Abstract

In response to escalating concerns about environmental pollution from conventional plastic packaging, there is a growing interest in ecological and sustainable materials for food packaging. Consequently, biopolymer-based electrospun materials, particularly polysaccharides such as chitosan (CH), starch, and cellulose, have emerged as promising alternatives to synthetic ones due to their remarkable barrier properties and mechanical strength. Moreover, following the trend of employing polysaccharides as ecological and sustainable solutions for packaging materials, natural colorants have also been recognized as safer alternatives to synthetic dyes, addressing concerns about potential adverse effects on human health and the environment. These natural colorants add color to food packaging and enhance food freshness, possibly extending shelf life and promoting consumers' perception of food quality and safety. Therefore, this review summarizes recent advancements in fabricating and characterizing electrospun materials based on polysaccharides and natural colorants for sustainable food packaging. It explores various electrospinning techniques and highlights the incorporation of natural colorants, including bacterial pigments, for active and intelligent packaging applications. Moreover, it emphasizes the increasing role of the biobased industry in developing sustainable packaging materials with bioactive coloration. Lastly, the review addresses challenges, opportunities, and future research directions.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Food packaging plays a vital role in safeguarding the quality and safety of food products, conferring protection from contamination, physical damage, and spoilage (Azaz Ahmad Azad et al. 2019). Over the past years, the emergence of active and intelligent food packaging has transformed the packaging industry, offering innovative approaches to extending the shelf-life of perishable foods and enhancing food safety through quality monitoring and crucial information regarding their freshness (Han et al. 2018; Cheng et al. 2021; Guo et al. 2024). Furthermore, besides its function in food preservation, food packaging can also play a substantial role in food waste reduction once proper packaging can prevent spoilage, preserve freshness, and extend the shelf-life of food products, which ultimately reduces food waste and promotes sustainability (Brennan et al. 2021).

Nonetheless, despite the aforementioned benefits, the negative impacts of traditional synthetic packaging materials on the environment have led to a growing interest in their replacement with biodegradable alternatives (Ncube et al. 2020). Regarding this, biopolymers, mainly polysaccharides, have emerged as promising substitutes due to their biodegradability, biocompatibility, renewable nature, and low environmental impact. Besides, polysaccharides, being compatible with food products, are an attractive option for packaging applications (Aleksanyan 2023; Wang et al. 2023a; Wu et al. 2024). They facilitate the development of edible and biodegradable films and coatings, which can prolong the shelf-life of perishable products by inhibiting the growth of pathogens and mitigating environmental factors such as oxygen and moisture, thus ensuring the preservation of food’s sensory qualities and preventing spoilage. Moreover, films and coatings based on polysaccharides have been incorporated with antimicrobial agents to increase food safety standards (Janik et al. 2024). Additionally, these materials have been applied to intelligent food packaging, offering functionalities like temperature monitoring and freshness indicators, ensuring consumer safety, and enhancing convenience (Wang et al. 2023b). Furthermore, polysaccharides have been employed in packaging, especially in developing biodegradable food containers and cups, aiding in reducing plastic waste and environmental impact (Perera et al. 2023).

Currently, amongst the various widely available fabrication techniques, electrospinning technology has emerged as a promising method for fabricating nanofibers and nanostructured materials with high surface area-to-volume ratios, mechanical strength, and porosity, among several other advantages for food packaging applications (Huang et al. 2022). For instance, the high surface area-to-volume ratio of the fibers can improve gas and moisture barrier properties due to increased contact area. In contrast, the small fiber diameter improves the mechanical strength of the electrospun materials through increased alignment and packing of the nanofibers (Min et al. 2022). Additionally, electrospinning enables incorporating food additives, namely natural colorants with bioactive properties like antioxidant and antimicrobial properties, into the fibers, providing added functionality to the packaging material (Min et al. 2022).

Therefore, incorporating natural colorants into food packaging improves their aesthetic appeal, impacting shelf visibility, consumer perception, and purchase decisions. It also aligns with the growing consumer preference for natural and healthy food products (Ekrem Parlak et al. 2024). These benefits emphasize the importance of exploring the potential applications of natural colorants in food packaging, which will be further investigated in this paper.

Hence, this review provides a concise overview of the role of food packaging in preserving food quality and safety, as well as reducing waste. Recognizing the urgent need for sustainable packaging materials, it focuses on the potential beneficial effects of combining polysaccharides and natural colorants through electrospinning. The aim is to fabricate environmentally friendly and sustainable food packaging materials with bioactive coloring for active and intelligent applications. Specifically, it will provide an overview of the latest developments in active and intelligent packaging produced through electrospinning, highlighting the impact of the polysaccharides and natural colorants on the functional properties of the nanofibrous packaging materials.

Food packaging

Foods can spoil or deteriorate for various reasons. Fruits and vegetables release ethylene while stored, causing them to ripen and spoil faster. Meat can oxidize, leading to changes in color and flavor during storage. Temperature-sensitive foods like sausages are particularly vulnerable to high temperatures, which increase the risk of spoilage. Honey and other sticky foods can also adhere to packaging, resulting in food loss (Zhang et al. 2023). Therefore, various food packaging materials have been designed to extend shelf life and monitor food quality. In this way, packaging can be divided into two main types: active food packaging and intelligent packaging (Jiang et al. 2023; Zhang et al. 2023).

Active food packaging aims to delay food deterioration, while intelligent packaging detects changes during transport and storage, providing information about food quality and freshness to consumers or manufacturers. A prominent trend in active packaging involves adding bioactive agents to packaging materials to maintain and enhance the quality and safety of packaged food (Jiang et al. 2023). Among these agents, antibacterial and antioxidant compounds have been widely studied and are effective in inhibiting various foodborne bacteria and preventing oxidation, which can affect food quality (Jiang et al. 2023; Zhang et al. 2023). For instance, protein oxidation reduces meat moisture content, while lipid oxidation leads to food deterioration, resulting in sensory changes and nutrient losses (Zhang et al. 2023). Incorporating antioxidants in food packaging can effectively eliminate free radical oxidation, while antibacterial agents help prevent the growth of harmful bacteria. Additionally, bioactive agents that absorb water vapor and oxygen produced during food storage, enhancing the packaging’s barrier properties, have also been applied to ensure food quality and safety (Jiang et al. 2023; Zhang et al. 2023).

In turn, intelligent packaging can detect changes in temperature, humidity, and oxygen levels, among other factors, responding to the surrounding environment. These measurements help identify food deterioration during storage, thereby facilitating the assessment of its quality. To achieve this goal, indicators providing real-time information on food safety and quality, as well as sensors for rapid food condition measurements, are incorporated (Jiang et al. 2023; Zhang et al. 2023). Common applications in intelligent food packaging include Leakage Indicators (LIs), Time–Temperature Indicators (TTIs), Freshness Indicators (FIs), and radio frequency identification tags (RFIDs) (Zhang et al. 2023).

Despite the distinct functions and capabilities of active and intelligent food packaging, their development is driven by common goals: efficiency and sustainability, demonstrating their potential for cooperative advancement. Therefore, there is a growing interest in using biodegradable and environmentally friendly natural resources, such as polysaccharides and natural bioactive compounds, which offer inherent biocompatibility, biodegradability, and renewable properties, instead of synthetic polymer packaging made from non-biodegradable petroleum-based resources. Moreover, modern fabrication techniques can efficiently blend bio-based constituents to produce novel food packaging materials with enhanced functionality and performance, as represented in Fig. 1.

Electrospinning techniques for innovative food packaging

In recent years, diverse methods have been employed to develop innovative packaging materials that can minimize food waste and enhance the quality and safety of food products. These methodologies encompass a wide range of approaches, including solvent casting, extrusion, electrospinning, layer-by-layer assembly, homogeneous emulsification, and dip-coating (Min et al. 2022; Zhang et al. 2023; Ekrem Parlak et al. 2024). However, electrospinning stands out among these options as a highly effective and promising technique for producing food packaging materials due to its high production efficiency, cost-effectiveness, and the exceptional properties of the electrospun nanofibers (Aman Mohammadi et al. 2020; Min et al. 2022; Zhang et al. 2023; Ekrem Parlak et al. 2024).

