Abstract

Ionic Liquids (ILs) have been used to address issues such as recyclability, cost-effectiveness, and tailored thermophysical properties. This is most relevant to recent efforts directed at dissolving cellulose for filament spinning and bioproduct development. Herein, we introduce a simple method to investigate how interactions between cellulose films (roughness, Rh = 37 nm) and ILs specifically 1-butyl-3-methylimidazolium acetate ([bmim][OAc]), 1-butyl-3-methylimidazolium chloride ([bmim][Cl]), 1-ethyl-3-methylimidazolium acetate ([emim][OAc]), and 1-ethyl-3-methylimidazolium chloride ([emim][Cl]), along with their water mixtures (0, 5, and 10 wt%) affect thermophysical properties relevant to cellulose dissolution (surface tension, γ; contact angle, θ; diffusivities, D; and bulk density, ρ) at 363.15 K and 0.1 MPa under argon and air atmospheres. Thermophysical properties relevant to cellulose dissolution were measured at 363.15 K and 0.1 MPa under argon (surface tension, γ, contact angle, θ), and air (diffusivities, D and bulk density, ρ) atmospheres to reveal the effect of the IL counter ions on the involved interactions with water. In general, water increased γ, θ, but reduced D, which supports experimental observations indicating the detrimental effect of water on IL-cellulose interactions. The [emim]+ cation (in [emim][OAc] and [emim][Cl]), produced a lower contact angle with cellulose while the interfacial properties (γ, θ, D) for ILs with the [OAc]− anion were marginally affected by water. By contrast, the two ILs carrying [Cl]− anions exhibited a significant reduction in D (from 11.7\(\cdot {10}^{-13}\) to 2.9\(\cdot {10}^{-13} {m}^{2}{s}^{-1}\)) in the cation shift from [emim]+ to [bmim]+ at 363.15 K and 0.1 MPa, with 0% water content. Overall, we present a methodical approach rooted in experimental and theoretical approaches to facilitate our understanding of ionic liquids (ILs), especially within the domain of bioprocessing.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Cellulose-derived materials are gaining importance due to their potential to replace oil-based counterparts, resulting in new recyclable and biodegradable products used in the packaging, textiles, and energy sectors, among others (Fu et al. 2020). Unfortunately, due to the recalcitrance of cellulose, only a limited number of common solvents can fully dissolve it, limiting the potential of cellulose in the technosphere (Mohd et al. 2017). Cellulose dissolution is possible with Ionic Liquids (ILs) (Swatloski et al. 2002; Zhang et al. 2005; Reyes et al. 2022) due to cellulose inter and intramolecular H-bonds disruption (Mohd et al. 2017; El Seoud et al. 2019). In general, ILs have been described as organic salts with melting points below 100 °C, hence displaying low volatility (Verma et al. 2017) also enabling the possibility for IL recovery and recyclability (Laus et al. 2005). Moreover, ILs are design solvents given the possibility of adjusting their physical and chemical properties by the selection of the counter ions (Montalbán et al. 2017). A notable example is the Ioncell® process, which uses ILs-based technology to produce cellulose-based textiles (Michud et al. 2015). Additionally, ILs have been utilized for fiber welding, (Reyes et al. 2018) enabling the functionalization necessary to obtain composites.

Cellulose dissolution in ILs is often carried out in dry or inert conditions, given the sensitivity of IL properties to moisture (Manna and Ghosh 2019). There are few studies reporting the mechanism of cellulose dissolution in ILs in the presence of moisture, and mostly focused to measurements of bulk properties such as turbidity (Mazza et al. 2008) and rheology (Nazari et al. 2017), ignoring relevant interfacial effects such as wettability, surface tension, and molecular transport. These latter properties require a controlled environment (impurities, moisture, and water content) (Almeida et al. 2012b). For instance, the water content in ILs plays an essential role in the mass transfer rate at the gas-liquid interface (Aghaie et al. 2018) and, overall, the interfacial properties are crucial for understanding, optimizing, and scaling up related process technologies (Tariq et al. 2011; Barati-Harooni et al. 2016).

Considering the importance of ILs and the effect of water during cellulose dissolution and regeneration, the present work presents a methodical study on the impregnation and diffusion of ILs into cellulose films and the effect of water moieties. The IL homologous series of four ILs [emim][OAc], [bmim][OAc], [emim][Cl], [bmim][Cl], has been chosen based on their intensive use for cellulose processing, and commercial relevance (Anokhina et al. 2017). Their mixtures with water (0, 5, 10 wt%) were examined by measuring contact angles, surface tensions, bulk densities, and diffusivities (Mazza et al. 2008; Szabó et al. 2023). Measurements involved direct optical microscopy, scanning electron microscopy (SEM), tensiometry, and gravimetry. The results revealed the role of the IL counter ions and water content on the wettability and diffusion through homogenous cellulose surfaces at 90oC (typical temperature for cellulose partial/total dissolution) (Zhu et al. 2006), most relevant for green cellulose transformation. Furthermore, our study intentionally focuses on unraveling the nuanced interplay between water, ionic liquid counterions, and associated interfacial properties during cellulose dissolution, with the selected water concentrations strategically chosen to illuminate limiting factors.

