Abstract

The search for solid electrolytes which have good proton conductivity in anhydrous conditions, thermal and mechanical stability, and are at the same time environmentally friendly and easy to manufacture is a big challenge which we have undertaken. This work presents new solid electrolytes based on cellulose nanocrystals with protic ionic liquid 1-methylimidazolium bis(trifluoromethylsulfonyl) imide (PIL) which have been obtained and whose thermal and conductivity properties and nanoscale organization has been determined. Two membranes were synthesized which differ as to the amount of absorbed PIL. They show excellent thermal stability up to 200 °C. The maximum value of ionic conductivity is about 10−2 S/m at 200 °C in anhydrous conditions and falls in the range of 10−3–10−2 S/m for temperatures from 150 to 200 °C. The correlation between the transport properties of membranes and their nanostructure has been probed by solid-state nuclear magnetic resonance spectroscopy. The thermal and conductivity properties of the new materials can compete with currently available membranes. Further work on a composite with a similar chemical composition should lead to obtaining a membrane capable of operating in next-generation fuel cells (T > 120 °C).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The polymer electrolyte membrane fuel cells (PEMFCs) (Hwang et al. 2022; Scofield et al. 2015) are energy-conversion devices based on the phenomenon of proton conduction. They are an attractive alternative to electrical devices that generate energy based on fossil fuels. The growing awareness of societies worldwide regarding the need to protect the environment for future generations causes a constant increase in interest in this type of energy source. PEMFCs are expected to become the leading technology to power vehicles, especially heavy-duty and long-range ones (Zhao and Li 2020). Many laboratories are working on obtaining polymer electrolyte membranes, which are the heart of PEMC, with dedicated properties such as mechanical, chemical, and thermal stability over a long time and high proton conductivity under anhydrous conditions. Currently used membranes are mostly based on perfluorosulfonic acid polymers containing sulfonic groups, such as Nafion, Aciplex, and Flemion (Kusoglu and Weber 2017). Despite the very good conductive properties, and thermal and mechanical resistance of such membranes, PEMFCs with their use have a limited operating temperature of about 90 °C because their electrical conductivity depends on the proton conductivity of the hydrated membrane. The proton conductivity of Nafion-based membranes falls in the range from 1 to 20 S/m, but the highest value is only achieved under highly hydrated conditions and drops drastically due to membrane dehydration at high temperatures (Liu et al. 2016). In addition to the above-mentioned issue, the serious disadvantages of Nafion-based membranes are the high cost of their production, the limited lifetime associated with operation below 100 °C, and the lack of environmental friendliness. The latter factor is now extremely important as we observe the global fight to stop climate change. Thus, there is still a need for further development of membrane material with thermal, mechanical, and conductivity properties similar to or better than Nafion but environmentally friendly and proton-conductive in anhydrous conditions. The last property will allow the fuel cells to work above 100 °C, preferably up to 150 °C, and thus, eliminate the problems with a low-temperature operation, such as poor electrode performance due to the slow rate of oxygen reduction at the cathode, low tolerance of platinum catalyst in the electrode to the fuel impurities (e.g., CO), low heat rate transfer, and water management (Chandan et al. 2013; Maheshwari et al. 2018; Zhao and Li 2020). To meet the condition of membrane proton conductivity in anhydrous conditions, water, which is a proton carrier in Nafion-type membranes, must be replaced, for example, with nitrogen-containing heterocyclic molecules (Kreuer 1997). Heterocycles can act as donors or acceptors because of the conductive charge with intermolecular proton transfer. Besides, heterocyclic molecules have a high boiling point, form hydrogen bond networks, and are characterized by a high degree of self-dissociation, which is beneficial for proton transfer (Kreuer 1996). To ensure the thermal stability of such molecules at the high-temperature application of PEFCs they must be incorporated into a polymer matrix, preferably a biopolymer, to make the new membrane environmentally friendly. In composites, the heterocycle attached to the biopolymer backbone acts as a solid protic solvent that does not evaporate at high temperatures, while the biopolymer acts as a matrix stabilizing the heterocycle, but at the same time ensuring high local dynamics of heterocycles and protons. Cellulose deserves special attention among biopolymers as the most common naturally occurring polymer, environmentally friendly, easy, and cheap in production and recycling, characterized by unique properties including biodegradability, biocompatibility, and high thermal stability, high strength, and a great possibility of surface modifications. All these features have led to an interest in cellulose and cellulosic materials in terms of their possible applications as membranes in fuel cells (Asandulesa et al. 2023; Selyanchyn et al. 2020; Shojaeiarani et al. 2021; Vilela et al. 2019). It has been found that the proton conductivity of pure cellulosic materials is too low (order of 10 −11 to 10−5 S/m at 90 °C (Jankowska et al. 2018) for real applications. To obtain a proton conductivity in cellulose that is satisfactory for potential applications in electrical devices, it must be chemically modified or mixed with other polymers or small molecules (Selyanchyn et al. 2020; Shojaeiarani et al. 2021; Vilela et al. 2019). In our group, we have experience in the functionalization of cellulose and cellulose nanocrystals (CNCs) with imidazole (Im) and triazole (Tri) (Lindner et al. 2021; Smolarkiewicz et al. 2015; Tritt-Goc et al. 2019, 2020). CNC–Im composites of CNCs functionalized with Im show conductivity up to 10−1 S/m at 160 °C under anhydrous conditions, but their thermal stability is unsatisfactory (Tritt-Goc et al. 2019). While CNC–Tri composites are characterized by appropriate thermal properties and the required service life, their highest conductivity value of 10−4 S/m at 160 °C is much lower than CNC–Im and insufficient for potential applications as membranes in fuel cells (Lindner et al. 2021).

Protic ionic liquids (PILs) are receiving increasing interest as another proton transfer media that can be used as an alternative to water as a charge carrier in PEMFCs (Armand et al. 2009; Martinelli et al. 2007; Shaari et al. 2021). They are a subclass of ionic liquids, which, in addition to properties such as low vapor pressure, high thermal stability, high ionic conductivity, and relatively low viscosity, also have an exchangeable proton, usually residing on the cation (Armand et al. 2009). Unfortunately, ionic liquids alone cannot form membranes in PEMFCs. They must be absorbed by a material with adequate strength and chemical and thermal stability to function in the PEMFC. In the context of biopolymers, ionic liquids are best known as solvents (Swatloski et al. 2002), but under certain conditions, they can form composites with biopolymers, sometimes also called ionogels (Hopson et al. 2021; Kaszynska et al. 2017; Takada and Kadokawa 2015). Among them, cellulose ionogels are considered the most promising solid electrolytes of the future due to their high conductivity and wide electrochemical potential window. So far, they have been prepared with aprotic ionic liquids (APIL) (Zhang et al. 2022; Zhu et al. 2019).