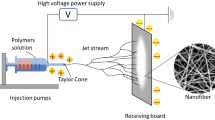

Electrospinning uses an electric field to create ultrafine polymer fibers. The process begins by applying a high voltage to a polymeric solution, which is then ejected through a spinneret or needle. Due to the electrostatic repulsive forces generated by the electric field, the solution stretches and forms a jet toward a grounded collector. During this flight path, the solvent evaporates, causing the polymer to solidify, resulting in dried nanofibers deposited on the collector (Abdulhussain et al. 2023). The obtained nanofibers possess unique properties, such as high surface area to volume ratio, high porosity, small pore size, flexibility, absorption capacity, and huge portable nature, making them ideal for food packaging applications (Aman Mohammadi et al. 2020; Min et al. 2022; Zhang et al. 2023; Ekrem Parlak et al. 2024). In addition, the electrospun nanofibers can act as a physical barrier to protect the food from contamination, exhibit high mechanical and thermal stability, as well as a crucial role in coordinating gaseous exchange by regulating oxygen and carbon dioxide levels. This control over barrier properties helps to prolong the freshness, particularly in perishable products like fruits and vegetables (Zhang et al. 2023). Additionally, electrospinning has demonstrated exceptional efficacy in incorporating food additives, such as antioxidant and antibacterial agents, as well as natural colorants, into nanofibers. Besides, the nanofibers produced via electrospinning can provide a controlled release of these compounds, further enhancing shelf life and ensuring food quality and safety. To achieve this, different electrospinning operational modes have been employed, as represented in Fig. 1, resulting in nanofibers with a wide range of structures and morphologies, like uniaxial, hollow, core–shell, and porous structures. These configurations encompass uniaxial, coaxial, and needleless electrospinning techniques (see the following topics for further details) (Min et al. 2022).

Furthermore, electrospinning does not require high temperatures during the process, making it suitable for improving the stability of the incorporated compounds. Besides, the solvents used to dissolve the polymers for the electrospinning process evaporate rapidly, reducing safety concerns associated with toxic solvents in the resulting nanofibers (Jiang et al. 2023).

Uniaxial electrospinning

Blending electrospinning

The uniaxial blending method involves pre-blending food additives with a wide range of food-grade, biodegradable, and biocompatible polymers intended to act as carrier materials. These blends are subsequently ejected using a single needle by applying an electric field. However, although blending electrospinning is more straightforward to operate, cost-effective, and versatile, its potential is limited due to its relatively low productivity. In addition, the uniaxial blending electrospinning can result in an uncontrolled distribution of the food additives within the nanofibers, leading to a burst release of the incorporated compounds (Ramos et al. 2021; Min et al. 2022). Nevertheless, food additives with similar polarity to the polymer material that can be completely dissolved in the polymer solution can promote a slower release (Min et al. 2022). Therefore, hydrophobic compounds dissolved in a hydrophobic polymer solution and hydrophilic compounds dissolved in a hydrophilic polymer solution can more readily achieve a controlled release profile (Min et al. 2022). In turn, sensitive compounds, like essential oils, proteins, and enzymes, when incorporated into the nanofibers through uniaxial blending electrospinning, are more prone to denaturation and degradation during the process, potentially resulting in reduced efficiency. Therefore, to avoid these issues, sensitive food additives have been encapsulated into nanostructures, like cyclodextrins, before their incorporation into the polymer blend solution (Min et al. 2022).

Emulsion electrospinning

Blending electrospinning enables nanofibers to exhibit a uniform composition across their structure. However, this method often led to a burst or premature release of the incorporated bioactive compounds used as food additives and pigments. To overcome this limitation, emulsion electrospinning has emerged as a viable uniaxial electrospinning technique capable of producing nanofibers with a core–shell structure through a single capillary (Min et al. 2022).

In this technique, droplets are dispersed within a food-grade polymer or polymer blend solution dissolved in a solvent containing an emulsifying agent through stirring or homogenization. This process is essential to create a uniform and homogeneous food-grade polymer-based emulsion, where one constituent forms the core of the nanofibers while the other makes up the outer layer or shell (Min et al. 2022). This well-defined structure imparts different properties and enables diverse applications, including the controlled release of food-bioactive compounds or specific functionalities in materials (Min et al. 2022; Wang and Su 2023).

During the emulsion electrospinning, the solvent surrounding the droplet’s surface evaporates rapidly compared to the solvent within the central region, promoting the migration of the emulsion droplets from the surface toward the center. Under the influence of a high-voltage electric field, these droplets are stretched into an elliptical shape, resulting in the deposition of core–shell nanofibers onto the collector (Min et al. 2022). Consequently, emulsion electrospinning is an effective method to safeguard unstable food-bioactive molecules within the core of the nanofibers, allowing controlled release via gradual diffusion and degradation of the shell polymer. Nevertheless, emulsion electrospinning presents limitations in production of core–shell nanofibers for food packaging applications. Specifically, difficulties related to limited efficiency and the intricate processability of natural polymers stand out as predominant factors among these limitations (Min et al. 2022). Moreover, emulsion electrospinning’s efficiency depends on the emulsions’ stability and rheological behavior. Additionally, the type and concentration of emulsifying agents used during the emulsion preparation also play a crucial role in producing uniform and homogeneous food-grade-polymer-based emulsions (Min et al. 2022).

Coaxial electrospinning

Coaxial electrospinning, a modification of the uniaxial procedure, facilitates the creation of nanofibers with a core–shell structure (Akshay Kumar et al. 2021; Angel et al. 2022; Min et al. 2022). This technique employs two needles and multiple food-grade polymer solutions, enabling the encapsulation of traditionally non-spinnable food-bioactive compounds within a protective outer shell during the electrospinning process. This is achieved by simultaneously ejecting the food-grade polymer solution and the food-bioactive compound from distinct needles under a high-voltage electric field (Angel et al. 2022; Min et al. 2022). Moreover, integrating food-bioactive compounds into the core portion of the core–shell structure provides enhanced protection against degradation induced by external environmental factors. This safeguarding preserves the compounds and imparts an additional advantage, as the structure is a carrier for the controlled and sustained release of the encapsulated food compounds (Angel et al. 2022; Min et al. 2022).

Nevertheless, the efficiency of coaxial electrospinning in protecting these compounds and enabling controlled release is challenging, especially due to the complexity of the equipment, the selection of appropriate food-grade polymers, and the uncontrollability of parameters, even though coaxial configuration allows greater control of the flow system (Min et al. 2022).

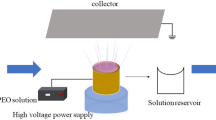

Needleless electrospinning

The needleless electrospinning technique employs spinnerets with different geometries, such as a disk, cylinder, or ball. These spinnerets are immersed directly in a container filled with the food-grade polymeric solution to overcome limitations associated with traditional electrospinning, specifically addressing needle clogging issues and enhancing nanofiber production (Akshay Kumar et al. 2021; Angel et al. 2022; Min et al. 2022).

Moreover, a growing interest in needleless electrospinning has been growing, leading Ellmarco s.r.o. (Liberec, Czech Republic) to introduce the first commercially available needleless electrospinning setup under the brand name Nanospider. The Nanospider system uses a rotating cylinder partially submerged in a container with the food-grade polymeric solution (Gouveia and Mouro 2023). This setup enables the simultaneous production of multiple polymeric jets from the top of the cylinder by applying an electrical field, facilitating the fabrication of nanofibers (Angel et al. 2022; Min et al. 2022).

Nonetheless, needleless electrospinning presents challenges due to the absence of a needle, resulting in variations in the electric field caused by instabilities like jet whipping, splitting, and bending. Despite this, the technique typically employs high voltages to create the Taylor cones, resulting in the ejection of food-grade polymer for fiber formation with unique morphologies and diameters, which is advantageous for various packaging applications (Angel et al. 2022; Min et al. 2022). Additionally, needleless electrospinning allows for more straightforward scale-up, reducing manufacturing costs and increasing efficiency. Furthermore, if food-bioactive compounds are blended into the polymeric solution, needleless electrospinning may distribute them within the nanofibers. Therefore, this technique shows promise in creating food packaging materials that improve food product quality and provide sustainability benefits (Angel et al. 2022; Min et al. 2022).