Materials and methods

1-ethyl-3-methylimidazolium acetate ([emim][OAc], CAS 143314-17-4, > 95 wt% purity), 1-ethyl-3-methylimidazolium chloride ([emim][Cl], CAS 65039-09-0, 98 wt% purity), 1-butyl-3-methylimidazolium acetate ([bmim][OAc], CAS 284049-75-8, \(\ge\) 95 wt% purity), 1-butyl-3-methylimidazolium chloride ([bmim][Cl], CAS 79917-90-1, \(\ge\) 99 wt% purity) were purchased from Merck with no further purification and stored under inert conditions. The ILs + water mixtures were prepared using Merck Milli-Q® type I water ultrapure. Due to IL hygroscopicity, they were dried before preparing the samples, (12 h, 200 mbar) in a Thermo Scientific VT 6025 vacuum drying oven (Thermo Electron LED GmbH, 63,505 Langenselbold, Germany) (Gordon et al. 2007).

The water content present in pure ILs was determined using a Coulometric Karl Fischer titrator 831 (Metrohm AG, Switzerland) with an accuracy of 0.3% mass. The water content determination for the pure ILs was less than 10 ppm based on a Coulomb metric titration using a CombiCoulomat frit solution (Merck).

Birch kraft pulp (BKP) (provided by UPM-Ky Finland, kappa number 1; DP 4700; no fines) was microfluidized (6 passes at 2000 bar, Microfluidics M-110P, International Corporation, USA) and used to produce nanocellulose (CNF) and CNF films following a previously reported method (Reyes et al. 2018). The nano-fibrillated material has a micrometer-scale length and an average diameter of 37 ± 9 nm as measured by Atomic Force Microscopy AFM (Digital Instruments Multimode Atomic Force Microscope, Bruker, UK), see Supporting Information Figure S1. The prepared films were stored at 25 °C and 45% relative humidity until their final use. The selection of nanocellulose in our study is justified by its superior purity and reduced surface roughness compared to commercially available cellulose options, allowing for a more accurate investigation of properties such as contact angle and diffusivities (Chen et al. 2016; Rojas et al. 2011).

Density

The IL density (ρ) was assessed through the vibrating tube method in a densitometer Anton Paar (DMA 5000, Austria) with 0.005 kg·m−3 uncertainty. The device was calibrated by using ultrapure water and air at 363.15 K and 0.1 MPa.

Imaging

CNF morphology before and after contact with ILs mixtures were analyzed using a scanning electron microscope (SEM) (Phenom Pure G5 Desktop SEM, ThermoFisher Scientific, UK). The SEM device used has a resolution of 30 nm and electron optics with a long-life thermionic source (CeB6), a magnification range of 70-20000x, and was operated at an accelerating voltage of 5 kV. Samples were placed on aluminum stubs using carbon tape and sputtered with Au/Pd- 80/20 coating in a sputtering device using 20 mA current for 20 s (Q150R S Plus, Quorum Technologies Ltd, UK).

Surface tension

The surface tension (γ) was measured in a pendant drop tensiometer with pressure and temperature control in a closed chamber (TEMCO IFT-10, USA). The technique involves the introduction of a sample drop from a syringe needle (ϕ = 1.5 mm) into the stainless-steel cylinder chamber flooded with argon gas at 0.1 MPa. The surface tension was assessed by collecting data from the pendant drop until reaching equilibrium ( Δγ ≤ 1 mN∙m-1); for this purpose, a camera connected to a data acquisition card and image analysis software (DROPimage Avance version 1.5 Rame-Hart Instruments, Inc., USA) were used. The system was operated on a vibration-free table (Vibraplane 2210, EEUU) (Mejía et al. 2014).

Contact angle

Contact angle (Ɵ) measurements were obtained inside the same chamber used for surface tension by depositing suspended droplets onto the CNF film surface. Three samples were taken for each IL or IL + water mixture. The data collection was performed using the same software and data collection card (DROPimage Advance version 1.5 Rame-Hart Instruments, co USA).

Diffusivity

Using the method described in Fig. 1. The apparent diffusion coefficient (D) was measured using CNF square samples of 1 cm × 1 cm.

Initially, the CNF films were stored in a conditioned laboratory until final use (298.15 K, 45% relative humidity). The square CNF films were placed between two glass slides, and the IL was placed on the edges to promote unidirectional diffusion (Fig. 1). The mass gain was measured by a high precision scale (0.1 mg) (Mettler Toledo Balance XPR404S, Switzerland). The samples were immersed and measured at different times until reaching saturation (Croitoru and Roata 2021). Excess IL + water mixture was removed from each CNF film before each measurement using a Whatman® lens cleaning tissue (Sigma Aldrich, Grade 105). The experiments were carried out in triplicate for each solution at 363.15 K.

The diffusivity was evaluated from the mass transport Eq. (1), assuming that the mass transfer only takes place in the (x) direction. (Hines and Maddox 1985):

In Eq. (1), CA represents the liquid concentration, and the apparent diffusivity coefficient D is assumed to be constant with temperature, pressure and concentration. The analytical solution of Eq. 1, requires the assumption of one initial condition and two boundary conditions (Crank 1975):

The solution of Eq. (1), considering the initial and boundary conditions Eqs. (2–4) leads to (Crank 1975):

The mass transferred into the CNF film at a given time can be determined by the integration of Eq. (5) between x = 0 and x = l. Therefore, the amount of matter transferred at any time (Mt) is given by Eq. (6) (Crank 1975):

The maximum mass uptake is found at \(t\to \infty\) as expressed in Eq. (7).

A time resolved approximation can be applied, provided that the ratio of the transferred mass to the equilibrium mass is between 0 and 0.8 (0 ≤ \({M}_{t}/{M}_{\infty }\) ≤ 0.8) with an expected error < 5% (Hedlund et al. 2017):

where \({M}_{\infty }\) represents the maximum mass uptake, and Mt is the amount of mass transferred to the CNF film of a thickness (d) at a time (t).

