Abstract

A commercial TEMPO-oxidized cellulose (TOC) and three laboratory-made TOC samples prepared under different conditions were converted to aqueous 0.4% dispersions of TEMPO-oxidized cellulose nanofibrils (TEMPO-CNFs) by high-pressure homogenization in water under the same conditions. The obtained TEMPO-CNF/water dispersions were irradiated with ultraviolet (UV) light for 0–48 h using a high-pressure mercury lamp at a main wavelength of 365 nm. The changes in the light transmittance, viscosity, pH, zeta-potential, and average particle size of the dispersions, and mass recovery ratio, molar mass, and carboxylate content of the acid-insoluble and freeze-dried fractions separated and isolated from the UV-irradiated dispersions were investigated. The results were analyzed in terms of the UV-irradiation time. The dispersion pH, and the mass recovery ratio, carboxylate content, and mass-average degree of polymerization (DPw) of the acid-soluble fraction decreased with increasing UV-irradiation time. This shows that some acid-soluble acidic compounds were formed from the TEMPO-CNFs via UV-induced depolymerization, degradation, and removal of carboxylate groups from the TEMPO-CNFs in water, depending on the UV-irradiation time. The average CNF length, which was determined from atomic force microscopy images, decreased with increasing UV-irradiation time. After UV irradiation of dispersions of the laboratory-made TEMPO-CNFs for 12 h, the average CNF lengths were 130–150 nm and their length distributions were narrower. UV irradiation of TEMPO-CNF/water dispersions is therefore a promising method for efficiently decreasing the dispersion viscosity, DPw, and average CNF length, depending on the TEMPO-CNF properties and UV-irradiation conditions.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Materials are inevitably affected by various environmental factors such as humidity, temperature, gases, and light irradiation. Ultraviolet (UV) irradiation is a primary source of damage to cellulosic materials under ambient conditions. Not only lignin- or hemicellulose-rich paper materials but also pure cellulose materials tend to be discolored, and their mechanical properties deteriorate, on exposure to UV light, depending on the UV-irradiation conditions (Schmidt et al. 1995; Malešič et al. 2005). Cellulose shows pronounced absorption in the near-UV spectral region, and cellulose molecules undergo photooxidative reactions (Hon 1975, 1979; Ogiwara and Kubota 1973; Malešič et al. 2005). Various types of reactive species are generated from cellulose during UV irradiation, and this leads to increases in the numbers of carbonyl, carboxy, and hydroperoxide groups in and from UV-irradiated cellulose materials along with partial depolymerization (Malešič et al. 2005; Auger et al. 2018). The UV-induced photodegradation of cellulose molecules also results in anisotropic position-selective degradation of cellulose fibers as a result of heterogeneous UV-light/solid reactions. Understanding the photodegradation behavior of cellulose under UV irradiation is therefore of great importance.

Cellulose nanofibril (CNFs) and cellulose nanocrystals (CNCs) prepared from abundant plant resources are promising bio-based nanomaterials because of their low densities, nanoscale morphologies, surface chemical structures, and large surface areas (Klemm et al. 2011; Moon et al. 2011; Isogai 2013, 2018; Li et al. 2021). Various chemical pretreatments of cellulose materials such as wood, ramie, cotton, bacterial, and tunicate cellulose materials have been reported to achieve efficient conversions to CNFs or CNCs by mechanical disintegration in water (Isogai 2021). When 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) is used as a catalyst for the oxidation of wood cellulose with NaBr and NaOCl in water at pH ~ 10, large amounts of sodium carboxylate groups are efficiently, densely, and position-selectively formed from the C6–OH groups present on the crystalline cellulose microfibril surfaces, depending on the oxidation conditions and cellulose sources (Isogai et al. 2018).

When TEMPO-oxidized cellulose (TOC) fibers with sodium carboxylate contents greater than approximately 1 mmol/g are prepared from wood cellulose fibers such as bleached kraft pulps by TEMPO catalytic oxidation in water, the TOC fibers can be converted to transparent and highly viscous TEMPO-oxidized cellulose nanofibril (TEMPO-CNF)/water dispersions with large average CNF lengths, i.e., > 500 nm, and homogeneous and small CNF widths of ~ 3 nm (i.e., aspect ratios > 160) by gentle mechanical disintegration in water (Isogai et al. 2011). High-aspect-ratio TEMPO-CNFs are preferable for improving the mechanical properties of polymer/TEMPO-CNF composite materials with small CNF contents (Soeta et al. 2015; Noguchi et al. 2023). However, TEMPO-CNF/water dispersions consisting of TEMPO-CNFs with high aspect ratios are highly viscous and have low CNF concentrations, i.e., < 2%. Such TEMPO-CNF/water dispersions are therefore difficult to handle and store, their delivery costs are high, and their coating and/or drying involve high energy consumption.

In some applications, it is therefore necessary to reduce the dispersion viscosity and increase the CNF concentration by efficiently decreasing the average CNF length. In our previous study, TEMPO-CNF/water dispersions were subjected to ultrasonication for lengthy time periods, i.e., up to 120 min. Needle-like TEMPO-CNCs of average length < 200 nm were quantitatively obtained from TEMPO-CNFs. This resulted in an increase in the gelation (or network formation) concentration from 0.4% for the original TEMPO-CNFs to 1.7% after ultrasonication (Zhou et al. 2018, 2019). However, prolonged ultrasonication involves higher electric-power consumption, and is not an efficient method for decreasing the dispersion viscosity or average CNF length. UV irradiation is another method for simultaneously decreasing the average CNF length and viscosity by appropriate amounts. However, to the best of our knowledge, UV irradiation of TEMPO-CNF/water dispersions has not been studied. In addition to efficient reduction of the viscosity and average length of TEMPO-CNFs, some side reactions caused by UV-induced degradation of TEMPO-CNFs are anticipated, depending on the conditions.