Only recently Danyliv et al. (2021) published the first example of CNC-based membranes embedded with protic ionic liquids such as 1-hexylimidazolium trifluoromethylsulfonate ([HC6Im][TfO]) and 1-hexylimidazolium bis(trifluoromethylsulfonyl) imide ([HC6Im][TFSI. The composites obtained are characterized by good thermal stability up to 200 °C and good conductivity values between 10−2 and 10−1 S/m in the temperature range between 120 and 160 °C under anhydrous conditions. The use of imidazole-based ionic liquids for the preparation of cellulose/PIL composites was motivated by their higher thermal stability compared to ammonium-based ionic liquids (MacFarlane et al. 2002) and immiscibility with water (Danyliv and Martinelli 2019). The latter property will prevent possible washing out of the ionic liquid from the membrane by water which is a product of the oxygen reduction reaction at the cathode in the PEMFC, even in the case of a conductive electrolyte in anhydrous conditions. The properties of CNC-based membranes with protic ionic liquids are very promising in their use as membranes in fuel cells. Therefore research on this type of material is worth continuing.

Having extensive experience in the synthesis and study of the properties of cellulose membranes functionalized with heterocyclic compounds (Smolarkiewicz et al. 2015; Tritt-Goc et al. 2019, 2020), we decided to investigate composites of CNCs with chosen proton ionic liquid 1-methylimidazolium bis(trifluoromethylsulfonyl) imide ([MIm][TFSI]) and contribute to the still little explored field of biopolymer/PIL composites.

We hypothesize that protic ionic liquid will be a better replacement for heterocycles as charge carriers in CNC-based membranes, leading to better performance in terms of thermal and conductivity properties.

Two composites with different soaking times of cellulose with ionic liquid were prepared, resulting in different liquid content in the cellulose matrix. The composites were obtained in the form of a film. The synthesis of composites is described in detail and explained why an imidazole-functionalized CNC matrix (CNC–Im) was used for soaking with ionic liquid instead of a pure CNC matrix. The thermal and conductivity properties of the composites were characterized by thermogravimetric analysis (TGA + DTA) and electrical impedance spectroscopy (EIS). The microstructure and CNC–ionic liquid interactions were determined based on solid-state nuclear magnetic resonance (NMR) spectroscopy in the magic angle spinning (MAS) conditions. The combination of EIS and NMR data allowed us to propose a conductivity mechanism in composites and to distinguish two contributions to conductivity in one of the composites. The properties of the new composites were compared with each other and with the properties of previously studied CNC–Im/PILs (Danyliv et al. 2021). The current work presents the results of the conducted research. Composites of synthetic polymers with ionic liquids are known in the literature, but the reports of biopolymers with protic ionic liquids are unique. To our knowledge, our paper gives a second example of such compositions.

Experimental section

Materials

Cellulose nanocrystals (CNCs) were purchased from Blue Goose Biorefineries Inc., from Canada, and delivered as an aqueous suspension at a concentration of 8.0% w/w. The average length and diameter of the nanocrystal were equal to 100–150 nm and 9–14 nm, respectively. The crystallinity index of purchased CNCs was equal to 83%. In the process of CNC preparation, strong inorganic acids were not used, thanks to which no additional acid groups and other elements such as sulfur or nitrogen were introduced, which was confirmed by elemental analysis. The imidazole of the spectroscopic grade was purchased from the Sigma-Aldrich Company. Ionic liquid 1-methylimidazolium bis(trifluoromethylsulfonyl) imide ([MIm][TFSI]) was purchased from IoLiTec (Ionic Liquids Technologies GmbH). All chemical compounds were of spectroscopic grade used without further processing. At room temperature, the chemical compound was in the form of a white powder.

The synthesis of the CNCs with imidazole was started by intensively mixing 25 g of CNCs (2 g dry matter) with 80 ml water. A high-speed magnetic stirrer with a special stirrer with a triangle cross-section was used to mix the gelling solutions. After obtaining a homogeneous mass, 20 ml of an aqueous solution of imidazole was added and stirred for 2 h. Then the suspension was subjected to ultrasonication for 20 min. Afterward, the whole amount of solution was transferred to a laminar flow chamber and stirred for 48 h. The colorless liquid obtained this way was finally transferred to a PTFE Petri dish and dried under the normal pressure of filtered air for 14 days. As a result, a composite labeled CNC–Im was obtained as a colorless, transparent film with a thickness of 0.5 mm. The CNC film without the imidazole was obtained by the same method except for the addition of imidazole.

The synthesized CNCs and CNC–Im films were used to obtain CNC/PIL composite membranes.

Their preparation method consisted of soaking the CNCs or CNC–Im in the selected ionic liquid. Due to the relatively high melting point of [MIm][TFSI] (50 °C), the swelling of membranes could not be carried out at room temperature. Knowing that the kinetics of swelling increases with temperature, we chose T = 85 °C, which is safe for the imidazole present in CNC–Im (see Fig. 1). In the first approach, the pure CNC film was checked for swelling with the [MIm][TFSI]. 10 g of ionic liquid was placed in a thermostatic chamber without access to air and the temperature was set at 85 °C. Next, a piece of the 5 × 10 mm CNC film was immersed in the molten ionic liquid. The sample was thermostated under these conditions for 6 days. After this time, the material was removed, and the liquid was allowed to drain. The sample thus obtained was placed between two layers of cellulose filter paper and placed in an air dryer at 95 °C for 10 min. To completely remove the excess ionic liquid adsorbed on the material’s surface, this procedure was repeated 3 times using fresh pieces of paper. The degree of ionic liquid uptake was estimated from the difference in weight before and after the swelling process. The mass analysis showed that the mass of the pure CNC film did not change, meaning that CNCs swell in the [MIm][TFSI] did not occur. A similar effect was observed when soaking the CNCs with ionic liquids ([HC6Im][TfO] and ([HC6Im][TFSI]) (Danyliv et al. 2021). Penetration of large ionic liquid molecules is most likely difficult or even impossible due to the strong intramolecular, intermolecular, and intercrystalline interactions in the CNC film (Nishiyama 2018). These interactions can be weakened by imidazole incorporated into the cellulose matrix during CNC–Im synthesis. Therefore, to overcome the problem of the CNC film not swelling, we repeated the same procedure with the CNC–Im film at 85 and 95 °C. As a result, we got two membranes, whose composition and preparation key parameters are gathered in Table 1. The maximum weight gain measured was about 9.5 wt% for the membrane swollen at 85 °C and 12.4 wt% for the membrane swollen at 95 °C. These samples will be referred to throughout the article as CNC–Im/PIL(9) and CNC–Im/PIL(12), respectively. PIL is the selected ionic liquid 1-methylimidazolium bis(trifluoromethyl sulfonyl) imide ([MIm][TFSI]).

