarly, fresh-cut pineapple, guava, and banana treated with 0.72 mmol ozone for 30 min also reported significant decrease in ascorbic acid (Alothman et al., 2010). Other studies on carrot, parsley, and fresh-cut lettuce also reported reduction in ascorbic acid content by gaseous ozone (Karaca and Velioglu, 2014; Chauhan et al., 2011; Ölmez and Akbas, 2009). On the other hand, few reports say that gaseous ozone treatment in the case of tomato fruits had no significant effect on ascorbic acid (Tzortzakis et al., 2007; Simão et al., 2015). Aguayo et al. reported increase in ascorbic acid content of whole and sliced tomato. The decrease in ascorbic acid content has been explained by Beltrán et al. 2005 in which the ascorbate oxidase enzyme under ozone stress can enhance the oxidation of ascorbic acid into dehydroascorbic acid which can be further degraded due to its instability and thus resulting in reduction of total vitamin C. Dehydroascorbic acid can be reduced to ascorbic acid or irreversibly oxidized further to diketogulonic acid that exhibits no vitamin activity.

Also, free radicals such as hydroxyl radicals (OH•), superoxide radicals (O2•), and hydrogen peroxide (H2O2) are formed by the decomposition of ozone. Ascorbic acid plays a role in scavenging and detoxifying the free radicals formed and hence results in the reduction of ascorbic acid content in ozone-treated fruit and vegetables. Conversely, the increase in ascorbic acid content in ozone-treated fruits in some studies can be attributed to the inhibitory roles of ozone on the activity of several enzymes such as ascorbate oxidase and ascorbate peroxidase.

In the present study, decrease in ascorbic acid content indicated that created ozone stress enhanced the oxidation of ascorbic acid.

Effect on polyphenols

Apples contain flavanol monomers such as epicatechin and small quantities of stilbenes, hydroxycinnamic acids, several quercetin glycosides, and anthocyanins such as cyanidin 3-glucoside in the skin of red varieties. Oxidation reactions result in the formation of polymerized substances, which can lead to changes in the quality of foods, particularly the color characteristics (Manach et al., 2004). Various food processing techniques also affects polyphenol content. As fruit peeling can result in a loss of some polyphenols. Grinding of plant tissues may lead to oxidative degradation of polyphenols as a result of cellular decompartmentation and contact between cytoplasmic polyphenol oxidase and phenolic substrates present in the vacuoles. Polyphenols are then transformed into brown pigments that are polymerized to different degrees (Spanos et al., 1990).

In this study, major anthocyanin cyanidin-3-glucoside present in the peel of the apple was found to decrease with ozonation. In earlier studies, antioxidant compounds in citrus leaves (Iglesias et al., 2006) and phenolic contents in strawberries (Allende et al., 2007) were reported to reduce after gaseous ozone treatments. Additionally, anthocyanin pigments in blackberry (Barth et al., 1995) were reported not to be adversely affected by ozone treatments. However, antioxidant status and phenolic contents were not affected in tomatoes exposed to ozone concentrations up to 1.0 μmol mol−1 (Tzortzakis et al. 2007). In addition, ozone treatment (156 μg m−3, for 2 months of storage) did not cause any significant changes in the antioxidant activities and phenolic contents in strawberry fruits (Keutgen and Pawelzik, 2008).

In the present study, polyphenols considered in general, the total phenolic content was found to be increased in ozonated samples. However, when samples were analyzed for individual 11 different polyphenols by LC-MS, a mixed trend was seen. Concentration of several compounds was decreased while others were found to be increased. Maximum increase was observed in the case of syringic acid. The structures of this acid form a part of higher biomolecules such as anthocyanidins, malvidin, cyanidin, delphinidin, etc. The ozonation at the first instance might degrade such molecules by changing glycosides to aglycones. As a result, a net increase of some of the phenolic acids is expected as well as the increased phenolic contents. The increase in such molecules may be a part of defence mechanisms created due to ozone stress. Prolonged ozonation may lead to oxidative degradation of polyphenols and acids specially the rings with heteroatoms. Thus, the decrease in concentration of other polyphenols can be explained due to oxidative cleavage.