In this study, TEMPO-CNF/water dispersions were prepared from a commercial TOC and three laboratory-made TOC samples by high-pressure homogenization in water. The 0.4% TEMPO-CNF/water dispersions were UV-irradiated for 0–48 h to prepare UV-irradiated TEMPO-CNF/water dispersions and UV-irradiated and freeze-dried TEMPO-CNFs because of their potential applications in functional dispersions and nanomaterials. It was expected that the high viscosities of TEMPO-CNF/water dispersions containing CNFs with large average lengths would be efficiently reduced. This would improve the handling, coating, and drying of TEMPO-CNF/water dispersions by increasing their CNF concentrations.

Materials and methods

Samples

Never-dried softwood bleached kraft pulp (SBKP) and a commercial TOC (with protonated carboxy groups, produced from SBKP) were kindly provided by Nippon Paper (Tokyo, Japan). Trimethylsilyldiazomethane (2 M, TMSD) in diethyl ether was obtained from Sigma-Aldrich (USA). TEMPO, NaBr, NaOCl solution (2 M), NaOH, NaBH4, and other reagents and solvents were laboratory grade (Fujifilm Wako Chemicals Co., Ltd., Tokyo, Japan) and used as received.

Preparation of TEMPO-CNF/water dispersions

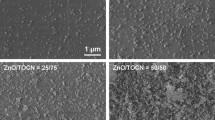

Laboratory-made TOC samples with sodium carboxylate groups were prepared from SBKP in a TEMPO/NaBr/NaOCl system in water at pH 10 with NaOCl of concentrations 3.8, 5.0, and 10.0 mmol/g-SBKP, and subsequent reduction with NaBH4, according to previously reported methods (Shinoda et al. 2012; Takaichi et al. 2014). The samples were assigned the codes TOC (3.8), TOC (5.0), and TOC (10.0). The obtained TOC samples with protonated carboxy groups were stored in the never-dried state at 4 °C before use. These TOC samples were dispersed in water, and the pH was adjusted to 8–9 by addition of 0.05 M NaOH to the TOC/water slurry. A 0.4% TEMPO-CNF/water dispersion was prepared by mechanical disintegration of the slurry at 120 MPa using a high-pressure homogenizer (Star Burst Labo HJP-25005 × , Sugino Machine Ltd., Toyama, Japan); three passes were performed. The small unfibrillated fraction was removed by centrifugation at 12,000 × g for 15 min; the supernatant was a transparent TEMPO-CNF/water dispersion. Partial removal of water from the TEMPO-CNF/water dispersions by rotary evaporation at 40 °C was performed to accurately adjust the TEMPO-CNF concentrations to 0.4%; the adjustments were based on the dry masses of the unfibrillated fractions removed by centrifugation. The 0.4% TEMPO-CNF/water dispersions prepared from the commercial TOC and laboratory-made TOC samples were assigned the codes c-TEMPO-CNFs, TEMPO-CNFs (3.8), TEMPO-CNFs (5.0), and TEMPO-CNFs (10.0).

UV irradiation of TEMPO-CNF/water dispersions

A photochemical reaction system (VG500 + HB100P-1(5/6) + JW-1Q(1G) + HL100GL-1, Sen Light Corporation, Japan) equipped with a high-pressure mercury lamp (50 Hz) with the main wavelength at 365 nm was used to provide homogeneous UV irradiation of the TEMPO-CNF/water dispersions (Fig. S1 in the Electronic Supplementary Material). The TEMPO-CNF/water dispersion (500 mL) was placed in the reactor and continuously stirred at ~ 25 °C temperature using a magnetic stirring bar. After UV irradiation for a designated time, a portion of the UV-irradiated TEMPO-CNF/water dispersion was separated and its UV–vis transmittance, shear viscosity/shear rate relationship, dispersion pH, average zeta-potential, and average particle size were determined. Atomic force microscopy (AFM) images of the dispersions were collected after dilution with water to give ~ 0.0001% TEMPO-CNF/water dispersions. A HCl solution (1 M) was added to another portion of the UV-irradiated TEMPO-CNF/water dispersion to pH ~ 2, and the acid-insoluble and -soluble fractions were separated by centrifugation at 12,000×g for 15 min (Homma et al. 2013). The acid-insoluble fraction in the UV-irradiated TEMPO-CNF/water dispersion was washed thoroughly with water by centrifugation, and then freeze-dried. Ethanol was added to the acid-soluble fraction, and the precipitate was washed thoroughly with ethanol and dissolved in water. The ethanol was removed by evaporation and the fraction was freeze-dried.

SEC/MALLS analysis of acid-insoluble fractions

The mass- and number-average molar masses (Mw and Mn, respectively) were determined by performing size-exclusion chromatography with multi-angle laser-light scattering (SEC/MALLS) on the freeze-dried acid-insoluble fractions in the UV-irradiated TEMPO-CNF/water dispersions after position-selective methylation of the carboxy groups with TMSD in N,N-dimethylacetamide (DMAc) (Hiraoki et al. 2014). The methylated sample (~ 8 mg) was dissolved in 8% LiCl/DMAc (2 mL) by stirring the mixture at room temperature for 1 week. The clear solution was diluted with fresh DMAc to 1% LiCl/DMAc, and subjected to SEC/MALLS analysis with 1% LiCl/DMAc as the eluent. The Mw and Mn values were calculated from the SEC/MALLS data using ASTRA software (version 6.1, Wyatt Technologies, USA) (Hiraoki et al. 2015; Ono and Isogai 2021). The mass- and number-average degrees of polymerization (DPw and DPn, respectively) of the UV-irradiated TEMPO-CNFs were calculated from their Mw and Mn values, and the carboxylate contents of the TEMPO-CNFs.