Polysaccharides in food packaging

Building upon the electrospinning techniques previously outlined, the wide range of polymers that can be applied in the electrospinning presents numerous opportunities for producing innovative materials for food packaging. In this context, biopolymers are commonly used as principal constituents in food packaging and are generally categorized into three distinct groups based on their source (Zhang et al. 2023; Ekrem Parlak et al. 2024). These encompass natural or biomass substances, including polysaccharides and proteins, biopolymers synthesized through chemical processes utilizing bio-derived and petrochemical monomers, and those biosynthesized by microorganisms, like exopolysaccharides (Ekrem Parlak et al. 2024). Biopolymers, particularly those derived from natural sources like polysaccharides and proteins, offer effective barrier properties against gases, moisture, odors, and bioactivity (Zhang et al. 2023; Ekrem Parlak et al. 2024).

Therefore, polysaccharides assume a significant role in food packaging production through electrospinning, which is distinguished by their unique characteristics, such as high stability, renewability, biocompatibility, biodegradability, and non-toxicity. These properties make them crucial for creating innovative and sustainable packaging materials, improving food safety compared to traditional plastic packaging (Akshay Kumar et al. 2021; Angel et al. 2022; Perera et al. 2023; Wang et al. 2023b; Ekrem Parlak et al. 2024).

The polysaccharides used in electrospinning are derived from various sources, including animals (like chitosan (CH)), plants (such as cellulose and starch), microbes (including bacterial cellulose (BC), kefiran, dextran, and pullulan), and algae (like alginate), (see Fig. 2) (Akshay Kumar et al. 2021; Angel et al. 2022; Díaz-Montes 2022; Jabeen and Atif 2023; Wang et al. 2023b; Nath et al. 2023; Ekrem Parlak et al. 2024). In addition, these polysaccharides display a range of desirable bioactive properties for food packaging, including antioxidant and antimicrobial capabilities (Angel et al. 2022; Wang et al. 2023b; Ekrem Parlak et al. 2024).

Chitosan (CH) is a natural polymer derived from fungi cell walls and the shells of crustaceans like crabs, insects, and shrimps. It is obtained through the variable deacetylation of chitin. Its amino groups can be protonated in acidic environments, particularly in solutions of acetic acid, hydrochloric, and formic acids (Perera et al. 2023; Wang et al. 2023b; Zhang et al. 2023; Nath et al. 2024). Thus, CH's dissolution ability in acidic solvents, its excellent film-forming ability, and its inherent antibacterial and antifungal properties contribute to its wide application in food packaging (Angel et al. 2022; Perera et al. 2023; Wang et al. 2023b; Zhang et al. 2023). However, CH has a low surface area and poor mechanical properties despite the high number of amino and hydroxyl groups present in CH, which can serve as coordination and reaction sites during the electrospinning process. Due to this limitation, CH can be combined with other biopolymers to enhance its properties, making it more suitable for food packaging applications (Perera et al. 2023; Wang et al. 2023b; Zhang et al. 2023).

In turn, alginate is derived from seaweed or exopolysaccharides found in specific bacterial strains, including Pseudomonas aeruginosa (Akshay Kumar et al. 2021; Angel et al. 2022; Perera et al. 2023; Nath et al. 2023, 2024). The molecular architecture of alginate is characterized by repetitive units of α-(1→4)-L-guluronic acid (GG) and β-(1→4)-D-mannuronic acid (MM). These units’ arrangement significantly influences the biological and physical characteristics of alginate in an aqueous environment. Additionally, alginate is an anionic polysaccharide due to the carboxylate groups present in the GG and MM units (Akshay Kumar et al. 2021; Angel et al. 2022; Perera et al. 2023). Thus, the negative charge confers its unique properties, particularly the ability to form gels in the presence of calcium ions, imparting it valuable for applications in the food industry. However, electrospinning naturally charged polysaccharides, such as alginate, has proven to be challenging, requiring the use of a copolymer due to the complex entanglement of molecular chains in solution and the diverse rheological properties that such polysaccharides exhibit (Akshay Kumar et al. 2021; Angel et al. 2022; Perera et al. 2023).

On the other hand, starch is biosynthesized as a storage material in higher plants and has been extensively employed in diverse food applications due to its edible and biodegradable nature. Moreover, its versatility and environmentally friendly characteristics make it a preferred choice in various packaging materials (Zhang et al. 2023; Nath et al. 2023; Ekrem Parlak et al. 2024). Structurally, starch is a complex polysaccharide comprising two main components: amylose and amylopectin. The ratio of amylopectin to amylose varies depending on the botanical source of the starch, and this ratio significantly influences its properties (Akshay Kumar et al. 2021; Perera et al. 2023). Consequently, techniques like cross-linking, grafting, and self-assembly can be employed to optimize the functionality of electrospun starch nanofibers, specifically designed for applications in food packaging (Perera et al. 2023; Zhang et al. 2023). These modifications allow starch nanofibers to be tailored to different food products and incorporate them into rigid and flexible packaging (Ekrem Parlak et al. 2024). Furthermore, these modifications confer several valuable functionalities to the nanofibers, such as antibacterial properties, antioxidants, thermal resistance, ultraviolet (UV) light resistance, and pH responsiveness (Perera et al. 2023).

Cellulose is a polysaccharide widely distributed in nature and predominantly found in plants, particularly in the cell wall. It stands out as a linear polymer composed of repeating D-glucose units. Its distinct structure is characterized by high crystallinity and exceptional thermal and chemical stability (Angel et al. 2022; Perera et al. 2023; Wang et al. 2023b; Zhang et al. 2023; Nath et al. 2023; Ekrem Parlak et al. 2024). Moreover, cellulose’s hydrophilic and biocompatible nature makes it a promising material for food packaging, offering significant potential for innovative and sustainable packaging solutions (Angel et al. 2022; Wang et al. 2023b; Sharma et al. 2024). Nevertheless, cellulose is not soluble in water or many organic solvents, making its use challenging in specific production processes, namely in electrospinning. In this way, to overcome these limitations, researchers have been exploring the use of ionic solvents in electrospinning to enhance cellulose dissolution (Angel et al. 2022; Perera et al. 2023).

Additionally, diverse cellulose derivatives, including esters like cellulose acetate and ethers such as methylcellulose, carboxymethyl cellulose, hydroxypropyl methylcellulose, and hydroxypropyl cellulose, exhibit notable solubility in aqueous and organic solvents and superior film-forming capability (Wang et al. 2023b; Zhang et al. 2023; Sharma et al. 2024). These unique attributes endow these derivatives with valuable potential for applications in advanced food packaging.

In addition to these derivatives, nanocellulose has been recognized as a promising material of notable relevance due to its renewability, biodegradability, biocompatibility, high mechanical strength, high surface area, and thermal stability (Wang et al. 2023b).

Based on factors such as size, shape, processing methods, and origin, nanocellulose can be categorized into three main types. These types include nanocrystals of cellulose (CNCs) and nanofibrils of cellulose (CNFs), obtained from plants, as well as BC synthesized by bacterial strains. Additionally, each type exhibits unique structural characteristics and properties, specifically tailored for diverse applications (Wang et al. 2023b; Nath et al. 2023, 2024; Sharma et al. 2024).

BC, a pure cellulose source, is produced by specific bacteria, such as Komagataeibacter xylinus. It is known for its high degree of purity, extensive polymerization, high water-holding capability, and high strength (Syed Abdullah et al. 2022; Amorim et al. 2023; Nath et al. 2023; Sharma et al. 2024). These bacteria form thin cellulose fibrils in the nanometer range, resulting in a film at the gas–liquid interface. To promote the production of BC, this process requires a liquid medium composed of carbon, nitrogen, and other nutrient sources (Wang et al. 2023b). Nonetheless, alternative feedstock from agro-industrial wastes can replace high-cost synthetic carbon and nitrogen sources and reduce the overall BC production costs (Amorim et al. 2023; Nath et al. 2024). In addition, BC can be transformed into BC nanocrystals (BCNCs) through acid hydrolysis and into BC nanofibrils (BCNFs) through mechanical fibrillation. Therefore, BC and its derivatives provide a promising alternative for producing biodegradable packaging. In fact, BC can be used as a reinforcing agent in the production of edible films and can also be amalgamated with diverse materials to fabricate composite materials characterized by superior strength, durability, and flexibility (Wang et al. 2023b). Furthermore, functionalizing the BC with bioactive agents and sensors for monitoring temperature, pH, freshness, and other relevant indicators presents an avenue for active and intelligent food packaging (Amorim et al. 2022c, 2023).

