Abstract

One of the main challenges in the preservation of paper materials is the development of compatible and eco-friendly cleaning systems suitable for the wet removal of hydrophobic, aged compounds, such as greasy materials or synthetic adhesives, whose presence enhances paper degradation and worsens its optical features. To avoid the use of organic solvents that can be potentially harmful to operators, in this work we propose a new water-based gel obtained by chemical modification of gellan gum gel, a well-known paper cleaning hydrogel. With the aim of obtaining a cleaning system that is able to interact and adsorb not only hydrophilic cellulose degradation byproducts, but also greasy materials and synthetic adhesives, methacrylation has been applied on gellan gum. First, the chemical modification process of gellan gum has been monitored by means of NMR and ATR-FTIR spectroscopy. Then, the mechanical and physical–chemical properties of the resulting gel have been evaluated by using rheological, AFM, and wettability measurements. Finally, the compatibility and cleaning efficiency of the newly synthetized gel have been tested on paper with different age (from eighteenth and twentieth centuries) and composition by means of a multi-technique framework consisting of spectroscopic, chromatographic, SEM, colorimetric and pH measurements. This work shows a first interesting step towards the development of single component paper cleaning system, easy to use, for the removal of both cellulose hydrophilic degradation products and hydrophobic compounds from different paper typologies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Paper is a complex multicomponent material, mainly consisting of biopolymers. A mat of cellulose fibers is the main component, but hemicelluloses and lignin can also be present. Other substances can be included in the paper, the most common ones being sizing agents, glue, fillers, and media. Paper materials inevitably undergo degradation over time that occurs through the synergistic action of acid hydrolysis and oxidation processes whose evolution over time is dependent on environmental conditions, such as high humidity and temperature, air pollution, dust, and radiation (Proniewicz et al. 2001; Chiriu et al. 2018; Carter 1996; Łojewska et al. 2006; Margutti et al. 2001; Corsaro et al. 2013). Macroscopically, paper degradation causes a weakening of the material mechanical properties, due to the de-polymerization of the cellulose chains, and a yellowing and loss of optical quality, because of the formation of chromophores from the oxidation processes of cellulose, as well as hemicellulose and lignin (if these latter are present) (Łojewska et al. 2005; Mosca Conte et al. 2012; Liu et al. 2021; Łojewski et al. 2010). Overall, these degradation processes lead to the formation of low molecular mass products, among which organic acids are the most harmful compounds that have been detected (Potthast et al. 2022; Mazzuca et al. 2014). While up to the end of the eighteenth century western paper was mainly produced from cellulose fibers deriving from rags, from the nineteenth century paper manufacturing began to be based on wood-derived fibers made by mechanical and/or chemical pulping, which may contain also hemicelluloses and lignin. However, this manufacturing procedure of modern paper leads to a more fragile and degradable support, easily subjected to oxidation processes (Carter 1996; Librando et al. 2012; Chiriu et al. 2018).

During restoration, if wet cleaning procedure becomes necessary, (conservators might consider dry cleaning insufficient), several strategies could be taken into account. They are for example washing methods (immersion, blotter washing, suction table washing), using of hydroalcoholic solution, or eters of cellulose packs (Uchida et al. 2007; Iannuccelli et al. 2010; Zidan et al. 2017). In the last decades, the use of hydrogels for paper cleaning have been taken hold, due to their retentive properties as well as their easiness in preparation and application on paper samples. Proposed cleaning hydrogels can be obtained from natural precursors such as agar (Casoli, et al. 2013; Isca et al. 2015), Laponite (Warda et al. 2007) and gellan gum (Iannuccelli and Sotgiu 2010; Li et al. 2021). Recently, synthetic poly(vinylalcohol) based hydrogels, (Mazzuca et al. 2020) or Nanorestore gels (commercially available), like those based on poly(2-hydroxyethyl methacrylate) and poly(vinyl pyrrolidone) polymers (Leroux 2016; Mazzuca et al. 2017; Bonelli et al. 2018; Ferrari et al. 2018), caught on widely.

A great challenge in the restoration of paper materials involves the removal of specific added materials, such as oils, rust from clips, adhesives or natural glue, which can also be present due to past restoration operations. The great variety of chemical-physical properties of the products that need to be removed from paper requires specific multistep treatments to fulfill the cleaning procedure (Mills and White 1980; Gorassini et al. 2016; Micheli et al. 2018). The removal of these compounds is necessary not only for aesthetic reasons, but mostly because they further boost paper degradation leading to yellowing, mold, smell, and acidity increase, thus inducing a decrease of the shelf life of paper artworks (Pan et al. 2019). One of the problems to face, is the removal of greasy stains from paper sheets, due for example to oily residues from lamp oil, widely used near pages to facilitate reading. Indeed, until the mid-nineteenth century, the fuel for lamps was from natural source, later replaced by petroleum. Lamp oil are made up of vegetal (i.e. nuts, linseed) or animal (i.e. fish oil) and therefore can be composed by hydrophobic unsaturated triglycerides (Vereshchagin and Novitskaya 1965; Nykter et al. 2008; Mills and White 2012) that are the main causes of oxidation and crosslinking in air (Kochhar 1993; Lazzari and Chiantore 1999) that in turn, lead to paper yellowing and a decrease of the pH value with a consequent acceleration of cellulose depolymerization (Juita et al. 2012). Another example of added materials that need to be removed from paper concerns polymeric coatings, such as pressure sensitive tapes. Since their commercialization, tapes have been widely used to repair paper, as fasteners or as part of conservation treatments, with excellent results, but also with long-term disadvantages. Synthetic adhesives turn brownish and become hard and brittle over time, thus damaging paper optical quality (Comelli et al. 2014; Gómez et al. 2019). Removal of greasy materials or synthetic adhesives can be achieved with the use of neat organic solvents which are harmful for operators and can cause ink spreading (Müller et al. 2022). A valid alternative is represented by opportunely loaded gels, as for example, for greasy materials removal gellan gum hydrogel loaded with pluronic polymers (Mazzuca et al. 2016) or, for the removal of pressure adhesive tapes, the combined use of organic solvent in silicates or cellulosic poultice and suction points (Smith et al. 1984; Wahba et al. 2022). More recently, the use of highly retentive chemical Nanorestore gels loaded with oil in water microemulsion (Bonelli et al. 2018) or green solvent, i.e. diethyl carbonate, loaded in a chemical organogel, based on poly (ethyl methacrylate)-poly (methyl methacrylate) scaffolds have been proposed (Ferrari et al. 2018; Mirabile et al. 2020; Wahba et al. 2022). Loading step is essential (Leroux 2016); neat hydrogels indeed are not efficient enough for the removal of these materials from paper artworks. In the last years, the combined use of poly(vinylalcohol) (PVA) shelled microbubbles and ultrasounds has proven to be a valid alternative to the classic use of hydrogels in removing polymer-based tapes, but it requires good dexterity during the application of the ultrasound field to avoid irreversible damaging of the paper (D’Andrea et al. 2021). Nonetheless their cleaning action has only been evaluated on adhesive tapes ( Bonelli et al. 2018; Ferrari et al. 2018; Mirabile et al. 2020).