Elementary analysis

An elemental analyzer Vario EL III GmbH Germany, equipped with a standard CHN detector was used to analyze the synthesized nanocomposites. The analysis was repeated three times for each of them, and the differences between the results were less than 0.2%.

Thermogravimetric analysis (TGA + DTG)

Thermogravimetric analysis (TGA) measurements and derivative thermogravimetry analysis (DTG) were carried out on a PerkinElmer TGA8000 apparatus. Thermal degradation of CNC–Im, CNC–Im/PIL composite films, and [MIm][TFSI] was studied by observation of their mass loss upon heating. The measurements were performed under a nitrogen flow in the temperature range from 30 to 600 °C with a heating rate of 10 °C/min. The samples were cut from the appropriate 0.5 mm thick foils in the shape of a circle and placed in a platinum dish.

13C and 19F MAS NMR spectroscopy

The 13C and 19F NMR spectra were measured on an 11.7 T Bruker AVANCE III HD spectrometer, corresponding to the 13C and 19F frequencies of 125.76 MHz and 470.38 MHz, respectively. They were recorded using the magic-angle spinning technique (MAS) employing 4 mm rotors and an HR-MAS probe with a spinning frequency of 10 kHz for carbons and fluorine. The 13C spectra were recorded with a 1H-13C cross-polarization (CP) and 13C direct-polarization (DP) sequences to detect the cellulose, imidazole, and ions of the ionic liquid molecule. For 1H–13C CP spectra, the contact time of 1500 µs was used, and proton decoupling was obtained using two-pulse phase-modulated decoupling (TPPM) at an 83 kHz radiofrequency field. The recycle time was set to 4 s, the acquisition time was 40 ms, the spectral window was set to 300 ppm, and 4096 scans were added, leading to 4.5 h of data accumulation per spectrum. The 13C DP spectra were recorded with a speed-synchronized spin echo inside the experimental pulse sequence to get undistorted line shapes and filter out background probe signals. The echo time was identical for all 13C spectra and equal to one rotation period. The total echo time was 100 µs, the acquisition time was 50 ms, the spectral window was set to 300 ppm, the recycle delay was 7 s, and the number of scans was 4096, leading to 8 h of data accumulation per spectrum. The spectra were referenced to the 13C methylene peak of adamantine set to 37.85 ppm (Morcombe and Zilm 2003) and measured as a function of temperature from 203 to 313 K, stabilized for 15 min before performing each experiment. The experiments were performed on the 13C natural abundance of imidazole, cellulose, and ionic liquid embedded in the CNC matrix.

The 19F spectra were recorded using a direct-polarization (DP) sequence with direct observation of the FID signal. The spectral width was set to 100 ppm, the acquisition time was 80 ms, and the recycle delay was set to 3 s, 256 scans were added, leading to almost 15 min of data accumulation per spectrum. The experiments were performed on 19F natural abundance in used ionic liquid.

Impedance spectroscopy

A broadband dielectric spectrometer (Alpha-A High-Performance Frequency Analyzer) from Novocontrol GmbH was used to measure the electrical conductivity in the frequency range of 1–10 MHz, with voltage oscillations of ± 1 V. The film samples had a thickness of 0.5 mm and a diameter of 8.55 mm. For measurements, they were coated with electrodes made from silver paste (Hans Wolbring GmbH). The complex impedance measurements carried out in the procedure included: the first heating cycle (0-110 °C), the annealing (at 110 °C for 0.5 h), the cooling cycle (110-0 °C), and the second heating cycle (0-250 °C). Materials are measured at every 5 °C, as follows: the sample is heated/cooled with a heating rate of 1 °C/min, then the system stabilizes for 5 min and measurements are collected. We analyze the last measurement at the selected temperature. The temperature was stabilized using a Quatro Cryosytem with an accuracy of ± 0.1 °C.

Results and discussion

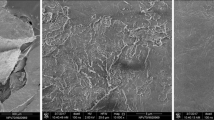

Structure characterization

The chemical composition of the synthesized CNC–Im membrane was determined by elemental analysis based on the average percentage of carbon, hydrogen, and nitrogen atoms. The elemental analysis showed that the CNC–Im contained 1 imidazole molecule per 1.68 cellulose units. The elemental analysis confirmed that no additional acid groups were introduced during the synthesis. The mass analysis showed that CNC–Im/PIL(9) and CNC–Im/PIL(12) membranes differ in the amount of absorbed ionic liquid [MIm][TFSI], which is 9.5 and 12.4 wt%, respectively.

Thermal properties

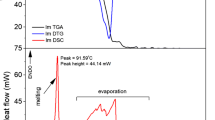

The thermal stability of the newly synthesized membranes was analyzed by thermogravimetric analysis, which provides information on the mass loss of materials with increasing temperature. Figure 1 shows TGA thermograms and the corresponding DTG curves for the neat PIL, CNC–Im, CNC–Im/PIL(9), CNC–Im/PIL(12) swollen with different amounts of [MIm][TFSI]. During the temperature increase to about 100 °C, the initial weight loss for all composites is associated with the evaporation of weakly bonded water and adsorbed humidity. The process of decomposition of CNC–Im displays three mass loss steps above 100 °C, with maximum decomposition temperatures at 150, 226, and 337 °C. The DTG peak at 150 °C can be assigned to the evaporation of strongly bonded water and the loss of imidazole bonded to the CNC matrix through the water (Smolarkiewicz et al. 2015; Tritt-Goc et al. 2018). The second peak at around 226 °C on the DTG curve is associated with the subsequent loss of imidazole attached via hydrogen bonds to the cellulose OH– groups. The boiling point of imidazole is 256 °C, but the loss of imidazole molecules in the cellulose composites occurs at lower temperatures. The third maximum decomposition temperature at about 337 °C for the CNC–Im membrane is related to the pyrolysis of the CNC matrix (Tritt-Goc et al. 2018). Our previous study analyzed the decomposition processes of neat CNC film and neat imidazole (Bielejewski et al. 2020a). The characteristic weight losses for those components related to decomposition occur at 345 °C and around 200 °C, respectively. In the CNC–Im/PIL(9) thermal degradation profile, a slight mass loss is observed up to 170 °C, but the DTA peak at 150 °C corresponding to the first stage of imidazole evaporation is almost invisible but the second mass loss related to second-stage imidazole loss with the maximum at 226 °C for CNC–Im/PIL(9) is still observed on the TGA thermogram. While for CNC–Im/PIL(12), both the mass losses and the DTG peaks associated with the loss of imidazole disappeared. This result indicates that imidazole is washed out from the CNC–Im membrane during swelling, as demonstrated by NMR spectra (see next paragraph). The DTG peak at around 295 °C, connected with cellulose pyrolysis, is observed for both composites CNC–Im/PIL(9) and CNC–Im/PIL(12). This temperature is lower by about 42 °C compared to the temperature of cellulose pyrolysis in pure CNC–Im. This fact can be explained by the greater plasticity of the CNC–Im matrix soaked with ionic liquid compared to the CNC–Im matrix.