Therefore, polysaccharides are widely recognized for their numerous advantages in electrospun food packaging. Their biocompatibility ensures safety for direct contact with food, while their renewable and biodegradable nature makes them eco-friendly alternatives to traditional synthetic packaging materials. Additionally, their versatility allows packaging development with tailored properties and functions to meet specific needs. As a result of these beneficial characteristics, polysaccharides have been widely reported as critical components in electrospun food packaging materials (Table 1). Moreover, although several polysaccharides naturally display beneficial properties like antioxidants and antimicrobial effects, different bioactive agents have been incorporated to enhance their effectiveness in food packaging applications.

In a recent study, Duan et al. (2023b) explored the potential use of nisin, a bacteriocin peptide, for antibacterial active food packaging (Duan et al. 2023b). However, due to its susceptibility to degradation by the external environment, the authors utilized the coaxial electrospinning technique to fabricate core–shell nanofibers. The core layer consisted of pullulan, while the shell layer comprised carboxymethyl chitosan (CMCS)/polyethylene oxide (PEO), which protected the CMCS-nisin nano gels loaded into the core layer (Duan et al. 2023b). The impact of nisin concentration on the nanofibers' properties was also investigated, and the authors observed that increasing the nisin concentration up to 8 mg/mL led to enhanced mechanical strength, which could be attributed to the hydrogen bonds and electrostatic interactions formed by nisin with other molecules, tightening the fibrous entanglement (Duan et al. 2023b). Likewise, the nanofibers loaded with CMCS-nisin nano gels exhibited enhanced thermal stability due to their dense structure. The core–shell nanofibers were applied to bass fish preservation. Due to nisin antibacterial properties, the shelf-life of bass fish extended from 9 to 15 days with a nisin concentration of 8 mg/mL in the CMCS-nisin nano gel (Duan et al. 2023b). Similarly, Tajfiroozeh et al. (2023) developed core–shell nanofibers loaded with nisin for active food packaging applications. However, in this case, the authors also included another bioactive compound, gallic acid, to endow the nanofibrous mats with additional antioxidant properties (Tajfiroozeh et al. 2023). The core and shell of the stretchable nanofibers were fabricated with CH and PEO, but the core was loaded with gallic acid, while the shell was loaded with nisin. The study found that the core–shell nanofibrous membranes exhibited sustained release of gallic acid, 12–20 days, and nisin, 30–60 days, due to their interconnected porous structure with large surface area (Tajfiroozeh et al. 2023). Additionally, the electrospun CH/PEO mats showed almost no antioxidant activity, but the addition of gallic acid resulted in a substantial boost in the scavenging capacity of the nanofibrous mats. On the other hand, the incorporation of nisin resulted in increased antibacterial activity against various microbial strains (Tajfiroozeh et al. 2023). Zhu et al. (2023) also explored the coaxial electrospinning technique to incorporate thymol into PEO/CH to form core–shell nanofibers. The crosslinker-genipin, a chemical agent enabling the bonding of polymer chains, was also encapsulated into the core layer for in-situ crosslinking with the CH during the electrospinning process. These crosslinked core–shell nanofibers exhibited improved mechanical properties, thermal stability, and sustained release profiles, as well as antioxidant activity, besides effective growth inhibition of common food spoilage bacteria (Zhu et al. 2023).

Dede et al. (2022) explored the emulsion electrospinning technique to prepare edible active food packaging materials encapsulating basil oil, which contains several allyl-phenol derivatives, one of which, estragole, has antibacterial activity against a wide variety of bacteria, yeast, and mold (Dede et al. 2022). Therefore, the authors dispersed different basil oil concentrations in the continuous phase, prepared with zein and alginate. Soy lecithin was also added to the continuous phase to reduce fiber hydrophobicity. The diameter of nanofibers increased significantly with the increasing amount of oil, and the nanofibrous samples with the highest oil concentration tested by the authors (20%) exhibited suitable antimicrobial properties and high tensile strength compared to nanofibers with lower basil oil concentrations (Dede et al. 2022). Moreover, due to the edible nature of the nanofibrous mats and the healing effects of basil oil for acute gastric ulcer disease, the authors also evaluated the in vitro release of basil oil in a gastric medium. They revealed that the release rate depends on both diffusion and swelling (e.g., the ability to absorb and retain fluids leading to expansion of the nanofibrous mats), and the diffusion is controlled and proportional to oil concentration (Dede et al. 2022). Another essential oil, ginger essential oil, was also recently explored by Pires et al. (2024) due to its remarkable antibacterial activity. The essential oil was encapsulated into starch, obtained from avocado seeds, by blending electrospinning, and ultrafine fibers were produced. The essential oil encapsulation promoted its gradual release, which can be advantageous for food packaging applications with prolonged antimicrobial activity (Pires et al. 2024).

Electrospun polysaccharides in food packaging: patents

Polysaccharide applications are widespread in diverse fields, such as medicine, cosmetics, the paper industry, and even battery technology, which is also supported by the increasing number of patents granted for such applications (Mobarak et al. 2021). Similarly, using the international Espacenet (EPO) database, it is possible to find several patents involving electrospun materials based on polysaccharides for food packaging applications due to the market interest and potential of such novel material. For instance, patent number CN112391697A describes the preparation method of wintergreen essential oil/Lycium barbarum polysaccharide antibacterial nanofibers (Haiying and Hong 2021a). The patent addresses the limitations of essential oils, such as volatility and instability, by embedding wintergreen essential oil into β-lactoglobulin nanoparticles. These nanoparticles are then incorporated into a spinning solution containing Lycium barbarum, a water-soluble polysaccharide with synergistic antibacterial properties, which is electrospun to produce uniform antibacterial nanofibers (Haiying and Hong 2021a). Similarly, patent CN112391696A also addresses essential oils limitations with nanoparticles of dill essential oil with rice bran protein and subsequently using Pleurotus eryngii polysaccharide as a substrate for electrospinning, thus yielding antibacterial nanofibers (Haiying and Hong 2021b). On the other hand, patent CN107190422A introduces a novel antibacterial packaging material of citrus essential oil in combination with CH (Wangkai et al. 2017). The invention involves forming a citrus essential oil/cyclodextrin inclusion compound followed by preparing a CH spinning solution and mixing both for electrospinning. The nanofibrous material obtained can inhibit microbial growth in food products (Wangkai et al. 2017).

Meanwhile, the invention by CN113755968A unveils the preparation of polysaccharide nanofibrous membrane by synergizing plant essential oils due to their broad-spectrum antibacterial and antioxidant properties, alongside the inhibitory effects of organic acids on bacterial and fungal growth and polysaccharides to develop antibacterial and antioxidant packaging materials without altering food attributes, namely food flavors. The invention focuses on optimizing ingredient ratio to enhance packaged foods’ preservation, freshness, and shelf life (Yuan et al. 2021). On the other hand, CN114717752A proposes a method for preparing a nanofibrous membrane for intelligent food packaging applications capable of detecting fruit freshness through the nanofibrous materials' light transmittance (Jiazi et al. 2022). This invention involves polymers and natural polysaccharides with specific refractive indexes (such as starch, cellulose and its derivatives, chitin, sodium alginate, and ammonium alginate) to create a core–shell structure nanofibrous membrane through coaxial electrospinning. The resulting membrane, with optimal fiber diameter and thickness, provides a visible indication of fruit freshness, thus offering real-time monitoring by observing the light transmittance of the nanofibers (Jiazi et al. 2022). Compared to existing methods, this innovation promises cost-effectiveness and improved responsiveness.

Overall, using of electrospinning technology to produce novel polysaccharide-based materials for food packaging applications offers sustainable, efficient, and innovative solutions to enhance food preservation and safety while minimizing the environmental impact, which explains the increasing number of patents and research studies in the field.

Natural colorants

Highlighting the inherent properties of the polysaccharides for food packaging, researchers have explored their potential for encapsulating several bioactive compounds, such as proteins, essential oils, and enzymes, using electrospinning techniques, as previously described (Min et al. 2022; Ekrem Parlak et al. 2024). However, natural colorants and other active substances have also been incorporated into the electrospun nanofibers to improve packaging functionality and visual appearance. This enhancement is crucial as it increases visibility on the shelf, shapes consumer perception, and ultimately influences their purchase decisions (Min et al. 2022; Ekrem Parlak et al. 2024).

