Abstract

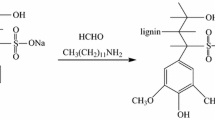

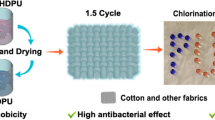

Cellulosic-based materials such as hemp fabric and paper have combined characteristics of renewability, biodegradability, flexibility, and recyclability. However, regular products are not suitable for use in unconventional applications due to inherent limitations, and accordingly, enabling new capabilities is a necessity. To this end, the conversion of regular hemp fabric and paper into high-strength products with hydrophobic function via surface engineering was explored. The fluorinated waterborne polyurethane (FWPU) emulsions were first synthesized as functional coatings by in-situ polymerization. The structure and properties of the FWPU emulsion and film were characterized by FTIR, XRD, SEM, TG, and XPS. The results showed that the grafting of perfluorooctanol imparts WPU film excellent hydrophobicity, and the water contact angle increases from 71.2° to 105.9°. After the FWPU coating, the water contact angles of the hemp fabric and paper increase from 0° to 117.1° and 112.8°, respectively. Quite encouragingly, the coating generation of waterborne polyurethane-derived functional additives led to the increase of mechanical strength by more than 23% and 82%, in the case of qualitative filter paper and hemp fabric. Meanwhile, the folding strength of filter paper is increased by 132 times. Overall, this functionalized waterborne polyurethane coating would direct paper and hemp fabric toward diversified applications.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the fundings of this study are available within the article.

References

Alberti S, Dodero A, Saptori E, Vicini S, Ferretti M, Castellano M (2021) Composite water-borne polyurethane nanofibrous electrospun membranes with photocatalytic properties. ACS Appl Polym Mater 3:6157–6166. https://doi.org/10.1021/acsapm.1c01029

Cai JC, Murugadoss V, Jiang JY, Gao X, Lin ZP, Huang MN, Guo J, Alsareii SA, Algadi H, Kathiresan M (2022) Waterborne polyurethane and its nanocomposites: a mini-review for anti-corrosion coating, flame retardancy, and biomedical applications. Adv Compos Hybrid Mater 5:641–650. https://doi.org/10.1007/s42114-022-00473-8

Dacrory S, Haggag EA, Masoud AM, Abdo SM, Eliwa AA, Kamel S (2020) Innovative synthesis of modified cellulose derivative as a uranium adsorbent from carbonate solutions of radioactive deposits. Cellulose 27:7093–7108. https://doi.org/10.1007/s10570-020-03272-w

Gao ZI, Zhai XL, Liu F, Zhang M, Zang DL, Wang CY (2015) Fabrication of TiO2/EP super-hydrophobic thin film on filter paper surface. Carbohydr Polym 128:24–31. https://doi.org/10.1016/j.carbpol.2015.04.014

Gong C, Ni JP, Tian C, Su ZH (2021) Research in porous structure of cellulose aerogel made from cellulose nanofibrils. Int J Biol Macromol 172:573–579. https://doi.org/10.1016/j.ijbiomac.2021.01.080

Guo YL, Cai L, Guo G, Xie HB, Zhang LH, Jin LM, Liang SM, Hu LJ, Xu QQ, Zheng Q (2021) Cellulose membranes from cellulose CO2-based reversible ionic liquid solutions. ACS Sustain Chem Eng 9:11847–11854. https://doi.org/10.1021/acssuschemeng.1c03609

Honarkar H, Minoofar G, Barikani M (2022) Effect of the type of anionic center on the characteristics of eco-friendly waterborne polyurethane/acrylate hybrids. Monatsh Chem 153:1269–1275. https://doi.org/10.1007/s00706-022-02996-8

Huang SS, Liu GJ, Hu H, Wang JD, Zhang KK, Buddingh J (2018) Water-based anti-smudge NP-GLIDE polyurethane coatings. Chem Eng J 351:210–220. https://doi.org/10.1016/j.cej.2018.06.103

Jiang SL, Yuan CQ, Guo ZW, Bai XQ (2019) Effect of crosslink on tribological performance of polyurethane bearing material. Tribol Int 136:276–284. https://doi.org/10.1016/j.triboint.2019.03.064