Other analyses

UV–vis light transmittance spectra of the UV-irradiated TEMPO-CNF/water dispersions were recorded with a V-670 UV–vis spectrophotometer (JASCO, Tokyo, Japan). The viscosities of the TEMPO-CNF/water dispersions were determined using a rotational rheometer (MCR 302, Anton Paar GmbH, Graz, Austria) with a cone–plate geometry (plate diameter 50 mm, angle 2°). Viscosity flow curves were obtained at shear rates of 0.001–1000 (1/s) at 25 °C. Dynamic light scattering and zeta-potential measurements were performed on the TEMPO-CNF/water dispersions at 25 °C using a particle analyzer (DelsaNano HC, Beckman Coulter, Inc., CA, USA) after dilution of the dispersions with water to ~ 0.04%. The carboxylate contents of the UV-irradiated TEMPO-CNFs were determined using an electric conductivity titration method (Zhou et al. 2018).

The pH of each UV-irradiated TEMPO-CNF/water dispersion was adjusted to neutral, and the dispersion was centrifuged at 12,000×g for 15 min to remove TEMPO-CNF aggregates partly formed by UV irradiation. The supernatant was diluted to ~ 0.0001%, a drop (10 μL) of the dispersion was placed on a freshly cleaved mica surface of area ~ 1 cm2 and then dried in a vacuum oven at 60 °C for 30 min. AFM images of the TEMPO-CNFs were collected (NanoScopeV/MultiMode 8, Bruker, Billerica, MA, USA). The PeakForce QNM imaging mode was adopted, using a cantilever with a spring constant of 0.4 N/m and a SCANASYST-AIR probe (Bruker) at a resonance frequency of 70 kHz (Zhou et al. 2018). The lengths and heights of the isolated CNFs (n = approximately 200 for each sample) in the AFM images were measured using NanoScope Analysis 1.70 software and ImageJ software.

The freeze-dried samples were pressed to disk pellets and subjected to X-ray diffraction (XRD) using a diffractometer (Rigaku RINT 2000, Tokyo, Japan) with monochromated Cu Kα radiation (λ = 0.15418 nm) at 40 mV and 40 mA; the reflection method was used. The freeze-dried samples were subjected to solid-state cross polarization/magic angle sample spinning 13C-NMR analysis (JNM-ECA II 500, JEOL, Tokyo, Japan) (Funahashi et al. 2017; Ono et al. 2022). Each spectrum was acquired by performing 12,000 scans over 16 h.

Results and discussion

Changes in properties of c-TEMPO-CNF/water dispersions induced by UV irradiation

In preliminary experiments, a 0.4% dispersion of a commercial TEMPO-CNF sample (c-TEMPO-CNFs) was UV-irradiated for up to 48 h. The changes in the UV–vis light transmittance and shear viscosity/shear rate relationship caused by UV irradiation of the c-TEMPO-CNF/water dispersion were investigated (Fig. 1a). The c-TEMPO-CNF/water dispersion retained its original transparency for up to 12 h. However, UV irradiation for 24 and 48 h decreased the UV–vis light transparency. This shows that the originally stable c-TEMPO-CNF/water dispersion was transformed by formation of water-non-dispersible gel particles.

The shear viscosity of the 0.4% c-TEMPO-CNF/water dispersion at a shear rate of 1/s was decreased by UV irradiation for up to 6 h, and the dispersions did not show clear shear-thinning behavior. At 0.4%, the concentration of the c-TEMPO-CNF/water dispersion was probably lower than the gelation or network-formation concentration of c-TEMPO-CNFs (Zhou et al. 2019). It is possible that the lengths of some of the c-TEMPO-CNFs decreased under UV irradiation for 2–6 h, which resulted in a decrease in the shear viscosity. The shear viscosity of the c-TEMPO-CNF/water dispersion increased at a 1/s shear rate under UV irradiation for 12 h, but those of samples UV-irradiated for 24 and 48 h decreased (Fig. S2 in the Electronic Supplementary Material). Clear shear-thinning behavior was observed for these three UV-irradiated dispersions, probably because of partial formation of network structures among c-TEMPO-CNFs in water.

The changes in pH, average zeta-potential, and average particle size were determined for the 0.4% c-TEMPO-CNF/water dispersion under UV irradiation for 0–48 h. The pH of the dispersion decreased from 5.9 to 3.5 with increasing UV-irradiation time up to 48 h. This shows that acidic compounds formed from c-TEMPO-CNFs by UV irradiation were present in the dispersion. TEMPO-CNFs are nanodispersible in water because large amounts of anionic carboxylate groups are densely and position-selectively present on the CNF surfaces. The pKa values of the C6-carboxy groups of polyglucuronic acids are ~ 3.5 (Zhu et al. 2004), therefore the UV-irradiated c-TEMPO-CNFs, if their chemical structures were unchanged, could be nanodispersed in water even at pH ~ 3.5 by almost complete dissociation of the carboxy groups, as in the case of the original dispersion. However, the formation of acidic compounds from c-TEMPO-CNFs under UV irradiation may have decreased the amount of anionic carboxylate groups in the UV-irradiated c-TEMPO-CNFs. Consequently, the anionic zeta-potentials decreased, and gel particles were formed in the dispersion. This resulted in the average particle size, calculated on the assumption that the particles were spherical, increasing from ~ 200 nm to ~ 4.8 μm during UV irradiation for 48 h. The results shown in Figs. 1 and 2 suggest that UV irradiation of the 0.4% c-TEMPO-CNF/water dispersion for < 10 h is best for obtaining UV-irradiated TEMPO-CNF/water dispersions with similar UV–vis light transmittance spectra, average zeta-potentials, and average particle sizes to those of the original dispersion but with lower shear viscosities.