Among the diverse natural colorants, pigments sourced from plants, microalgae, and microbial origins stand out due to their safety and recognized benefits compared to synthetic dyes, which may contain potentially harmful chemicals and lack the nutritional advantages offered by natural sources (Ekrem Parlak et al. 2024).

Plant pigments such as anthocyanins, betalains, carotenoids, and chlorophylls, are extracted from various plant parts, including vegetables, fruits, leaves, and flowers. They exhibit vibrant colors and diverse bioactive properties (Martins et al. 2023b; Ekrem Parlak et al. 2024).

Anthocyanins, water-soluble flavonoid pigments, contribute to the vibrant red, orange, purple, and blue colors in fruits, vegetables, and flowers (Martins et al. 2023b; Ekrem Parlak et al. 2024). Well-known anthocyanin types like cyanidin, delphinidin, and malvidin are commonly used in food applications due to their unique hues. Beyond their role as colorants, anthocyanins also exhibit significant antimicrobial and antioxidant properties (Martins et al. 2023b; Ekrem Parlak et al. 2024). Moreover, these pigments are sensitive to environmental factors such as light exposure, temperature variations, and pH levels, which makes them ideal for both active and intelligent packaging applications. Particularly, anthocyanins remain stable under acidic conditions, resulting in red hues, while in basic environments, they adopt a blue coloration (Ekrem Parlak et al. 2024).

Betalains, also water-soluble pigments, consist of betacyanins (reddish-purple pigments) and betaxanthins (yellowish-orange pigments). Like anthocyanins, betalains pigments can be used in active and intelligent packaging (Martins et al. 2023b; Ekrem Parlak et al. 2024). In fact, the betalains generally exhibit stability in acidic and neutral environments. However, in alkaline conditions (pH 8–9), their color changes to orange, and, at pH 10–12, they turn yellow due to the degradation of betacyanin. Additionally, in strong alkaline solutions, betalains can degrade further, resulting in colorless compounds and yellow betaxanthins (Ekrem Parlak et al. 2024).

In turn, carotenoids are natural lipophilic pigments found in foods and come in a wide range of colors, from yellow to red, including orange. Common carotenoids used for food coloring include α-carotene, β-carotene, lycopene, and lutein (Martins et al. 2023b). Moreover, chlorophylls, particularly chlorophyll a and b, are lipid-soluble pigments in plants, cyanobacteria, and mosses (Martins et al. 2023b; Ekrem Parlak et al. 2024). Like the bioactive pigments mentioned above, chlorophylls display biological properties, namely antioxidant activity and a high nutritional value (Martins et al. 2023b; Ekrem Parlak et al. 2024). Furthermore, chlorophylls can act as a temporal temperature indicator in the range of 50 °C to 70 °C in order to effectively monitor the quality of fresh foods. Chlorophyll can also change color at different pH levels (Ekrem Parlak et al. 2024).

However, although these natural colorants are predominantly found in plants, they may also be present in microalgae and used in advanced food packaging (Martins et al. 2023a, b). Additionally, curcumin, a widely recognized natural colorant classified as a polyphenolic compound derived from plants, is commonly used in various food products. It presents diverse benefits, such as bioactive properties and changing color based on pH variations (Roy et al. 2022; Ekrem Parlak et al. 2024). Regarding that, at pH levels below 8, curcumin exhibits a yellow hue, while at pH 8, it appears pale yellow. Curcumin displays a reddish-brown hue within the pH range of 9 to 11 (Ekrem Parlak et al. 2024).

Nevertheless, while plant-derived natural colorants offer numerous benefits, including the ability to monitor food freshness in pH-sensitive packaging materials and biological properties, they also present several limitations related to seasonality, availability, stability, and the complexity of the extraction process (Amorim et al. 2022a). In this sense, natural pigments from microorganisms, particularly bacteria, provide promising alternatives. Bacteria can quickly produce significant amounts of pigments, often at lower costs, and can be easily genetically modified. In addition, the bacterial pigments also exhibit various beneficial properties, including UV protection, antimicrobial activity, antioxidant effects, and potential health benefits (Amorim et al. 2022a, c). Among them, pigments sourced from bacteria, such as prodigiosin, violacein, and flexirubin-type pigments that impart red, purple, and yellow colors, have captured researchers’ interest. Moreover, given their sensitivity to pH changes, these pigments have been explored for potential applications in active food packaging and used as pH indicators for food monitoring (Amorim et al. 2022a, c).

Prodigiosin, a secondary metabolite commonly produced by various species, including Serratia sp., exhibits useful bioactive properties such as antimicrobial activity against several pathogenic bacteria, including pathogens responsible for foodborne diseases (Amorim et al. 2022d). Moreover, prodigiosin has shown remarkable color changes. It shifted from bright pink at pH 9 to vivid coral red at pH 10, orange at pH 11, and yellow from pH 12 to 14 (Amorim et al. 2022c). In turn, flexirubin-type pigments are yellowish-orange pigments produced by various genera, including Flexibacter, Cytophaga, Sporocytophaga, and Chryseobacterium (Amorim et al. 2022b). These pigments are recognized for their antioxidant and antimicrobial properties, as well as their appealing color in packaging that engages consumers' attention. Besides, the color change exhibited by the flexirubin-type pigment in a buffer solution with pH 12, from pale yellow to pale orange, can indicate freshness or spoilage (Amorim et al. 2022c). Further, the violacein, a purple pigment produced by Chromobacterium violaceum, exhibits a range of bioactive functions, including antibacterial, antiviral, antifungal, and antioxidant effects. pH changes also influence the color of violacein. It shifts slightly to bluish at pH 12 and greenish at pH 13 and 14 (Amorim et al. 2022c).

Therefore, various natural colorants with bioactive properties have been successfully incorporated into electrospun materials for food packaging applications, as summarized in Table 2, which outlines several recent studies.

Natural colorants in polysaccharide-based electrospun food packaging materials

In recent research endeavors, several studies have investigated using different electrospinning techniques to develop innovative food packaging solutions. These efforts have focused on utilizing the functional properties of polysaccharides and natural colorants with bioactive properties (Table 2). For instance, Amjadi et al. (2020b) reported the fabrication of zein/sodium alginate nanofibers incorporated with titanium dioxide nanoparticles (TiO2NPs) and betanin, a plant pigment (Amjadi et al. 2020b). This novel active packaging material was designed to possess antibacterial and antioxidant properties. The authors identified a synergistic effect between betanin and TiO2NPs, where betanin acted as a sensitizer, stimulating the production of reactive oxygen species (ROS) by TiO2NPs, thereby increasing the antibacterial activity of the nanofibrous material (Amjadi et al. 2020b). The electrospun fibers also demonstrated high antioxidant activity, attributed to the high levels of phenolic and cyclic amine groups in betanin, which act as electron donors, along with the presence of α-zein and polysaccharide sodium alginate (Amjadi et al. 2020b).

Shavisi & Shahbazi (2022) designed nanofibrous mats with antioxidant and pH-responsive color change properties to monitor the freshness of raw chicken fillets during refrigerated storage (Shavisi and Shahbazi 2022). They explored a combination of CH and gum arabic to produce the nanofibers loaded with Rosa damascena extract, containing anthocyanins. The plant extract incorporation into the nanofibrous mats was found to reduce the tensile strength of the materials and result in larger nanofiber diameters, possibly due to variations in the spinning solution properties such as conductivity, surface tension, and viscosity (Shavisi and Shahbazi 2022). Nonetheless, an improvement in nanofibers' water barrier and thermal stability was also reported after the incorporation of Rosa damascena extract, which could be partially attributed to the formation of hydrogen bonding interactions between the plant extract and polymer matrix (Shavisi and Shahbazi 2022). Moreover, the nanofibrous mats showed enhanced antioxidant activity due to the presence of anthocyanins. Additionally, a noticeable color change occurred when pH and volatile nitrogen components reached the maximum acceptable limits in chicken fillets (Shavisi and Shahbazi 2022). As aforementioned, the natural colorants anthocyanins, besides antioxidant and antimicrobial properties, exhibit distinct color changes by modifying their chemical structure by protonating or deprotonating depending on the medium in contact and depending on their source (Tang et al. 2023).

