Abstract

Spinning of cellulose dissolved in 3-alkyl-1-methylimidazolium ionic liquids is a current approach to manmade cellulosic fibers. To curb cellulose degradation in the dope, stabilizers have to be used. Generation of chromophores in the dope and the resulting fibers is unavoidable, with most of the discoloration resulting from the employed antioxidants. In the present work, the chemical structures of the chromophores derived from the most common “green” stabilizers currently used, namely propyl gallate (a gallic acid derivative), hydroxytyrosol (and antioxidant from olives), and tocopheramines (vitamin E derivatives), were elucidated by a combination of analytical techniques and final confirmation by comparison with independently synthesized samples. While most compounds are oxidation and rearrangement products of the antioxidants themselves, coupling products with the ionic liquid´s imidazolium cations were also found. Identification of the colored compounds is a critical issue for both the optimization of fiber bleaching steps and solvent purification/recovery in the spinning process. Now that the nature of the generated chromophores is known, milder yet more effective bleaching treatments can be developed and solvent purification/recycling can be specifically optimized.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

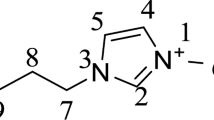

Spinning of cellulosic fibers requires prior dissolution of the cellulosic pulp. This dissolution can either be affected by chemical means, i.e., permanent or temporary derivatization to form soluble derivatives. Such a temporary cellulose modification for solution purposes is employed, for instance, in the viscose (rayon) process: cellulose is converted into alkali-soluble cellulose xanthate, which is spun into aqueous acidic medium and at the same time re-converted into (regenerated) cellulose by removal of the xanthate groups. Alternatively, cellulose can be dissolved in “direct solvents” which, in theory, dissolve cellulose in a merely physical process. In real-world systems, accompanying chemical processes and side reactions cannot be prevented, only minimized. Examples of this type of cellulose dissolution are processes based on N-methylmorpholine N-oxide monohydrate (NMMO) for Lyocell fiber production. About two decades ago, ionic liquids (ILs) have been introduced as possible solvent alternatives. N-Alkyl-N-methylimidazolium ILs belong to the first generation of cellulose-dissolving ILs which, at that time, were rather unsuccessful at diverse pulping and biomass fractionation scenarios, because of unsurmountable recycling and purification problems of the solvents. These initial attempts were later followed by approaches with higher-generation ionic liquids which were able to largely overcome these obstacles. This eventually led to the development of the Ioncell® technology (Sixta et al. 2013, 2015; Stepan et al. 2016; Asaadi et al. 2018; Guizani et al. 2021). Recently, N-alkyl-N-methylimidazolium ILs, paired with high-purity dissolving pulps and optimized recycling concepts, have found renewed interest in the production of special high-strength cellulose fibers (Zhang et al. 2019, 2020). However, this dope system is also not free of side reactions and byproduct formation and needs to be stabilized, which is the general topic of this account.

The degradation products of 3-alkyl-1-methylimidazolium ionic liquids are known (Liebner et al. 2010), and their side reactions with celluloses have been established (Ebner et al. 2008). In addition to this general reaction of the cation, different side reactions with co-reacting anions, such as acetylation in the case of acetates (Zweckmair et al. 2015), might occur. In general, side reactions in cellulose fiber spinning dopes are very complex and their effects on cellulose are generally hard to investigate individually and to assign to a particular process: cellulose degradation can be either caused by general (acidic) hydrolysis, by the effect of specific agents or can be the effect of oxidation and subsequent chain cleavage. In previous work, we have established that the cellulose degradation in imidazolium-type ionic liquids is a consequence of – mainly homolytic – degradation processes which can be effectively suppressed by the addition of antioxidants (Hettegger et al. 2022). However, this stabilization comes at the expense of an increased discoloration of the spinning dope. This translates into lower brightness of the spun fibers and might imply decreased bleachability, higher chemical needs for bleaching treatments, and lower brightness stability. To address this discoloration issue, it is imperative to know more about the chemical structures of the generated chromophores. This study thus describes our attempts to identify the antioxidant-derived chromophores that cause dope discoloration in N-alkyl-N-methylimidazolium IL/cellulose fiber spinning.

Materials and methods

General

Commercial chemicals from Sigma-Aldrich (Schnelldorf, Germany) were of the highest grade available and were used without further purification. Distilled water was used for all aqueous solutions. Thin layer chromatography (TLC) was performed on Silica gel 60 F254 pre-coated glass plates (Merck, Darmstadt, Germany). Flash column chromatography was performed on Silica gel 60 from Merck. Solvents were purchased in synthesis grade from Roth, Sigma-Aldrich and VWR and were used as received. Melting points were determined on a Kofler hot-stage microscope and are uncorrected. Elemental analyses were performed on a EURO EA 3000 CHNS-O instrument from HEKAtech (Wegberg, Germany) at the Microanalytical Laboratory of the University of Vienna.

The same cellulosic pulps, having α-cellulose contents of 97.0–97.5% according to the manufacturer, and fibers produced thereof, were used as in previous work (Zhang et al. 2019, 2020). Table 1 gives the molecular weight (Mn, Mw, degree of polymerization (DP), dispersity Ɖ = Mw/Mn) and brightness data of the pulps used. The imidazolium acetate ionic liquid was obtained from Nippon Nyukazai Co., Ltd. (Tokyo, Japan) and imidazolium chloride ionic liquids from Sigma-Aldrich (Tokyo, Japan and Schnelldorf, Germany).

UV/Vis spectra were recorded on a LAMBDA 45 UV/Vis spectrophotometer (Perkin Elmer, Waltham, MA, USA): range of 400 to 700 nm, scanning speed 480 nm min−1, quartz glass cuvettes (l = 1.0 cm).