Conclusion

The study suggested that ozonation is an effective method for postharvest reduction of pesticide residues on apples. Removal increased with increase in ozonation time; however, the percent reduction of each pesticide varied. Out of the six pesticides studied, chlorothalonil was best removed while cypermethrin was least removed by ozonation. The nutritional content of the fruit was found to be altered with ozonation. Considerable decrease was observed in ascorbic acid and cyanidin-3-glucoside antioxidants are useful for the human system. Polyphenols showed a mixed trend. Therefore, further studies need to be done in this direction before recommending the ozonation technique foolproof for pesticide removal from fruits and vegetables.

References

Aguayo, E., Escalona, V. H., & Artés, F. (2006). Effect of cyclic exposure to ozone gas on physicochemical, sensorial and microbial quality of whole and sliced tomatoes. Postharvest Biology and Technology, 39, 169–177.

Allende, A., Marin, A., Buendia, B., Tomas-Barberan, F., & Gil, M. I. (2007). Impact of combined postharvest treatments (UV-C light, gaseous O3, super atmospheric O2 and high CO2) on health promoting compounds and shelf-life of strawberries. Postharvest Biology and Technology, 46, 201–211.

Alothman, M., Kaur, B., Fazilah, A., Bhat, R., & Karim, A. A. (2010). Ozone-induced changes of antioxidant capacity of fresh-cut tropical fruits. Innovative Food Science & Emerging Technologies, 11, 666–671.

Balawejder, M., Antos, P., & Sadło, S. (2012). Potential of ozone utilization for reduction of pesticide residue in food of plant origin—a review. Roczniki Panstwowego Zakladu Higieny, 64, 13–18.

Barth, M., Zhou, K., Mercier, J., & Payne, F. A. (1995). Ozone storage effects on anthocyanin content and fungal growth in blackberries. Journal of Food Science, 60, 1286–1288.

Beltrán, D., Selma, M. V., Marín, A., & Gil, M. I. (2005). Ozonated water extends the shelf life of fresh-cut lettuce. Journal of Agricultural and Food Chemistry, 53, 5654–5663.

Carrozza, S. E., Li, B., Wang, Q., Horel, S., & Cooper, S. (2009). Agricultural pesticides and risk of childhood cancers. International Journal of Hygiene and Environmental Health, 212, 186–195.

Cengiz, M. F., & Certel, M. (2012). Decontamination techniques of pesticide residues before food processing or consumption. Akademik Gıda, 10(2), 69–74.

Chauhan, O. P., Raju, P. S., Ravi, N., Singh, A., & Bawa, A. S. (2011). Effectiveness of ozone in combination with controlled atmosphere on quality characteristics including lignification of carrot sticks. Journal of Food Engineering, 102, 43–48.

Chen, J. Y., Lin, Y. J., & Kuo, W. C. (2013). Pesticide residue removal from vegetables by ozonation. Journal of Food Engineering, 114, 404–411.

Iglesias, D. J., Calatayud, Á., Barreno, E., Primo-Millo, E., & Talon, M. (2006). Responses of citrus plants to ozone: leaf biochemistry, antioxidant mechanisms and lipid peroxidation. Plant Physiology and Biochemistry, 44, 125–131.

Karaca, H., & Velioglu, Y. S. (2014). Effects of ozone treatments on microbial quality and some chemical properties of lettuce, spinach, and parsley. Postharvest Biology and Technology, 88, 46–53.

Keutgen, A. J., & Pawelzik, E. (2008). Influence of pre-harvest ozone exposure on quality of strawberry fruit under simulated retail conditions. Postharvest biology and technology, 49, 10–18.

Kusvuran, E., Yildirim, D., Mavruk, F., & Ceyhan, M. (2012). Removal of chlorpyrifos ethyl, tetradifon and chlorothalonil pesticide residues from citrus by using ozone. Journal of Hazardous Materials, http://dx.doi.org/10.1016/j.jhazmat.2012.09.043.