The value of the diffusivity coefficient can be obtained by a least-squares fit given by the following objective function Eq. (10):

where N is the total number of data, \({M}_{exp}\) is the experimental mass and \({M}_{cal}\) is the mass calculated with Eq. (9).

Results and discussion

The density values of the phases involved are needed to calculate the excess volume and surface tension. The density values at 363.15 K for the four IL (water concentrations of 0, 5, 10 wt%) are shown in Fig. 2a. The density of ILs with [OAc]− counter-anions is directly proportional to the increase in water content. In contrast, the density of IL with [Cl]− was reduced, agreeing with the results of the excess volumes and surface tension (Fig. 2b): [OAc]− ILs demonstrated enhanced ionic interactions and structural organization with increased water concentration (see Fig. 2 for the excess volume of the solvents).

Bulk properties for the ILs + water mixtures at 363.15 K, and 0.1 MPa. a densities for the ILs + water mixtures, the standard deviations are < 0.03 kg\(\cdot\)m−3, smaller than the corresponding symbols. b excess volumes (VE) for ILs. (Standard deviations are less than 0.005 cm3\(\cdot\)mol−1, smaller than the corresponding symbols)

The ILs-water mixture shows a strong attractive interaction (see Fig. 2b), this is reflected in negative values of the excess molar volume. Furthermore, an interesting disparity was observed when comparing [OAc]− and [Cl]− anions, as well as [bmim]+ and [emim]+ cations. The excess molar volume does not show a significant variation between [bmim]+ and [emim]+ compared to [OAc]− and [Cl]− anions, where ILs with an [OAc]− anion exhibit lower values in excess molar volume compared to ILs with a [Cl]− anion. This is because the ionic liquids with [OAc]− anions have a higher affinity for the formation of specific molecular structures in the presence of water. This latter observation corroborates the importance of water-IL anion interactions in contrast to the corresponding interactions with the cations.

This latter observation agrees with the observed influence of water molecules in the respective ILs surface tension values (see Fig. 3 and Figure S2) where [OAc]−-based ILs tend to equilibrate faster when compared to the respective [Cl]− ILs (Moreno et al. 2008).

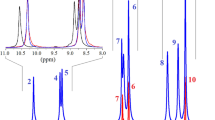

Surface tension versus time profiles of [bmim][Cl] (dotted lines correspond to minimum square regressions using Eq. 11)

Dynamic and equilibrium surface tensions(γ)

The contact of the solvent drops with cellulose in the argon atmosphere involves several phenomena (due to the low solubility of ILs at 0.1 MPa (Song et al. 2020); for instance, the argon molecules diffuse into the liquid drop, and the water molecules are transferred from the liquid bulk out to the drop surface and the gas phase (Bird et al. 2006; Reyes et al. 2013). The simultaneous mass transfer processes are manifested then as a dynamic exponential decay on the surface tension (Reyes et al. 2013). Figure 3 illustrates this phenomenon for the [bmim][Cl] + H2O mixtures.

In general, the presence of water content tends to increase the ILs equilibrium surface tension considering the absolute change from 0 to 10 wt%, with an evident increase specifically at 5 wt%; however, Fig. 3 shows that for the case of [bmim][Cl] + H2O mixtures, the initial surface tension (t = 0) displays a different shift as it approaches the equilibrium (time t→\(\infty\)). In general, the four IL + water mixtures exhibited a significant drop in their initial dynamic surface tensions (see Figure S.2 in Supporting Information). In particular, the ILs with the [emim]+ cation (see Figure S2.b-c in Supporting Information) are more significantly affected by water and the corresponding values of the mixtures are higher compared with that of the neat IL. In contrast, ILs with the [bmim]+ cation (see Figure S2.a in Supporting Information) are less affected by the presence of water, exhibiting similar values in their respective initial surface tensions with a more limited increase of the equilibrium surface tensions (Fig. 3, and Figure S2a). Additionally, [bmim]+ ILs dynamic surface tensions equilibrated faster (t < 200 min.) when compared to their homologous [emim]+ mixtures; this later behavior is attributed to the mass transfer involved. The surface tension time dependency observed in Fig. 3 can be further modeled using the following exponential decay expression Eq. (11)

where \({\gamma }_{eq}\) represents the steady-state surface tension value, a and b are empirical parameters adjusted from the experimental data to Eq. (11) using a nonlinear least square. Table 1 summarizes the parameters obtained after fitting the experimental data to Eq. 11 (Russo and Hoffmann 2010).

Parameter (a), in Table 1, reflects the magnitude of the change between the initial and final equilibrium surface tension, and it is related to the cation-anion affinity or interaction; therefore, lower (a) values are expected for ionic liquids with stronger interactions. It can be observed that parameter (a) is higher for [emim]+ compared to those with [bmim]+; furthermore, for the same type of cations, the [OAc]− anion exhibits lower values, demonstrating a significant affinity between the [bmim]+ cation and the [OAc]− anion due to the anion electron pairs. This can be explained because ILs with [bmim]+ cation can only donate one H-bond, in contrast to the anion, which can potentially accept more than one, leading to a large electrostatic mismatch of the IL, deriving in a strong attraction for H donors to reduce the electrostatic mismatch (Khan et al. 2014).