Preparation of spinning dopes and dry-jet wet-spinning

The cellulosic pulps were dried at 100 °C for 3 h. In a stainless-steel vessel, a pulp aliquot (5 wt% rel. to the IL solvent) was added to the respective ionic liquid containing the stabilizer (2 wt% rel. to the mass of cellulosic pulp) and stirred at RT for 1 h. The mixture was heated to 100 °C under stirring to affect the dissolution of the pulp. Complete dissolution, occurring after an additional 1–2 h, was confirmed using a polarized optical microscope (Olympus BHT-P, Tokyo, Japan) under crossed Nicols.

Spinning was carried out according to a dry-jet wet spinning process as reported previously (Zhang et al 2019, 2020; Hettegger et al. 2022). At a temperature of 100 °C, the spinning dopes were extruded through the spinning nozzles into an air gap (15 cm) and distilled water (without any additives) as the coagulation bath, at a constant speed of 0.1 mL min−1 and a constant winding speed of 107 m min−1. The resulting fibers were washed with hot distilled water (70 °C) to remove the major part of the solvent and byproducts, loosely coiled on bobbins, agitated in water overnight to remove residues of solvent and byproducts, and eventually dried at RT.

Extraction of lipophilic compounds and chromophores from the spinning baths

The combined spinning baths and aqueous washings were adjusted to pH 6 by the addition of 0.1 M aq. HCl. An aliquot (500 mL) was extracted with 50 mL of toluene, and the extraction was repeated twice with the same volumes. For optimization, other extractants were also used, see main text. The combined organic extracts were washed with 20 mL of water. An aliquot (5 mL) was dried over anhydrous MgSO4 and used for preliminary analysis by HP-TLC and GC/MS. The solvent of the main part was removed at RT in vacuo. A separate drying step was not necessary as toluene is an efficient entrainer for water and removes contained moisture efficiently in the evaporation process. The obtained colored, oily residue was stored under Ar at 4 °C. Separation of the compounds was done by flash chromatography with a toluene/n-heptane eluant (v/v = 6:1).

NMR analysis

All NMR spectra were recorded on a Bruker Avance II 400 (resonance frequencies: 400.13 MHz for 1H and 100.63 MHz for 13C) equipped with a 5 mm N2-cooled cryo-probehead (Prodigy™) with z-gradients at room temperature with standard Bruker pulse programs. All samples were dissolved in CDCl3 (0.6 mL, 99.9% D). Chemical shifts are given in ppm, referenced to residual solvent signals. 1H NMR data were collected with 32 k complex data points and apodized with a Gaussian window function (lb = − 0.3 Hz and gb = 0.3 Hz) prior to Fourier transformation. The 13C spectra with WALTZ16 1H decoupling were acquired using 64 k data points. Signal-to-noise enhancement was achieved by multiplication of the FID with an exponential window function (lb = 1 Hz). All two-dimensional experiments were performed with 1 k × 256 data points, while the number of transients (2–16 scans) and the sweep widths were optimized individually. HSQC experiment was acquired using adiabatic pulse for inversion of 13C and GARP-sequence for broadband 13C-decoupling, optimized for 1 J(CH) = 145 Hz. For the NOESY spectrum, a mixing time of 0.8 s was used.

In the case of tocopherol derivatives, the nomenclature and the numbering of the carbon atoms proposed by the IUPAC (IUPAC-IUB Commission 1974 and 1982) have been used throughout (see the respective formula schemes). The carbon δ-values for the isoprenoid side chain of tocopherol derivatives (C-1' to C-13') are only slightly (< 0.1 ppm) affected by modifications of the chroman structure (Urano and Matsuo 1980; Brownstein et al. 1989) and are listed only once (compound 10) and not repeated for the other tocopherol derivatives. In the spiro-dimeric compounds 11 and 12, the aromatic moiety is conventionally numbered, while the keto moiety is indicated by “#”.

Identification of the chromophores

Gallic acid (5). Off-white solid. 1H NMR: δ 6.91 (2H, s), 8.34 (OH-4, H, s), 9.20 (OH-3,5, 2H, s), 12.16 (1H, s, COOH). 13C NMR: δ 108.7 C-2,6), 120.3 (C-1), 138.2 (C-4), 145.4 (C-3,5), 168.0 (COOH).

Ellagic acid (6). Yellow powder. 1H NMR: δ 7.46 (H-Ar), 8.12 (OH). 13C NMR: δ 107.4 (C-2), 110.2 (C-6) 112.4 (C-1), 136.3 (C-3), 140.1 (C-4), 148.1 (C-5), 159.1 (COO).

Ellagobis(ortho-quinone) (7). Black powder. 1H NMR: δ 8.05 (CH). 13C NMR: δ 116.1 (C-6), 115.9 (C-1), 118.8 (C-2), 145.0 (C-3), 155.9 (COO), 177.5 (C-4), 180.4 (C-5).

Hydroxytyrosol ortho-quinone (8). Red oil. 1H NMR: δ 2.69 (2H, t, Ar-CH2), 3.70 (2H, t, CH2-OH), 6.60 (1H, dd, H-6), 6.72 (1H, dd, H-2), 6.78 (1H, dd, H-5). 13C NMR: δ 31.2 (Ar-CH2), 61.4 (CH2-OH), 127.7 (C-5), 129.2 (C-2), 143.2 (C-6), 151.1 (C-1), 180.3 (C-4), 182.4 (C-3).