The acid-insoluble fraction, which consisted of high-molar-mass and nanofibrous compounds, was separated from the acid-soluble, and presumably low-molar-mass, fraction in the UV-irradiated c-TEMPO-CNFs (Homma et al. 2013), according to the scheme shown in Fig. S1 in the Electronic Supplementary Material. Figure 3 shows plots of the mass recovery ratio and carboxylate content of the acid-insoluble fraction against the UV-irradiation time (Fig. 3). Both the mass recovery ratio and carboxylate content decreased with increasing UV-irradiation time. UV-induced degradation of the c-TEMPO-CNF molecules therefore occurred and acid-soluble and low-molar-mass compounds were formed in association with partial removal of carboxylate groups from the c-TEMPO-CNF surfaces. This UV-induced degradation of the c-TEMPO-CNFs caused the changes in the dispersion properties shown in Figs. 1 and 2.

The pH of the dispersion decreased with increasing UV-irradiation time (Fig. 2), which indicates that UV irradiation induced formation of some acidic groups from the c-TEMPO-CNFs. However, the carboxylate content of the acid-insoluble fraction decreased under UV irradiation (Fig. 3). Water-soluble and low-molar-mass acidic compounds (which cause the dispersion pH to decrease) formed from the c-TEMPO-CNFs by UV irradiation were therefore present in the acid-soluble and low-molar-mass fractions.

The relationship between the carboxylate content and mass recovery ratio of the acid-insoluble fraction is shown in Fig. S3 in the Electronic Supplementary Material. A linear relationship was observed between these two factors, which shows that the mass recovery ratio of the acid-insoluble fraction decreased with decreasing content of anionic carboxylate groups. In general, TOC or pulp samples with carboxylate contents < 0.4 mmol/g cannot be completely converted to individual TEMPO-CNFs with homogeneous ~ 3 nm widths, even after harsh mechanical disintegration in water, because of their low carboxylate contents (Isogai et al. 2011). However, the results in Fig. S3 indicate that TEMPO-CNFs with such low carboxylate contents, i.e., < 0.4 mmol/g, are nanodispersible in water, probably because of the low molar-mass values of the UV-irradiated TEMPO-CNFs (as described in the following section) when the samples were prepared from a c-TEMPO-CNF/water dispersion by UV irradiation.

Changes in M w and M n values of acid-insoluble fractions in c-TEMPO-CNF/water dispersion induced by UV irradiation

Figure 4 shows the changes in the molar-mass plots and SEC-elution patterns, and the corresponding Mw, Mn, and Mw/Mn values for the acid-insoluble fractions in a UV-irradiated c-TEMPO-CNF/water dispersion. The carboxylate-group-containing compounds in the fractions were position-selectively methyl-esterified to enable complete dissolution in 8% LiCl/DMAc. The solution was then diluted to 1% LiCl/DMAc before SEC/MALLS analysis. The calculated mass values obtained by SEC/MALLS (Ono and Isogai 2021) show that all the fractions were almost completely dissolved in 8% LiCl/DMAc after methylation, and their SEC-elution patterns were detected.

All the acid-insoluble fractions gave molar-mass plots on the same line against the SEC-elution volume. This shows that all the molecules have the same conformations in 1% LiCl/DMAc. UV irradiation caused the peak-top position of the SEC-elution pattern to shift to a higher elution volume or smaller radius of gyration. The samples prepared by UV irradiation for 12 and 24 h gave bimodal SEC-elution patterns. Figure 4b shows that Mw and Mn decreased sharply from 64000 and 24100 g/mol, respectively, for the original c-TEMPO-CNFs, to 19500 and 8400 g/mol, respectively, during UV irradiation for 12 h, and then gradually decreased to 14600 and 6500 g/mol during UV irradiation for 48 h. These Mw values of 64000, 19500, and 14600 g/mol correspond to DPw values of 380, 120, and 90, respectively; the DPw values were calculated from the Mw values of the acid-insoluble fractions and their carboxylate contents (Fig. S4 in the Electronic Supplementary Material). Considerable depolymerization of the c-TEMPO-CNFs therefore occurred, and the extent depended on the conditions used for UV irradiation of the dispersion.

UV irradiation of laboratory-made TEMPO-CNF/water dispersions

On the basis of the results discussed in the previous sections, three TOCs were prepared from SBKP by using TEMPO/NaBr/NaOCl systems with different concentrations of NaOCl, i.e., 3.8, 5.0, and 10.0 mmol/g-SBKP. The corresponding TEMPO-CNF/water dispersions were prepared by high-pressure homogenization of TOC/water slurries under the same conditions to prepare aqueous dispersions of TEMPO-CNFs (3.8), TEMPO-CNFs (5.0), and TEMPO-CNFs (10.0). The TEMPO-CNF (3.8) sample was expected to have the highest Mw and largest average CNF length because the CNF molecules would be less damaged because the lowest amount of NaOCl was used as the primary oxidant (Ono et al. 2021).

