Abstract

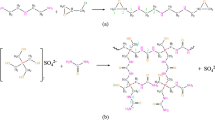

In this investigation, combination of ammonium sulfamate (AS), sodium stannate (SS) and zinc acetate (ZA) (as external reagent) was applied by simple double bath pad-dry-cure method to acquire fire-retardancy (FR) on cotton woven fabric. This chemical combination is eco-friendly as it neither releases taxic formaldehyde nor produces any bi-hazardous corrosive gases. During preliminary study with an aim to keep total added chemical around 20–30%, optimum FR result obtained at 16%AS + 8%SS + 5%ZA with a synergistic effect. Reaction mechanism showed that proton (H+ ion) developed from AS during heating, dehydrated the cellulose causing increase in char formation and other two chemicals (SS and ZA) formed protective coating on cotton. With this optimum chemical combination, limiting oxygen index value was achieved 38.30 with char length of 6.7 cm at 45° inclined plane flammability test but there was around 30% loss of fabric tenacity. The data obtained from thermo gravimetric analysis showed change in path of pyrolysis by lowering decomposition temperature with almost 29% increase in residual char formation indicating good FR property. Surface topography analysis by SEM, functional groups by analysis of FTIR, element identification by XPS confirmed surface deposition of these chemical compound along with agglomerated precipitation of “Zinc Hydroxy Stannate”. During wash stability analysis, it was found that after application of 5% ZA, wash stability was better than without ZA after 10 wash cycles.

Similar content being viewed by others

Data availability

All data generated during experiments, testing and analysis for the present study are included in this article.

References

Bartosova A, Soldan M, Sirotiak M, Prachova M (2015) Novel environmental friendly fire retardants. Adv Sci Eng 11(1):1–8. https://doi.org/10.32732/ase.2019.11.1.1

Basak S, Ali W (2016) Sustainable fire retardancy of textiles using bio-macromolecules. Polymer 133:47–64. https://doi.org/10.1016/j.polymdegradstab.2016.07.019

Basak S, Samanta KK, Chattopadhyay SK (2015a) Fire retardant property of cotton fabric treated with herbal extract. J Text Inst 106(12):1338–1347. https://doi.org/10.1080/00405000.2014.995456

Basak S, Samanta KK, Chattopadhyay SK, Narkar RS, Mahangade R (2015b) Flame retardant cellulosic textile using bannana pseudostem sap. Int J Clothing Sci Technol 27(2):247–261. https://doi.org/10.1108/IJCST-12-2013-0135

Bright DA, Dashevsky S, Moy PY, Williams B (1997) Resorcinol bis(diphenyl phosphate), a non-halogen flame-retardant additive. J Vinyl Add Tech 3(2):170–174. https://doi.org/10.1002/vnl.10184

Chen L, Wang YZ (2010) Aryl Polyphosphonate: useful halogen-free flame retardants for polymers. Materials 3(10):4746–4760. https://doi.org/10.3390/ma3104746

Cheng XW, Zhang C, Jin WJ, Huang YT et al (2021) Facile preparation of a sustainable and reactive flame retardant for silk fabric using plant extracts. Ind Crops Prod 171:113966. https://doi.org/10.1016/j.indcrop.2021.113966

El-Hady MMA, Farouk A, Sharaf S (2013) Flame retardancy and UV protection of cotton-based fabrics using nano ZnO and polycarboxylic acids. Carbohydr Polym 92(1):400–406. https://doi.org/10.1016/j.carbpol.2012.08.085

El-Tahlawy K (2008) Chitosan phosphate: A new way for production of eco-friendly flame-retardant cotton textiles. J Text Inst 99(3):185–191. https://doi.org/10.1080/00405000701584311

El-Tahlawy K, Eid R, Sherif F, Hudso S (2008) Chitosan: a new route for increasing the efficiency of stannate/phosphate flame retardants on cotton. J Text Inst 99(2):157–164. https://doi.org/10.1080/00405000701570773