Taking advantage of anthocyanins’ excellent pH sensitivity and color response, Jiang et al. (2024) and Lv et al. (2024) fabricated intelligent polysaccharide-based food packaging materials, not only able to monitor the freshness of high protein foods (pork and shrimp) but the materials also enabled the distinction of foods freshness states (fresh, sub-fresh, and spoiled) during storage, were “fresh state” indicates the good quality of food products, “sub-fresh state” indicates near spoilage and should be consumed as soon as possible, and “spoiled state” refers to inedible food products due to contamination/deterioration (Lv et al. 2024; Jiang et al. 2024).

Due to their high protein content, meat products are highly perishable. As a result, numerous studies have explored innovative solutions for food packaging applications that can address this issue. Likewise, Yildiz et al. (2021) also explored the development of nanofibrous mats responsive to pH and volatile nitrogen components to monitor the freshness of refrigerated chicken (Yildiz et al. 2021). In their approach, the nanofibrous mats were fabricated with a blend of CH with biodegradable PEO, which was selected as a co-spinning agent to facilitate the spinnability of CH (Yildiz et al. 2021). Curcumin was loaded into the nanofibrous mats, and the authors tested different polymer ratios, verifying that increasing the CH amount in nanofibers decreased the diameter of the fibers. The nanofibrous mats, with the smaller fiber size, were used to evaluate the material’s response to chicken breast spoilage. Upon spoilage, a distinct color change was observed, indicating the suitability of the nanofibrous mats for chicken products’ freshness monitoring. Moreover, in this study, the antioxidant properties of the nanofibrous mats were evaluated, but only to indirectly determine the active amount of curcumin embedded into the nanofibers (Yildiz et al. 2021).

Contrary to the single-layer nanofibrous mats mentioned in the previous examples, Guo et al. (2020) used the conventional electrospinning setup to produce a double-layer structure, with each layer designed to have different functionalities (Guo et al. 2020). The double-layer fiber mats displayed a colorimetric layer made of pullulan polysaccharide and a purple sweet potato extract rich in anthocyanins. The color change of the electrospun double-layer material was reversible, and the colorimetric response was highly sensitive, attributed to the material’s porosity plus to pullulan hydrophilicity that facilitated the color reaction by providing water molecules and contact sites (Guo et al. 2020). The second layer was successively electrospun on the surface of the colorimetric layer and was composed of zein, glycerol, and carvacrol. This layer was labeled the antibacterial layer due to the pathogenic bacterial inhibition observed after carvacrol release from the nanofibrous mats. Both layers contributed to the materials’ antioxidant activity due to anthocyanins in the purple sweet potato extract and carvacrol (Guo et al. 2020). Moreover, the double-layer material effectively extended the shelf-life of pork by 24 h at 25 °C, owing to its antibacterial and antioxidant properties. Therefore, the reported materials could serve as an active-intelligent food packaging system, extending the shelf-life while still acting as a freshness indicator (Guo et al. 2020). More recently, Khaledian et al. (2024) also developed and characterized a double-layer nanofibrous material for active and intelligent food packaging applications, with color-changeable potato starch-turnip peel extract nanofibrous layer due to the anthocyanins from the turnip peel extract and an antibacterial guar gum-cinnamaldehyde nanofibrous layer, due to cinnamaldehyde strong antimicrobial activity against pathogenic and spoilage-related microorganisms. The double-layer nanofibrous materials were successfully applied in freshness monitoring of lamb meat, exhibiting distinct color change from white (fresh lamb meat) to purplish red (spoiled lamb meat), and in enhancing lamb meat shelf-life during cooled storage conditions due to the nanofibrous materials’ antioxidant and antibacterial properties (Khaledian et al. 2024).

As previously mentioned, needleless electrospinning offers a significant advantage over traditional needle-based methods by providing a more efficient and scalable process. Amorim et al. (2022b) and Amorim et al. (2022d) reported the production of double-layer structures for active food packaging applications produced by needleless electrospinning (Amorim et al. 2022b, d). In one of their works, double-layer materials were produced with an inner layer of nanofibers made from electrospun polyvinyl alcohol (PVA) and CH and an outer layer of oxidized BC to provide mechanical support. Bacterial pigment prodigiosin incorporation into either the inner nanofibrous layer or the outer BC layer resulted in two different materials, as shown in Fig. 3 (Amorim et al. 2022d). The pigment incorporation into the inner nanofibrous layer aimed to minimize food deterioration by inhibiting foodborne pathogens, whereas pigment incorporation in the outer oxidized BC layer aimed to prevent external contamination and reduce the risk of cross-contamination during food processing. Both double-layer materials reported could inhibit the growth of pathogenic bacteria, owing to prodigiosin and CH antibacterial properties. The material's physical and mechanical properties remained unaffected after incorporating the bacterial pigment (Amorim et al. 2022d).

Schematic representation of the production strategies used in double-layer composites preparation by Amorim et al. (a) 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO)-activated bacterial cellulose (BC) was used as a substrate for polyvinyl alcohol (PVA)-chitosan (CH)_prodigiosin (PG) nanofibers deposition, producing a BC/PVA-CH_PG composite material. (b) TEMPO-activated BC was functionalized with PG and used as a substrate for the coating layer, made of PVA-CH nanofibers, producing a double-layer BC_PG/PVA-CH material (Amorim et al. 2022d)

In another work, Amorim et al. (2022b) reported a double-layer structure for potential active food packaging applications due to the antioxidant potential of the bacterial flexirubin-type pigment and kefiran exopolysaccharide (Amorim et al. 2022b). The first layer was prepared by blending kefiran with PVA, while the outer layer was assembled using a biodegradable aliphatic polyester, polycaprolactone (PCL). Flexirubin pigment incorporation, in both layers, during electrospinning did not compromise the material's mechanical properties or high porosity (Amorim et al. 2022b). Furthermore, the double-layer material exhibited favorable antioxidant properties due to its ability to scavenge 2,2′-Azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt radical cation (ABTS+) and reduce enzymatic browning in apple slices. These materials displayed desirable properties for applications in active food packaging, owing to the antioxidant properties and the color provided by the bacterial pigment. In addition, the needleless electrospinning technology increases the potential to scale up the production of double-layer materials without further optimizations (Amorim et al. 2022b).

Another active food packaging application based on natural colorants and biopolymer nanofibrous mats was investigated by Luo et al. (2021) (Luo et al. 2021). The researchers examined a range of zein concentrations to produce dextran/zein nanofibrous mats loaded with curcumin. Zein addition at low concentrations led to poor miscibility between dextran and zein. However, increasing zein concentration allowed for the formation of hydrogen bonds between the biopolymers, resulting in a homogeneous dispersion of dextran and zein and achieving the desired functional and mechanical properties (Luo et al. 2021). The curcumin-loaded dextran/zein electrospun fibers displayed efficient antioxidant properties and a controlled release behavior of curcumin that is well-suited for active food packaging applications (Luo et al. 2021).

Using a blend of polymers is an efficient approach for producing materials with desirable properties, allowing the combination of different polymer characteristics to achieve a specific set of properties that cannot be obtained otherwise. Similarly, combining two natural colorants with active properties and pH sensitivity for active-intelligent packaging provides the advantage of enhanced bioactivity and visual indication of changes in pH levels, making it a more effective and reliable solution for ensuring product safety and quality. Thus, Duan et al. (2021) investigated the combination of two natural colorants, curcumin and anthocyanins, loaded into pullulan/chitin nanofibrous mats (Duan et al. 2021). The nanofibers’ diameters increased with the addition of the colorants, and the thermal stability of the nanofibers was also reportedly improved. Moreover, due to synergistic effects, the nanofibrous mats containing curcumin and anthocyanins revealed improved antioxidant and antimicrobial properties compared to the nanofibers containing only one colorant (Duan et al. 2021). The nanofibrous mats also exhibited pH sensitivity, with evident color change and progressive fish spoilage, which were monitored at room temperature. Combining natural colorants to produce materials for active-intelligent food packaging applications appears to be a promising approach to mitigate any limitations that may be inherent in individual colorants (Duan et al. 2021).