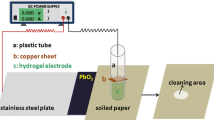

Motivated by these reasons, in this work we propose for the first time a system designed for the removal of substances with different hydrophobicity, such as oils, pressure adhesive tapes, and cellulose degradation products, consisting of a single component wall-to-wall hydrogel and capable of being completely and easily removed in one operation. The starting point is represented by the wet cleaning technique based on the use of deacylated gellan gum (GG) rigid hydrogel, whose effectiveness and compatibility with paper material have been well established (Iannuccelli and Sotgiu 2010; Bicchieri 2012; Di Napoli et al. 2020). More in detail, we propose to overcome the loading step by developing a single-component hydrogel which is made of a polymer matrix more hydrophobic than that the original one based on GG. In this way, by using a single water-based treatment, two important goals can be reached at the same time: (i) the polymer constituting the hydrogel preferentially interacts with the hydrophobic dirt fragments and removes them; and (ii) the hydrogel retains water within its matrix and absorbs hydrophilic degradation products deriving from cellulose. To this aim, the natural polysaccharide gellan gum has been chemically modified with methacrylic groups to obtain methacrylated gellan gum (GGMA). It is important to note that, to the best of our knowledge, up to now, GGMA has been employed mainly as a photo-crosslinkable polymer, in the pointing up of double network gel for tissue engineering, culturing, and, as a substrate in 3D bioprinting (Shin et al.2012; Osmalek et al. 2014; Viera et al. 2019; Jongprasitkul et al. 2022). In this article it is the first time that GGMA is characterized in the ionic hydrogel form and its properties are evaluated for application in the cultural heritage field. Resulting GGMA hydrogels were characterized by using rheological measurements and by means of Atomic Force Microscopy (AFM). Cleaning efficacy was evaluated through several non- and micro- invasive techniques, such as Attenuated Total Reflection FTIR spectroscopy (ATR-FTIR), High Performance Liquid Chromatography (HPLC), colorimetry, and pH measurements on both ancient and modern paper. On the other hand, the efficiency of hydrophobic components removal of GGMA hydrogel was evaluated by using it on a paper soiled with aged linseed oil and on an a sample with pressure sensitive adhesive tape. Cleaning efficacy results were compared with those obtained using unmodified gellan gum hydrogel.

Materials

Reagents and materials

Gellan gum powder Kelcogel® was purchased from CP Kelco (San Diego, California). Glycidyl methacrylate, calcium acetate, sodium hydroxide, methanol, sodium phosphate, and Whatman™ n°1 filter paper samples were purchased from Merck (Merck KGaA, Darmstadt, Germany). Linseed oil was purchased from Erboristeria Magentina (Turin, Italy). The 12,000 14,000 Da cut off dialysis tubes were purchased from Olinto Martelli srl (Florence, Italy). All reagents used were analytical grade and, except for gellan gum, were used without further purification. In all cases, bi-distilled water (Millipore, Billerica, MA, USA) was used in the preparation of solutions. Naturally aged paper samples (ancient paper) were from “Breviarium Romanum ad usum fratum” belonging to eighteenth century, while modern paper samples consisted of 1990s notebook paper. All samples come from a private collection.

Methods

Purification of gellan gum (GG)

GG was dissolved in distilled water at a concentration of 1% (w/v); then the solution was dialysed against distilled water using dialysis tubes (12,000 14,000 Da cut off) at room temperature for several days until the conductivity of the water was 0 μS. The dialysis step is necessary to remove salts, small molecules, and impurities derived from the industrial preparation process of GG. Finally, the solution was freeze dried to obtain purified GG polysaccharide.

Synthesis of gellan gum methacrylate (GGMA)

The purified GG was dissolved in distilled water at a concentration of 1% (w/v) at 90 °C and a proper amount of glycidyl methacrylate (GMA) was added at 50 °C to reach a final concentration of 7% (w/v). The reaction was maintained for 48 h at 50° C while the pH of the solution was maintained at 8 by adding 1 M NaOH solution. Then the solution was dialyzed in distilled water using dialysis tubes (12,000 × 14,000 Da cut off) at 4 °C for 5 days. Finally, the solution was freeze-dried to obtain pure GGMA (Shin et al. 2012; Pacelli et al. 2015; Jiang et al. 2020).

Preparation of gellan gum (GG) and gellan gum methacrylate (GGMA) hydrogels

GG hydrogels were prepared following protocols reported by Mazzuca et al., (2014, 2016). Briefly, GG and calcium acetate powder were dissolved in double-distilled water, stirring, with final concentration of 2% and 0.04% (w/v), respectively. The resulting mixture was put for almost a minute in the microwave at 600 W (Mars Microwave, CEM Corporation, Matthews, NC, USA) until it became boiling and transparent. Then, the homogeneous solution was poured and cooled to room temperature in a polyethylene terephthalate (PET) vessel of the desired dimensions for 1 h. The preparation of GGMA hydrogels was carried out with the same protocol, but using a final concentration of GGMA and calcium acetate of 2.5% and 0.08% (w/v), respectively. The slight differences between the concentrations of polysaccharide (GG and the GGMA) and relative calcium acetate contents were necessary to prepare hydrogels with similar rheological properties and therefore suitable for use as paper cleaning agents (see the “Results and Discussion” section).

1 H and 13 C NMR spectroscopy

1H (400 MHz) and 13C (101 MHz) NMR spectra were recorded at 40 °C using a Varian Mercury 400 spectrometer. Samples were dissolved in DMSO-d6 at a concentration of 10 mg/mL. Several drops of D2O were also added to the NMR tube to eliminate hydroxyl peaks and reduce viscosity. As the T1 values of the samples by inversion recovery were lower than 1 s, an acquisition time of 3 s was used with a 45° pulse. The water signal in qualitative 1H spectra was presaturated to improve signal-to-noise ratio. The sequence was not adopted for spectra exploited for quantitative purpose. DOSY spectra were acquired with a recycling delay of 5 s, diffusion delay of 500 ms, and 90° pulse.

ATR-FTIR spectroscopy

FTIR spectra of freeze-dried GG and GGMA were acquired with the Thermo-Scientific instrument (model is 50) (Thermo Scientific Inc., Madison WI, USA) in Attenuated Total Reflectance (ATR) mode using a single reflection diamond ATR cell. Spectra were recorded in the wavenumbers region from 4000 to 525 cm−1, averaging over 32 scans with a resolution of 2 cm−1. All experiments were performed in triplicate in same points (RSD < 1%) and in different points throughout the area of interest, obtaining consistent and repeatable results.

Contact angle measurement

The contact angles were measured on a KRÜSS DSA100 instrument. Measurement of the static contact angle was performed using the sessile drop method by placing a drop of bi-distilled water, at room temperature, using a micropipette. A set of 3 images was captured, with a simple digital camera, within 5 s after placing a drop of bi-distilled water on the dried hydrogel surface, and subsequent contact angle was measured by means of the Image Acquisition and Measurement Software (IC Measure software).

