Abstract

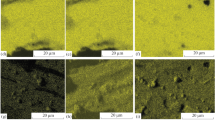

Coatings on titanium targets are obtained under conditions of a shaped-charge explosion; the maximum microhardness of the coatings at certain segments of the target can reach 4000 kg/mm2. A conical liner with a cone angle of 20° prepared from a mixture of fine powders of amorphous boron and ammonium nitrate is used in the experiments. A comparative quantitative X-ray powder diffraction analysis of various segments of the coating is performed. The values of the unit cell parameters indicate the formation of complex phases. The dynamics of the results of the X-ray study with the cone angle of the liner decreasing from 45 to 20° is demonstrated.

Similar content being viewed by others

References

S. A. Gromilov, A. V. Alekseev, S. A. Kinelovskii, and I. B. Kireenko, “Phase composition of coatings applied to titanium targets by means of shaped-charge jets,” Combust., Expl., Shock Waves, 40, No. 3, 363–369 (2004).

S. A. Gromilov, A. V. Alekseev, S. A. Kinelovskii, and I. B. Kireenko, “Layers produced by entrapment of a shaped-charge jet in a titanium target,” Combust., Expl., Shock Waves, 39, No. 6, 727–734 (2003).

S. A. Gromilov, S. A. Kinelovskii, and I. B. Kireenko, “Surface of a titanium target after interaction with shaped-charge jet particles,” Combust., Expl., Shock Waves, 39, No. 5, 601–605 (2003).

S. A. Gromilov, S. A. Kinelovskii, Yu. N. Popov, and Yu. A. Trishin, “Method of applying coatings of refractory metals and their compounds with light nonmetals,” Patent of the Russian Federation No. 2144574C1, Otkr. Izobr., No. 2 (2000).

G. V. Samsonov, “Investigation of the physicochemical nature of metal-like and nonmetal refractory compounds using the microhardness method,” in: Methods of Microhardness Testing. Instruments [in Russian], Nauka, Moscow (1965), pp. 59–71.

W. Kraus and G. Nolze, “POWDER CELL — a program for the representation and manipulation of crystal structures and calculation of the resulting X-ray powder patterns,” J. Appl. Cryst., 29, 301 (1996).

“Metals and alloys. Method of measuring the Vickers hardness,” USSR State Standard No. 299-75, Adopted 07.01.76.

“Microhardness measurements by means of diamond indentation,” USSR State Standard No. 9450-76, Adopted 01.01.77.

Author information

Authors and Affiliations

Additional information

__________

Translated from Fizika Goreniya i Vzryva, Vol. 42, No. 2, pp. 121–127, March–April, 2006.

Rights and permissions

About this article

Cite this article

Kinelovskii, S.A., Alekseev, A.V., Gromilov, S.A. et al. Formation of a specific layer on the surface of a metallic target interacting with a shaped-charge jet of boron-containing liners. Combust Explos Shock Waves 42, 231–236 (2006). https://doi.org/10.1007/s10573-006-0044-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s10573-006-0044-4