In recent literature, various food packaging materials reported combined polysaccharides with natural colorants obtained through diverse processes other than electrospinning techniques. For instance, Ezati et al. (2019) used a dip-coating method to prepare a pH indicator film with starch and cellulose-containing the natural colorant alizarin, to monitor the freshness of rainbow trout fillet (Ezati et al. 2019). In another work, Sun et al. (2023) investigated a series of whey protein isolate and cellulose nanocrystal cast films containing different ratios of three natural colorants: curcumin, phycocyanin, and lycopene to evaluate how the composite packaging films’ physicochemical and sensory characteristics affected consumer preference for some products (Sun et al. 2023). Among these processes, solvent casting, a process where a polymer solution is cast onto a substrate, followed by evaporation of the solvent, stands out as a conventional and frequently utilized method for producing materials for food packaging applications due to its simplicity, versatility, cost-effectiveness, and ease of production. Nonetheless, nanofibrous food packaging materials exhibit a more advantageous porous nanofiber network with enhanced active sites for target molecules interaction, which increases sensitivity and responsiveness, as reported in the study published by Forghani et al. (2022) where the authors compared the performance of a film produced by solvent casting with a nanofibrous material produced by uniaxial blend electrospinning as food freshness indicators (Forghani et al. 2022). Both materials were fabricated with PVA, κ-carrageenan, and incorporated with Centaurea arvensis anthocyanins. The results showed that the nanofibrous material outperformed the film, with high responsiveness to pH changes. The electrospun nanofibers’ response time was 10 s, whereas the colorimetric film was 15 min (Forghani et al. 2022).

Challenges and future research directions

Electrospun materials fabricated with polysaccharides and natural colorants offer a promising approach to sustainable, multifunctional, and safe food packaging solutions. However, several shortcomings must be addressed to allow the production of efficient and economically viable polysaccharide and natural colorant-derived food packaging systems, Fig. 4.

Regarding the electrospinning process, the generalized polysaccharides’ poor electrospinnability often requires the use of toxic solvents or the blend with polymers with better spinnability properties. Therefore, it is crucial to optimize the nanofibers’ production through the evaluation of the relationship between varying parameters and the morphology of the nanofibers, and the focus should also be on greener alternatives to replace the toxic solvents. In fact, Yu et al. (2023) reported the use of green solvents, such as ionic liquids (ILs) and deep eutectic solvents (DESs), particularly choline-based ILs and DESs, as a significant development in polysaccharide-based film production (Yu et al. 2023). These solvents offer notable advantages, including high polysaccharide dissolving capacity and inherent antibacterial and antioxidant properties, while overcoming the challenges associated with polysaccharides’ poor electrospinnability and the use of toxic solvents, making them highly suitable for active food packaging materials. Furthermore, ILs and DESs can be efficiently recycled, contributing to sustainability in the packaging industry (Yu et al. 2023).

Moreover, the scale-up of the production of nanofibrous materials should be considered to accommodate industrial demands. Herein, needleless electrospinning systems should increase production rates and overcome the characteristic needle-clogging challenges associated with conventional electrospinning process. The layer-by-layer assembly of the nanofiber mats by needleless electrospinning can help to produce materials with favorable properties for use in the food packaging industry. One example is the BC and PVA-CH double-layered composite material produced by needleless electrospinning and functionalized with the bacterial pigment prodigiosin. The acquired data revealed promising results for the composite’s internal and external layers, suggesting its potential for active food packaging by effectively combating foodborne pathogens and external contamination (Amorim et al. 2022d).

However, despite advancements in this area, current research has some areas for improvement, including a lack of practical cases demonstrating the real-world utilization of these materials, which impedes their widespread uptake and commercialization on a larger scale. Nevertheless, needleless electrospinning equipment is already available for industrial applications, such as the Nanospider system produced by Elmarco. Moreover, several factories have begun the industrial-scale production of nanofiber-based membranes, like Jiangxi Xiancai Nanofibers Technology Co., Ltd., in China, highlighting the promise for future production of food packaging materials through the electrospinning technique (Zhao et al. 2020; Min et al. 2022; Janik et al. 2024). Additionally, there are also some patents focused on the production of polysaccharide-based packaging materials via electrospinning, highlighting the increasing interest and potential for further innovation in this field, as well as their potential implementation in the industry.

Apart from the upscale of the production process, the reduction of the overall cost of the materials is also a factor in obtaining commercially viable food packaging materials, even for smaller materials, such as smart sensors in intelligent food packaging, which should only account for a small fraction of the total packaging cost. Additionally, novel packaging materials should be tested on a wider range of food products, especially high-value ones, where the technology's extra costs are justified.

Moreover, a high demand exists to increase the functional performance of polysaccharide-derived packaging materials to compete with the desirable properties of petroleum-based plastic materials. In particular, natural polysaccharides may not provide the same mechanical and barrier properties as synthetic materials when applied as the main component. Enhancing the barrier properties of electrospun materials to protect packaged food products from moisture, oxygen, and light exposure is a critical challenge. However, several approaches have recently been proposed, including blending polysaccharides with other polymers or fabricating multilayer structures through electrospinning techniques (Janik et al. 2024). In addition, natural colorants have been shown to enhance both the mechanical and barrier properties of polysaccharide-based materials (Goudarzi et al. 2023). For example, Goudarzi et al. (2023) produced electrospun fiber mats using a blend of k-carrageenan and PVA, incorporating natural colorants such as Prunus domestica extract (PDE) and epigallocatechin gallate (EGCG). Their results demonstrated significant enhancements in thermal stability, moisture resistance, and barrier properties against oxygen and water vapor when PDE and EGCG were incorporated (Goudarzi et al. 2023).

On the other hand, there is a wide variety of plant-derived colorants being explored for active and intelligent food packaging solutions, nonetheless, the seasonality and geographic variability of these colorants should be taken into account, and other viable alternatives should be further investigated to overcome these issues. In these instances, microbial pigments offer several advantages over plant-derived colorants due to their easy and controlled production, higher yield, scalability, and potentially lower production costs. They also use of strain improvement techniques to increase pigment production. Another aspect that must be taken into account regarding the use of natural colorants in colored food packaging materials is color stability. Natural colorants can be sensitive to environmental factors, such as light and oxygen, leading to color fading or changes over time. Maintaining color stability in electrospun packaging materials is essential for consumer appeal and crucial in intelligent food packaging materials such as pH-responsive color indicators. To achieve this, it is essential to select natural colorants known for their stability and compatibility with the polysaccharide packaging matrix. Additionally, when pH-responsive color indicators are desired, choosing natural colorants known for their sensitivity to pH changes within the intended range is essential. Moreover, it is essential to conduct rigorous stability testing under simulated storage conditions to accurately assess the color stability over time, as well as explore different encapsulation techniques to protect the natural colorants from environmental factors and preserve their stability within the electrospun nanofibers. Thus, by addressing these considerations, manufacturers can maintain electrospun packaging materials’ visual appeal and functionality, ensuring consumer satisfaction and safety.

Furthermore, the research published up to date concerning innovative food packaging materials is majorly focused on the prevention of food spoilage and the evaluation of the materials’ bioactive properties. Nonetheless, the nutritional content, the attributes related to the foods’ sensory aspects, and the physicochemical features of foods packaged in these novel packaging materials should be considered and further evaluated. Likewise, developing novel food packaging materials must comply with food safety regulations, and researchers should thoroughly assess the migration of components from the packaging into the foods.

Lastly, there is the need to promote consumer awareness and acceptance of sustainable food packaging and to encourage sustainable consumer behavior, once, even though concerns for the environment are growing, the awareness does not always translate into immediate changes in consumers’ buying habits. Consumers need to understand how their choices impact the environment to promote more sustainable consumption practices. To drive adoption and foster positive changes, consumer education, and marketing strategies should be tailored to align with consumer preferences for eco-friendly packaging materials.

Conclusion

Electrospinning allows the fabrication of eco-friendly, active and intelligent food packaging that combines polysaccharides with other compounds loading. The incorporation of bioactive compounds, such as natural colorants, provides added functionality to the fabricated packaging materials, such as antimicrobial properties, antioxidant activity, and spoilage real-time monitoring, besides imparting color, which may influence consumer behavior.