Rheology

Rheological measurements on GG and GGMA hydrogels were performed with a Rheometer MCR102, Anton Paar, with a plate-plate geometry (diameter = 49.97 mm). Temperature was controlled using a Peltier system, and solvent evaporation was avoided thanks to an evaporation blocker and an isolation hood. The samples were measured ~ 18 h and ~ 43 h after preparation, to test if samples were characterized by aging and to verify reproducibility. They remained stable for the entire investigated time interval. Storage (G′) and loss (G″) moduli were measured at T = 25 °C ~ 18 h after preparation as a function of the shear strain γ at frequency f = 1 Hz (strain or amplitude sweep test).

Atomic force microscopy (AFM)

AFM measurements were performed in air at room temperature using a DIMENSION ICON instrument (Bruker AXS, Germany) equipped with a Nanoscope V controller and enclosed in an insulating box. Images were collected in tapping mode using high resolution rotated-tapping mode etched silicon probes (RTESP), with a nominal tip radius of 8 nm. The samples were prepared by depositing a piece of hydrogel on freshly cleaved mica for 30 s, then gently rinsing with 1 mL of bi-distilled water and drying in air for 30 min. Gwyddion free software was used to correct images by eliminating background and levelling defects.

Sample preparation and hydrogel application on paper samples

Whatman filter paper samples soiled with linseed oil were prepared in 2013 by dipping paper samples for 20 s in linseed oil and leaving to dry at room temperature (Mazzuca et al. 2016) and successively, artificially aged for 20 days at 80 °C (Lazzari and Chiantore 1999).

To perform the cleaning process, a piece of gel was taken from the stock and, if necessary, cut to obtain the desired size. During the procedure, the paper sample was fully covered with the gel of about 1 cm thickness. A uniformly pressed PET film was applied over it to minimize the evaporation of water and to ensure a close contact between the gel and the sample. After cleaning, the gel was manually peeled off in one step.

The solubilization and spreading effects of GGMA hydrogel (and for comparison, of GG hydrogel) towards handwritten words, in the margins of a paper sheet, have been carefully evaluated. A blank part of Breviarium sample was written using the following media: blue pencil (Faber Castell GA, Stein, Germany) a retractable ballpoint pen with blue, black and red inks (Carioca spa, Settimo Torinese, Italy), and a home-made indian ink. Handwritten paper sheets were prepared 7 days before hydrogels application.

Determination of hydrogel retentive properties

During hydrogels application, the weight of the paper sheets was recorded every 15 min to monitor the water uptake during the experiment. For this, a dual-range XS105 Mettler Toledo precision balance (up to 0.0001 g; Mettler Toledo Inc., Columbus, Ohio USA) was used; wet samples were placed on an aluminum foil. Experiments were performed at 20 °C and RH = 50%.

Determination of paper fibers composition

The paper fibers composition was estimated by exposing them to graff “C” stain (Adamopoulos and Oliver 2006). Graff “C” was prepared by mixing in 52mL of a ZnCl2 saturated solution 0.06 mol of AlCl3 and 0.06 mol of CaCl2, 0.64 mmol of I2 and 1.4 mmol of KI. To analyze paper materials, a drop of stain was applied to a very small portion of each sample, previously chopped with the help of a drop of water. The sample was then placed on a microscope slide and observed on the Nikon Eclipse Ti–E microscope using a 20 × objective.

Scanning electron microscopy (SEM)

Scanning electron microscopy measurements were performed using a field emission scanning electron microscope (FE-SEM), (SUPRA 35, Carl Zeiss SMT, Oberkochen, Germany). Punched samples were previously metallized to allow electronic conduction on the sample surface to have high-quality images without deteriorating the samples or creating any kind of artifacts. The metallization, 1 min at 25 mA, was performed using a sputter coater (EMITECH K550X, Quorum Technologies Ltd., West Sussex, United Kingdom) with a gold target. The detector used was the secondary electron detector, since interest was mainly focused on the morphology of paper fibers and on the presence of residues from the cleaning agents. The main operating parameters of the instrument were 10 keV as the gun voltage and a working distance of about 8 mm.

Surface pH and colorimetry

pH measurements were carried out on paper and hydrogel surface, before and after every cleaning treatment, using a Crison pH meter, mod. Basic-20 (Crison Instruments s.a. Alella, Barcelona, Spain), equipped with a flat surface pH electrode (mod. HI1413B; Hanna Instruments Inc., Woonsocket, RI, USA). Colorimetry measurements concerning the optical quality of paper were performed using an Eoptis Digital Handheld Colorimeter (mod. CLM-194, Eoptis srl, TN, Italy). The coordinates in the CIELAB color space (L* = brightness, a* = red/green color component, b* = blue/yellow color component) were obtained using a D65 illuminant and a 10° observer. Chromatic variation tests before and after cleaning were reported in terms of ∆E = [(∆L*)2 + (∆a*)2 + (∆b*)2]1/2, which is the distance between two points in the CIELAB color space. All experiments were performed in triplicate in same points (RSD < 1%) and in different points throughout the area of interest, obtaining consistent and repeatable results.

High pressure liquid chromatography (HPLC)

HPLC analyses were performed using an Agilent 1100 HPLC system with autosampler (G1329A) equipped with four pumps (G1311A), and a 1100 Series Diode-array Detector (Agilent Technologies, CA, USA) with column C18 reverse phase (5 μm 250 × 4.6 mm PINNACLE II, RESTEK, USA). Analyses were performed on extracts obtained by treating 1 cm2 of paper samples with 1 mL of methanol, stirring on the rotating wheel (Dynal AS, Sweden) for 24 h at room temperature. After centrifugation at 6000 rpm, the supernatant was filtered on RephiQuik PTFE filter with pore size 0.45 μm (RephiLe Bioscience Ltd, Shanghai, China) and analyzed by HPLC. The analysis was carried out using gradient conditions of the mobile phase using bi-distilled water with 2% acetic acid at pH 3 (solution A) and methanol (solution B, organic modifier in the aqueous solvent A). The gradient starts at 5% methanol and increases as reported in Table S1. Each chromatographic analysis was repeated three times on the same day and also on different days for all samples, to compare the reproducibility of results.

Results and discussion

Gellan gum methacrylate functionalization

Deacetylated gellan gum is a linear hetero-polysaccharide whose repeating unit is a tetramer of one (1,3)-β-d-glucose, one (1,4)-β-d-glucose, one (1,3)-β-d-glucuronic acid, and one (1,4)-α-l-rhamnose (Morris et al. 2012), as illustrated in the chemical structure reported in Fig. 1. In order to design a smart material with peculiar features, GG has been chemically modified to obtain methacrylated gellan gum by exploiting the high content of hydroxyl groups that can undergo a methacrylation reaction in the presence of glycidyl methacrylate. The chemical functionalization is schematically shown in Fig. 1.