TGA thermograms (a) and the corresponding derivatives DTG (b) of CNC–Im, CNC–Im/PIL(9), CNC–Im/PIL(12), and neat PIL measured at the heating rate of 10 K/min. The TGA/DTG data of neat CNCs and Im are reported in Bielejewski et al. (2020a)

For CNC–Im with ionic liquid, the additional process related to the degradation of [MIm][TFSI] is observed above 340 °C (Fig. 1). The maximum decomposition due to this process occurs at about 480 °C for CNC–Im/PIL(9) and at around 460 °C for CNC–Im/PIL(12). These temperatures are slightly higher than other alkyl-imidazolium salts (Awad et al. 2004). The maximum degradation temperature of pure [MIm][TFSI] equals 425 °C. Generally, the higher the content of the ionic liquid in CNC–Im, the closer the degradation temperature is to that of pure ionic liquid.

TGA studies have shown that CNC–Im/PIL(9) and CNC–Im/PIL(12) membranes are thermally stable up to around 200 °C. Thus, in this respect, they will meet the requirements for materials used as membranes in fuel cells operating above 100 °C.

Solid-state 13C and 19FNMR spectroscopy

Solid-state NMR experiments, including 13C and 19F MAS and 1H–13C CPMAS, were employed to probe the local microstructure organization of CNC–Im/PIL and molecular-level interactions between ions and cellulose in composites.

1H–13C and 13C CPMAS spectra of composites

Figure 2 shows the 1H–13C CPMAS NMR spectra of PIL ([MIm][TFSI]), CNC–Im and CNC–Im/PIL(9), and CNC–Im/PIL(12). The observed 13C peak at 35 ppm is assigned to the CH3 carbon atoms of PIL anions. The spectra in a frequency range from 50 to 110 ppm exhibit well-defined 13C peaks attributed to the cellulose matrix (Bielejewski et al. 2020b) and thus not seen in the ionic liquid spectrum. The observed 13C peaks above 110 ppm are assigned to the imidazole carbons in CNC–Im and imidazolium cation in ionic liquid.

The spectra are presented in more detail in Fig. 3. The spectrum of the imidazolium cation is typical of a rigid imidazole and consists of three signals: two of the chemically non-equivalent C4 and C5 carbons in the basal position observed at about 120 and 124 ppm, respectively and the C2 carbon at the imidazole apical position at 133.5 ppm. In contrast, the CNC–Im spectrum, in which the imidazole is bound to the cellulose matrix, contains a line from the C2 carbon, and only one resonance line located between the C4 and C5 resonances of rigid Im. In previous studies of CNC–Im composites, we showed that this line corresponds to rapidly reorienting imidazole rings and that this movement starts below room temperature (Bielejewski et al. 2020b).

Zoom of the 1H–13C CPMAS NMR spectra from Fig. 2 in the frequency range from 40 to 110 ppm showing the spectra of imidazole of CNC–Im and imidazolium cation of ionic liquid (a) and 13C DPMAS NMR spectra of these composites without CNC–Im spectrum (b)

As seen in Fig. 3a, the 13C NMR spectrum of CNC–Im/PIL(9) is a superposition of the spectrum of pure ionic liquid and CNC–Im. Therefore, we observe two peaks from the C2 carbons (imidazole in the CNC matrix and the ionic liquid cation), the C4 and C5 peaks from the cation, and the averaged C4/C5 peak from the imidazole in CNC–Im. However, in the analogous spectrum for CNC–Im/PIL(12), there are no 13C peaks assigned to imidazole carbons from the CNC matrix. The only difference in the preparation of both membranes concerned the temperature at which the CNC–Im soaked the ionic liquid. It was equal to 85 °C for CNC–Im/PIL(9) and 95 °C for CNC–Im/PIL(12). No 13C NMR peaks in the spectrum in Fig. 3a indicate that the imidazole from the cellulose matrix was washed out during the swelling of the CNC–Im membrane with the PIL at 95 °C and possibly exchanged for imidazolium cation. An accurate analysis of the positions of the C2 peaks in the spectra in Fig. 3 shows that the frequency of this peak increases when [MIm][TFSI] is inside the CNC–Im matrix. The downfield shift has a value of 0.6 ppm for CNC–Im/PIL(9) and 1.4 ppm for CNC–Im/PIL(12). This indicates stronger interactions of imidazolium cations through the H-bond at the C2 position in CNC–Im/PIL(12) than in pure PIL and CNC–Im/PIL(9).

Figure 3b shows the 13C MAS NMR spectra analogous to that in Fig. 3a but collected using a direct polarization pulse sequence. The 13C peaks of the imidazolium cation and imidazole are visible in the spectrum. In addition, the 13C peak of TFSI− CF3 groups appears in the spectrum as a single broad line in neat PIL, and an intense quartet peak is observed at 123.1, 120.6, 118.1, and 115.6 ppm in CNC–Im/PIL composites, respectively. This fact proves the presence of anions in both swollen CNC–Im composites.

19F CPMAS spectra of ionic liquid anion

The 19F MAS NMR is appropriate to study the state of the anions of ionic liquid. In the case of neat [MIm][TFSI], above the melting point, a single intense 19F peak is observed originating from the CF3 of TFSI− (Fig. 4a). However, in the case of the CNC–Im/PIL membranes, the 19F peak splits into two peaks of different intensity. These two signals are readily visible in the CNC–Im/PIL (12) (Fig. 4a, b) and indicate two “fractions” of anions.