In Table 1, parameter (b) reveals the time required to reach the equilibrium, associated with the dynamic surface tension and argon diffusion. The b values are inversely proportional to the time required to reach equilibrium; therefore, its magnitudes are higher for the ILs with [bmim]+ cation when compared to the corresponding mixtures with the [emim]+ cations, which required longer times to equilibrate. A good example of this latter observation is the [bmim][OAc] IL, presenting the higher b (t = 2.14 min) and the shortest equilibration time (t = 11 min). In general, according to Fig. 3, the dynamic behavior of the surface tension can be divided into three zones. Zone 1 (t > 0, t << \({t}_{eq}\)) represents the instantaneous surface tension free from the influence of the gas molecules; Zone 2 (t > 0, t < \({t}_{eq}\)) is characterized by the mass diffusion mentioned before, causing a transient state towards equilibrium, and zone 3 (t ≈ \({t}_{eq}\)) corresponds to equilibrium.

In the transient state, the dynamic behavior of the surface tension is closely related to the argon mass transfer, which can be modeled by considering the following mass transport equation (Bird et al. 2006; Reyes et al. 2013).

Although the drop deviates from sphericity this does not significantly affect the calculation of diffusivity. In Eq. (12) \({C}_{Ar}\) is the concentration of the argon gas for a given position (r) inside the droplet and time (t), \({D}_{Ar-I{L}_{m}}\) is the apparent diffusion coefficient of argon into the IL + water liquid drop. The solution of Eq. (12) requires the following initial and boundary conditions.

In Eqs. (13–15), R refers to the droplet radius and \({C}_{Ar}^{*}\) is the gas saturation concentration. The analytical solution of Eq. 12 with the initial and boundary conditions given by Eqs. (13–15) (Georgiadis 2011):

where \({R}^{*}=r/R\; \text{and}\; {D}_{Ar-I{L}_{m}}^{*}={D}_{Ar-I{L}_{m}}/{R}^{2}\)

The diffusivity of the gas into the IL can be approximately predicted at 303.15 K, considering the semiempirical relationship given by Morgan et al. (2005):

where \({\mu }_{IL}\) is the viscosity of the IL at 303.15 K in [cP], \({\stackrel{\sim}{V}}_{Ar}\) is the saturated molar volume of argon in liquid state at normal boiling point in [cm3/mol], and \({D}_{Ar-IL}\)is the diffusivity coefficient in [cm2/s]. In order to obtain the diffusion coefficient at the experimental condition, one can use the scaling law presented by Bird et al. (2006):

Combining the information from Eqs. 16–18, and available experimental data on the IL viscosity and Ar molar volumes (Tegeler et al. 1999; Seddon et al. 2002; Freire et al. 2011; Almeida et al. 2012a; Yang et al. 2017), it is possible to obtain the Ar concentration profiles in the IL droplets at a given time; for instance, Fig. 4, presents the concentration profiles resulting for the Ar diffusion into the [bmim][Cl] pure IL.

Figure 4 and Figure S3 (supporting information) show the argon concentration profiles versus droplet radius position for pure ILs at different times (1 s < t < 7200 s). From Fig. 4, it is observed that the argon concentration reaches equilibrium at approximately 7200 s (120 min); this result agrees well with the information presented in Fig. 3, where the surface tensions for IL [bmim][Cl] started to equilibrate in the period between 100 and 220 min (zone 2 in Fig. 3). Furthermore, this value is almost equal to the prediction made considering the parameter b of Eq. 11. This latter observation confirms that the dominant process governing the dynamic behavior of the surface tension is the argon gas molecular diffusion into the liquid droplet.

Figure S3 also shows the profiles of argon concentration for other pure ILs. The behavior exhibited for the Ar diffusion into the IL [bmim][OAc] (Figure S3a), agrees well with the time scale necessary to reach the equilibrium surface tension (Figure S2a); however, for the case of [emim][OAc] IL, the time scale of the Ar diffusion presented in Figure S3b, does not agree with the times observed for the dynamic surface tensions. This latter observation confirms that IL [emim][OAc], water interactions, and diffusion are more important and cannot be neglected. The equilibrium surface tension is presented in Table 1 and illustrated in Fig. 5 (determined by parameter \({\gamma }_{eq}\) of Eq. 11, zone 3).

Figure 5 summarizes the equilibrium surface tension for the ionic liquids with different water concentrations in an argon atmosphere; the surface tensions absolute value tends to increase considering the range from 0 to 10 wt% water content, except for the [bmim][Cl], which is less affected by water. Regarding the surface tensions for the pure ILs, it is observed that ILs with the acetate anion tend to have lower surface tensions (30.03 mN\(\cdot\)m−1 [bmim][OAc] and 40.40 mN\(\cdot\)m−1 [emim][OAc]) compared to pure ILs containing [Cl]− anion (45.20 mN\(\cdot\)m−1 [bmim][Cl] and 46.77 mN\(\cdot\)m−1 [emim][Cl]). In addition, ILs with the [bmim]+ cation possess lower surface tensions than ILs with the [emim]+ cation, given that an increase in the alkyl chain of the imidazolium- cations results in a decreased surface tension (Sánchez et al. 2009). However, the dynamic behavior of the surface tension can be attributed mainly to the Ar diffusion into the droplet of IL + water mixtures, which is reflected in the obtained values of parameter (a) and (b), where ILs with an [OAc]− anion exhibited the lowest (a) values and the highest (b) values. This phenomenon is mainly attributed to water molecules interacting with ILs ions by establishing hydrogen bonds with the anion and cation, occupying the space above and below the imidazolium ring, resulting in a decrease of the electrostatic attractions between the ions and, therefore, in a decrease of the overall cohesion energy (Freire et al. 2007). Additionally, these results can be contrasted, considering the evaluation of the corresponding excess molar volumes for the mixtures (VE). It is worth noting that the values of the excess volume tend to decrease and surface tension to increase with the addition of water, indicating strong IL + water interactions and detrimental effects on cellulose dissolution (Niazi et al. 2013). Table S1, summarizes the values for the corresponding excess molar volumes.