Jin XR, Dong JX, Guo XF, Ding MZ, Bao R, Luo YZ (2022) Current advances in polyurethane biodegradation. Polym Int 71:1384–1392. https://doi.org/10.1002/pi.6360

Jo HM, Lee YH, Lee JY (2022) Fabrication of eco-friendly time indicator using cellulose-based materials. BioResources 17:1120–1135. https://doi.org/10.15376/biores.17.1.1120-1135

Kang MM, Oderinde O, Han XL, Fu GD, Zhang ZH (2021) Development of oxidized hydroxyethyl cellulose-based hydrogel enabling unique mechanical, transparent and photochromic properties for contact lenses. Int J Biol Macromol 183:1162–1173. https://doi.org/10.1016/j.ijbiomac.2021.05.029

Khattak S, Wahid F, Liu LP, Jia SR, Chu LQ, Xie YY, Li ZX, Zhong C (2019) Applications of cellulose and chitin/chitosan derivatives and composites as antibacterial materials: current state and perspectives. Appl Microbiol Biotechnol 103:1989–2006. https://doi.org/10.1007/s00253-018-09602-0

Li PZ, Shen YD, Yang XW, Li GH (2012) Preparation and properties of waterborne cationic fluorinated polyurethane. J Polym Res 19:1–10. https://doi.org/10.1007/s10965-011-9786-0

Lu YS, Richard CL (2008) New Hybrid latexes from a soybean oil-based Waterborne polyurethane and acrylics via Emulsion polymerization. Biomacromol 8:3108–3114. https://doi.org/10.1021/bm700522z

Lu JL, Lang JY, Wang N, Wang XH, Lan P, Zhang H (2021) Preparation and thermostability of hydrophobic modified nanocrystalline cellulose. Nord Pulp Pap Res J 36:157–165. https://doi.org/10.1515/npprj-2020-0048

Obele CM, Ibenta ME, Chukwuneke JL, Nwanonenyi SC (2021) Carboxymethyl cellulose and cellulose nanocrystals from cassava stem as thickeners in reactive printing of cotton. Cellulose 28:2615–2633. https://doi.org/10.1007/s10570-021-03694-0

Ono Y, Takeuchi M, Zhou YX, Isogai A (2022) Characterization of cellulose and TEMPO-oxidized celluloses prepared from Eucalyptus globulus. Holzforschung 76:169–178. https://doi.org/10.1515/hf-2021-0159

Onyianta AJ, O’Rourke D, Sun DY, Popescu CM, Dorris M (2020) High aspect ratio cellulose nanofibrils from macroalgae Laminaria hyperborea cellulose extract via a zero-waste low energy process. Cellulose 27:7997–8010. https://doi.org/10.1007/s10570-020-03223-5

Pan DW, Ye HZ, Wang XQ, Zhang Y (2020) Modified geopolymer-based Wood Adhesive using Waterborne polyurethane. BioResources 15:7573–7585. https://doi.org/10.15376/biores.15.4.7573-7585

Ren SB, Yan JM, Li M, Tao Z, Yang M, Wang G (2023) High thermal conductive shape-stabilized phase change materials based on water-borne polyurethane/boron nitride aerogel. Ceram Int 49:8945–8951. https://doi.org/10.1016/j.ceramint.2022.11.049

Ren LF, Yu SJ, Niu QX, Qiang TT (2023) Triethoxysilane end-functional branched waterborne polyurethane adhesives for leather substrates. ACS Appl Polym Mater 5:4351–4359. https://doi.org/10.1021/acsapm.3c00492

Smiechowicz E, Kulpinski P, Niekraszewicz B, Bacciarelli A (2011) Cellulose fibers modified with silver nanoparticles. Cellulose 18:975–985. https://doi.org/10.1007/s10570-011-9544-9

Su WY, Hui LF, Yang Q, Wang LY, Ma XY, Zhao YM (2022) Electrospinning hydrophobically modified polyvinyl alcohol composite air filter paper with water resistance and high filterability properties. Nord Pulp Pap Res J 37(2):356–365. https://doi.org/10.1515/npprj-2021-0066