In CNC–Im/PIL (12), as shown from TGA and NMR data, the imidazoles are washed out from the CNC matrix during swelling and their positions are replaced by the imidazolium cations. Consequently, we have a “fraction” of imidazolium cations interacting with the CNC matrix and a second fraction of cations very much, as in the neat ionic liquid case. The CNC–cation interaction decreases the strength of cation-anion interactions, which is attributed to the weaker hydrogen bonds between cation and TFSI anion. Consequently, a part of the TFSI anions is found to be progressively less bound to the cations than the other “fraction” of anions attached to cations not bound to CNCs. The two 19F peaks observed in the spectra of the CNC–Im/PIL (12) (Fig. 4) reflect different cation-anion associations. The peak of greater intensity corresponds to the CF3 of TFSI anions more strongly bound to the cation (as in pure PIL), while the peak of lower intensity corresponds to anions interacting with cations bound to the CNCs. The observed shift of the first peak to a higher frequency than the peak in neat PIL results from stronger cation-ion interaction. In addition to a position shift of 0.55 ppm, the broadening of this peak (FWHM = 0.3 ppm) is also observed compared to pure PIL (FWHM = 0.15 ppm). This may be due to the entrapment effect, which may reduce the mobility of the ions and/or increase the strength of the interactions between them.

The 19F MAS NMR spectra of CNC–Im/PIL(9) also confirm the TGA and NMR results. In this case, during the swelling of CNC–Im with PIL, the exchange of CNC-bound imidazole for imidazolium cation is negligible. The second 19F peak is almost hardly visible in the spectra of this membrane (Fig. 4a, b).

Figure 4c shows the spectra of 19F MAS CNC–Im/PIL(12) as a function of temperature. As temperature increases, position shift and narrowing of both 19F NMR lines are observed. On the other hand, the local nanostructure of the cellulose matrix and the “organization” of the ionic liquid in it is stable in the measured temperature range, as evidenced by the presented spectra. The different types of local structures of both composites: imidazole bound to CNCs as proton donors or acceptors together with ions of PIL, driven by different nature of hydrogen bonds in CNC–Im/PIL (9) and only ions in CNC–Im/PIL(12), results in different transport behavior in two studied composites.

Electrical conductivity

The electric conductivity of composites was studied using impedance spectroscopy. Exemplary impedance spectra are shown in Fig. 5 for the temperature of 120 °C and second heating mode. They are presented as the Nyquist plots (− Z′′ versus Z′′), in the frequency.

Nyquist plots for CNC–Im (a) CNC–Im/PIL(9) (b) and CNC–Im (12) (c) at 120 °C during the second heating. Solid lines represent the best fits, respectively of Eqs. (1) and (2) to the experimental points (open circles). The dash lines show two contributions to the complex impedance Z* (see text). At the lowest frequencies, an ion-blocking effect is visible

window from 1 Hz to 10 MHz. The characteristic wing visible in the lowest frequency range is associated with the so-called ion-blocking electrode effect. This effect indicates the ionic nature of the measured conductivity (Macdonald and Johnson 2005). The Nyquist plot obtained for CNC–Im and CNC–Im/PIL(12) (Fig. 5a, c) shows a single symmetrical semicircle whose center lies close to the real impedance axis. Therefore, the experimental data were analyzed assuming the Cole-Cole impedance model with a Cole equation (Cole and Cole 1941):

where Z′ (ω) and Z″ (ω) are the real and imaginary part of the complex impedance Z*(ω) at angular frequency ω = 2πf (f – the linear frequency of the probing electric field); R is the sample direct current resistance, C is the electric capacity, and α is an empiric exponent which takes the values: 0 < α ≤ 1, related to the deviation from the Debye model. The solid lines in Fig. 5a, c represent the best fit of Eq. (1) to the experimental points with R = 1122 ± 9 Ω, C = 25.4 ± 0.5 pF, α = 0.74 ± 0.01. for CNC–Im and R = 14800 ± 100 Ω, C = 137.0 ± 3.0 pF, α = 0.72 ± 0.01 for CNC–Im/PIL(12).

The simple impedance response presented in Fig. 5a and c reflects one contribution to the resistivity (or corresponding conductivity) in CNC–Im and CNC–Im/PIL(12). In the CNC–Im composite, as shown in our previous paper (Bielejewski et al. 2020b), the Grotthuss mechanism (Miyak and Rolandi 2016) is postulated to be responsible for the observed electrical conductivity, which involves proton hopping from one imidazole to an adjacent imidazole in a network of hydrogen bonds in the CNC matrix. The hopping takes place via the CNC hydroxyl groups and/or possibly residual water molecules and is conditioned by the reorientation of imidazole, which causes continuous breaking and re-formation of hydrogen bonds. In The CNC–Im/PIL(12) also, one contribution to the resistivity is observed (Fig. 5c) but attributed to the mobility of the protons that are part of the protonated imidazolium cations ions of [MIm][TFSI]. However, our understanding of proton conduction dynamics in PIL is still limited (Ingenmey et al. 2018; Watanabe et al. 2020), and we cannot determine whether ionic conduction occurs through Grotthuss-like proton conduction, or via vehicle mechanism, or both (Kreuer et al. 1982). A certain indication that both mechanisms can be responsible for the conductivity in CNC–Im/PIL(12) may be the slightly heterogeneous response of the system visible in the high-frequency range in Fig. 5c.

A more complex impedance response is observed for CNC–Im/PIL (9). As shown in Fig. 5b, the Nyquist plot shows a flattened semicircle that can be represented by two semicircles representing two contributions to the resistivity (or corresponding conductivity). Thus, the impedance can be described by two double RC parallel circuits connected in series:

where R1, C1, and α1 are respectively the dc resistance and electric capacity of the first contribution, and R2 and C2 are the dc resistance and electric capacity of the second contribution. The solid line in Fig. 5b represents the best fit of Eq. (2) to the experimental data with the high- (blue dash line—R1) and low-frequency (magenta dash line—R2) contributions. The values of the fitted parameters are: R1 = 4900 ± 100 Ω, C1 = 26.6 ± 0.4 pF, α1 = 0.79 ± 0.04, and R2 = 4500 ± 100 Ω, C2 = 496.0 ± 40.0, α2 = 0.57 ± 0.05. The two contributions are observed in the temperature range from about 10 to 170 °C. Above this temperature range, the component related to the low-frequency contribution (R2) gradually disappears. This fact, based on the TGA results and electrical conductivity results presented in Fig. 6, allows us to assign the R2 component to the imidazole protons bound to the CNC matrix. In this situation, it seems reasonable to assume that the high-frequency contribution (R1) for the CNC–Im/PIL(9) is associated with the contribution to conductivity related to the PIL ions as in CNC–Im/PIL(12). The R2 component is not observed in the CNC–Im/PIL(12) composite (Fig. 5c) as the results of TGA and NMR spectroscopy showed that in this composite, the imidazole from the CNC matrix is leached out during swelling of the CNC–Im membrane with PIL at 95 °C.