In sum, ILs and water mixtures’ equilibrium surface tensions, densities, and diffusivities strongly depend on the water content. The next section discusses the dynamic and equilibrium properties of the liquid (IL + water) and gas (Ar, air) mixtures in contact with cellulose model surfaces.

Contact angle and diffusivities on cellulose surfaces

The contact of liquids and solids with different molecular species results in different interactions in such a way that the excess surface free energy is minimized (Liu and Jiang 2016). As a result of such intermolecular interactions and surface energy minimization, the liquid-solid interphase is characterized by the contact angle formed by the molecules on the surface of the liquids with those of the solid. Larger contact angles evidence weak intermolecular interactions. Pereira et al. (2015) measured the contact angle of various ILs on glass, Al, and PTFE, concluding that the higher the basicity of the hydrogen bond of the anion, the higher the ability of the IL anion to accept protons, translated to an easier IL wettability with the surfaces (Pereira et al. 2015). Figure 6 presents the equilibrium contact angle for the corresponding IL + water mixtures.

In Fig. 6, it is observed that [bmim][Cl] contact angles are statistically unaffected by the presence of water due to the anion-cation interactions discussed earlier, where the chloride anion has a lower negative charge density than the acetate anion, causing the [bmim]+-[Cl]− interaction to be weak (Khan et al. 2014). In contrast, the [bmim]+-[OAc]− interaction is strong enough to cause a change in contact angle at different water content, obtaining a maximum at 5 wt% (55 ± 15 [deg]). In comparison [emim][Cl] presents a maximum contact angle at 0% water (63 ± 15 [deg]), indicating lower affinity towards the cellulose surface.

Table S3 summarizes the contact angle values of the four ionic liquids studied with their respective water mixtures. The values reported do not show a clear trend that can be explained within the framework of a well funded theoretical model; therefore this is an area that deserves further research and study. However, ILs with [bmim] + cation tended to increase the wettability with increased water content. The IL + water mixtures contact angles followed the trend: [bmim][OAc]0wt% < [bmim][Cl]5wt% < [bmim][Cl]10wt% < [bmim][Cl]0wt% < [emim][Cl]5wt% < [bmim][OAc]10wt% < [emim][OAc]10wt% < [emim][OAc]0wt% < [bmim][OAc]5wt% < [emim][Cl]10wt% < [emim][OAc]5wt% < [emim][Cl]0wt%.

Contact angles in the present study cannot be considered as isolated equilibrium phenomena; this property is intimately linked with the simultaneous diffusion of the molecular species from the liquid and gas phases through the solid surface. Cellulose dissolution results from the solvent’s ability to remove inter and intramolecular hydrogen bonds between the biopolymer molecules (Hedlund et al. 2017), this is intimately linked to the solvent ability to diffuse and transfer large amounts of the liquid into the solid bulk. Figure 7 depicts the mass gain (diffusion) vs. time for [emim][Cl] mixtures, and Figure S6 shows the equilibrium or total mass gain for the different ILs + water mixtures.

Figure 7 and Figure S5 (supporting information) show the profiles of the measured mass (\({M}_{IL})\) versus time for the corresponding ILs. It is possible to distinguish three diffusion regimes or zones (Fig. 7). Zone 1 is characterized by a linear relationship between the measured mass and time, represented by Eq. 9. Zone 2 exhibits a logarithmic profile indicating the proximity to the saturation point. In zone 3, the diffusion plateau is reached, indicating the equilibrium state where the CNF is saturated with IL and begins to dissolve massively. The three zones are observed in all ILs + water mixtures (see Figure S5).

According to Figure S5, the CNF saturation by pure [emim][OAc] is at 420 s, while the saturation by [emim][Cl] is at 600 s. In general, faster IL saturations can be related to subsequent faster dissolutions (Li et al. 2015). In the case of [emim][OAc] the dissolution ability is attributed to its optimized counter ions size (steric effects), which loosened the cellulose intermolecular H-bonds causing more ions to enter the interfibrillar network (Li et al. 2015). Furthermore, Figure S6 shows the equilibrium mass (\({M}_{\infty })\) of IL + water absorbed into the CNF, for the IL mixtures set. \({M}_{\infty }\) values are presented, together with the saturation time and diffusion coefficients (calculated from Eq. 9) in Table 2.

Table 2 and Figure S6, show the different values of the equilibrium mass \({M}_{\infty }\) reached by the IL + water. It is observed that the cellulose films absorbed similar mass in the case of pure ILs (Figure S6). However, at 5% water content, the ILs with [OAc]− anion absorbed less compared to the analogous [Cl]− ILs. At 10 wt% water content, this trend is shifted to higher sorption, with the [emim] [OAc] IL presenting the highest mass sorption. The selection of the proper counter ion and water content have an essential impact on the amount of solvent absorbed and the saturation time of films, confirming why ILs can be considered designing solvents in the context of cellulose dissolution (Montalbán et al. 2017; Zhang et al. 2010; Lu et al. 2014). In general, the water content tends to increase the saturation time, making further dissolution of cellulose slower, nonetheless, the [emim][OAc] and [emim][Cl] ILs exhibited better tolerance toward higher water contents, displaying the highest sorption saturation mass at shorter times (Table 2). The apparent diffusion coefficients are presented in Table 2 and Figure S7.