To monitor the occurrence of the chemical modification of gellan gum, 1H NMR spectra of GGMA and GG have been recorded, as reported in Fig. 2A and 2B. The 1H NMR spectrum of GG (Fig. 2B) is characterized by the presence of four main peaks that correspond to –CH of rhamnose (δ 5.05 ppm, R1), –CH of glucuronic acid (δ 4.28 ppm, GA1), –CH of glucose (δ 4.40 ppm, G21), and –CH3 of rhamnose (δ 1.14 ppm, R6). Differently, the 1H NMR spectrum of GGMA (Fig. 2A) shows the appearance of distinctive peaks in the double bond region (δ 6.04 and 5.65 ppm) and a sharp peak (δ 1.86 ppm) that corresponds to the –CH3 of the methacrylate moiety (see label C in Fig. 2). In addition, the 13C NMR spectrum of GGMA has signals at 167.1 ppm (C=O), 136.1 (CH2=), 126.6 ppm (CH=), and 18.3 ppm (CH3) that are not detected in the pristine GG, as shown in Fig. S1 of the Supporting Information (SI). A further validation was carried out through 2D DOSY analysis (Fig. S2 of the SI) which suggests that the assigned H resonance peaks belong to moieties that diffuse at the same rate as the polysaccharide main chain, thus confirming that the methacrylate functional groups are successfully bound to the macromolecular structure. Moreover, the methacrylation of GG was also confirmed by ATR-FTIR analysis through the broadening of the band at approximately 1640 cm−1, due to the presence of a double carbon bond (C=C), and the characteristic signal around 1730 cm−1, ascribed to the stretching of the C=O belonging to methacrylic ester (Fig. S3). Both bands were absent in the starting GG spectra.

1H NMR spectra of A GGMA and B GG in DMSO-d6 at 40 °C after water presaturation. Assigned peaks are labeled as: (R1) –CH of rhamnose, (GA1) –CH of glucuronic acid, (G21) –CH of glucose, (R6) –CH3 of rhamnose, and C –CH3 of the methacrylate moiety. Red vertical lines highlight the chemical shift of the distinctive peaks that appear in GGMA, but not in GG

The derivatization degree (DD) of GGMA, defined as the fraction of hydroxyl groups (OH) modified with-methacrylated moieties, was calculated by comparing the integral value of the methyl peak of methacrylate (δ 1.86 ppm, see label C in Fig. 2) in the 1H NMR spectrum to that of a reference polysaccharide peak (Fig. S4 of the SI), by using the following equation:

where \({I}_{1.86}\) is the integral value of the methacrylate methyl peak; 3 is the number of equivalent protons of the methyl group; \({I}_{ref}\) is the integral value of a reference peak of the polysaccharide; \({n}_{r}\) is the number of equivalent protons of the reference signal; and 10 is the number of hydroxyl groups in repeating unit of gellan gum. The methyl rhamnose peak (R6 in Fig. 2, \({n}_{r}=3\)) or the anomeric rhamnose peak (R1 in Fig. 2, \({n}_{r}=1\)) can be chosen as a reference, being the furthest from the water signal. However, independently on the choice of the reference peak, the calculated DD value is 0.014.

To investigate the reaction mechanism of gellan gum chemical functionalization, 13C NMR spectra of GG and GGMA were collected. Two different reaction pathways may be identified as responsible for the polysaccharide functionalization with GMA, i.e. transesterification or addition of the oxirane ring to any hydroxyl group of GG (see Fig. S5 of the SI). The comparison between the 13C NMR spectra of GG and GGMA in the 65–75 ppm region reported in Fig. 3A shows that only for GGMA two carbon peaks are detected at 65.6 and 67.7 ppm. However, in the case of the addition of the oxirane ring, three extra peaks corresponding to the carbons 5, 6 and 7 would be expected (see Fig. 3A). On the contrary, no extra peaks with the chemical shift expected for carbon 6 are detected. In addition, as shown by the distortionless enhancement polarization transfer spectra (DEPT) at 135° reported in Fig. 3B, negative signals for both new peaks are observed, thus excluding that they belong to CH. Indeed, in DEPT 135 CH and CH3 peaks are positive, CH2 is negative, and quaternary carbons are absent. These results reveal that negligible modification of GG by the addition pathway occurred. Thus, transesterification is the preferred reaction pathway for gellan gum methacrylation. Under this assumption, the carbon peak at 65.6 ppm can be identified as the CH2 carbon of the substituted polysaccharide units, i.e. G1 or G2 or both, as shown in Fig. 1. On the other hand, the less intense carbon peak at 67.7 ppm can have two possible origins: (i) it is a signal related to a CH2 carbon of substituted polysaccharide which contains less substituted units, or (ii) it belongs to a methacrylated group formed by addition of oxirane whose other signals are not detectable because of the reduced probability of this reaction pathway. In any case, the much higher intensity of the 65.6 ppm peak reveals that the glucose CH2 carbon is the preferred reactive site for the methacrylate derivatization.

Gellan gum methacrylate hydrogels

Having verified the occurrence of gellan gum methacrylate functionalization, the capability of modified gellan gum to form hydrogels, suitable for paper cleaning applications, has been investigated. As shown in Fig. S6 of the Supporting Information, GGMA is still able to form hydrogels by decreasing temperature in the presence of divalent cations, with only a slight change in the concentrations of the constituents. The wettability of both GG and GGMA dried hydrogels was also determined at room temperature. This measurement allows to investigate the hydrophobicity of the material and to understand how a polar solvent may interact with it. Before measurements, both samples were placed on glass slides and dried at room temperature overnight, in order to emphasize the possible different properties (Vanbeek et al. 2008). As shown in Fig. 4A, the contact angle value (θ) for the GG dried hydrogel is 0°, indicating a complete material wettability and a high water affinity. A different behavior is observed for the GGMA dried hydrogel, whose measured contact angle is 88° ± 2° (Fig. 4B). These results reveal the higher hydrophobicity of the modified gellan gum.

To ascertain the effect of methacrylation on the internal structure of GGMA hydrogels, rheological measurements were performed. Figure 5 shows the comparison between two strain sweeps performed on GG and GGMA hydrogels, respectively. Both the storage and loss moduli show almost constant behavior at small strains with G′ > G″, indicating that the samples behave like an elastic solid with a hard structure, as suggested by the high value of the zero-strain moduli (order of 104 Pa). Then, at γ ∼ 1% G′ and G″ intersect. This point, which is defined as the critical stain γc, corresponds to the breaking point of the gel. It denotes the rupture of the macroscopic structure, and for γ > γc samples behave like a viscous liquid with G″ > G’. These data suggest that with a small change in the polysaccharide concentration (Cw = 2.0% for GG and Cw = 2.5% for GGMA) and in salt content (Cs = 2.5 mM for GG and Cs = 5 mM for GGMA) a very similar rheological behavior of the two hydrogels is observed.

This feature is important because the measured mechanical properties ensure an optimal removal ability of compounds from the surface. Indeed, a uniform contact between the gel and the paper is feasible, and, even after the cleaning treatment, hydrogels are not breakable during handling and, importantly, their shape does not change, allowing for an efficient and localized action.