Michael product (9). 1H NMR: δ 2.45 (2H, m, Ar-CH2), 2.56 (2H, d, 5-CH2), 3.37 (1H, m, 6-CH), 3.75 (2H, m, CH2-O), 5.11 (1H, d, 2-CH). 13C NMR: δ 29.8 (Ar-CH2) 63.4 (CH2-O), 42.3 (C-5), 134.1 (C-2), 70.4 (C-6), 110.4 (C-1), 181.6 (C-4), 183.4 (C-3).

Michael product, hydrate (9a). Light yellow oil. 1H NMR: δ 2.44 (2H, m, Ar-CH2), 2.56 (2H, d, 5-CH2), 3.33 (1H, m, 6-CH), 3.74 (2H, m, CH2-O), 5.23 (1H, d, 2-CH). 13C NMR: δ 29.6 (Ar-CH2), 63.2 (CH2-O), 29.9 (C-5), 132.1 (C-2), 71.0 (C-6), 109.8 (C-1), 98.8 (C-4), 186.4 (C-3).

α-Tocopheryl-para-quinone (10). Dark yellow oil, UV λmax (toluene): 264 nm. 1H NMR: δ 2.55 (2H, m, 4-CH2), 2.08 (3H, s, 5a-CH3), 2.03 (3H, s, 7a-CH3), 2.03 (3H, s, 8b-CH3), 1.08–1.54 (m, 23H, 3-CH2, 9 × CH2 in side chain [1´-CH2, 2´-CH2, 3´-CH2, 5´-CH2, 6´-CH2, 7´-CH2, 9´-CH2, 10´-CH2, 11´-CH2], 3 × CH in side chain [4-CH, 8-CH, 12-CH]), 1.23 (3H, s, 2a-CH3), 0.86 (9H, d, J = 6.3 Hz, 4a-CH3, 8a-CH3, 12a-CH3), 0.84 (3H, d, J = 6.3 Hz, 13-CH3). 13C NMR: δ 187.5 (C-8a), 140.3 (C-8), 12.3 (C-8b), 140.0 (C-7), 12.3 (C-7a), 186.6 (C-6), 140.6 (C-5), 12.0 (C-5a), 144.4 (C-4a), 21.5 (C-4), 40.4 (C-3), 72.7 (C-2), 26.7 (C-2a). Isoprenoid side chain: 38.5 (C-1´), 20.4 (C-2´), 36.7 (C-3´), 31.8 (C-4´), 19.7 (C-4a´), 36.5 (C-5´), 23.5 (C-6´), 36.5 (C-7´), 31.6 (C-8´), 19.8 (C-8a´), 36.4 (C-9´), 23.8 (C-10´), 38.4 (C-11´), 27.0 (C-12´), 21.6 (C-12a), 21.7 (C-13´). NMR data fully agree with the literature (e.g., Urano and Matsuo 1980).

Spiro-dimer of α-tocopherol (11). Yellow oil, UV λmax (toluene): 272 nm. 1H NMR: δ 2.62 (2H, m, 4-CH2), 2.46 (2H, m, 4#-CH2), 2.52 (3H, s, 5a-CH2), 2.08 (3H, s, 5a#-CH2), 2.12 (3H, s, 7a-CH3), 1.88 (3H, s, 7a#-CH3), 2.05 (3H, s, 8b-CH3), 2.01 (3H, s, 8b#-CH3), 1.64–1.60 (4H, m, 3-CH2 and 3#-CH2), 1.06–1.54 (m, 42H, 18 × CH2 and 6 × CH in two isoprenoid side chains), 1.22 (3H, s, 2a-CH3), 1.20 (3H, s, 2a#-CH3), 0.82–0.90 (24H, m, 4a-CH3, 8a-CH3, 12a-CH3, 13-CH3, 4a#-CH3, 8a#-CH3, 12a#-CH3, 13#-CH3). 13C NMR: δ 143.7 (C-8a), 141.8 (C-8a#), 122.4 (C-8, C-8#), 10.7 (C-8b), 13.0 (C-8b#), 121.1 (C-7), 126.0 (C-7#), 10.8 (C-7a), 10.2 (C-7a#), 144.7 (C-6), 201.4 (C-6#), 114.5 (C-5), 80.0 (C-5#), 16.9 (C-5a), 27.1 (C-5a), 114.0 (C-4a), 114.4 (C-4a#), 18.6 (C-4), 16.6 (C-4#), 29.7 (C-3), 30.2 (C-3#), 73.3 (C-2), 75.0 (C-2), 22.3 (C-2a), 22.5 (C-2a#). Isoprenoid side chains: see compound 10 above. NMR data are in complete agreement with the literature (e.g. Schröder and Netscher 2001).

Spiro-dimer of N-methyl-α-tocopheramine (12). Yellow oil, UV λmax (toluene): 278 nm. 1H NMR: δ 2.60 (2H, m, 4-CH2), 2.46 (2H, m, 4#-CH2), 2.36 (3H, s, 5a-CH3), 2.18 (3H, s, 5a#-CH3), 2.05 (3H, s, 7a-CH3), 1.84 (3H, s, 7a#-CH3), 2.01 (3H, s, 8b-CH3), 1.96 (3H, s, 8b#-CH3), 1.64–1.59 (4H, m, 3-CH2 and 3#-CH2), 1.06–1.54 (m, 42H, 18 × CH2 and 6 × CH in two isoprenoid side chains), 1.22 (3H, s, 2a-CH3), 1.21 (3H, s, 2a#-CH3), 0.82–0.92 (24H, m, 4a-CH3, 8a-CH3, 12a-CH3, 13-CH3, 4a#-CH3, 8a#-CH3, 12a#-CH3, 13#-CH3). 13C NMR: δ 145.4 (C-8a), 142.4 (C-8a#), 122.8 (C-8), 122.6 (C-8#), 10.7 (C-8b), 12.9 (C-8b#), 123.2 (C-7), 125.8 (C-7#), 10.9 (C-7a), 10.4 (C-7a#), 138.6 (C-6), 251.3 (C-6#), 111.2 (C-5), 68.7 (C-5#), 18.8 (C-5a), 25.5 (C-5a), 116.2 (C-4a), 116.0 (C-4a#), 18.8 (C-4), 16.6 (C-4#), 30.2 (C-3, C-3#), 73.8 (C-2), 75.1 (C-2), 22.3 (C-2a, C-2a#), 38.8 (CH3-N), 42.4 (CH3-N =). Isoprenoid side chains: see compound 10 above.