The diffusivity values for the ILs with [bmim]+ cation tracked with the amount of water added; therefore, it is possible to conclude that these ILs presented an increasing diffusion resistance with water. In contrast, the ILs with the [emim]+ cation tolerate a more significant amount of water; despite the favorable interactions with water, as discussed before, this seems to favor sorption in cellulose. These latter observations explain why this type of ILs with [emim]+ cation, and in particular [emim][OAc], are preferred for cellulose and biomass processing technologies (Reyes et al. 2022). The solubility of cellulose in ILs mainly depends on the ionic liquid’s effective polarity and hydrogen bonding capacity (Pinkert et al. 2009). ILs with cellulose dissolution ability possess less bulky and unsaturated heterocyclic cations with delocalized \(\pi\) electrons that provide stronger interactions with cellulose, faster diffusion (for steric reasons), and allow for anions such as acetate, to form hydrogen bonds with cellulose (Li et al. 2017; Zhang et al. 2017).

The diffusion of ILs-water mixtures through the cellulose has an evident impact on the morphology, mechanical, and physical properties of the films, as reported earlier (Reyes et al. 2018). For instance, ILs that dissolve cellulose increase the light transmittance (Reyes et al. 2018), Fig. 8.

The Fig. 8 in the lower left corner shows the reference unmodified cellulose. The figure shows the evolution of the morphology after contact with IL (swelling stage) and when the maximum amount of IL has been absorbed, causing partial dissolution. Initially, when the ILs are in contact with cellulose, tiny bubbles (upper right) are formed due to cellulose swelling, later when the maximum amount of IL has been absorbed, the surface exhibits characteristic holes and defects in the micron scales (lower right image), due to partial dissolution. The appearance and dissolution changes are more drastic for the case of [emim][OAc] IL, agreeing with previously reported studies where [emim][OAc] has been shown as an effective IL for cellulose dissolution, producing films of higher optical transmittance (Reyes et al. 2018).

Conclusions

A methodical study about imidazolium ILs [emim][Cl], [emim][OAc], [bmim][Cl], and [bmim][OAc], and their water mixtures are presented in the context of cellulose processing potential. Significant effects emerged from the gas diffusion and water content on the interfacial properties at the gas-liquid interface (surface tension) and liquid-gas-solid interphase (contact angle, diffusion). The two [emim]+ ILs exhibited strong interactions with water, without hindering the diffusion into CNF model surfaces. On the other hand, the [bmim]+ cation presented a remarkable interaction with the acetate anion, confirmed by the surface tension values, the excess molar volumes, and the contact angle. As for the two ILs with chloride ions, it was observed that they have a faster surface tension equilibration time than the ILs with acetate ions. In general, new data is presented regarding bulk properties for the ILs + water mixtures at 363.15 K, and 0.1 MPa under argon atmosphere and the interfacial properties at the gas-liquid and liquid-solid (cellulose) interphases.

This work contributes to the understanding of ILs in bioprocessing and brings valuable insights for designing cellulose processing technologies, offering a foundation for future research and thermodynamic models. While our current mass transfer model effectively captures the impact of various water and counterions interactions on surface tension, it is acknowledged that an enhanced model considering both argon diffusion and water evaporation, supported by additional gas-phase measurements, is warranted for a more comprehensive understanding. Furthermore, the intricate dynamics of contact angle variations and the effects of the acetate-chloride switch deserve a deeper exploration.

Data availability

The data that support the findings of this study are included within the manuscript, any other data are available from the corresponding author upon reasonable request.

References

Aghaie M, Rezaei N, Zendehboudi S (2018) A method review on CO2 capture with ionic liquids: current status and future prospects. Renew Sustain Energy Rev 96:502–525. https://doi.org/10.1016/j.rser.2018.07.004

Almeida H, Passos H, Lopes-da-Silva J et al (2012a) Thermophysical properties of five acetate-based ionic liquids. J Chem Eng Data 57:3005–3013. https://doi.org/10.1021/je300487n

Almeida HFD, Teles ARR, Lopes-da-Silva JA et al (2012b) Influence of the anion on the surface tension of 1-ethyl-3-methylimidazolium-based ionic liquids. J Chem Thermodyn 54:49–54. https://doi.org/10.1016/j.jct.2012.03.008

Anokhina T, Pleshivtseva T, Ignatenko V et al (2017) Fabrication of composite nanofiltration membranes from cellulose solutions in an [Emim]OAc–DMSO mixture. Pet Chem 57:477–482. https://doi.org/10.1134/s0965544117060020

Barati-Harooni A, Najafi-Marghmaleki A, Arabloo M, Mohammadi AH (2016) An accurate CSA-LSSVM model for estimation of densities of ionic liquids. J Mol Liq 224:954–964. https://doi.org/10.1016/j.molliq.2016.10.027

Bird RB, Stewart WE, Lightfoot EN (2006) Transport phenomena, 2nd edn. Wiley, New York

Chen C, Duan C, Li J et al (2016) Cellulose (dissolving pulp) manufacturing processes and properties: a mini-review. BioRes 11:5553–5564

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, Oxford

Croitoru C, Roata IC (2021) Alkylimidazolium ionic liquids absorption and diffusion in wood. Appl Sci 11:7640. https://doi.org/10.3390/app11167640