Fang Y, Sun W, Li J, Liu H, Liu X (2021a) Eco-friendly flame retardant and dripping-resistant of polyester/cotton blend fabrics through layer-by-layer assembly fully bio-based chitosan/phytic acid coating. Int J Biol Macromol 175:140–146. https://doi.org/10.1016/j.ijbiomac.2021.02.023

Fang Y, Sun W, Li L, Wang Q (2021b) Bio-based phytic acid/chitosan and polycarboxylic acid for eco-friendly flame retardant and anti-crease of cotton fabric. J. Nat. Fibers 45:2543. https://doi.org/10.1080/15440478.2021.1964123

Fang Y, Sun W, Liu H, Liu X (2021c) Construction of eco-friendly flame retardant and dripping-resistant coating on polyester fabrics. Surf Eng 37(8):1067–1073. https://doi.org/10.1080/02670844.2021.1911458

Feng J, Ma Z, Xie Z, Lu Y, Maluk C et al (2022) A Si-containing polyphosphoramide via green chemistry for fire-retardant polylactide with well-preserved mechanical and transparent properties. Chem Eng J 431:134259. https://doi.org/10.1016/j.cej.2021.134259

Hejazi SM, Lotfi F, Fashandi H, Alirezazadeh A (2017) Serishm: an eco-friendly and biodegradable flame retardant for fabrics. Environ Ecosyst Sci 1(2):05–08

Huong NT, Khanh VTH, Linh NPD (2021) Optimizing content of Pyrovatex CP New and Knittex FFRC in flame retardant treatment for cotton fabric. Industria Textila 72(3):315–323

Inbakumar S, Morent R, Geyter D, Desmet T (2010) Chemical and physical analysis of cotton fabrics plasma-treated with a low-pressure DC glow discharge. Cellulose 17(2):417–426. https://doi.org/10.1007/s10570-009-9369-y

Jalalah M, Zulfiqar S, Afzal A, Khaliq Z et al (2023) Microencapsulation based fire retardant eco-friendly jute composite. Polym Polym Compos 31:096739112211477. https://doi.org/10.1177/09673911221147702

Javed A, Wiener J, Saskova J, Mullerova J (2022) Zinc oxide nanoparticles (ZnO NPs) and N-Methylol dimethyl phosphonopropion amide (MDPA) system for flame retardant cotton fabrics. Polymers 14(16):3414. https://doi.org/10.3390/polym14163414

Jeon H, Lee J, Park J, Kang C (2021) Eco-friendly, less toxic and washing durable flame-retardant finishing for Cotton fabrics using a blocked isocyanate and 3-(dimethylphosphone)-N-methylopropionamide. Mater Chem Phys 273:125149. https://doi.org/10.1016/j.matchemphys.2021.125149

Jia Y, Hu Y, Zhengn D et al (2017) Synthesis and evaluation of an efficient, durable, and environmentally friendly flame retardant for cotton. Cellulose 24:1159–1170. https://doi.org/10.1007/s10570-016-1163-z

Lewin M (1997) Flame retarding of polymers with sulfamates I. sulfation of cotton and wool. J Fire Sci 15(4):263–276. https://doi.org/10.1177/073490419701500401

Lewin M, Zhang J, Pearce E, Gilman J (2007) Flammability of polyamide 6 using the sulfamate system and organo-layered silicate. Polym Adv Technol 18(9):737–745. https://doi.org/10.1002/pat.964

Lin D, Zeng X, Li H et al (2019) One pot fabrication of super hydrophobic and flame-retardant coatings on cotton via sol-gel reaction. J Colloid Interface Sci 533:198–206. https://doi.org/10.1016/j.jcis.2018.08.060

Ling C, Guo L (2023) Recent developments and applications of hyperbranched polymers as flame retardants. J Anal Appl Pyrolysis 169:105842. https://doi.org/10.1016/j.jaap.2022.105842