α-Tocopheryl-ortho-quinone (α-tocored, 13). Red oil, UV λmax (toluene): 288 nm. 1H NMR: δ 2.44 (2H, m, 4-CH2), 2.05 (3H, s, 7a-CH3), 1.98 (3H, s, 8b-CH3), 1.73 (2H, t, 3-CH2), 1.08–1.54 (m, 21H, 9 × CH2 in side chain [1´-CH2, 2´-CH2, 3´-CH2, 5´-CH2, 6´-CH2, 7´-CH2, 9´-CH2, 10´-CH2, 11´-CH2], 3 × CH in side chain [4-CH, 8-CH, 12-CH]), 1.28 (3H, s, 2a-CH3), 0.84–0.86 (12H, d, J = 6.3 Hz, 4a-CH3, 8a-CH3, 12a-CH3), 0.84 (3H, d, J = 6.3 Hz, 13-CH3). 13C NMR: δ 163.5 (C-8a), 110.3 (C-8), 11.7 (C-8b), 134.4 (C-7), 13.8 (C-7a), 180.1 (C-6), 181.0 (C-5), 143.8 (C-4a), 22.6 (C-4), 40.0 (C-3), 71.4 (C-2), 28.0 (C-2a). Isoprenoid side chain: see compound 10 above. NMR data are fully consistent with the literature (e.g., Yamauchi et al. 1990).

Results and discussion

Side reactions in the spinning dope: autoxidative processes

Previous work (Hettegger et al. 2022) has established the necessity to stabilize cellulose solutions in imidazolium ionic liquids against autoxidation processes which are inevitably caused by the presence of atmospheric oxygen. The occurrence of such processes was evident from a progressive chain degradation of the cellulosic pulp by oxidation, i.e., the introduction of carbonyl and carboxyl groups (Ahn et al. 2019), which is followed by beta-alkoxy-elimination processes starting from these groups. These alkali-triggered degradation reactions start already at pH values as low as 8 (Hosoya et al. 2018), in the present case the basicity of the medium is generated by N-methylimidazole and imidazole as the two common – and nearly ubiquitous – degradation products of 1-alkyl-3-methyl-imidazolium-type ionic liquids.

The cellulose integrity was largely preserved when working in a degassed solvent under inert gas. Evidently, this is not practicable under industrial conditions, but it nicely supports molecular oxygen to be the cause of the degradation processes. Working in an oxygen-enriched atmosphere, for demonstration purposes, is the other extreme, which drastically enforced cellulose chain degradation (Hettegger et al. 2022). The use of antioxidants to hold the autoxidation processes at bay under industrial conditions was therefore an obvious countermeasure to cellulose oxidation and degradation.

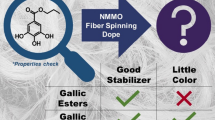

In our previous work, we focused on four different antioxidants, propyl gallate (1), hydroxytyrosol (2), α-tocopherol (3), and N-methyl-α-tocopheramine (4), see Scheme 1. These compounds – among a group of 12 candidates tested previously – were the only ones that met the three requirements for a viable stabilizer: a) the prevention of cellulose degradation, b) only moderate color generation in the spinning dope, and c) a low tendency to generate color in the spun fibers upon aging. As an additional plus, all four are economically viable and can be considered “green” antioxidants, as they are obtained from biomass either directly by extraction (hydroxytyrosol (2), α-tocopherol (3)) or by a simple one-step modification of a natural parent compound (gallic acid for propyl gallate (1) and N,N-dimethyl-α-tocopheramine for N-methyl-α-tocopheramine (4)).

The protection of dissolved cellulose in the spinning dope against oxidation and degradation comes at the expense of color generation. All four stabilizers form – in some cases quite potent – chromophores which are reaction and degradation products of the stabilizers themselves and more color-intense than the weak chromophores generated from carbohydrate degradation products (Korntner et al. 2015) without stabilizer addition. However, cellulose degradation is detrimental and irreversible while color formation can well be counteracted by washing and/or bleaching steps, so the use of stabilizers is inevitable. This “tradeoff” is also known from other spinning processes, such as viscose or Lyocell fiber manufacture.

