Abstract

Cellulose nanocrystals (CNCs) are biomass-based nanoparticles with attractive properties. Using a zone-casting technique, transparent films 2 cm wide and 4 cm long, and 2 µm thick, with uniaxially oriented CNCs were prepared from aqueous suspension of CNCs. The nanocrystals were aligned within the entire film perpendicular to the zone-casting direction. The orientation of the CNCs was confirmed by polarized light microscopy, X-ray diffraction and atomic force microscopy. The intensity of the light transmitted through the films depended on its polarization direction and was the strongest for the light polarized perpendicularly to the crystal orientation direction. The orientation of CNCs in the films resulting in optical anisotropy makes them promising materials for applications in optoelectronics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

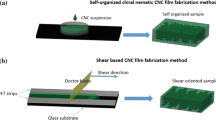

Nowadays, intensive research focuses on the development of biobased polymers (Kimura 2009; Nakajima et al. 2017; Piorkowska 2019) as it plays an important role in struggling with carbon dioxide emissions causing global warming, and in diminishing dependence on fossil resources. Cellulose, a biodegradable polysaccharide present in plant cell walls, is the most abundant natural polymer on Earth (Pauly and Keegstra 2008). Recently, cellulose rod-shaped nanocrystals isolated from native cellulose draw increasing attention. Due to cellulose abundance, its low weight, high strength and stiffness, and renewability, numerous studies have been reported on the isolation of cellulose nanocrystals (CNCs) from different sources, their morphology, and properties, as well as their use in high-performance applications (Mendoza-Galvan et al. 2019; Querejeta-Fernandez et al. 2015; Sanchez-Botero et al. 2018). The applications of CNCs include green electronics and optoelectronics. For example, a nanocellulose/epoxy composite with improved thermal stability, flexibility, and high optical transparency of ca. 90% was described as suitable for application as a substrate for polymer-based flexible solar cells (Wang et al. 2020). CNCs can form nematic or chiral nematic structures in water (Cherpak et al. 2018; Habibi et al. 2010; Parker et al. 2018). This allowed obtaining CNC films with the order preserved on a mesoscopic scale using processing methods, such as drop-casting, spin-coating, and dip-coating (Diaz et al. 2013; Kontturi et al. 2007; Mendoza-Galvan et al. 2019; Rofouie et al. 2018; Sanchez-Botero et al. 2018; Tran et al. 2020). Interestingly, Droguet et al. (Droguet et al. 2022), optimized the self-assembly of CNC suspensions into photonic films using a continuous roll-to-roll technique and obtained meter-scale structurally colored CNC films. Alignment of CNCs leading to nematic order was induced by shearing of CNC suspension (Chowdhury et al. 2017; Edgar and Gray 2003; Khelifa et al. 2013; Parker et al. 2018). The nanometer and micrometer thick films were prepared with CNCs aligned in the shearing direction, also with the assistance of an electric field (Csoka et al. 2011; Diaz et al. 2013; Hoeger et al. 2011). In turn, shearing during spin coating resulted in the radial orientation of CNCs from the centre of the sample (Edgar and Gray 2003).

However, the preparation of CNCs films with the order on a macroscopic scale is still a problem.

We hypothesized that it would be possible to orient CNCs using a zone-casting technique. The zone casting technique was developed to obtain from solutions highly oriented networks of the molecular metal, tetrathiotetracene-tetracyanoquinodimethane (TTT-TCNQ), embedded in a polymer matrix (Tracz et al. 2007). During the casting process, the solution was continuously supplied through a flat nozzle onto a moving substrate. Appropriate rates of solvent evaporation and solution supply resulted in a stationary gradient concentration within the meniscus, as shown in Fig. 1, which enforced directional crystallization. To achieve stationary conditions, a solution supply rate, substrate velocity, initial solution concentration, solvent evaporation rate, and crystallization rate had to be chosen properly. The last two parameters could be influenced by a choice of solvent and a control of casting temperature. Depending on the casting conditions, different crystal orientation in the obtained layers was achieved (Tracz et al. 2007). This method was used in the past to obtain films of materials with structures oriented over large areas (Makowski et al. 2014; Tracz et al. 2007). Many materials were efficiently processed for an organic field-effect transistor (Duffy et al. 2008; Pisula et al. 2005), organic photovoltaic devices (Liu et al. 2013), and even thin films of diblock copolymer with a large-scale alignment of lamellae (Tang et al. 2005). In each case, the oriented structure was formed from a solution of the respective compound. So far, the zone casting technique was not used to obtain films with oriented crystals from their suspension.