The temperature dependencies of the dc conductivity of all studied membranes are presented in Fig. 6 in the form of an Arrhenius plot (logσ(1/T)). The values of the bulk direct current conductivity were calculated from the formula: \({\sigma }_{dc}=\frac{1 d}{RS}\), where d denotes the thickness of the sample, S describes the sample area, and R is the resistance at a given temperature corresponding to the point of intersection of the semicircle with the real axis (Z’) in the plots from Fig. 5.

The data in Fig. 6 presented conductivity values determined during the second heating cycle performed in the range from 0 to 200 °C. Therefore, no contribution to the conductivity of water molecules has been observed, as it was evaporated during the first heating cycle (Cole and Cole 1941; Macdonald and Johnson 2005; Smolarkiewicz et al. 2015; Tritt-Goc et al. 2018) and additionally during the annealing of composites at 110 °C for half an hour. The conductivity increase for each membrane as a function of temperature. However, in CNC–Im, after reaching a maximum value equal to 1.15 × 10−2 S/m at 140 °C decreases and finally reaches the value of that characteristic of pure CNCs (Tritt-Goc et al. 2018). The sudden drop in conductivity is associated with the start of the imidazole evaporation process and the gradual loss of imidazole molecules from composites. Consequently, the number of proton charge carriers successively decreases and we observe a decrease in conductivity. The membranes swollen with different amounts of PIL show a decrease in conductivity of about 1 order of magnitude compared to pure CNC–Im. The lower conductivity value in the CNC–Im/PIL(9) compared to the CNC–Im results from the following reasons: partial leaching of Im from the CNC–Im matrix during its PIL swelling (first stage of imidazole evaporation is invisible in DTA—Fig. 1), proton hopping constraints caused by the presence of ions in the matrix, and the entrapment effect of the CNC matrix on ions. The latter effect leads to a decrease in ions’ mobility and an increase in their interaction with the CNCs. Similar reasons affect the conductivity in CNC–Im/PIL(12) and its lower conductivity value compared to CNC–Im/PIL(9) is related to the fact that in the first composite, the conductivity source is only ions, while in the second composite conductivity is due to two shares of R1 and R2 (see insert in Fig. 6). The maximum conductivity obtained for CNC–Im/PIL(9) and CNC–Im/PIL(12) at 200 °C is 1.50 × 10−2 S/m and 0.50 × 10−2 S/m, respectively. The activation energy, Ea, of the proton transport process that leads to the measured conductivity in membranes, was calculated from the data in Fig. 6 but within the narrow temperature range of 100–200 °C (marked in color in Fig. 6), where the conductivity shows close to linear dependence on inverse temperature and thus justifying the use of the Arrhenius relation:

where σ0 denotes the pre-exponential factor, Ea—the activation energy of proton conductivity, k—the Boltzmann constant, and T— temperature. The values of Ea obtained in the fitting procedure of Eq. 3 to the experimental data are equal to 0.34 ± 0.02 eV for CNC–Im/PIL(9) and 0.45 ± 0.02 eV for CNC–Im/PIL(12). While for CNC–Im, the determined activation energy in the temperature range from 70 to 120 °C is 0.60 ± 0.02 eV and is comparable to our previous results (Tritt-Goc et al. 2018, 2020). Additionally, we calculated the Ea for two contributions to the electrical conductivity of CNC–Im/PIL(9) (the insert in Fig. 6) in the temperature range of 80–170 °C. The activation energy Ea1 associated with the participation of R1 in conductivity is equal to 0.40 ± 0.01 eV, and Ea2 with the participation of R2 is equal to 0.58 ± 0.02 eV. The first energy value is comparable with the value obtained for CNC–Im/PIL(12) and the second for CNC–Im. This fact is confirmed by the correct assignment of two contributions in the impedance spectra (Fig. 5) to the imidazole protons bound to the CNC matrix (R2) and the PIL ions (R1).

Swelling of the CNC–Im matrix with the PIL increases the upper limit of the operating temperature range of the new composites up to 200 °C—above the boiling point of water, in an anhydrous condition. This is a shift of about 70 °C concerning CNC–Im composites, for which the maximum conductivity was in the range of 130–160 °C (Tritt-Goc et al. 2018, 2019, 2020). In addition, it is worth emphasizing that the new CNC-based composites swollen with a selected proton ionic liquid show a lower activation energy than previously synthesized composites based on cellulose materials functionalized only with imidazole molecules.

The tested membranes show ionic conductivity in anhydrous conditions in the range of 10−4–10−2 S/m for temperatures from 120 to 160 °C. In this temperature range, ionic conductivity in the first reported CNC membranes with protic ionic liquids: [HC6Im][TfO]) and [HC6Im][TFSI] is in the range 10−4−–10−3 S/m (Danyliv et al. 2021). The lower conductivity value in the new CNC–Im/[MIm][TFSI] composites is due to the significantly lower absorption of [MIm][TFSI], which was limited to about 9 and 12 wt% and perhaps to the properties of the chosen protic ionic liquid. In the case of previously reported membranes (Danyliv et al. 2021), the maximum uptake of PILs was around 80 and 30% wt. The production of these CNC–Im/PILs membranes was similar to the presented work. The question then arises as to why there is such a big difference in the amount of PIL absorbed. In the preparation of our membranes, we paid a lot of attention to the removal of excess ionic liquid adsorbed on the surface of the composites (films) before reweighing the sample to determine the maximum PIL uptake.