Lu, H. Y., Shen, Y., Sun, X., Zhu, H., & Liu, X. J. (2013). Washing effects of limonene on pesticide residues in green peppers. Journal of the Science of Food and Agriculture, 93, 2917–2921.

Manach, C., Scalbert, A., Morand, C., Rémésy, C., & Jiménez, L. (2004). Polyphenols: food sources and bioavailability. American Journal of Clinical Nutrition, 79, 727–747.

MPRNL (Monitoring of Pesticide Residues at National Level) Annual Progress Report 2013-14 retrieved May 24, 2015 from http://agricoop.nic.in/PPfinal2732015.pdf.

Ölmez, H., & Akbas, M. Y. (2009). Optimization of ozone treatment of fresh-cut green leaf lettuce. Journal of Food Engineering, 90, 487–494.

Simão, R., Neto, D. G. T., & Loose, C. E. (2015). The ozonation as competitive advantage in post-harvest treatment of tomato. Mediterranean Journal of Social Sciences, 6, 529.

Spanos, G. A., Wrolstad, R. E., & Heatherbell, D. A. (1990). Influence of processing and storage on the phenolic composition of apple juice. Journal of Agriculture and Food Chemistry, 38, 1572–1579.

Tiwari, B. K., O’Donnell, C. P., Patras, A., Brunton, N., & Cullen, P. J. (2009). Effect of ozone processing on anthocyanins and ascorbic acid degradation of strawberry juice. Food Chemistry, 113, 1119–1126.

Tzortzakis, N., Borland, A., Singleton, I., & Barnes, J. (2007). Impact of atmospheric ozone-enrichment on quality-related attributes of tomato fruit. Postharvest Biology and Technology, 45, 317–325.

Upadhyay, A., Kalra, S., Saini, P., Niwas, R., Kumar, R., & Gopal, M. (2014). Determination of imidacloprid from tomato by ozone treatment and edible alkali. Annal of Plant Protection Sciences, 22, 238–239.

Watada, A. E. (1982). A high performance liquid chromatography for determination of ascorbic acid content of fresh fruits and vegetables. Horticulture Science, 17, 334–335.

Whangchai, K., Uthaibutra, J., Phiyanalinmat, S., Pengphol, S., & Nomura, N. (2011). Effect of ozone treatment on the reduction of chlorpyrifos residues in fresh lychee fruits. Ozone: Science and Engineering, 33, 232–235.

Wu, J., Luan, T., Lan, C., Lo, T. W. H., & Chan, G. Y. S. (2007). Removal of residual pesticides on vegetable using ozonated water. Food Control, 18, 466–472.

Yehudah, B., Korchinsky, G., Redel, R., Ovadya, G., Oren-Shamir, R., & Cohen, Y. (2005). Colour accumulation patterns and the anthocyanin biosynthetic pathway in 'Red Delicious' apple variants. Journal of Horticultural Science and Biotechnology, 80, 187–192.

Yeoh, W. K., Ali, A., & Forney, C. F. (2014). Effects of ozone on major antioxidants and microbial populations of fresh-cut papaya. Postharvest Biology and Technology, 89, 56–58.

Acknowledgements

The authors are thankful to the Indian Council of Agricultural Research, New Delhi, India for providing Senior Research Fellowship toward the Ph.D. program of the first author. We are also grateful to the Division of Agricultural Chemicals, Indian Agricultural Research Institute, New Delhi for providing the necessary facilities for the undertaking of this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Swami, S., Muzammil, R., Saha, S. et al. Evaluation of ozonation technique for pesticide residue removal and its effect on ascorbic acid, cyanidin-3-glucoside, and polyphenols in apple (Malus domesticus) fruits. Environ Monit Assess 188, 301 (2016). https://doi.org/10.1007/s10661-016-5294-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-016-5294-3