Figure 5 shows 0.4% TEMPO-CNF(3.8)/water dispersions after UV irradiation for 0–12 h. The dispersions prepared by UV irradiation for 6 and 12 h were transparent, as in the case of the original dispersion (Fig. 5a), and showed birefringence between cross-polarizers. However, after UV irradiation for 24 h the dispersion was cloudy because of the formation of water-non-dispersible gel particles in the dispersion (Fig. 5b), similarly to the results obtained for the c-TEMPO-CNF/water dispersion (Figs. 1a and 2). The photographs in Fig. 5c show that the flow behaviors of the dispersions were the same as those observed for the UV-irradiated c-TEMPO-CNF/water dispersion. The viscosity of the TEMPO-CNF (3.8)/water dispersion decreased and then increased under UV irradiation for 6 and 12 h, respectively. The viscosity decreased again under UV irradiation for 24 h. These decreasing, increasing, and decreasing behaviors of the dispersion correlate well with the results shown in Fig. S2 in the Electronic Supplementary Material for the 0.4% c-TEMPO-CNF/water dispersion.

The mass recovery ratio and carboxylate content of the acid-insoluble fraction decreased with increasing UV-irradiation time of the three TEMPO-CNF/water dispersions (Fig. 6), similarly to those obtained for the c-TEMPO-CNF/water dispersion in the previous section (Fig. 3). Thus, the C6-carboxylate groups are removed from the TEMPO-CNFs by UV irradiation of the dispersions, associated with the decrease in mass recovery ratio.

The molar-mass plots and SEC-elution patterns of the acid-insoluble fractions prepared from the three 0.4% TEMPO-CNF/water dispersions after UV irradiation for 0–12 h are shown in Fig. 7a, b, and c. The corresponding Mw, Mn, and Mw/Mn values calculated from the SEC/MALLS data are plotted against the UV-irradiation time in Fig. 7d. Before UV irradiation, each of the three TEMPO-CNFs gave a broad main peak and a small shoulder peak at SEC-elution volumes of 6–9 and 9–11 mL, respectively. These SEC-elution patterns differ from that of the c-TEMPO-CNFs, which showed a single peak at a SEC-elution volume of 7–11 mL (Fig. 4a).

SEC-elution patterns and corresponding molar-mass plots for acid-insoluble fractions of a TEMPO-CNFs(3.8), b TEMPO-CNFs(5.0), and TEMPO-CNFs(10.0) after UV irradiation of dispersions for 0, 6, and 12 h, and d their mass- and number-average molar masses (Mw and Mn, respectively) and Mw/Mn values. Dashed line in a, b, and c shows molar-mass plots for c-TEMPO-CNFs (Fig. 4a)

The Mw values of the laboratory-made TEMPO-CNFs(3.8), TEMPO-CNFs(5.0), and TEMPO-CNFs(10.0) before UV irradiation were 389,000, 340,000, and 299,000 g/mol (corresponding to DPw values of 2320, 2030, and 1750, respectively), whereas that of the c-TEMPO-CNFs was 64,000 g/mol (i.e., DPw = 380). The molar masses of the laboratory-made TEMPO-CNFs were therefore much higher than that of the c-TEMPO-CNFs. The Mw values of the TEMPO-CNFs before UV irradiation decreased with increasing addition of NaOCl during TEMPO-mediated oxidation from 3.8 to 10.0 mmol/g-SBKP. This is because oxidative depolymerization of cellulose molecules occurs during TEMPO-mediated oxidation with NaOCl as the primary oxidant (Ono et al. 2021).

The SEC-elution patterns of the three TEMPO-CNF samples before UV irradiation are similar to those of the original SBKP before TEMPO-mediated oxidation (Ono et al. 2018). The patterns correspond to high-molar-mass cellulose molecules and glucomannan molecules chemically linked to high-molar-mass cellulose molecules, and low-molar-mass hemicellulose molecules with no chemical linkages with cellulose molecules in the original SBKP. At the same SEC-elution volume, the molar-mass plot of the TEMPO-CNFs(3.8) before UV irradiation was clearly shifted in the high-molar-mass (or upper) direction compared with those of the c-TEMPO-CNFs and TEMPO-CNFs prepared by UV irradiation for 6 and 12 h. This shows that the cellulose/glucomannan chemical linkages (probably through lignin fragments) (Ono et al. 2018) were still present, particularly in the TEMPO-CNFs (3.8) and TEMPO-CNFs(5.0), even after TEMPO-mediated oxidation. The degree of cellulose/glucomannan chemical linkage in the TEMPO-CNFs (3.8) decreased with increasing amount of NaOCl added during TEMPO-mediated oxidation. Furthermore, the degree of cellulose/glucomannan chemical linkage in the TEMPO-CNFs decreased with increasing UV-irradiation time of the dispersions.

UV irradiation of the dispersions caused the SEC-elution patterns of the acid-insoluble fractions to shift to a higher elution volume or smaller radius of gyration. This shows that UV irradiation of the dispersions caused considerable depolymerization of the TEMPO-CNF molecules. The SEC-elution patterns became bimodal after UV irradiation, which indicates that molecules with relatively high and low molar masses were formed under UV irradiation and were present in the acid-insoluble fractions. The originally high Mw values of the TEMPO-CNFs decreased to 33000–37000 g/mol (or DPw 200–220, Fig. S5 in the Electronic Supplementary Material) during UV irradiation for 6 h, and further decreased to 25000–22000 g/mol (or DPw 130–150) during UV irradiation for 12 h. UV irradiation of dispersions of the laboratory-made TEMPO-CNFs therefore caused considerable depolymerization, which was associated with decreases in the mass recovery ratios and carboxylate contents of the TEMPO-CNFs.