Conclusion

The presented research results show that preparing a membrane based on CNCs and protic ionic liquid is possible. However, direct absorption of the ionic liquid into the biopolymer is impossible due to the strong intramolecular, intermolecular, and intercrystalline interactions (Morcombe and Zilm 2003). These interactions can be weakened by imidazole introduced into the CNC matrix. As we have shown, the material prepared in this way (CNC–Im) absorbs the ionic liquid. The obtained CNC–Im/PIL membranes show excellent thermal stability up to 200 °C and as evidenced by the TGA data the presence of PIL in the composite has a positive impact on the thermal stability of the cellulose. The membranes show ionic conductivity in anhydrous conditions with a maximum value of about 10−2 S/m at 200 °C and in the range of 10−3 − 10−2 S/m for temperatures from 150 to 200 °C. A thorough analysis of the impedance spectra allowed us to determine that in CNC–Im/PIL(9) composite, apart from ions of the ionic liquid, protons of the imidazole bound to the CNC–Im matrix also participate in the measured conductivity, while in CNC–Im/PIL(12) only ions are responsible for conductivity. The presence of imidazole and imidazolium cation and the measured low activation energy allow the obtained composites to be classified as good proton conductors.

Our work verifies the hypothesis that the selected protic ionic liquid is a better replacement for heterocycles as charge carriers in CNC-based membranes. CNC/PIL composites obtained.

can successfully compete with CNC/heterocycle membranes and even show higher thermal stability (200 °C vs. 150 °C in CNC–Im). We believe that new membranes have the potential to be used in fuel cells at high operating temperatures well above the target for next-generation fuel cells (T > 120 °C). Therefore, we will continue to work on obtaining a composite with similar chemical composition and optimal parameters for use in electrochemical devices.

Data availability

The data used in presented manuscript are available upon request from the authors.

References

Armand M, Endres F, Macfarlane DR, Ohno H, Scrosat B (2009) Ionic-liquid materials for the electrochemical challenges of the future. Nat Mater 8:621–629. https://doi.org/10.1038/nmat2448

Asandulesa M, Chibac-Scutaru AL, Culica ME, Melinte V (2023) Cellulose-based films with an enhanced load of nitrogen containing heterocycles: the impact on the surface morphology and proton conductivity. Appl Surf Sci 607:155077. https://doi.org/10.1016/j.apsusc.2022.155077

Awad WH, Gilman JW, Nydena M, Harris RH, Sutto TE, Callahan J, Trulove PC, DeLong HC, Fox DM (2004) Thermal degradation studies of alkyl-imidazolium salts and their application in nanocomposites. Thermochim Acta 409:3–11. https://doi.org/10.1016/S0040-6031(03)00334-4

Bielejewski M, Lindner Ł, Pankiewicz R, Tritt-Goc J (2020) The kinetics of thermal processes in imidazole-doped nanocrystalline cellulose solid proton conductor. Cellulose 27:1989–2001. https://doi.org/10.1007/s10570-019-02898-9

Bielejewski M, Pinto-Salazar M, Lindner Ł, Pankiewicz R, Buntkowsky G, Tritt-Goc J (2020) Dynamics and proton transport in imidazole-doped nanocrystalline cellulose revealed by high-resolution solid-state nuclear magnetic resonance spectroscopy. J Phys Chem C 124:18886–18893. https://doi.org/10.1021/acs.jpcc.0c04905

Chandan A, Hattenberger M, El-kharouf A, Du S, Dhir A, Self V, Bujalski W (2013) High temperature (HT) polymer electrolyte membrane fuel cells (PEMFC): a review. J Power Sources 231:264–278. https://doi.org/10.1016/j.jpowsour.2012.11.126

Cole K, Cole R (1941) Dispersion and absorption in dielectrics. J Chem Phys 9:341–345. https://doi.org/10.1063/1.1750906

Danyliv O, Martinelli A (2019) Nafion/Protic ionic liquid blends: nanoscale organization and transport properties. J Phys Chem C 123(23):14813–14824. https://doi.org/10.1021/acs.jpcc.9b02874

Danyliv O, Strach M, Nechyporchuk O, Nypelö T, Martinelli A (2021) Self-standing, robust membranes made of cellulose nanocrystals (CNCs) and a protic ionic liquid: toward sustainable electrolytes for fuel cells. ACS Appl Energy Mater 4:6474–6485. https://doi.org/10.1021/acsaem.1c00452

Hopson C, Villar-Chavero MM, Domínguez JC, Alonso MV, Oliet M, Rodriguez F (2021) Cellulose ionogels, a perspective of the last decade: a review. Carbohyd Polym 274:118663. https://doi.org/10.1016/j.carbpol.2021.118663

Hwang S, Lee H, Jeong Y, Choi C, Hwang I, Song S, Nam SY, Lee JH, Kim K (2022) Polymer electrolyte membranes containing functionalized organic/inorganic composite for polymer electrolyte membrane fuel cell applications. Int J Mol Sci 23:14252. https://doi.org/10.3390/ijms232214252

Ingenmey J, Gehrke S, Kirchner B (2018) How to harvest grotthuss diffusion in protic ionic liquid electrolyte systems. Chemsuschem 11:1900–1910. https://doi.org/10.1002/cssc.201800436

Jankowska I, Pankiewicz R, Pogorzelec-Glaser K, Ławniczak P, Łapiński A, Tritt-Goc J (2018) Comparison of structural, thermal, and proton conductivity properties of micro- and nanocelluloses. Carbohyd Polym 200:536–542. https://doi.org/10.1016/j.carbpol.2018.08.033

Kaszynska J, Rachocki A, Bielejewski M, Tritt-Goc J (2017) Influence of cellulose gel matrix on BMIMCl ionic liquid dynamics and conductivity. Cellulose 24:1641–1655. https://doi.org/10.1007/s10570-017-1223-z

Kreuer KD (1996) Proton conductivity: materials and applications. Chem Mater 8(3):610–641. https://doi.org/10.1021/cm950192a

Kreuer K (1997) On the development of proton conducting materials for technological applications. Solid State Ion 97:1–15. https://doi.org/10.1016/S0167-2738(97)00082-9

Kreuer K-D, Rabenau A, Weppner W (1982) Vehicle mechanism, a new model for the interpretation of the conductivity of fast Proton conductors. Angew Chem Int Ed 21(3):208–209. https://doi.org/10.1002/anie.198202082

Kusoglu A, Weber AZ (2017) New insights into perfluorinated sulfonic-acid ionomers. Chem Rev 117(3):987–1104. https://doi.org/10.1021/acs.chemrev.6b00159

Lindner Ł, Bielejewski M, Markiewicz E, Łapiński A, Pankiewicz R, Tritt-Goc J (2021) Synthesis and characterization of triazole based nanocrystalline cellulose solid proton conductors. Eur Polym J 161:110825. https://doi.org/10.1016/j.eurpolymj.2021.110825