Extraction of chromophores

While the conventional chromophore analysis in cellulosic materials according to the chromophore release and identification (CRI) method (Rosenau et al. 2004a) works well for solid cellulosic matrices, such as pulps, fibers or derivatives, it cannot be applied to liquid phases, such as the spinning baths from fiber processing. In the present case, the spinning dopes were extruded in a dry-jet wet spinning process (Zhang et al. 2019, 2020) through the spinning nozzles at a temperature of 100 °C into an air gap (15 cm) and then into water as the coagulation bath. The resulting spinning bath, after separation of the fibers, thus represents a homogeneous liquid phase consisting of water and ionic liquid. After combination of the spinning bath with the water from fiber washing, a water/IL composition of approx. 5:1 to 10:1 (v/v) results. As all stabilizers are moderately to strongly hydrophobic compounds, with high lipophilicity for the tocopherol derivatives due to their isoprenoid C16 side chain, medium lipophilicity for propyl gallate and hydrophilicity for hydroxytyrosol, it was thus likely that the resulting chromophoric products were rather lipophilic as well and thus extractable with apolar solvents. A preliminary screening of extraction solvents (see Fig. 1) showed that quite a few solvents were able to extract chromophoric compounds. The extraction efficiency was simply tested by relating the VIS absorption (λ = 457 nm) of the aqueous phase before and after extraction. The extraction conditions were always constant (see experimental part). Toluene turned out to be the solvent of choice because the chromophore extraction was quantitative and the extracts were free of adhering ionic liquid, since the very polar IL and the highly apolar solvent were completely immiscible. While other solvents also removed the UV/VIS-active components quantitatively from the spinning bath liquid, the extracts contained residual IL, which interfered with TLC detection and rendered GC detection problematic (danger of permanent damage of the capillaries). It was therefore obvious that the absence of IL in the extracts was the decisive advantage when using toluene. Although n-hexane gave the same satisfying results regarding extraction efficiency, toluene was preferred due to n-hexane´s neurotoxicity and the fact that the toluene extracts could be readily dried by partial evaporation of the solvent, because toluene acts as efficient entrainer for water.

Spinning of fibers from cellulose solution in EMIm-OAc stabilized by different antioxidants: Efficiency of chromophore extraction from the aqueous fiber spinning baths by different solvents and extent of coextraction of IL and IL degradation products under different conditions. Top left: propyl gallate (1), top right: hydroxytyrosol (2), bottom left: α-tocopherol (3), bottom right: N-methyl-α-tocopheramine (4)

The aqueous spinning bath has a pH between 9 and 11.5, depending on the concentration of the dissolved substances. The alkalinity is caused by the almost ubiquitous byproducts of imidazolium ILs, i.e., N-methylimidazole and imidazole (Liebner et al. 2010). While the chromophore extraction at these pH values was quantitative in the case of the tocopherol antioxidants, some UV/VIS-activity remained in the aqueous phase in the case of hydroxytyrosol and propyl gallate. At pH values of 8 and 6, extraction was quantitative for all antioxidants used. Therefore, the pH was generally set to 6 with 1 M hydrochloric acid before the extraction. At pH 6, no imidazole and N-methylimidazole are extracted, while at pH 8 the extracts contained traces of these two IL degradation products. Addition of brine or neutral salts to improve extractability of the chromophores by the salt-out effect is unnecessary, because the antioxidants – and obviously the derived chromophores as well – had a very good solubility in the organic solvents already from the beginning. While brine addition had no effect on the extraction with toluene, it even increased the amount of residual IL in less apolar extraction solvents, and thus can generally not be recommended.

Identification of antioxidant-derived chromophores and suggested formation mechanisms

The obtained toluene extracts were evaporated in vacuo. The residues were subjected to a first screening by HP-TLC and GC/MS for a preliminary comparison with the parent antioxidants (1 – 4) and some of their common degradation products (such as ellagic acid from propyl gallate or α-tocopherylquinone from α-tocopherol). The extraction mixture was then separated by flash chromatography on siliga gel with a toluene/n-heptane eluant for all mixtures. The parent compounds were in all cases the major constituent of the mixture, showing that the antioxidants were still present in excess and had not been completely consumed in the dope. The byproducts amounted to 28.2% of 1, 24.8% of 2, 26.4% of 3 and 28.4% of 4, and were thus in a surprisingly narrow conversion range. The individual compounds, as shown below, were characterized by NMR and mass spectrometry. Only when a compound was identical to an authentic sample was the structure of the byproduct considered to be unambiguously confirmed. The authentic reference samples for comparison were mostly available from previous work and were newly synthesized in two cases.

Propyl gallate is a very commonly used antioxidant which is used both for stabilization of polymeric materials, fibers as well as food and cosmetic preparations where it is well-known as additive E 310 (for general applications as an antioxidant: Adegoke et al. 1998; for application in fibers: Ding et al. 2019, Wendler et al. 2005). The isolated byproducts derived from propyl gallate (1) were small amounts of gallic acid (5), ellagic acid (6) and the bis(ortho-quinone) 7, see Scheme 2. Gallic acid, in pure form a colorless compound, is simply the ester cleavage product of propyl gallate. Such saponification can readily occur under the prevailing conditions (slightly alkaline medium due to the imidazolium byproducts, temperatures up to 100 °C). Ellagic acid is the primary product of the radical-scavenging action of gallates. The primary phenoxyl radical intermediates recombine to 3,3´, 4,4´, 5,5´-hexahydroxydiphenic acid dipropyl ester (1a), which forms ellagic acid (6) under release of two equivalents of the esterified alcohol, driven by entropic favorization of the bislactone over the dipropyl ester. Pure ellagic acid has a slightly yellow color. Further oxidation of ellagic acid causes formation of its bis(ortho-quinone) (7), a dark black solid and very potent chromophore with a highly conjugated double bond system. While conversion of two equivalents of 1 to 6 is a two-electron oxidation, further oxidation to the bis(ortho-quinone) 7 is a four-electron process. The bis-quinone is the main contributor to the discoloration of propyl gallate-stabilized spinning dopes. This is also true for Lyocell spinning dopes in the cellulose solvent N-methylmorpholine-N-oxide, which are also commonly stabilized by propyl gallate (Rosenau et al. 2005a).