Lu SY, Hamerton I (2002) Recent developments in the chemistry of halogen-free flame-retardant polymers. Prog Polym Sci 27(8):1661–1712. https://doi.org/10.1016/S0079-6700(02)00018-7

Mostashari SM, Mostashari SZ (2008) Combustion pathway of cotton fabric treated by ammonium sulfate as a flame retardant studied by TG. J Therm Anal Calorim 91:437–441. https://doi.org/10.1007/s10973-007-8332-0

Nguyen N, La VT, Le TX, Huynh ST (2020) Synthesis and characterization of new eco-friendly fire-retardants based on soda-silicate glass. ASEAN J Chem Eng 20(2):120. https://doi.org/10.22146/ajche.53954

Ozer MS, Gaan S (2022) Recent developments in phosphorus based flame retardant coatings for textiles: synthesis, applications and performance. Prog Org Coat 171:107027. https://doi.org/10.1016/j.porgcoat.2022.107027

Pal A, Samanta AK, Bagchi A, Samanta P, Kar TR (2020) A review on fire protective functional finishing of natural fibre based textiles: present perspective. Curr Trends Fashion Technol Text Eng 7(1):11–30. https://doi.org/10.19080/CTFTTE.2020.07.555705

Patil VM, Desmukh A (2012) Some studies of temporary and permanent flame retardants on 100% cotton fabric. SAGE India 2012:272–278

Rajpoot Y, Sharma V, Basak A, Ali W (2021) Calcium borate particles: synthesis and application on the cotton fabric as an emerging fire retardant. J Nat Fibers. https://doi.org/10.1080/15440478.2021.1889431

Rakotomalala M, Wagner S, Doring M (2010) Recent developments in halogen free flame retardants for epoxy resins for electrical and electronic applications. Materials 3(8):4300–4327. https://doi.org/10.3390/ma3084300

Ren J, Wang C, Zhang X, Carey T et al (2017) Environmentally-friendly conductive cotton fabric as flexible strain sensor based on hot press reduced graphene oxide. Carbon 111:622–630. https://doi.org/10.1016/j.carbon.2016.10.045

Salmeia KA, Gaan S, Malucelli G (2016) Recent advances for flame retardancy of textiles based on Phosphorus chemistry. Polymers 8(9):319. https://doi.org/10.3390/polym8090319

Samanta AK, Bagchi A (2017) Eco friendly fire retardant and rot resistance finishing of jute fabric using tin and boron based compound. J Inst Eng India Ser E 98(1):25–31. https://doi.org/10.1007/s40034-017-0092-1

Samanta AK, Biswas SK, Mitra S, Basu G, Mahalanabis KK (2008) Chemical modification of jute fabric with ethylene glycol and its mixtures with glyoxal and amino-silicone compound under different catalyst systems for improving its textile related properties and thermal behaviour. J Polym Mater 24(4):325–348

Samanta AK, Roy RB, Chowdhury R (2014) Eco-friendly fire retardant finishing of jute fabric by impregnation or coating phosphorylated PVA and its effect on physical properties and thermal behaviour of treated jute fabric. Int J Appl Eng Res 9(4):439–450

Samanta AK, Bhattacharya R, Jose S, Basu G, Chowdhury R (2017) Fire retardant finish of jute fabric with nano zinc oxide. Cellulose 24:1143–1157. https://doi.org/10.1007/s10570-016-1171-z

Samanta AK, Bhattacharya R, Bagchi A, Chowdhuri R (2020) Statistical optimization of ammonium sulfamate and urea-based fire protective finishing of jute fabric. In: Majumder A et al (eds) Functional Textiles and Clothing. Springer Singapore, Singapore, pp 99–128. https://doi.org/10.1007/978-981-15-9376-5_9

Selcen OH, Osman B (2023) An investigation on non-flammability properties of polypropylene knitted fabric. Industria Textila 74(2):184–191