In the study, the zone-casting method was used to achieve a large-scale orientation of CNCs. By optimization of the casting conditions of CNC aqueous suspension, the transparent film with the uniaxial orientation of crystals perpendicular to the casting direction was obtained. During the classical zone-casting, the crystal orientation is achieved through a crystallization process, whereas during the process with CNC suspension the ordering occurred at large length scales through alignment of the nanocrystals. The orientation of the nanocrystals was confirmed by polarized light microscopy, X-ray diffraction, and atomic force microscopy. The film exhibited optical anisotropy, with the strongest transmission of light polarized in the direction perpendicular to the crystal orientation direction.

Experimental

Materials

8 wt.% aqueous suspension of CNCs (BGB Ultra), produced with a transition metal-catalyzed oxidative process from a viscose grade dissolving pulp (wood source aspen and maple) was purchased from Blue Goose Biorefineries Inc. (Canada). According to the supplier (Blue Goose Biorefineries Inc. 2020), CNCs were of type I, with a crystallinity degree of 80%, determined by the Segal method, and able to form a chiral nematic network in water. The crystals were 100–150 nm long with transverse sizes of 9–14 nm, as determined by transmission electron microscopy. The carboxyl content was 0.15 mmol/g, and sulfate half ester moieties were absent.

Cover glasses, 35 mm × 50 mm, from Fisher Scientific (United Kingdom) were used as substrates for the films. The glasses were cleaned in distilled water for 10 min using an ultrasonic bath, then rinsed with ethanol and dried under nitrogen flow.

Film casting

The CNCs-based films were prepared using the zone casting method as shown schematically in Fig. 1. The CNC aqueous suspension was diluted with water to obtain a concentration of 2.5 mg/ml, and sonicated in an ultrasonic homogenizer Hielscher UP 200S (Germany) at 200 W, 15% amplitude, frequency 24 Hz at room temperature for 30 min.

To measure the ζ-potential of CNCs, the suspension was diluted with deionized water and admixed with an aqueous NaCl solution to obtain 0.05% CNC and 5 mM NaCl concentration. pH was varied by the addition of NaOH. The ζ-potential values are shown in Table S1 in Supplementary Information (SI). The values obtained for the CNC suspension ranged from −26 to −35 mV, and were similar to those provided by the producer (Blue Goose Biorefineries Inc. 2020).

The casting conditions were optimized to achieve a continuous and stable process allowing to obtain 2 μm thick films, 4 cm long and 2 cm wide, with oriented CNCs. The temperature of the aqueous CNC suspension and CNC concentration were varied from 25 to 60 °C and from 1 to 4 mg/ml, respectively. In addition, substrate movement rates ranging from 5 to 9 μm/s were tested. Too low or too high suspension temperature resulted in the lack of CNC orientation due to the unstable meniscus. Insufficient CNC concentration resulted in too thin and discontinuous layers. Excessive concentration caused self-assembly of CNCs starting during deposition, whereas too slow substrate movement resulted in too small meniscus, both worsening the uniaxial orientation.

Finally, at the optimized conditions, the films with uniaxial orientation of CNCs were obtained. The suspension with a CNC concentration of 2.5 mg/ml, kept at 50 °C, was pushed by the piston of a 1 ml injector to flow through a slit-like nozzle at a constant rate of 1.3 × 10−4 ml/s. The suspension was deposited on the glass substrate, also kept at 50 °C, and moving at a rate of 9 μm/s. The evaporation of water resulted in the formation of the solid CNC film.