Hydroxytyrosol (2) is a main antioxidant component in olive oil and olive water (Britton et al. 2019, Quiles et al. 2006), which apart from food applications is widely used as stabilizer in polymers (Peltzer et al. 2010; Fortunati et al. 2016, 2017) and fibers (Haddar et al. 2015, Bayraktar 2018). From the spinning dopes stabilized with hydroxytyrosol, two byproducts (Scheme 3) were isolated. Apparently, oxidation via the corresponding phenoxyl radical (2a) causes formation of an ortho-quinone (8), which has an yellow-orange color. Intramolecular Michael addition of the aliphatic hydroxy group, favored entropically by ring formation, causes formation of the heterobicyclic compound 9. This compound shows weak solvatochromism, i.e., its color, when dissolved in solvents of different polarity, changes from faint yellow in apolar toluene to light red in polar protic ethanol. In water the compound is in equilibrium with its 1-ketohydrate (a geminal diol), compound 9a. The Michael addition product is not an artifact of the work-up and had apparently already formed in the spinning bath, as a quick TLC screening at different times of dope preparation showed. Dissolution of 9 in trifluoroacetic acid reverses the Michael addition and regenerates the ortho-quinone 8.

The chromophores isolated from spinning dopes stabilized with α-tocopherol (3) agreed with the expectations (Scheme 4). The compound, also known as the main component of vitamin E, can be considered as the most widely used lipophilic antioxidant, not just in food, feed and cosmetics (E 307, Preedy and Watson 2007; Catala 2012), but also as stabilizer, antioxidant and scavenger of radicals and reactive oxygen species in a variety of (synthetic) polymers and fibers (Dahe et al. 2011; Wu et al. 2016; Ghaheh et al. 2017; Yokota et al. 2008). Its action mechanism is that of a typical radical chain-breaking antioxidant.

The two degradation products found are quite typical, para-tocopherylquinone (10) and the spiro-dimer of α-tocopherol (11). The latter is an almost ubiquitous reaction product of 3 which is formed via a central, equally frequently occurring intermediate in vitamin E chemistry, the α-tocopherol-derived ortho-quinone methide (3-QM). The formation of this intermediate with the selective involvement of C-5a is a peculiarity of α-tocophorol that has been comprehensively studied (Rosenau et al. 2002, 2005b). Its dimerization, from the viewpoint of mechanism a hetero-Diels–Alder reaction with inverse electron demand, generates the spiro-dimer of α-tocopherol (11). Both para-quinone and spiro-dimer are intensively yellow compounds.

Four reaction products were isolated from spinning dopes containing N-methyl-α-tocopheramine (4) as the stabilizer (Scheme 5). α-Tocopheramine is the less well-known sibling of the prominent antioxidant α-tocopherol (Itoh et al. 1994, Smith et al. 1942). One of them, para-tocopherylquinone (10) was also isolated as direct degradation product of α-tocopherol. It was the major component in the mixture of degradation products. N-Methyl-α-tocopheramine (4) also formed a spiro-dimer (12) as oxidation product, although contained only in traces. We assumed that the formation mechanism, by analogy to α-tocopherol, involves an ortho-quinoid intermediate – in this case an iminoquinone methide (4-IQM) – which dimerizes to the spiro-compound 12, a methyl-aza (aminomethyl) analogue of spiro-dimer 11. Considering the small amounts of 12 formed, the dimerization seems to be less favored than in the α-tocopherol case, either by steric reasons (C = O vs. C = N-CH3) or by less favorable HOMO–LUMO gaps. As the third chromophoric component, ortho-quinone 13, the so-called “α-tocored”, was formed. This compound is well-known as an oxidation-rearrangement product of α-tocopherol (Rosenau et al. 1997), its color being obvious from its pseudonym. The two other degradation products of 4, para-tocopherylquinone (10) and spiro-dimer 12, are yellow compounds.

A side remark seems necessary to clarify why the mono-N-methyltocopheramine was used and what distinguishes it from the parent (non-methylated) tocopheramine and the N,N-dimethyl derivative. Notably, the N-methyl group in 4 prevents formation of the dark red azo-tocopherol, a common oxidation product of α-tocopheramine. Also, the direct N-oxidation is significantly suppressed – if not even completely prevented: no corresponding products were found. In particular, the intensively yellow colored and irritant 5-deoxy-5-nitro-α-tocopherol (Patel et al. 2007) was absent. The N,N-dimethyl analogue is the starting material for preparation of 4 which is obtained by its simple one-pot demethylation (Rosenau et al. 2004b) rather than by methylation of tocopheramine, which gives hard-to-separate product mixtures.

Conclusions

In the presented study, we report the identification of the main chromophoric degradation products from four natural antioxidants which were used to stabilize the spinning dopes. The chromophores, along with unused stabilizers and some non-chromophoric degradation products, were directly isolated from the fiber spinning bath by extraction with inert organic solvents. The extraction procedure was optimized. The identification of the degradation products was based on the compounds´ NMR data with full resonance assignment on the 1H and 13C domain, complemented by comparison with an independent authentic sample which was either available from previous work or synthesized separately. Only after confirmation of identity with the reference was the structure of the compound considered established.

Future work will now have to address two issues. Firstly, aging tests with the spun fibers must establish their aging and brightness behavior. It is known that the spun fibers still contain some of the stabilizer used. This could be positive due to their continued stabilizing effect, but on the other hand it could also be negative due to the formation of new degradation products. It must therefore be determined whether the residual stabilizers also form chromophoric degradation products in the fibers, and whether the degradation products generated upon fiber aging (under ambient conditions) are identical to those generated in the spinning bath (in the presence of IL and higher temperatures). Second, washing or bleaching treatments need to be designed and optimized so that the chromophore traces still adhering to the fibers are completely removed or destroyed. Now that their chemical structures are known, this can be done in a targeted manner.

Data availability

No datasets were generated or analysed during the current study.

Code availability

Not applicable.