The internal structure of GG and GGMA hydrogels was also characterized through AFM measurements, as shown in Fig.6A, B, respectively. Both systems form extended branched networks, with long and interconnected fibers. In addition, the distributions of values of fiber height shown in Fig. 6 C, D suggest the presence of different structural levels of order, from helix structures to side-by-side aggregation of double helices induced by divalent cations, in agreement with previous studies (Diener et al. 2020; Tavagnacco et al. 2023). These results reveal that the derivatization degree of 0.014 used in this work allows to obtain a good balance between the increased hydrophobicity of the modified material and its maintained ability to form hydrogels. It must be emphasized that DD of gellan gum with methacrylic moieties was kept low in order to avoid alteration in both gelation properties, due to the addition of relatively bulky substituents, and water solubility (Coutinho et al. 2010; Shin et al. 2012; Tavagnacco et al. 2023). Moreover, a lower DD is an advantageous goal from a point of view of economic savings, process scaling, and sustainability for the environment. Furthermore, the pH of the GGMA hydrogel is almost neutral (6.3 ± 0.1) and therefore suitable for paper cleaning applications.

Evaluation of paper compatibility

The compatibility of GGMA hydrogels with paper was tested on reference samples made of pure cellulose. First, the retentive properties of GGMA gels were measured by determining the amount of water released on Whatman filter paper sheets at fixed times. Information on the water release properties is fundamental to avoid sample damaging because of an excessive solvent absorption during the cleaning procedure. The measured weight increase due to water uptake from the hydrogel for a Whatman filter paper after 1 h of application is about 140% using the GGMA hydrogel. This result is similar to that obtained for classic GG hydrogel (150%) with the same application time and reference treated paper, indicating that GG and GGMA hydrogels have comparable retentive properties (Li et al. 2021). Then, the presence of gel residues on paper or the occurrence of changes in the morphology of cellulose fibers were evaluated. With this aim, the hydrogel weight and dimension were monitored during the application process, finding weight variations lower than 3% and no detectable size changes. Complementary ATR-FTIR and SEM experiments were also carried out on paper by comparing results before and after gel application and finding the absence of significant changes, as shown in Fig. S7. Finally, the effect GGMA hydrogel on paper pH and colorimetry values was tested. The pH value changes from 6.1 ± 0.1 to 6.3 ± 0.1 with the application of a GGMA hydrogel (after cleaning with GG it is 6.4 ± 0.1), while the colorimetric variation is negligible, i.e., 0.2 ± 0.1 (see Table 1A). Overall, these findings assess the full compatibility with paper of the proposed hydrogel.

Paper cleaning ability

The paper cleaning ability of the GGMA hydrogel was tested on two well-known paper samples, i.e., “Breviarium romanum ad usum fratrum” (hereafter called Breviarium) and modern notebook paper (Di Napoli et al. 2020; D’Andrea et al. 2021; Mazzuca et al. 2016). The qualitative composition of the paper samples was estimated using optical microscopy, by exposing the paper fibers to Graff ‘‘C’’ stain (Fig. S8). This test allows to distinguish common papermaking processes and plant fibers sources on the basis of the measured color range (Hubbe et al. 2019). Fig. S8A shows that the Breviarium paper fibers are stained red, which is the signal of a high cellulose content and thus a papermaking process based on rag pulp, as expected for a eighteenth century paper (Collings and Milner 1984). Similar analyses carried out on 1990s modern paper give light bluish-grey fibers, as reported in Fig. S8B. This result suggests that the modern paper sample was produced from bleached chemically treated wood pulp (using the Kraft process, also named “sulphate process”) (Čabalová et al. 2017).

The retentive properties of GGMA and GG hydrogels were evaluated for both paper samples. In the case of Breviarium paper, the measured weight increase by paper after 1 h of gel application is about 105% and 110% for GGMA and GG gels, respectively. In the case of notebook paper, the measured weight increase by paper is about 90% and 95% for GGMA and GG gels, respectively. These measurements confirm that, as in the case of Whatman paper, the retentive properties of the GG and GGMA hydrogels are the same and thus, the water uptake of a paper sheet in contact with GGMA hydrogel is similar to that of GG hydrogel.

Comparative diagnostic analyses before and after the hydrogel application were performed on the two kind of paper samples. The FTIR spectra reported in Fig. 7 show a decrease of the peaks intensity in the spectral region between 1750 and 1550 cm−1 after GG or GGMA gel application for both Breviarium and notebook modern paper samples, which is attributable to a reduction of cellulose degradation byproducts (Drábková et al. 2020). The difference in the variation of peaks intensity among the two paper samples is mainly attributable to a more pronounced degradation stage of Breviarium paper, because of a strong natural aging, and to the presence of waterproofing sizing agents in modern paper (Hubbe et al. 2019). The FTIR spectra also reveal that no peaks related to the presence of hydrogels residues are detected.

The effect of the hydrogel application on the paper acidity was then evaluated. The pH value of Breviarium surface increased from 6.7 ± 0.2 to 8.1 ± 0.3 and 7.6 ± 0.1 after cleaning with GGMA and GG hydrogel, respectively. On the other hand, modern notebook paper exhibited a starting pH value of 5.0 ± 0.2 which increased up to 5.7 ± 0.1 and 5.5 ± 0.1 after cleaning with GGMA and GG hydrogel, respectively (see Table 1B and C). These results demonstrate the ability of both hydrogels to remove acidic compounds deriving from cellulose degradation and from slightly acid peptides arising from gelatin used for sizing (Bronzato et al. 2015). The optical quality of cleaned paper has also been investigated by means of colorimetry experiments. For Breviarium paper ΔE* is 7.3 and 6.9 using GGMA and GG gels, respectively, while in the case of notebook paper ΔE* is 2.9 and 3.3 for GGMA and GG gels, respectively (see Table 1B and C). These findings suggest that the proposed treatment is able to remove molecules responsible for the paper yellowing. Importantly, microscope images reported in Figs. S9 and S10 in SI show that the contour of the printing inks and a selection of handwritten media (see Materials and Methods) remains stable in both paper samples and thus prove that GGMA cleaning does not cause ink spreading or solubilization on paper. Overall, the cleaning power of GG and GGMA hydrogels is similar, even on paper with different properties, demonstrating the efficacy and suitability of the proposed methacrylate-based system, as compared to well-established cleaning tools.