Solid-state structures of UV-irradiated TEMPO-CNFs

The acid-insoluble fractions in the UV-irradiated TEMPO-CNF (3.8)/water dispersion were isolated, washed with water, and freeze-dried, and their XRD patterns were recorded (Fig. S6 in the Electronic Supplementary Material). The original TEMPO-CNFs (3.8) had a low-crystalline cellulose I structure. The crystallinity values of the samples could not be quantitatively determined from the broad XRD patterns. Scherrer’s equation was used to calculate the crystal widths from the full-width at half-height of the (2 0 0) peak. The values were all ~ 1.9 nm, which shows that UV irradiation did not affect the crystal widths of the TEMPO-CNFs.

Figure 8 shows the solid-state 13C-NMR spectra of the acid-insoluble fractions in the UV-irradiated TEMPO-CNF(3.8)/water dispersion. The C6-carboxy carbons gave a broad signal at ~ 173 ppm. This signal decreased with UV-irradiation time, which is consistent with the results shown in Fig. 6. The crystalline C4 and non-crystalline C4 carbon signals, and the C6–OH carbon signals with the tg conformation at ~ 65 ppm and those with the gt and gg conformations at ~ 63 ppm, were deconvoluted by using Gaussian–Lorentzian functions and the least-squares method. The cellulose I crystallinity values for the four samples in Fig. 8, which were calculated from the C4cry/C4 signal area ratios, were 0.33–0.35 and similar to each other. The C6tg/C6 signal area ratios were also similar, with values of 0.32–0.36 for the four samples in Fig. 8. The C6 peaks at ~ 65 ppm are ascribed to the tg conformations of the C6–OH groups, which correspond to crystalline cellulose I (Horii et al. 1983; Viëtor et al. 2002; Newman and Davidson 2004; Funahashi et al. 2017; Yang et al. 2018; Zhou et al. 2020). The mass ratios of the crystalline regions of cellulose I in the acid-insoluble fractions were therefore almost constant, irrespective of the UV-irradiation time of the dispersion. UV irradiation of the TEMPO-CNF (3.8)/water dispersion for 0–12 h did not affect the C4cry/C4 crystallinity values.

The acid-soluble fraction in the TEMPO-CNF (3.8)/water dispersion prepared by UV irradiation for 12 h was isolated and freeze-dried, and dissolved in 0.1 M NaCl for SEC/MALLS analysis with 0.1 M NaCl as the eluent (Fig. S7 in the Electronic Supplementary Material). The acid-soluble fraction consisted of low-molar-mass compounds, but their detailed structures were not determined in this study.

Morphologies of UV-irradiated TEMPO-CNFs

AFM images of the UV-irradiated TEMPO-CNFs were obtained after neutralization of the dispersion, dilution from 0.4 to ~ 0.0001% with water (without removing the low-molar-mass and water-soluble fraction from the dispersion), and drying on a mica plate. The AFM images of the TEMPO-CNFs (3.8) after UV irradiation for 0–12 h and their CNF length distributions are shown in Fig. 9a and b, respectively. The originally long TEMPO-CNFs were shortened by UV irradiation. Figure 9b shows that the length and length distribution of the original TEMPO-CNFs (3.8) became smaller and narrower, respectively, with UV-irradiation time.

The TEMPO-CNFs after UV irradiation for 12 h were short, although each CNF had many kinks. Shorter TEMPO-CNFs can also be prepared from TEMPO-CNF/water dispersions by lengthy ultrasonication, i.e., ~ 120 min. In this case, TEMPO-CNCs are obtained quantitatively and have needle-like morphologies, unlike those prepared from TEMPO-CNFs (3.8) by UV irradiation (Zhou et al. 2020). Because the mass recovery ratios and carboxylate contents of the acid-insoluble fractions in the UV-irradiated TEMPO-CNFs decrease with increasing UV-irradiation time, the TEMPO-CNFs may suffer more damage, e.g., depolymerization and partial removal of acidic carboxylate groups, at the molecular level during UV irradiation.

The average lengths and heights of the TEMPO-CNFs prepared from the three TEMPO-CNF/water dispersions by UV irradiation for 0–12 h were determined from their AFM images; the results are shown in Fig. 10a and b, respectively. The average heights of the three TEMPO-CNFs were almost unchanged by UV irradiation, whereas the average lengths decreased with increasing UV-irradiation time, especially for the TEMPO-CNFs (3.8). In the cases of the TEMPO-CNFs (5.0) and TEMPO-CNFs (10.0), the average lengths decreased after UV irradiation for 2 h and then remained almost the same. In the case of the TEMPO-CNFs with Mw values < 341000 g/mol, e.g., TEMPO-CNFs (5.0) and TEMPO-CNFs(10.0), TEMPO-CNFs with average lengths < 170 nm were prepared by UV irradiation for 2 h, without significant decreases in the mass recovery ratio or carboxylate content.

The three TEMPO-CNFs prepared by UV irradiation for 12 h had number-average CNF lengths of 130–170 nm (Fig. 10a). The DPn values of these TEMPO-CNFs were 51–55, which correspond to 25.5–27.5 nm if the lengths of both glucosyl and glucuronosyl units are assumed to be ~ 0.5 nm. One UV-irradiated single nanofiber therefore consisted of 5–7 (= 130/27.5–170/25.5) cellulose and/or oxidized cellulose chains on average without glycoside bonds, but the reducing and non-reducing ends of the chains were close to each other in the longitudinal direction of each CNF (Fig. S8 in the Electronic Supplementary Material). A similar packing model of the cellulose and/or oxidized cellulose molecules along the longitudinal direction of each TEMPO-CNF was hypothesized from the average lengths and DP values of the TEMPO-CNCs (Zhou et al. 2020).