Shao ZB, Cui J, Li XL, Palencia JLD, Wang DY (2021) Chemically inorganic modified ammonium polyphosphate as eco-friendly flame retardant and its high fire safety for epoxy resin. Compos Commun 28:100959. https://doi.org/10.1016/j.coco.2021.100959

Shukla A, Sharma V, Basak S, Ali SW (2019) Sodium lignin sulfonate: a bio-macromolecule for making fire retardant cotton fabric. Cellulose 26:8191–8208. https://doi.org/10.1007/s10570-019-02668-7

Tang W, Zhang S, Sun J, Gu X (2016) Flame Retardancy and thermal stability of polypropylene composite containing ammonium sulfamate intercalated kaolinite. Ind Eng Chem Res 55(28):7669–7689. https://doi.org/10.1021/acs.iecr.6b01722

Thilagavathi T, Geetha D (2013) Low-temperature hydrothermal synthesis and characterization of ZnO nanoparticles. Indian J Phys 87:787–750. https://doi.org/10.1007/s12648-013-0290-8

Tu J, Xie S, Zhao Q, Guan J, Wu C, Wang P (2022) Reactive P/S/N-containing synergistic flame retardant towards eco-friendly durable flame-retardant cotton fabric: flame-retardant property, durability and mechanism. Polym Test 118:107918. https://doi.org/10.1016/j.polymertesting.2022.107918

Wendels S, Chavez T, Salmeia K, Gaan S (2017) Recent developments in organophosphorus flame retardants containing P-C bond and their applications. Materials 10(7):784. https://doi.org/10.3390/ma10070784

Xia L, Wang H, Shentu B, Weng Z (2010) Ammonium sulfamate flame retarded polyamide 6: morphology and thermal degradation. Chin J Polym Sci 28:753–759. https://doi.org/10.1007/s10118-010-9116-8

Yang WJ, Wei CX, Hao LY, Lu HD, Yang W (2022) Recent advances in zinc hydroxystannate-based flame-retardant polymer blends. Polymers 14(11):2175. https://doi.org/10.3390/polym14112175

Zhang AN, Zhao HB, Cheng JB, Li ME, Li SL et al (2021) Construction of durable eco-friendly biomass-based flame-retardant coating for cotton fabrics. Chem Eng J 410:128361. https://doi.org/10.1016/j.cej.2020.128361

Zhou X, Chen K, Yi H (2014) Synthesis and application of a formaldehyde-free flame retardant for bamboo viscose fabric. Text Res J 84(14):1515–1527. https://doi.org/10.1177/0040517514525877

Acknowledgments

Authors would like to thank laboratory of BTRA (The Bombay Textile Research Association) Mumbai, India; IIT (Indian Institute of Technology) Jammu, India; NITRA (Northern India Textile Research Association) Ghaziabad, India; Textiles Committee, Kolkata, India; Textiles Committee, Ludhiana and Department of Jute and Fibre Technology, University of Calcutta, India for extending kind co-operation to help in testing of different parameters for present study.

Funding

No funds, grants, or other support was received.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Mr. Ayan Pal, Prof. (Dr.) Ashis Kumar Samanta and Dr. Tapas Ranjan Kar. The first draft of the manuscript was written by Mr. Ayan Pal and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose, The authors have no competing interests to declare that are relevant to the content of this article, All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript, The authors have no financial or proprietary interests in any material discussed in this article.

Ethical approval and consent to participate

The authors declare that they have no conflicts of interest with respect to the research, authorship, and/or publication of this article. Informed consent was obtained from all individual participants included in the study. This article does not contain any studies with human participants or animals performed by any of the authors.

Consent for publication

Authors has given consent to publish the article including data of experiments, results of testing and analysis of the present work to the publisher.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pal, A., Samanta, A.K. & Kar, T.R. Eco-friendly fire-retardant finishing of cotton fabric with mixture of ammonium sulfamate and sodium Stannate with and without zinc acetate as external reagent. Cellulose 30, 11813–11828 (2023). https://doi.org/10.1007/s10570-023-05543-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05543-8