Hydrophobic compounds removal capacity

Having established the compatibility and cleaning effectiveness of GGMA hydrogels with paper, their removal ability of hydrophobic compounds was finally evaluated. As described in the Introduction, until the mid-nineteenth century linseed oil could be found in paper artifacts with the drawback of favoring paper yellowing and acidification, thus promoting cellulose depolymerization (Vereshchagin and Novitskaya 1965; Kochhar 1993; Lazzari and Chiantore 1999). For this reason, the hydrophobic compounds removal capacity was first studied on Whatman filter paper samples soaked with linseed oil and aged. Figure 8A shows the ATR-FTIR spectrum of a Whatman filter paper sample before cleaning. The bands detected at 1730 cm−1 and 1600 cm−1 can be assigned to the stretching mode of the carbonyl and carboxylate moieties, respectively, thus signaling the presence of acid and oxidation compounds deriving from oil (Lazzari and Chiantore 1999). To monitor the cleaning efficacy of GGMA and GG hydrogels, the intensity of the band at 1730 cm−1, attributable to oil, is compared with that at 1024 cm−1, mainly related to the CO and CC stretching and CCH and OCH bending modes of cellulosic units (see Fig. S11A) (Łojewska et al. 2006). Therefore, the amount of oil on the paper sample is proportional to the intensity of the band at 1730 cm−1 with respect to that at 1024 cm−1. After the cleaning procedure with GGMA hydrogel, there is a significant decrease in the intensities of spectroscopic bands attributable to oil, but they remain almost unchanged after the application of GG hydrogel (see Table S2). These results demonstrate that the use of a more hydrophobic material, such as GGMA, is necessary to efficiently remove oil stains from paper. Moreover, no unexpected peaks, due to the presence of hydrogel matrix residues, are visible.

The ability of GGMA hydrogel to adsorb hydrophobic compounds can be explained by hypothesizing that methacrylate side chains of GGMA polymers self-associate, forming hydrophobic domains, similarly to what detected in aqueous solution for some hydrophobic derivatives of hyaluronate, another anionic polysaccharide (Creuzet et al. 2006). Similarly, formed hydrophobic domains in GGMA hydrogel can target and segregate small hydrophobic molecules adsorbed by the gel, leading to their efficient removal from paper. The evidence that hydrogel is not just an “inert water reservoir” but rather that the constituent polymers have a role in the cleaning process, has been already pointed out in the literature (Mazzuca et al. 2014, 2017). In particular, it was reported (Mazzuca et al. 2017) that hydrogels made up of poly(2-hydroxyethyl methacrylate) and poly(vinyl pyrrolidone) polymers have different affinity for acidic cellulosic by-products with respect to GG hydrogel, explaining the different cleaning properties of these hydrogel matrices.

In Fig. 8B, the chromatograms obtained from the extraction in methanol of the paper sample soaked in linseed oil before and after the cleaning process with GGMA and GG hydrogels are compared. The chromatogram of untreated paper (red curve in Fig. 8B) shows the complex characteristic profile of the lipid component, identifiable by the peaks at 40–50 min which belong to traces of linseed oil fat acids. After application of GGMA and GG hydrogels, the intensity of these peaks decreased, signaling partial oil removal, with a higher variation induced by GGMA hydrogels (see Table S2) (Mazzuca et al. 2016). Moreover, the absence of detectable residues of GGMA and GG hydrogels was confirmed by HPLC experiments in both water (data not shown), and methanol. In addition, as shown in Table 1D, the pH value of the paper increased from 4.3 ± 0.2 for the untreated samples to 4.4 ± 0.1 and 5.5 ± 0.2 after cleaning with GG and GGMA, respectively (the pH of the linseed oil is 4.9 ± 0.2). These results indicate that paper is degraded due to the oil action, but GGMA hydrogel is able to remove acid compounds deriving from cellulose and oil deterioration. Furthermore, as shown in Table 1D after a GGMA hydrogel cleaning process, the brightness of the sample increases (∆L* > 0), while the values of the red and yellow tones decrease (∆a* < 0 and ∆b* < 0, respectively). The application of GGMA hydrogels favors a color variation (∆E* = 15.1 ± 0.1) compared to the untreated sample. These data evidence the higher ability of the GGMA hydrogel to remove chromophore compounds, with respect to the GG hydrogel.

As a final test of the hydrophobic compounds removal capacity of GGMA hydrogels, we investigated the cleaning efficiency of aged modern adhesive (from pressure adhesive tape), a more hydrophobic material that is usually found on modern paper surface. The adhesive composition consists of aged synthetic rubber (a copolymer made of styrene and isoprene), and polypropylene or poly(vinylchloride) backing, as determined by ATR-FTIR spectroscopy (D’Andrea et al. 2021). Over time, the copolymer is subjected to oxidation processes which lead to the production of carbonyl compounds, identifiable by the band at 1730 cm−1, as shown in Fig. S11B, and to a worsening of the macroscopic features, such as yellowing and hardening (Comelli et al. 2014; Gómez et al. 2019). The variations in the FTIR spectra after the cleaning treatment were used to evaluate adhesive removal (see Fig. 9A). As reported for linseed oil, the band at 1730 cm−1, attributable to the stretching mode of the carbonyl moiety of the adhesive, is compared to that at 1024 cm−1, assignable to the vibrational modes of cellulose units (see Fig. S11B) (Gorassini et al. 2016). After the cleaning treatment, the absorbance at 1730 cm−1 decreases from 0.339 to 0.328 and 0.172 for GG and GGMA hydrogels, respectively. Even if the adhesive removal is not complete, these results, together with colorimetric and pH surface measurements (see Table 1E), prove that the use of a more hydrophobic material, such as GGMA, is necessary for the efficient removal of adhesive stains from paper. Importantly, images reported in Figs. 9B and S12 clearly highlight the greatest removal efficacy of GGMA with respect to GG, without removing or fading out notebook lines. The SEM images reported in Fig. S13 of the SI further confirm that the translucent adhesive patina on paper has been removed by GGMA, but not by GG, and that no residues are left on the samples.

Conclusions

In this work, the use of GGMA hydrogels has been evaluated as a a single component system, tool for a green, water-based removal of potentially harmful hydrophobic substances, such as oily materials and synthetic adhesives. The treatment is also suitable for different paper typologies. Notwithstanding the chemical modification of the gellan gum polymer, GGMA hydrogels exhibit rheological behavior similar to that of GG, thus allowing an easy handling and a good adaptation to paper surfaces. The compatibility and cleaning efficiency of the GGMA hydrogel have been assessed on paper samples differing in composition and state of degradation and compared to the behavior of GG hydrogel. The removal capability of hydrophilic substances as cellulose degradation byproducts of GGMA hydrogel was found to be comparable to that of GG. Moreover, the GGMA hydrogel has been tested for the removal of natural aged linseed oil from Whatman paper and old rubber-based pressure adhesive tape from modern notebook paper. By using a multi-technique approach, based on spectroscopic, chromatographic, SEM, colorimetric, and pH measurements, it has been shown that GGMA hydrogels possess cleaning properties similar to those of the GG hydrogel regarding hydrophilic residues, but due to its higher hydrophobic character, with the addition of an interesting hydrophobic residues removal activity, almost absent in the GG hydrogel. Even if a total hydrophobic component removal is not reached yet, the studied GGMA hydrogel represents an improvement over the well-established GG one. This preliminary study opens the way to a new class of opportunely modified GG-based hydrogels for paper cleaning, whose hydrophobic materials removal efficiency can be tuned by varying the derivatization degree of gellan gum.

Data availability

Data will be made available upon request. Data are also available on the online repository Zenodo (https://doi.org/10.5281/zenodo.8341525).