Characterization

The zone-cast films were examined with polarized light microscopy (PLM) under a Nikon Eclipse E400 Pol microscope equipped with a SANYO VCC-3770P camera.

The crystalline structure of the films was studied with wide-angle X-ray diffraction (WAXD), using an X-ray diffractometer coupled to a sealed-tube source of filtered CuKα radiation (λ = 0.154 nm), operating at 40 kV and 8 mA, PANalytical XRD Aeris from Malvern Panalytical (United Kingdom). 2θ scans were collected in a reflection mode with a step of 0.02°.

Moreover, the orientation of CNCs in the films was investigated with 2D-WAXS in a transmission mode. Malvern Panalytical (the Netherlands) diffractometer was used, with nickel-filtered CuKα operating at 50 kV and 30 mA. The 2D-WAXS patterns were collected with a Pilatus 100 K detector from Dectris (Switzerland).

The morphology was investigated using atomic force microscopy (AFM) in a tapping mode at room temperature. Images were recorded under an ambient atmosphere using a Nanoscope IIIa MultiMode from Digital Instruments (USA), with a scanner sampling resolution of 512 × 512 data points. Probes with rectangular silicon cantilevers, RTESP from Veeco (USA) were used, with a nominal radius of curvature of 7–10 nm, a spring constant of 20−80 N/m, and a resonance frequency between 264 and 369 kHz. Image analysis was performed using SPIP Image Metrology software (Denmark). The thickness of the films was determined with AFM in a height mode. Three filmswere measured in at least three places to determine an average value.

Results and discussion

2 cm × 4 cm films with CNC uniaxial orientation were obtained. The thickness of CNC films, measured with AFM, was 2 µm, as illustrated in Fig. 2a. The film thickness was uniform and varied no more than ± 0.1 μm.

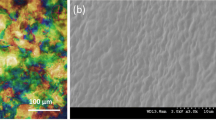

The cast films were transparent, as shown in Fig. 2b. The micrographs shown in Fig. 3 evidence orientation of CNCs. The film was birefringent and exhibited strong optical anisotropy. The incident beam, polarized in the direction parallel or perpendicular to the casting direction (CD), was extinguished by the analyzer. The maximum intensity of transmitted light was observed at 45° angle between CD and the analyzer and polarizer axes, as is also shown in Fig. 3.

WAXD curve of CNC film, in Fig. S1 in SI shows two overlapping peaks at 2θ of 14.75° and 16.5°, and a peak at 22.5° as it was observed for the same CNCs by others (Delepierre et al. 2021). These peaks are typical of the I form of cellulose crystals. 2D-WAXD pattern of CNC film is shown in Fig. 4a. The equatorial reinforcement of the 22.5° reflection evidences the orientation of CNCs in the film with the planes containing chain axes [(110)Iα and (200)Iβ (Kim et al. 2013)] perpendicular to the CD. The Hermans orientation factor calculated for this reflection was 0.7. The AFM image presented in Fig. 4b confirms the CNC orientation perpendicular to CD. Exemplary AFM height profiles are shown in Fig. S2 in SI. The mean transversal size of CNCs was 15.6 nm. In turn, Fig. S3 in SI shows exemplary vector field image, obtained using the OrientationJ plugin for ImageJ software, confirming the orientation of CNCs in the films perpendicular to CD. The coherency (C) was calculated with this software, based on the eigenvalues of the so-called structure tensor, which elements are convolutions of a tapering function and products of partial derivatives of the brightness function (Puspoki et al. 2016). The measurements were conducted for three films and the results were averaged. The details of the calculation of C are given in SI. The obtained value of C was 0.82. C is 1 when the local structure is oriented in one direction and C is 0 if the image is isotropic, thus the value of 0.82 confirms the good orientation of the nanocrystals.