El Seoud O, Kostag M, Jedvert K, Malek N (2019) Cellulose in ionic liquids and alkaline solutions: advances in the mechanisms of biopolymer dissolution and regeneration. Polymers 11:1917. https://doi.org/10.3390/polym11121917

Freire MG, Carvalho PJ, Fernandes AM et al (2007) Surface tensions of imidazolium based ionic liquids: anion, cation, temperature, and water effect. J Colloid Interface Sci 314:621–630. https://doi.org/10.1016/j.jcis.2007.06.003

Freire M, Teles A, Rocha M et al (2011) Thermophysical characterization of ionic liquids able to dissolve biomass. J Chem Eng Data 56:4813–4822. https://doi.org/10.1021/je200790q

Fu Q, Cui C, Meng L et al (2020) merging cellulose-derived materials: a promising platform for the design of flexible wearable sensors toward health and environment monitoring. Mater Chem Front 5:2051–2091. https://doi.org/10.1039/d0qm00748j

Georgiadis A (2011) Interfacial tension of aqueous and hydrocarbon systems in the presence of carbon dioxide at elevated pressures and temperatures. https://spiral.imperial.ac.uk/handle/10044/1/6912. Accessed 20 Dec 2022

Gordon CM, Muldoon MJ, Wagner M et al (2007) Synthesis and purification. In: Ionic liquids in synthesis. Wiley, Germany, pp 7–55

Hedlund A, Köhnke T, Theliander H (2017) Diffusion in ionic liquid–cellulose solutions during coagulation in water: mass transport and coagulation rate measurements. Macromolecules 50:8707–8719. https://doi.org/10.1021/acs.macromol.7b01594

Hines AL, Maddox RN (1985) Mass transfer: fundamentals and applications. Prentice-Hall, Michigan

Khan I, Kurnia KA, Mutelet F et al (2014) Probing the interactions between ionic liquids and water: experimental and quantum chemical approach. J Phys Chem B 118:1848–1860. https://doi.org/10.1021/jp4113552

Laus G, Bentivoglio G, Schottenberger H et al (2005) Ionic liquids: current developments, potential and drawbacks for industrial applications. Lenzinger Berichte 84:71–85

Li Y, Liu X, Zhang S et al (2015) Dissolving process of a cellulose bunch in ionic liquids: a molecular dynamics study. Phys Chem Chem Phys 17:17894–17905. https://doi.org/10.1039/C5CP02009C

Li Y, Liu X, Zhang Y et al (2017) Why only ionic liquids with unsaturated heterocyclic cations can dissolve cellulose: a simulation study. ACS Sustain Chem Eng 5:3417–3428. https://doi.org/10.1021/acssuschemeng.7b00073

Liu H, Jiang L (2016) Wettability by ionic liquids. Small 12:9–15. https://doi.org/10.1002/smll.201501526

Lu B, Xu A, Wang J (2014) Cation does matter: how cationic structure affects the dissolution of cellulose in ionic liquids. Green Chem 16:1326–1335. https://doi.org/10.1039/c3gc41733f

Manna B, Ghosh A (2019) Dissolution of cellulose in ionic liquid and water mixtures as revealed by molecular dynamics simulations. J Biomol Struct Dyn 37:3987–4005. https://doi.org/10.1080/07391102.2018.1533496

Mazza M, Catana D-A, Vaca-Garcia C, Cecutti C (2008) Influence of water on the dissolution of cellulose in selected ionic liquids. Cellulose 16:207–215. https://doi.org/10.1007/s10570-008-9257-x

Mejía A, Cartes M, Segura H, Müller EA (2014) Use of equations of state and coarse grained simulations to complement experiments: describing the interfacial properties of carbon dioxide + decane and carbon dioxide + eicosane mixtures. J Chem Eng Data 59:2928–2941. https://doi.org/10.1021/je5000764

Michud A, Tanttu M, Asaadi S et al (2015) Ioncell-F: ionic liquid-based cellulosic textile fibers as an alternative to viscose and lyocell. Text Res J 86:543–552. https://doi.org/10.1177/0040517515591774

Mohd N, Draman SFS, Salleh MSN, Yusof NB (2017) Dissolution of cellulose in ionic liquid: a review. AIP Conf Proc 1809. https://doi.org/10.1063/1.4975450

Montalbán M, Collado-González M, Díaz-Baños G, Víllora G (2017) Predicting density and refractive index of ionic liquids. In: Progress and developments in ionic liquids. IntechOpen, Croatia, pp 339–368

Moreno M, Castiglione F, Mele A et al (2008) Interaction of water with the model ionic liquid [bmim][BF4]: molecular dynamics simulations and comparison with NMR data. J Phys Chem B 112:7826–7836. https://doi.org/10.1021/jp800383g

Morgan D, Ferguson L, Scovazzo P (2005) Diffusivities of gases in room-temperature ionic liquids: data and correlations obtained using a lag-time technique. Ind Eng Chem Res 44:4815–4823. https://doi.org/10.1021/ie048825v

Nazari B, Utomo NW, Colby RH (2017) The effect of water on rheology of native cellulose/ionic liquids solutions. Biomacromolecules 18:2849–2857. https://doi.org/10.1021/acs.biomac.7b00789

Niazi AA, Rabideau BD, Ismail AE (2013) Effects of water concentration on the structural and diffusion properties of imidazolium-based ionic liquid–water mixtures. J Phys Chem B 117:1378–1388. https://doi.org/10.1021/jp3080496

Pereira M, Kurnia K, Sousa F et al (2015) Contact angles and wettability of ionic liquids on polar and non-polar surfaces. Phys Chem Chem Phys 17:31653–31661. https://doi.org/10.1039/c5cp05873b