Moreover, electrospun packaging materials exhibit a high surface-to-volume ratio, allowing higher bioactive agent encapsulation efficiency, reduced pore size between interwoven fibers, which could hinder bacterial entry, and small fiber diameters that enable a swift response for the timely release of bioactive compounds. In addition to these features, electrospun nanofibers present improved mechanical strength, thermal stability, and barrier properties against moisture, gases, oxygen, and aromas, ensuring the protection and preservation of the food packaged. This enhances the shelf life of perishable food products by preventing spoilage and maintaining freshness.

Nevertheless, despite these benefits, polysaccharides may not exhibit the same mechanical strength and barrier properties as synthetic materials when they are the main component in the electrospun solutions. In this sense, recent studies have addressed this issue by blending polysaccharides with other biopolymers, employing cross-linking agents, and incorporating food additives such as natural colorants, resulting in substantial enhancements in the performance of electrospun polysaccharide-based packaging materials. These improvements encompass advancements in mechanical, thermal, and barrier properties, as well as additional functionalities such as coloration and bioactive properties.

On the other hand, the inherent variability in the composition and properties of plant-derived colorants presents a significant challenge to their successful incorporation into electrospun materials for food industrial applications. Additionally, natural colorants derived from plant sources may exhibit sensitivity to environmental factors such as light, temperature, oxygen, and pH, making it difficult to maintain color stability throughout the electrospinning process and during the storage of the packaging materials. As a result, researchers have turned their attention to exploring microbial pigments as a viable alternative to enhance the functionality and reliability of these materials due to their superior stability and ability to withstand environmental changes.

However, despite all the advancements attained so far, several limitations persist. Concerning that, future studies should address scalability challenges in electrospun packaging materials production to meet the demands of larger industrial applications, where the implementation of advanced manufacturing technologies like needleless electrospinning should emerge as a viable and cost-effective option. Moreover, using polysaccharides biosynthesized by microorganisms, such as exopolysaccharides, may offer notable advantages due to their higher yields or production rates, making them more suitable for large-scale production. Additionally, optimizing culture conditions and applying low-cost alternative feedstocks sourced from agro-industrial waste for polysaccharide recycling can reduce production costs and promote circularity within the packaging industry.

Therefore, to successfully achieve scale-up in the production of electrospun food packaging, rigorous testing and validation studies are essential to ensure its stability, safety, and regulatory compliance. Such efforts are particularly critical due to the complex interactions among the polysaccharides, natural colorants, and food components.

Thus, in the near future, effective management of the regulatory process during the development and commercialization of such materials should be achieved through collaboration with regulatory experts and early engagement with regulatory authorities to meet rigorous quality standards. In addition, strategic partnerships with the food industries will play a critical role in technology transfer and the commercialization of these materials. Simultaneously, consumer education efforts should be directed towards promoting the acceptance of polysaccharide-based packaging's sustainability benefits, ensuring their successful introduction to the market as cost-effective and compliant solutions for packaging needs. Moreover, integrating life cycle assessment (LCA) tools can effectively address health and environmental concerns, further reinforcing these packaging solutions’ viability.

To summarize, this review has shown the great potential of combining cost-effective and sustainable polysaccharides with natural colorants through the electrospinning technique to fabricate active and intelligent food packaging materials. Moreover, the inherent biodegradability of polysaccharides provides environmentally friendly solutions for the packaging industry, contributing to sustainable practices by reducing environmental impact and waste accumulation. Nonetheless, despite the different approaches described herein, there is still extensive potential for developing new formulations to create cost-effective, sustainable, and safe food packaging materials that can reduce food waste and increase food product safety.

Data availability

No datasets were generated or analysed during the current study.

Abbreviations

- ABTS+ :

-

2,2′-Azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt radical cation

- BC:

-

Bacterial cellulose

- BCNCs:

-

Bacterial cellulose nanocrystals

- BCNFs:

-

Bacterial cellulose nanofibrils

- CH:

-

Chitosan

- CMCS:

-

Carboxymethyl chitosan

- CNCs:

-

Nanocrystals of cellulose

- CNFs:

-

Nanofibrils of cellulose

- DESs:

-

Deep eutectic solvents

- EGCG:

-

Epigallocatechin gallate

- EPO:

-

International Espacenet

- FIs:

-

Freshness Indicators

- GG:

-

Guluronic acid

- ILs:

-

Ionic liquids

- Lis:

-

Leakage indicators

- LCA:

-

Life cycle assessment

- MM:

-

Mannuronic acid

- O/W:

-

Oil-in-water

- PCL:

-

Polycaprolactone

- PEO:

-

Polyethylene oxide

- PG:

-

Prodigiosin

- PVA:

-

Polyvinyl alcohol

- PDE:

-

Prunus domestica Extract

- RFIDs:

-

Radio frequency identification tags

- ROS:

-

Reactive oxygen species

- TEMPO:

-

2,2,6,6-Tetramethylpiperidine-1-oxyl radical

- TTIs:

-

Time-temperature indicators

- TiO2NPs:

-

Titanium dioxide nanoparticles

- UV:

-

Ultraviolet

References

Abdulhussain R, Adebisi A, Conway BR, Asare-Addo K (2023) Electrospun nanofibers: exploring process parameters, polymer selection, and recent applications in pharmaceuticals and drug delivery. J Drug Deliv Sci Technol 90:105156. https://doi.org/10.1016/J.JDDST.2023.105156

Akshay Kumar KP, Zare EN, Torres-Mendieta R et al (2021) Electrospun fibers based on botanical, seaweed, microbial, and animal sourced biomacromolecules and their multidimensional applications. Int J Biol Macromol 171:130–149. https://doi.org/10.1016/J.IJBIOMAC.2020.12.205

Aleksanyan KV (2023) Polysaccharides for biodegradable packaging materials: past, present, and future (Brief review). Polymers (Basel) 15:451. https://doi.org/10.3390/POLYM15020451

Aman Mohammadi M, Hosseini SM, Yousefi M (2020) Application of electrospinning technique in development of intelligent food packaging: a short review of recent trends. Food Sci Nutr 8:4656–4665. https://doi.org/10.1002/FSN3.1781

Amjadi S, Almasi H, Ghorbani M, Ramazani S (2020a) Reinforced ZnONPs/ rosemary essential oil-incorporated zein electrospun nanofibers by κ-carrageenan. Carbohydr Polym 232:115800. https://doi.org/10.1016/J.CARBPOL.2019.115800

Amjadi S, Almasi H, Ghorbani M, Ramazani S (2020b) Preparation and characterization of TiO2NPs and betanin loaded zein/sodium alginate nanofibers. Food Packag Shelf Life 24:100504. https://doi.org/10.1016/J.FPSL.2020.100504

Amorim LFA, Fangueiro R, Gouveia IC (2022a) Characterization of bioactive colored materials produced from bacterial cellulose and bacterial pigments. Materials 15:2069. https://doi.org/10.3390/MA15062069

Amorim LFA, Fangueiro R, Gouveia IC (2022b) Novel functional material incorporating flexirubin-type pigment in polyvinyl alcohol_kefiran/polycaprolactone nanofibers. J Appl Polym Sci 139:e53208. https://doi.org/10.1002/APP.53208

Amorim LFA, Gomes AP, Gouveia IC (2022c) Design and preparation of a biobased colorimetric ph indicator from cellulose and pigments of bacterial origin, for potential application as smart food packaging. Polymers (Basel) 14:3869. https://doi.org/10.3390/polym14183869

Amorim LFA, Li L, Gomes AP et al (2023) Sustainable bacterial cellulose production by low cost feedstock: evaluation of apple and tea by-products as alternative sources of nutrients. Cellulose 30:5589–5606. https://doi.org/10.1007/S10570-023-05238-0/TABLES/5

Amorim LFA, Mouro C, Riool M, Gouveia IC (2022d) Antimicrobial food packaging based on prodigiosin-incorporated double-layered bacterial cellulose and chitosan composites. Polymers (Basel) 14:315. https://doi.org/10.3390/POLYM14020315

Angel N, Li S, Yan F, Kong L (2022) Recent advances in electrospinning of nanofibers from bio-based carbohydrate polymers and their applications. Trends Food Sci Technol 120:308–324. https://doi.org/10.1016/J.TIFS.2022.01.003

Azaz Ahmad Azad ZR, Ahmad MF, Siddiqui WA (2019) Food spoilage and food contamination. In: Health and Safety Aspects of Food Processing Technologies (1st edn.). Springer International Publishing, pp 9–28. https://doi.org/10.1007/978-3-030-24903-8