Liu L, Chen W, Li Y (2016) An overview of the proton conductivity of na fi on membranes through statistical analysis. J Membr Sci 504:1–9. https://doi.org/10.1016/j.memsci.2015.12.065

Macdonald JR, Johnson WB (2005) Fundamentals of impedance spectroscopy, in impedance spectroscopy: theory, experiment, and application. Wiley, Hoboken. https://doi.org/10.1002/0471716243

MacFarlane DR, Forsyth SA, Golding J, Deacon GB (2002) Ionic liquids based on imidazolium, ammonium and pyrrolidinium salts of the dicyanamide anion. Green Chem 4:444–448. https://doi.org/10.1039/B205641K

Maheshwari K, Sharma S, Sharma A, Verma S (2018) Fuel cell and its application: a review. IJERT 7(06):6–9

Martinelli A, Matic A, Jacobsson P, Börjesson L, Fernicola A, Panero S, Scrosati B, Ohno H (2007) Physical properties of proton conducting membranes based on a protic ionic liquid. J Phys Chem B 111(43):12462–12467. https://doi.org/10.1021/jp0735029

Miyak T, Rolandi M (2016) Grotthuss mechanisms: from proton transport in proton wires to bioprotonic devices. J Phys-Condens Mat 28:023001. https://doi.org/10.1088/0953-8984/28/2/023001

Morcombe CR, Zilm KW (2003) Chemical shift referencing in MAS solid state NMR. J Magn Reson 162:479–486. https://doi.org/10.1016/S1090-7807(03)00082-X

Nishiyama Y (2018) Molecular interactions in nanocellulose assembly. Philos Trans R Soc A 376:20170047. https://doi.org/10.1098/rsta.2017.0047

Scofield ME, Liu H, Wong SS (2015) A concise guide to sustainable PEMFCs: recent advances in improving both oxygen reduction catalysts and proton exchange membranes. Chem Soc Rev 44(16):5836–5860. https://doi.org/10.1039/C5CS00302D

Selyanchyn O, Selyanchyn R, Lyth SM (2020) A review of proton conductivity in cellulosic materials. Front Energy Res 8:1–17. https://doi.org/10.3389/fenrg.2020.596164

Shaari N, Ahmad NNR, Bahru R, Leo CP (2021) Ionic liquid-modified materials as polymer electrolyte membrane and electrocatalyst in fuel cell application: an update. Int J Energ Res 46:2166–2211. https://doi.org/10.1002/er.7362

Shojaeiarani J, Bajwa DS, Chanda S (2021) Cellulose nanocrystal based composites: a review. Compos C Open Access 5:100164. https://doi.org/10.1016/j.jcomc.2021.100164

Smolarkiewicz I, Rachocki A, Pogorzelec-glaser K, Pankiewicz R (2015) Proton-conducting microcrystalline cellulose doped with imidazole. Thermal and electrical properties. Electrochim Acta 155:38–44. https://doi.org/10.1016/j.electacta.2014.11.205

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellulose with ionic liquids. J Am Chem Soc 124(18):4974–4975. https://doi.org/10.1021/ja025790m

Takada A, Kadokawa J-i (2015) Fabrication and characterization of polysaccharide Ion gels with Ionic liquids and their further conversion into value-added sustainable materials. Biomolecules 5:244–262. https://doi.org/10.3390/biom5010244

Tritt-Goc J, Jankowska I, Pogorzelec-Glaser K, Pankiewicz R, Ławniczak P (2018) Imidazole-doped nanocrystalline cellulose solid proton conductor: synthesis, thermal properties, and conductivity. Cellulose 25:281–291. https://doi.org/10.1007/s10570-017-1555-8

Tritt-Goc J, Lindner Ł, Bielejewski M, Markiewicz E, Pankiewicz R (2019) Proton conductivity and proton dynamics in nanocrystalline cellulose functionalized with imidazole. Carbohyd Polym 225:115196. https://doi.org/10.1016/j.carbpol.2019.115196

Tritt-Goc J, Lindner Ł, Bielejewski M, Markiewicz E, Pankiewicz R (2020) Synthesis, thermal properties, conductivity, and lifetime of proton conductors based on nanocrystalline cellulose surface-functionalized with triazole and imidazole. Int J Hydrogen Energy 45(24):13365–13375. https://doi.org/10.1016/j.ijhydene.2020.03.071

Vilela C, Silvestre AJD, Figueiredo FML, Freire CSR (2019) Nanocellulose-based materials as components of polymer electrolyte fuel cells. J Mater Chem A 7(35):20045–20074. https://doi.org/10.1039/c9ta07466j

Watanabe H, Arai N, Kameda Y, Buchner R, Umebayashi Y (2020) Effect of Brønsted Acidity on ion conduction in fluorinated acetic acid and N–methylimidazole equimolar mixtures as pseudo-protic ionic liquids. J Phys Chem-US 124:11157–11164. https://doi.org/10.1021/acs.jpcb.0c07706

Zhang L, Gao H, Jin G, Liu S, Wu J, Wu H, Yang Y, Wan Q, Wang S (2022) Cellulose-based electrolytes for advanced lithium-ion batteries: recent advances and future perspectives. ChemNanoMat 8:e202200142. https://doi.org/10.1002/cnma.202200142

Zhao J, Li X (2020) A review of polymer electrolyte membrane fuel cell durability for vehicular applications: degradation modes and experimental techniques. Energ Convers Manag 199:112022. https://doi.org/10.1016/j.enconman.2019.112022

Zhu M, Yu L, He S, Hong H, Liu J, Gan L, Long M (2019) Highly efficient and stable cellulose-based ion gel polymer electrolyte for solid-state supercapacitors. ACS Appl Energy Mater 2:5992–6001. https://doi.org/10.1021/acsaem.9b01109

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

IJ, Investigation Validation, Formal analysis, Writing—original draft, Visualization. MB: Investigation, Methodology, Formal analysis, Writing—review and editing, Visualization. PŁ: Investigation, Formal analysis. RP: Resources, Methodology. JT-G: Conceptualization, Methodology, Supervision, Writing—original draft, Writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

The authors declare that preparing the manuscript, they have act accordingly to ethical rules stated in COPE.

Consent for publication

The authors have read and understood the publishing policy, and submit this manuscript in accordance with this policy.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jankowska, I., Bielejewski, M., Ławniczak, P. et al. Solid electrolytes based on cellulose nanocrystals with protic ionic liquid for next-generation fuel cells. Cellulose 31, 427–441 (2024). https://doi.org/10.1007/s10570-023-05640-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05640-8