References

Adamopoulos S, Oliver JV (2006) Fiber composition of packaging grade papers as determined by the Graff" C" staining test. Wood Fiber Sci 38:567–575

Bicchieri M, Monti M, Piantanida G, Pinzari F, Iannuccelli S, Sotgiu S, Tireni L (2012) The Indian drawings of the poet Cesare Pascarella: non-destructive analyses and conservation treatments. Anal Bioanal Chem 402:1517–1528. https://doi.org/10.1007/s00216-011-5229-3

Bonelli N, Montis C, Mirabile A, Berti D, Baglioni P (2018) Restoration of paper artworks with microemulsions confined in hydrogels for safe and efficient removal of adhesive tapes. Proc Natl Acad Sci 115:5932–5937. https://doi.org/10.1073/pnas.1801962115

Bronzato M, Calvini P, Federici C, Dupont AL, Meneghetti M, Di Marco V, Biondi B, Zoleo A (2015) Degradation by-products of ancient paper leaves from wash waters. Anal Methods 7(19):8197–8205. https://doi.org/10.1039/c5ay01114k

Čabalová I, Kačík F, Gojný J, Češek B, Milichovský M, Mikala O, Tribulová T, Ďurkovič J (2017) Changes in the chemical and physical properties of paper documents due to natural ageing. BioResources 12:2618–2634

Carter HA (1996) The chemistry of paper preservation: part 2. The yellowing of paper and conservation bleaching. J Chem Educ 73:1068. https://doi.org/10.1021/ed073p1068

Casoli A, Cremonesi P, Isca C, Groppetti R, Pini S, Senin N (2013) Evaluation of the effect of cleaning on the morphological properties of ancient paper surface. Cellulose 20:2027–2043. https://doi.org/10.1007/s10570-013-9975-6

Chiriu D, Ricci PC, Cappellini G, Carbonaro CM (2018) Ancient and modern paper: Study on ageing and degradation process by means of portable NIR μ-Raman spectroscopy. Microchem J 138:26–34. https://doi.org/10.1016/j.microc.2017.12.024

Collings T, Milner D (1984) The nature and identification of cotton paper making fibres in paper. T Pap Conserv 8:59–71. https://doi.org/10.1080/03094227.1984.9638458

Comelli D, Toja F, D’Andrea C, Toniolo L, Valentini G, Lazzari M, Nevin A (2014) Advanced non-invasive fluorescence spectroscopy and imaging for mapping photo-oxidative degradation in acrylonitrile–butadiene–styrene: a study of model samples and of an object from the 1960s. Polym Degrad Stab 107:356–365. https://doi.org/10.1016/j.polymdegradsTable2013.12.030

Corsaro C, Mallamace D, Łojewska J, Mallamace F, Pietronero L, Missori M (2013) Molecular degradation of ancient documents revealed by 1H HR-MAS NMR spectroscopy. Sci Rep 3:2896. https://doi.org/10.1038/srep02896

Coutinho DF, Sant SV, Shin H, Oliveira JT, Gomes ME, Neves NM, Khademhosseini A, Reis RL (2010) Modified gellan gum hydrogels with tunable physical and mechanical properties. Biomaterials 31:7494–7502. https://doi.org/10.1016/j.biomaterials.2010.06.035

Creuzet C, Kadi S, Auzély-Velty RM (2006) New associative systems based on alkylated hyaluronic acid. Synth Aqueous Solut Properties Polym 47(8):2706–2713. https://doi.org/10.1016/j.polymer.2006.02.052

D’Andrea A, Severini L, Domenici F, Dabagov S, Guglielmotti V, Hampai D, Micheli L, Placidi E, Titubante M, Mazzuca C, Paradossi G, Palleschi A (2021) Ultrasound-stimulated PVA microbubbles for adhesive removal from cellulose-based materials: a groundbreaking low-impact methodology. ACS Appl Mater Interfaces 13:24207–24217. https://doi.org/10.1021/acsami.1c01892

Di Napoli B, Franco S, Severini L, Tumiati M, Buratti E, Titubante M, Nigro V, Gnan N, Micheli L, Ruzicka B, Mazzuca C, Angelini R, Missori M, Zaccarelli E (2020) Gellan gum microgels as effective agents for a rapid cleaning of paper. ACS Appl Polym Mater 2:2791–2801. https://doi.org/10.1021/acsapm.0c00342

Diener M, Adamcik J, Bergfreund J, Catalini S, Fischer P, Mezzenga R (2020) Rigid, fibrillar quaternary structures induced by divalent ions in a carboxylated linear polysaccharide. ACS Macro Lett 9:115–121. https://doi.org/10.1021/acsmacrolett.9b00824

Drábková K, Ďurovič M, Škrdlantová M (2020) Limitations of methods used for monitoring of various cellulose degradation mechanisms. Text Res J 90:1770–1782. https://doi.org/10.1177/0040517520901354

Ferrari P, Chelazzi D, Bonelli N, Mirabile A, Giorgi R, Baglioni P (2018) Alkyl carbonate solvents confined in poly (ethyl methacrylate) organogels for the removal of pressure sensitive tapes (PSTs) from contemporary drawings. J Cult Herit 34:227–236. https://doi.org/10.1016/j.culher.2018.05.009

Gómez M, Reggio D, Lazzari M (2019) Detection of degradation markers from polymer surfaces by a novel SERS-based strategy. Talanta 191:156–161. https://doi.org/10.1016/j.talanta.2018.08.046

Gorassini A, Adami G, Calvini P, Giacomello A (2016) ATR-FTIR characterization of old pressure sensitive adhesive tapes in historic papers. J Cult Herit 21:775–785. https://doi.org/10.1016/j.culher.2016.03.005

Hubbe MA, Chandra RP, Dogu D, Van Velzen STJ (2019) Analytical staining of cellulosic materials: a review. BioResources 14:7387–7464

Iannuccelli S, Sotgiu S (2010) Wet treatments of works of art on paper with rigid gellan gels. Book Paper Group Annu 29(2010):25–39

Isca C, Fuster-López L, Yusá-Marco DJ, Casoli A (2015) An evaluation of changes induced by wet cleaning treatments in the mechanical properties of paper artworks. Cellulose 22:3047–3062. https://doi.org/10.1007/s10570-015-0712-1

Jiang J, Tang Y, Zhu H, Wei D, Sun J, Fan H (2020) Dual functional modification of gellan gum hydrogel by introduction of methyl methacrylate and RGD contained polypeptide. Mater Lett 264:127341

Jongprasitkul H, Turunen S, Parihar VS, Kellomäki M (2022) Two-step crosslinking to enhance the printability of methacrylated gellan gum biomaterial ink for extrusion-based 3D bioprinting. Bioprinting 25:e00185

Juita DBZ, Kennedy EM, Mackie JC (2012) Low temperature oxidation of linseed oil: a review. Fire Sci Rev 1:3. https://doi.org/10.1186/2193-0414-1-3

Kochhar SP (1993) Deterioration of edible oils, fats and foodstuffs. Atmospheric Oxidation and Antioxidants. Elsevier, pp 71–139

Lazzari M, Chiantore O (1999) Drying and oxidative degradation of linseed oil. Polym Degrad Stab 65:303–313. https://doi.org/10.1016/S0141-3910(99)00020-8