References

Adegoke GO, Vijay Kumar M, Gopala Krishna AG, Varadaraj MC, Sambaiah K, Lokesh BR (1998) Antioxidants and lipid oxidation in foods - a critical appraisal. J Food Sci Technol 35(4):283–298

Ahn K, Zaccaron S, Zwirchmayr NS, Hettegger H, Hofinger H, Bacher M, Henniges U, Hosoya T, Potthast A, Rosenau T (2019) Yellowing and brightness reversion of celluloses: CO or COOH, who is the culprit? Cellulose 26:429–444

Asaadi S, Kakko T, King AWT, Kilpeläinen I, Hummel M, Sixta H (2018) High-performance acetylated Ioncell-F fibers with low degree of substitution. ACS Sust Chem Eng 6(7):9418–9426

Bayraktar O (2018) Silk fibroin nanofibers loaded with hydroxytyrosol from hydrolysis of oleuropein in olive leaf extract. Textile Leather Rev 1(3–4):90–98

Brownstein S, Burton GW, Hughes L, Ingold KU (1989) Chiral effects on the carbon-13 resonances of alpha-tocopherol and related compounds. A novel illustration of Newman’s “rule of six.” J Org Chem 54(3):561

Britton J, Davis R, O’Connor KE (2019) Chemical, physical and biotechnological approaches to the production of the potent antioxidant hydroxytyrosol. Appl Microbiol Biotechnol 103(15):5957–5974

Catala A (2012) Tocopherol: Sources, uses and health benefits. Nova Science Pub Inc., UK

Dahe GJ, Teotia RS, Kadam SS, Bellare JR (2011) The biocompatibility and separation performance of antioxidative polysulfone/vitamin E TPGS composite hollow fiber membranes. Biomaterials 32(2):352–365

Ding T, Li T, Li J (2019) Preparation of coaxial polylactic acid-propyl gallate electrospun fibers and the effect of their coating on salmon slices during chilled storage. ACS Appl Mat Interfaces 11(6):6463–6474

Ebner G, Schiehser S, Potthast A, Rosenau T (2008) Side reaction of cellulose with common 1-alkyl-3-methylimidazolium-based ionic liquids. Tetrahedron Lett 49:7322–7324

Fortunati E, Luzi F, Dugo L, Fanali C, Tripodo G, Santi L, Kenny JM, Torre L, Bernini R (2016) Effect of hydroxy-tyrosol methyl carbonate on the thermal, migration and antioxidant properties of PVA-based films for active food packaging. Polymer Int 65(8):872–882

Fortunati E, Luzi F, Fanali C, Dugo L, Belluomo GM, Torre L, Kenny JM, Santi L, Bernini R (2017) Hydroxytyrosol as active ingredient in poly(vinyl alcohol) films for food packaging applications. J Renew Mat 5(2):81–95

Ghaheh FS, Khoddami A, Alihosseini F, Jing S, Ribeiro A, Cavaco-Paulo A, Silva C (2017) Antioxidant cosmetotextiles: Cotton coating with nanoparticles containing vitamin E. Process Biochem 59:46–51

Guizani C, Larkiala S, Moriam K, Sawada D, Elsayed S, Rantasalo S, Hummel M, Sixta H (2021) Air gap spinning of a cellulose solution in [DBNH][OAc] ionic liquid with a novel vertically arranged spinning bath to simulate a closed loop op-eration in the Ioncell® process. J Appl Polym Sci 138(5):49787

Haddar W, Baaka N, Meksi N, Ticha MB, Guesmi A, Mhenni MF (2015) Use of ultrasonic energy for enhancing the dyeing performances of polyamide fibers with olive vegetable water. Fibers Polym 16(7):1506–1511

Hettegger H, Zhang J, Koide M, Rinner U, Potthast A, Gotoh Y, Rosenau T (2022) Fiber spinning from cellulose solutions in imidazolium ionic liquids: Effects of natural antioxidants on molecular weight, dope discoloration and yellowing behavior. Fibers 10(6):50

Hosoya T, Bacher M, Potthast A, Elder T, Rosenau T (2018) Insights into degradation pathways of oxidized anhydroglucose units in cellulose by β-alkoxy-elimination – a combined theoretical and experimental approach. Cellulose 25(7):3797–3814

ISO 2470-1 (2009) Measurement of diffuse blue reflectance factor – Part 1: indoor daylight conditions (ISO brightness). International Organization for Standardization, Geneva, Switzerland

IUPAC-IUB Commission on Biochemical Nomenclature (CBN) (1974) Arch Biochim Biophys 165:1

IUPAC-IUB Commission on Biochemical Nomenclature (CBN) (1982) Eur J Biochim 123:473

Itoh S, Nagaoka SI, Mukai K, Ikesu S, Kaneko Y (1994) Kinetic study of quenching reactions of singlet oxygen and scavenging reactions of free radicals by α-, β-, λ- and σ-tocopheramines in ethanol solution and micellar dispersion. Lipids 29(11):799–802

Korntner P, Hosoya T, Dietz T, Eibinger K, Reiter H, Spitzbart M, Röder T, Borgards A, Kreiner W, Mahler AK, Winter H, French AD, Henniges U, Potthast A, Rosenau T (2015) Chromophores in lignin-free cellulosic materials belong to three compound classes. Chromophores in cellulosics, XII. Cellulose 22(2):1053–1062

Liebner F, Ebner G, Becker E, Potthast A, Rosenau T (2010) Thermal aging of 1-alkyl-3-methylimidazolium ionic liquids and its effect on dissolved cellulose. Holzforschung 64:161–166

Patel A, Liebner F, Netscher T, Mereiter K, Rosenau T (2007) Nitration of non-alpha tocopherols – products and mech-anistic considerations. J Org Chem 72(17):6504–6512