In general, the ability of CNCs to form stable suspensions and their ability to self-organize are governed by the orientation dependent attractive interactions due to van der Waals forces and the repulsive interactions either steric or electrostatic. The alignment of CNCs, favored by a higher concentration, results from a compromise between the rotational and translational entropies of individual nanocrystals and electrostatic effects (Parker et al. 2018).

The orientation of CNCs occurred during the zone-casting process due to the concentration gradient, resulting in the highest concentration in the vicinity of the zone of film formation.

In addition, it was undoubtedly influenced by the shape anisotropy of CNCs. Most research on evaporative film formation has focused on CNCs stabilized by strong acid sulfate half ester surface groups, which have a strong tendency to form chiral nematic films. Here, the CNCs used were stabilized by weak carboxyl groups, which minimized the tendency to form chiral nematic structures, and facilitated the observed uniaxial orientation. Moreover, the low CNC concentration, low flow rate, and low substrate movement rate permitted to avoid any shear-induced orientation along the motion direction, again facilitating the observed orientation.

One can expect that the transmission of light may depend on its polarization direction in respect to the orientation of CNCs in the film. Indeed, Fig. 5 shows a dependence of the intensity of light transmitted through the CNC film on an angle between the orientation direction of the crystals and the incident beam polarization direction. The transmission was the strongest for the light polarized in the direction perpendicular to the orientation direction of the crystals, that is in the CD.

Conclusion

8 cm2 CNC films, 2 µm thick, with uniaxially oriented nanocrystals were obtained from CNC aqueous suspension with the zone-casting technique, in an environmentally friendly process. Optimization of the zone-casting conditions permitted us to achieve the uniaxial orientation of the nanocrystals and the continuity and reproducibility of the production process of the novel films with the preserved crystal orientation on a macroscopic scale. It must be emphasized that there is a difference between the classical zone-casting process, where the crystal orientation was achieved through a crystallization and the process with CNC suspension, where the ordering occurs at larger length scales through alignment of the nanocrystals. It is worth mentioning that the zone-casting process was continuous and stable, and much longer films can be easily obtained on substrates of appropriate length. Moreover, the zone-casting was a one-step process on the glass substrate, which did not require any special preparation, and the obtained films did not require post-casting drying to remove water.

The uniaxial orientation of nanocrystals in the films perpendicular to the zone-casting direction was evidenced by PLM, AFM, and 2D-WAXD. The films were transparent and exhibited optical anisotropy. The transmission of light depended on its polarization direction in respect to the crystal orientation direction and was the strongest for the light polarized perpendicularly to the crystal orientation direction. The properties of the novel CNC films obtained in an environmentally friendly process make them interesting materials for optoelectronics.

Data availability

The data that support the findings of this study are available from the corresponding author, T.M., upon reasonable request.

References

Cherpak V, Korolovych VF, Geryak R, Turiv T, Nepal D, Kelly J, Bunning TJ, Lavrentovich OD, Heller WT, Tsukruk VV (2018) Robust chiral organization of cellulose nanocrystals in capillary confinement. Nano Lett 18:6770–6777. https://doi.org/10.1021/acs.nanolett.8b02522

Chowdhury RA, Peng SX, Youngblood J (2017) Improved order parameter (alignment) determination in cellulose nanocrystal (CNCs) films by a simple optical birefringence method. Cellulose 24:1957–1970. https://doi.org/10.1007/s10570-017-1250-9

Csoka L, Hoeger IC, Peralta P, Peszlen I, Rojas OJ (2011) Dielectrophoresis of cellulose nanocrystals and alignment in ultrathin films by electric field-assisted shear assembly. J Coll Interface Sci 363:206–212. https://doi.org/10.1016/j.jcis.2011.07.045

Delepierre G, Vanderfleet OM, Niinivaara E, Zakani B, Cranston ED (2021) Benchmarking cellulose nanocrystals part ii: new industrially produced materials. Langmuir 37:8393–8409. https://doi.org/10.1021/acs.langmuir.1c00550

Diaz JA, Wu XW, Martini A, Youngblood JP, Moon RJ (2013) Thermal expansion of self-organized and shear-oriented cellulose nanocrystal films. Biomacromol 14:2900–2908. https://doi.org/10.1021/bm400794e