Conclusions

When a 0.4% c-TEMPO-CNF/water dispersion with a carboxylate content of 1.1 mmol/g and DPw of 380 was used, its light transparency, zeta-potential, and average particle size were almost unchanged by UV irradiation for up to 12 h. However, the pH and viscosity of the dispersion, the mass recovery ratio, carboxylate content, and DPw of the acid-insoluble fractions decreased with increasing UV irradiation time. When three 0.4% dispersions of laboratory-made TEMPO-CNFs were subjected to UV irradiation for 0–12 h, the results were similar to those for c-TEMPO-CNFs. For example, when a TEMPO-CNF(3.8)/water dispersion was UV-irradiated for 6 h, the mass recovery ratio and carboxylate content of the acid-insoluble fractions decreased to 97% and 0.9 mmol/g, respectively. In the case of UV irradiation for 12 h, these values further decreased to 79% and 0.6 mmol/g, respectively. The DPw value of the acid-insoluble fractions of the TEMPO-CNFs(3.8) decreased from 2030 to 200 and 150 because of UV-induced depolymerization during irradiation for 6 and 12 h, respectively. The cellulose I crystallinity and crystal width for the acid-insoluble fractions in the TEMPO-CNF(3.8)/water dispersion, which were determined from their solid-state 13C-NMR and/or XRD patterns, were almost unchanged by UV irradiation for 0–12 h. The average CNF length decreased with increasing UV-irradiation time; the lengths of the three TEMPO-CNFs decreased to 130–150 nm, and the length distributions were narrower, after UV irradiation of their dispersions for 12 h. In contrast, the average CNF heights were almost unchanged during UV irradiation for 0–12 h. These results show that UV irradiation of a TEMPO-CNF/water dispersion, depending on the properties of the TEMPO-CNF/dispersion, is a promising method for efficiently decreasing the dispersion viscosity, and the DPw and average length of the CNFs.

Data availability

Not applicable.

References

Auger S, Henry C, Péchoux C, Suman S, Lejal N, Bertho N, Larcher T, Stankic S, Vidic V (2018) Exploring multiple effects of Zn0.15Mg0.85O nanoparticles on Bacillus subtilis and macrophages. Sci Rep 8:2227–2241. https://doi.org/10.1038/s41598-018-30719-9

Funahashi R, Okita Y, Hondo H, Zhao M, Saito T, Isogai A (2017) Different conformations of surface cellulose molecules in native cellulose microfibrils revealed by layer-by-layer peeling. Biomacromolecules 18:3687–3694. https://doi.org/10.1021/acs.biomac.7b01173

Hiraoki R, Fukuzumi H, Ono Y, Saito T, Isogai A (2014) SEC-MALLS analysis of TEMPO-oxidized celluloses using methylation of carboxyl groups. Cellulose 21:167–176. https://doi.org/10.1007/s10570-013-0090-5

Hiraoki R, Ono Y, Saito T, Isogai A (2015) Molecular mass and molecular-mass distribution of TEMPO-oxidized celluloses and TEMPO-oxidized cellulose nanofibrils. Biomacromolecules 16:675–681. https://doi.org/10.1021/bm501857c

Homma I, Isogai T, Saito T, Isogai A (2013) Degradation of TEMPO-oxidized cellulose fibers and nanofibrils by crude cellulase. Cellulose 20:795–805. https://doi.org/10.1007/s10570-013-9872-z

Hon NS (1975) Formation of free radicals in photoirradiated cellulose. VII. Radical decay. J Polym Sci Polym Chem Ed 13:2653–2669. https://doi.org/10.1002/pol.1975.170131202

Hon NS (1979) Photooxidative degradation of cellulose: reactions of the cellulosic free radicals with oxygen. J Polym Sci Polym Chem Ed 17:441–454. https://doi.org/10.1002/pol.1979.170170214

Horii F, Hirai A, Kitamaru R (1983) Solid-state 13C-NMR study of conformations of oligosaccharides and cellulose - conformation of CH2OH group about the exo-cyclic C-C bond. Polym Bull 10:357–361. https://doi.org/10.1007/BF00281948

Isogai A (2013) Wood nanocelluloses: fundamentals and applications as new bio-based nanomaterials. J Wood Sci 59:449–459. https://doi.org/10.1007/s10086-013-1365-z

Isogai A (2018) Development of completely dispersed cellulose nanofibers. Proc Jpn Acad Ser B 94:161–179. https://doi.org/10.2183/pjab.94.012

Isogai A (2021) Emerging nanocellulose technologies: recent developments. Adv Mater 33:2000630. https://doi.org/10.1002/adma.202000630

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85. https://doi.org/10.1039/c0NR00583E

Isogai A, Hänninen T, Fujisawa S, Saito T (2018) Review: catalytic oxidation of cellulose with nitroxyl radicals under aqueous conditions. Prog Polym Sci 86:122–148. https://doi.org/10.1016/j.progpolymsci.2018.07.007

Klemm D, Kramer F, Moriz S, Lindström T, Ankerfors M, Gray DG, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50:5438–5466. https://doi.org/10.1002/anie.201001273

Li T, Chen C, Brozena AH, Zhu JY, Xi L, Driemeier C, Dai J, Rojas OJ, Isogai A, Wågberg L, Hu L (2021) Developing fibrillated cellulose as a sustainable technological material. Nature 590:47–56. https://doi.org/10.1038/s41586-020-03167-7

Malešič J, Kolar J, Strlič M, Kočar D, Fromageot D, Lemaire J, Haillant O (2005) Photo-induced degradation of cellulose. Polym Degrad Stab 89:64–69. https://doi.org/10.1016/j.polymdegradstab.2005.01.003

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941. https://doi.org/10.1039/C0CS00108B