Peltzer M, Navarro R, López J, Jiménez A (2010) Evaluation of the melt stabilization performance of hydroxytyrosol (3,4-dihydroxy-phenylethanol) in polypropylene. Polym Degrad Stab 95(9):1636–1641

Preedy VR, Watson RR (eds) (2007) Encyclopedia of vitamin E. CABI Publishing, Oxford, Cambridge

Quiles JL, Ramírez-Tortosa MC, Yaqoob P (eds) (2006) Olive oil and health. CABI Publishing, UK

Rosenau T, Gruner M, Habicher WD (1997) Novel tocopherol compounds VIII reaction mechanism of the formation of α-tocored. Tetrahedron 53:3571–3576

Rosenau T, Potthast A, Elder T, Kosma P (2002) Novel tocopheryl compounds XIII. Stabilization and first direct spectroscopic evidence of the ortho-quinone methide derived from vitamin E. Org Lett 4(24):4285–4288

Rosenau T, Potthast A, Milacher W, Hofinger A, Kosma P (2004a) Isolation and identification of residual chromophores in cellulosic materials. Polymer 45(19):6437–6443

Rosenau T, Hofinger A, Potthast A, Kosma P (2004b) A general, selective high-yield N-demethylation procedure for tertiary amines by solid reagents in a convenient column chromatography-like setup. Org Lett 6(4):541–544

Rosenau T, Potthast A, Milacher W, Adorjan I, Hofinger A, Kosma P (2005a) Discoloration of cellulose solutions in N-methylmorpholine-N-oxide (Lyocell). Part 2: Isolation and identification of chromophores Cellulose 12(2):197–208

Rosenau T, Ebner G, Stanger A, Perl S, Nuri L (2005b) From a theoretical concept to biochemical reactions: strain in-duced bond localization (SIBL) in oxidation of vitamin E. Chem Eur J 11(1):280–287

Schröder H, Netscher T (2001) Determination of the absolute stereochemistry of vitamin E derived oxa-spiro compounds by NMR spectroscopy. Magn Reson Chem 39:701–708

Sixta H, Iakovlev M, Testova L, Roselli A, Hummel M, Borrega M, van Heiningen A, Froschauer C, Schottenberger H (2013) Novel concepts of dissolving pulp production. Cellulose 20(4):1547–1561

Sixta H, Michud A, Hauru L, Asaadi S, Ma Y, King AWT, Kilpeläinen I, Hummel M (2015) Ioncell-F: a high-strength regenerated cellulose fibre. Nordic Pulp Paper Res J 30(1):43–57

Smith LI, Renfrow WB, Opie JW (1942) The chemistry of vitamin E. XXXVIII. α-tocopheramine, a new vitamin E factor. J Amer Chem Soc 64:1082–1084

Stepan AM, Michud A, Hellstén S, Hummel M, Sixta H (2016) IONCELL-P&F: pulp fractionation and fiber spinning with ionic liquids. Ind Engin Chem Res 55(29):8225–8233

Urano S, Matsuo M (1980) 13C nuclear magnetic resonance studies on alpha-tocopherol and its derivatives. Chem Pharm Bull 28(7):1992

Wendler F, Meister F, Heinze T (2005) Studies on the thermostability of modified Lyocell dopes. Macromol Symp 223:213–224

Wu HL, Bremner DH, Li HY, Shi QQ, Wu JZ, Xiao RQ, Zhu LM (2016) A novel multifunctional biomedical material based on polyacrylonitrile: preparation and characterization. Mat Sci Engin C 62:702–709

Yamauchi R, Matsui T, Kato K, Ueno Y (1990) Reaction products of γ-tocopherol with an alkylperoxyl radical in benzene. Agric Biol Chem 54(10):2703–2709

Yokota S, Kitaoka T, Opietnik M, Rosenau T, Wariishi H (2008) Synthesis of gold nanoparticles for in situ conjugation with structural carbohydrates. Angew Chem Int Ed Engl 47:9866–9869

Zhang J, Kitayama H, Potthast A, Rosenau T, Gotoh Y (2019) Non-woven fabrics of fine regenerated cellulose fibers prepared from ionic-liquid solution via wet type solution blow spinning. Carbohydr Polym 226:115258

Zhang J, Yamagishi N, Gotoh Y, Potthast A, Rosenau T (2020) High performance cellulose fibers regenerated from 1-Butyl-3-methylimidazolium chloride solution: effects of viscosity and molecular weight. J Appl Polym Sci 137(19):48681–48688

Zweckmair T, Hettegger H, Abushamalla H, Bacher M, Potthast A, Laborie MP, Rosenau T (2015) On the mechanism of the unwanted acetylation of polysaccharides by 1,3-dialkylimidazolium acetate ionic liquids. Part 1: analysis, acetylating agent, influence of water, and mechanistic considerations. Cellulose 22(6):3583–3596

Acknowledgments

We would like to thank BOKU University and the county of Lower Austria for their financial support through the framework of the Austrian Biorefinery Center Tulln (ABCT-II).

Funding

Open access funding provided by University of Natural Resources and Life Sciences Vienna (BOKU). The financial support by the Austrian Biorefinery Center Tulln (ABCT-II) is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study's conception and design. Material preparation, data collection and analysis were performed by all authors. The first draft of the manuscript was written by T.R. All authors commented on previous versions and read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

All authors agreed to the publication in the submitted form.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rosenau, T., Zhang, J., Koide, M. et al. Chromophores in spinning dopes of cellulose and imidazolium ionic liquids. Cellulose 31, 4203–4215 (2024). https://doi.org/10.1007/s10570-024-05895-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-024-05895-9