Tajima K, Imai T, Yui T, Yao M, Saxena I (2022) Cellulose-synthesizing machinery in bacteria. Cellulose 29:2755–2777. https://doi.org/10.1007/s10570-021-04225-7

Ullah N, Zafar M, Malik H, Zaman K, Raheej M, Ali I, Younas M, Molaei MJ, Rezakazemi M (2021) Fabrication and characterization of functionalized nano-silica based transparent superhydrophobic surface. Mater Chem Phys 267:124694. https://doi.org/10.1016/j.matchemphys.2021.124694

Viron KP, Falcatan AM, Leano JL (2021) Ionic liquid-mediated synthesis of cellulose/montmorillonite nanocomposite. Cellul Chem Technol 55:169–175. https://doi.org/10.35812/CelluloseChemTechnol.2021.55.18

Wu GF, Li YC, Yang ZH, Zhang HX (2021) Preparation and characterization of glucose and Sulfamate double-modified biodegradable Waterborne polyurethane. ChemistrySelect 6:8140–8149. https://doi.org/10.1002/slct.202101706

Xiao XR, Zhang HW, Fang ZQ, Wang QW (2018) Enhancing mechanical properties of flexible graphene/cellulose conductive paper by chemically modifying cellulose fibers. J Nanosci Nanotechnol 18:7090–7094. https://doi.org/10.1166/jnn.2018.15035

Xu W, Wang W, Hao LF, Liu HN, Hai F, Wang XC (2021) Synthesis and properties of novel triazine-based fluorinated chain extender modified waterborne polyurethane hydrophobic films. Prog Org Coat 157:106282. https://doi.org/10.1016/j.porgcoat.2021.106282

Xu T, Xu H, Zhong Y, Zhang LP, Qian D, Hu YL, Zhu YZ, Mao ZP (2022) Preparation and characteristics of sepiolite-waterborne polyurethane composites. J Polym Eng 42:66–74. https://doi.org/10.1515/polyeng-2021-0175

Yang XW, Qiu LW, Shen YD, Wang C, Li PZ (2020) Preparation and properties of a novel waterborne fluorinated polyurethane-acrylate hybrid emulsion modified by long aliphatic chains. Polym Bull 77:2249–2267. https://doi.org/10.1007/s00289-019-02858-0

Yin X, Luo YJ (2021) Green fluorescent waterborne polyurethane polyols. Colloid Polym Sci 299:845–853. https://doi.org/10.1007/s00396-021-04807-8

You JX, Zhang X, Mi QY, Zhang JM, Wu J, Zhang J (2022) Mild, rapid and efficient etherification of cellulose. Cellulose 29:9583–9596. https://doi.org/10.1007/s10570-022-04879-x

Yu Y, Liao B, Jiang SL, Li GN, Sun F (2015) Synthesis and characterization of photosensitive-fluorosilicone-urethane acrylate prepolymers. Des Monomers Polym 18:199–209. https://doi.org/10.1080/15685551.2014.999458

Zhao B, Jia R, Zhang Y, Liu D, Zheng X (2019) Design and synthesis of antibacterial waterborne fluorinated polyurethane. J Appl Polym Sci 136:1–11. https://doi.org/10.1002/app.46923

Zhao YQ, Su YL, Zou WC, Chen G, Deng YQ, Cheng J, Ren HS, Zhao Q (2021) Influence of fluorine-containing side chain on the properties of waterborne polyurethane-urea. J Appl Polym Sci 138:50971. https://doi.org/10.1002/app.50971

Acknowledgments

Not applicable.

Funding

This work was supported by the Heilongjiang Provincial Department of Education for the Basic Research Funds Research Project (145209509) and the Qiqihar University Postgraduate Innovation Research Project (YJSCX2022025).

Author information

Authors and Affiliations

Contributions

WZ and ZS contributed to the experimental work and writing. QZ, LS and BZ were responsible for the literature search and analysis. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, W., Sui, Z., Zhang, Q. et al. Hydrophobic and mechanical strength enhancement of hemp fabric and paper enabled by waterborne polyurethane-derived functional coating. Cellulose 31, 1687–1703 (2024). https://doi.org/10.1007/s10570-023-05703-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05703-w