Pinkert A, Marsh KN, Pang S, Staiger MP (2009) Ionic liquids and their interaction with cellulose. Chem Rev 109:6712–6728. https://doi.org/10.1021/cr9001947

Reyes G, Cartes M, Rey-Castro C et al (2013) Surface tension of 1-ethyl-3-methylimidazolium ethyl sulfate or 1-butyl-3-methylimidazolium hexafluorophosphate with argon and carbon dioxide. J Chem Eng Data 58:1203–1211. https://doi.org/10.1021/je3013414

Reyes G, Borghei M, King A et al (2018) Solvent welding and imprinting cellulose nanofiber films using ionic liquids. Biomacromolecules 20:502–514. https://doi.org/10.1021/acs.biomac.8b01554

Reyes G, Pacheco C, Isaza-Ferro E et al (2022) Upcycling agro-industrial blueberry waste into platform chemicals and structured materials for application in marine environments. Green Chem 24:3794–3804. https://doi.org/10.1039/D2GC00573E

Rojas J, Lopez A, Guisao S, Ortiz C (2011) Evaluation of several microcrystalline celluloses obtained from agricultural by-products. J Adv Pharm Tech Res 2:144. https://doi.org/10.4103/2231-4040.85527

Russo JW, Hoffmann MM (2010) Influence of typical impurities on the surface tension measurements of binary mixtures of water and the ionic liquids 1-Butyl-3-Methylimidazolium tetrafluoroborate and chloride. J Chem Eng Data 55:5900–5905. https://doi.org/10.1021/je100949x

Sánchez L, Espel J, Onink F et al (2009) Density, viscosity, and surface tension of synthesis grade imidazolium, pyridinium, and pyrrolidinium based room temperature ionic liquids. J Chem Eng Data 54:2803–2812. https://doi.org/10.1021/je800710p

Seddon K, Stark A, Torres M (2002) Viscosity and density of 1-Alkyl-3-methylimidazolium ionic liquids. In: Clean solvents. American Chemical Society, pp 34–49. https://doi.org/10.1021/bk-2002-0819.ch004

Song T, Lubben M, Brennecke J (2020) Solubility of argon, krypton and xenon in ionic liquids. Fluid Phase Equilibria 504:112334. https://doi.org/10.1016/j.fluid.2019.112334

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellose with ionic liquids. J Am Chem Soc 124:4974–4975. https://doi.org/10.1021/ja025790m

Szabó L, Milotskyi R, Sharma G, Takahashi K (2023) Cellulose processing in ionic liquids from a materials science perspective: turning a versatile biopolymer into the cornerstone of our sustainable future. Green Chem 25:5338–5389. https://doi.org/10.1039/d2gc04730f

Tariq M, Freire MG, Saramago B et al (2011) Surface tension of ionic liquids and ionic liquid solutions. Chem Soc Rev 41:829–868. https://doi.org/10.1039/c1cs15146k

Tegeler C, Span R, Wagner W (1999) A new equation of state for argon covering the fluid region for temperatures from the melting line to 700 K at pressures up to 1000 MPa. J Phys Chem Ref Data 28:779–850. https://doi.org/10.1063/1.556037

Verma C, Ebenso EE, Quraishi MA (2017) Ionic liquids as green and sustainable corrosion inhibitors for metals and alloys: an overview. J Mol Liq 233:403–414. https://doi.org/10.1016/j.molliq.2017.02.111

Yang F, Wang X, Tan H, Liu Z (2017) Improvement the viscosity of imidazolium-based ionic liquid using organic solvents for biofuels. J Mol Liq 248:626–633. https://doi.org/10.1016/j.molliq.2017.10.107

Zhang H, Wu J, Zhang J, He J (2005) 1-Allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277. https://doi.org/10.1021/ma0505676

Zhang J, Zhang H, Wu J et al (2010) NMR Spectroscopic studies of cellobiose solvation in EmimAc aimed to understand the dissolution mechanism of cellulose in ionic liquids. Phys Chem Chem Phys 12:1941–1947. https://doi.org/10.1039/B920446F

Zhang J, Wu J, Yu J et al (2017) Application of ionic liquids for dissolving cellulose and fabricating cellulose-based materials: state of the art and future trends. Mater Chem Front 1:1273–1290. https://doi.org/10.1039/c6qm00348f

Zhu S, Wu Y, Chen Q et al (2006) Dissolution of cellulose with ionic liquids and its application: a mini-review. Green Chem 8:325. https://doi.org/10.1039/b601395c

Acknowledgments

The provision of facilities and technical support by Aalto University at OtaNano Nanomicroscopy Center (Aalto-NMC) is gratefully acknowledged.

Funding

Open Access funding provided by Technical Research Centre of Finland. No funding was received to support this study.

Author information

Authors and Affiliations

Contributions

G.R. contributed to the conceptualization, lead investigation, visualization, writing-original draft, review & editing; R.K. led investigation, visualization, writing-original draft, review & editing; M.C. contributed to the methodology and experiments; A.M. and O.R. contributed to supervision, funding acquisition, resources, validation, discussion, reviewing & editing. All authors contributed to writing the manuscript, and all authors read and approved the final version of the manuscript for submission.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

T., R., Reyes, G., Cartes, M. et al. Ionic liquid interactions with cellulose and the effect of water. Cellulose 31, 6597–6610 (2024). https://doi.org/10.1007/s10570-024-06016-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-024-06016-2