Droguet BE, Liang HL, Frka-Petesic B, Parker RM, De Volder MFL, Baumberg JJ, Vignolini S (2022) Large-scale fabrication of structurally coloured cellulose nanocrystal films and effect pigments. Nat Mater 21:352–358. https://doi.org/10.1038/s41563-021-01135-8

Duffy CM, Andreasen JW, Breiby DW, Nielsen MM, Ando M, Minakata T, Sirringhaus H (2008) High-mobility aligned pentacene films grown by zone-casting. Chem Mater 20:7252–7259. https://doi.org/10.1021/cm801689f

Edgar CD, Gray DG (2003) Smooth model cellulose I surfaces from nanocrystal suspensions. Cellulose 10:299–306. https://doi.org/10.1023/a:1027333928715

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110:3479–3500. https://doi.org/10.1021/cr900339w

Hoeger I, Rojas OJ, Efimenko K, Velev OD, Kelley SS (2011) Ultrathin film coatings of aligned cellulose nanocrystals from a convective-shear assembly system and their surface mechanical properties. Soft Matter 7:1957–1967. https://doi.org/10.1039/c0sm01113d

Blue Goose Biorefineries Inc. (2020). https://bluegoosebiorefineries.com/product/.

Khelifa F, Habibi Y, Leclere P, Dubois P (2013) Convection-assisted assembly of cellulose nanowhiskers embedded in an acrylic copolymer. Nanoscale 5:1082–1090. https://doi.org/10.1039/c2nr33194b

Kim SH, Lee CM, Kafle M (2013) Characterization of crystalline cellulose in biomass: Basic principles, applications, and limitations of XRD, NMR, IR, Raman, and SFG. Korean J Chem Eng 30: 2127–2141. https://doi.org/10.1007/s11814-013-0162-0

Kimura Y (2009) Molecular, structural, and material design of bio-based polymers. Polym J 41:797–807. https://doi.org/10.1295/polymj.PJ2009154

Kontturi E, Johansson LS, Kontturi KS, Ahonen P, Thune PC, Laine J (2007) Cellulose nanocrystal submonolayers by spin coating. Langmuir 23:9674–9680. https://doi.org/10.1021/la701262x

Liu JG, Gao X, Sun Y, Han YC (2013) A quasi-ordered bulk heterojunction of P3HT/PCBM solar cells fabricated by zone-casting. Solar Energy Mater Solar Cells 117:421–428. https://doi.org/10.1016/j.solmat.2013.06.031

Makowski T, Moustafa RM, Uznanski P, Zajaczkowski W, Pisula W, Tracz A, Kaafarani BR (2014) Structural, thermo-optical, and photophysical properties of highly oriented thin films of quinoxalinophenanthrophenazine derivative. J Phys Chem C 118:18736–18745. https://doi.org/10.1021/jp504750x

Mendoza-Galvan A, Tejeda-Galan T, Dominguez-Gomez AB, Mauricio-Sanchez RA, Jarrendahl K, Arwin H (2019) Linear birefringent films of cellulose nanocrystals produced by dip-coating. Nanomaterials 9:45. https://doi.org/10.3390/nano9010045

Nakajima H, Dijkstra P, Loos K (2017) The recent developments in biobased polymers toward general and engineering applications: polymers that are upgraded from biodegradable polymers, analogous to petroleum-derived polymers, and newly developed. Polymers 9:523. https://doi.org/10.3390/polym9100523

Parker RM, Guidetti G, Williams CA, Zhao TH, Narkevicius A, Vignolini S, Frka-Petesic B (2018) The self-assembly of cellulose nanocrystals: hierarchical design of visual appearance. Adv Mater 30:1704477. https://doi.org/10.1002/adma.201704477

Pauly M, Keegstra K (2008) Cell-wall carbohydrates and their modification as a resource for biofuels. Plant J 54:559–568. https://doi.org/10.1111/j.1365-313X.2008.03463.x