Newman RH, Davidson TC (2004) Molecular conformations at the cellulose-water interface. Cellulose 11:23–32. https://doi.org/10.1023/B:CELL.0000014778.49291.c6

Noguchi T, Bamba Y, Odaka I, Iwamoto R, Endo M, Isogai A (2023) Natural rubber composites with high strength, modulus, water-resistance, and thermal stability, prepared with cellulose nanofibrils and sodium methacrylate by elastic kneading. Compos -A: Appl Sci 173:107665. https://doi.org/10.1016/j.compositesa.2023.107665

Ogiwara Y, Kubota H (1973) Photo-induced radical formation in cellulose. J Polym Sci Part A Polym Chem 11:3243–3253. https://doi.org/10.1002/pol.1973.170111217

Ono Y, Isogai A (2021) Analysis of celluloses, plant holocelluloses, and wood pulps by size-exclusion chromatography/multi-angle laser-light scattering. Carbohydr Polym 251:117045. https://doi.org/10.1016/j.carbpol.2020.117045

Ono Y, Fujisawa S, Saito T, Isogai A (2018) Stability of branched structures of softwood cellulose, investigated by SEC/MALLS/RI/UV and sugar composition analyses. Cellulose 25:2667–2679. https://doi.org/10.1007/s10570-018-1713-7

Ono Y, Takeuchi M, Zhou Y, Isogai A (2021) TEMPO/NaBr/NaClO and NaBr/NaClO oxidations of cotton linters and ramie cellulose samples. Cellulose 28:6035–6049. https://doi.org/10.1007/s10570-021-03944-1

Ono Y, Takeuchi M, Kimura S, Puangsin B, Wu CN, Isogai A (2022) Structures, molar mass distributions, and morphologies of TEMPO-oxidized bacterial cellulose fibrils. Cellulose 29:4977–4992. https://doi.org/10.1007/s10570-022-04617-3

Schmidt JA, Rye CS, Gurnagul N (1995) Lignin inhibits autoxidative degradation of cellulose. Polym Degrad Stab 49:291–297. https://doi.org/10.1016/0141-3910(95)87011-3

Shinoda R, Saito T, Okita Y, Isogai A (2012) Relationship between length and degree of polymerization of TEMPO-oxidized cellulose nanofibrils. Biomacromol 13:842–849. https://doi.org/10.1021/bm2017542

Soeta H, Fujisawa S, Saito T, Berglund L, Isogai A (2015) Low-birefringent and transparent composites of nanocellulose-reinforced cellulose triacetate. ACS Appl Mater Interfaces 7:11041–11046. https://doi.org/10.1021/acsami.5b02863

Takaichi S, Saito T, Tanaka R, Isogai A (2014) Improvement of nanodispersibility of oven-dried TEMPO-oxidized celluloses in water. Cellulose 21:4093–4103. https://doi.org/10.1007/s10570-014-0444-7

Viëtor RJ, Newman RH, Ha MA, Apperley DC, Jarvis MC (2002) Conformational features of crystal-surface cellulose from higher plants. Plant J 30:721–731. https://doi.org/10.1046/j.1365-313X.2002.01327.x

Yang H, Wang T, Oehme D, Petridis L, Hong M, Kubicki JD (2018) Structural factors affecting 13C NMR chemical shifts of cellulose: a computational study. Cellulose 25:23–36. https://doi.org/10.1007/s10570-017-1549-6

Zhou Y, Saito T, Bergström L, Isogai A (2018) Acid-free preparation of cellulose nanocrystals by TEMPO oxidation and subsequent cavitation. Biomacromol 19:633–639. https://doi.org/10.1021/acs.biomac.7b01730

Zhou Y, Fujisawa S, Saito T, Isogai A (2019) Characterization of concentration-dependent gelation behavior of aqueous 2,2,6,6-tetramethylpiperidine-1-oxyl-cellulose nanocrystal dispersions using dynamic light scattering. Biomacromol 20:750–757. https://doi.org/10.1021/acs.biomac.8b01689

Zhou Y, Ono Y, Takeuchi M, Isogai A (2020) Changes to the contour length, molecular chain length, and solid-state structures of nanocellulose resulting from sonication in water. Biomacromol 21:2346–2355. https://doi.org/10.1021/acs.biomac.0c00281

Zhu L, Kumar V, Banker GS (2004) Examination of aqueous oxidized cellulose dispersions as a potential drug carrier. I. Preparation and characterization of oxidized cellulose-phenylpropanolamine complexes. AAPS PharmSciTech 5(4):69. https://doi.org/10.1208/pt050469

Acknowledgments

We thank Helen McPherson, PhD, from Edanz (https://jp.edanz.com/ac) for editing a draft of this manuscript.

Funding

Open Access funding provided by The University of Tokyo. This work was supported by the National Natural Science Foundation of China (No. 22104117), the Fundamental Research Funds for the Central Universities (No. XJS222220), Core Research for Evolutional Science and Technology (CREST, Grant No. JPMJCR13B2) of the Japan Science and Technology Agency (JST). RN is the recipient of a Japan Monbukagakusho Fellowship for Foreign PhD Students.

Author information

Authors and Affiliations

Contributions

All of the authors contributed to the conception, design, experiments, and analyses. All of the authors read and approved the final manuscript. The manuscript was approved by all of the authors for publication.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence this study.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent for publication

Not applicable.

Consent to participate

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ning, R., Ono, Y. & Isogai, A. Effects of UV irradiation of TEMPO-oxidized cellulose nanofibril/water dispersions on chemical structure, molar mass, and morphology. Cellulose 31, 2251–2265 (2024). https://doi.org/10.1007/s10570-024-05776-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-024-05776-1