Piorkowska E (2019) Thermal properties of biobased polymers. Adv Polym Sci 283:1–35. https://doi.org/10.1007/12_2019_52

Pisula W, Menon A, Stepputat M, Lieberwirth I, Kolb U, Tracz A, Sirringhaus H, Pakula T, Mullen K (2005) A zone-casting technique for device fabrication of field-effect transistors based on discotic hexa-peri-hexabenzoeoronene. Adv Mater 17:684–689. https://doi.org/10.1002/adma.200401171

Puspoki Z, Storath M, Sage D, Unser M (2016) Transforms and operators for directional bioimage analysis: a survey. Focus Bio-Image Inf 219:69–93. https://doi.org/10.1007/978-3-319-28549-8_3

Querejeta-Fernandez A, Kopera B, Prado KS, Klinkova A, Methot M, Chauve G, Bouchard J, Helmy AS, Kumacheva E (2015) Circular dichroism of chiral nematic films of cellulose nanocrystals loaded with plasmonic nanoparticles. ACS Nano 9:10377–10385. https://doi.org/10.1021/acsnano.5b04552

Rofouie P, Alizadehgiashi M, Mundoor H, Smalyukh II, Kumacheva E (2018) Self-assembly of cellulose nanocrystals into semi-spherical photonic cholesteric films. Adv Funct Mater 28:1803852. https://doi.org/10.1002/adfm.201803852

Sanchez-Botero L, Dimov AV, Li RP, Smilgies DM, Hinestroza JP (2018) In situ and real-time studies, via synchrotron x-ray scattering, of the orientational order of cellulose nanocrystals during solution shearing. Langmuir 34:5263–5272. https://doi.org/10.1021/acs.langmuir.7b04403

Tang CB, Tracz A, Kruk M, Zhang R, Smilgies DM, Matyjaszewski K, Kowalewski T (2005) Long-range ordered thin films of block copolymers prepared by zone-casting and their thermal conversion into ordered nanostructured carbon. J Am Chem Soc 127:6918–6919. https://doi.org/10.1021/ja0508929

Tracz A, Masirek S, Klos M (2007) Fabrication of thin oriented organic layers and micropatterns by zone casting. Israel J Chem 47:401–408. https://doi.org/10.1560/ijc.47.3-4.401

Tran A, Boott CE, MacLachlan MJ (2020) Understanding the self-assembly of cellulose nanocrystals-toward chiral photonic materials. Adv Mater 32:1905876. https://doi.org/10.1002/adma.201905876

Wang RP, Yu H, Dirican M, Chen LL, Fang DJ, Tian Y, Yan CY, Xie JY, Jia DM, Liu H, Wang JS, Tang FC, Asiri AM, Zhang XW, Tao JS (2020) Highly transparent, thermally stable, and mechanically robust hybrid cellulose-nanofiber/polymer substrates for the electrodes of flexible solar cells. ACS Appl Energy Mater 3:785–793. https://doi.org/10.1021/acsaem.9b01943

Acknowledgments

This work was supported by BioMedChem Doctoral School of the University of Lodz and Lodz Institutes of the PAS, and statutory funds of CMMS PAS.

Funding

This study was funded by statutory funds of Centre of Molecular and Macromolecular Studies Polish Academy of Sciences and Doctoral School Bio-Med-Chem Doctoral School of University of Lodz and Lodz Institutes of Polish Academy of Science.

Author information

Authors and Affiliations

Contributions

Conceptualization, I.S., T.M., E.P.; investigation, I.S.; data analysis, I.S., T. M., E.P.; writing, T.M., E.P. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethics approval and consent to participate

All authors have understood and complied with the code of ethics, approved, and agreed to participate.

Consent for publication

All authors agreed to publish the paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shkyliuk, I., Makowski, T. & Piorkowska, E. Uniaxial orientation of cellulose nanocrystals by zone-casting technique. Cellulose 30, 10117–10124 (2023). https://doi.org/10.1007/s10570-023-05503-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05503-2