Leroux M (2016) Soft matter: gel development for conservation treatment gellan gum and nanorestore gel®. The Book and Paper Group Annual, pp 43–47

Li H, Severini L, Titubante M, Gong D, Micheli L, Mazzuca C, Gong Y (2021) Gellan gum hydrogel as an aqueous treatment method for xuan paper. Restaur Int J Preserv Libr Arch Mater 42:37–54. https://doi.org/10.1515/res-2020-0010

Librando V, Minniti Z, Lorusso S (2012) Caratterizzazione di carta antica e moderna a mezzo spettroscopia FTIR e micro-Raman ancient and modern paper characterization by FTIR and micro-Raman spectroscopy https://doi.org/10.6092/ISSN.1973-9494/2700

Liu Y, Fearn T, Strlič M (2021) Factorial experimentation on photodegradation of historical paper by polychromatic visible radiation. Herit Sci 9:130. https://doi.org/10.1186/s40494-021-00602-4

Łojewska J, Miśkowiec P, Łojewski T, Proniewicz LM (2005) Cellulose oxidative and hydrolytic degradation: in situ FTIR approach. Polym Degrad Stab 88:512–520. https://doi.org/10.1016/j.polymdegradsTable2004.12.012

Łojewska J, Lubańska A, Miśkowiec P, Łojewski T, Proniewicz LM (2006) FTIR in situ transmission studies on the kinetics of paper degradation via hydrolytic and oxidative reaction paths. Appl Phys A 83:597–603. https://doi.org/10.1007/s00339-006-3529-9

Łojewski T, Zięba K, Knapik A, Bagniuk J, Lubańska A, Łojewska J (2010) Evaluating paper degradation progress. cross-linking between chromatographic, spectroscopic and chemical results. Appl Phys A 100:809–821. https://doi.org/10.1007/s00339-010-5657-5

Margutti S, Conio G, Calvini P, Pedemonte E (2001) Hydrolytic and oxidative degradation of paper. Restaurator. https://doi.org/10.1515/REST.2001.67

Mazzuca C, Micheli L, Carbone M, Basoli F, Cervelli E, Iannuccelli S, Sotgiu S, Palleschi A (2014) Gellan hydrogel as a powerful tool in paper cleaning process: a detailed study. J Colloid Interface Sci 416:205–211. https://doi.org/10.1016/j.jcis.2013.10.062

Mazzuca C, Micheli L, Lettieri R, Cervelli E, Coviello T, Cencetti C, Sotgiu S, Iannuccelli S, Palleschi G, Palleschi A (2016) How to tune a paper cleaning process by means of modified gellan hydrogels. Microchem J 126:359–367. https://doi.org/10.1016/j.microc.2015.12.016

Mazzuca C, Poggi G, Bonelli N, Micheli L, Baglioni P, Palleschi A (2017) Innovative chemical gels meet enzymes: a smart combination for cleaning paper artworks. J Colloid Interface Sci 502:153–164. https://doi.org/10.1016/j.jcis.2017.04.088

Mazzuca C, Severini L, Missori M, Tumiati M, Domenici F, Micheli L, Titubante M, Bragaglia M, Nanni F, Paradossi G, Palleschi A (2020) Evaluating the influence of paper characteristics on the efficacy of new poly(vinyl alcohol) based hydrogels for cleaning modern and ancient paper. Microchem J 155:104716

Micheli L, Mazzuca C, Missori M, Teodonio L, Mosca Conte A, Pulci O, Arcadipane L, Dominijanni S, Palleschi A, Palleschi G, Iannuccelli S, Sotgiu S (2018) Interdisciplinary approach to develop a disposable real time monitoring tool for the cleaning of graphic artworks. application on “le Nozze di Psiche.” Microchem J 138:369–378. https://doi.org/10.1016/j.microc.2018.01.022

Mills JS, White R (1980) Analyses of paint media. Natl Gallery Tech Bull 4:6567

Mills J, White R (2012) Organic chemistry of museum objects. Routledge

Mirabile A, Chelazzi D, Ferrari P, Montis C, Berti D, Bonelli N, Giorgi R, Baglioni P (2020) Innovative methods for the removal, and occasionally care, of pressure sensitive adhesive tapes from contemporary drawings. Herit Sci 8:42. https://doi.org/10.1186/s40494-020-00387-y

Morris ER, Nishinari K, Rinaudo M (2012) Gelation of gellan—a review. Food Hydrocoll 28:373–411. https://doi.org/10.1016/j.foodhyd.2012.01.004

Mosca Conte A, Pulci O, Knapik A, Bagniuk J, Del Sole R, Lojewska J, Missori M (2012) Role of cellulose oxidation in the yellowing of ancient paper. Phys Rev Lett 108:158301

Müller L, Henniges U, Schultz J, Wöllner A, Zumbühl S, Brückle I (2022) Pressure-sensitive tape removal in paper conservation: a review. J Paper Cons 23(2):59–75. https://doi.org/10.1080/18680860.2022.2060000

Nykter M, Kymäläinen H-R, Gates F (2008) Quality characteristics of edible linseed oil. Agric Food Sci 15:402. https://doi.org/10.2137/145960606780061443

Osmałek T, Froelich A, Tasarek S (2014) Application of gellan gum in pharmacy and medicine. Int J Pharma 466:328–340. https://doi.org/10.1016/j.ijpharm.2014.03.038

Pacelli S, Paolicelli P, Dreesen I, Kobayashi S, Vitalone A, Casadei MA (2015) Injectable and photocross-linkable gels based on gellan gum methacrylate: a new tool for biomedical application. Int J Biol Macromol 72:1335–1342. https://doi.org/10.1016/j.ijbiomac.2014.10.046

Pan C, Industry L, Tan W, Kuang B, Fang Y, Lin Y, Cai X (2019) A novel glue remover for pressure sensitive tapes on aged paper. Wood Res 64:759–772

Potthast A, Ahn K, Becker M, Eichinger T, Kostic M, Böhmdorfer S, Jeong MJ, Rosenau T (2022) Acetylation of cellulose–another pathway of natural cellulose aging during library storage of books and papers. Carbohydr Polym 287:119323

Proniewicz LM, Paluszkiewicz C, Wesełucha-Birczyńska A, Majcherczyk H, Barański A, Konieczna A (2001) FT-IR and FT-Raman study of hydrothermally degradated cellulose. J Mol Struct 596:163–169. https://doi.org/10.1016/S0022-2860(01)00706-2

Shin H, Olsen BD, Khademhosseini A (2012) The mechanical properties and cytotoxicity of cell-laden double-network hydrogels based on photocrosslinkable gelatin and gellan gum biomacromolecules. Biomaterials 33:3143–3152. https://doi.org/10.1016/j.biomaterials.2011.12.050

Smith MA, Jones NMM, Page SL, Dirda MP (1984) Pressure-sensitive tape and techniques for its removal from paper. J Am Inst Conserv 23:101–113. https://doi.org/10.1179/019713684806028241

Tavagnacco L, Chiessi E, Severini L, Franco S, Buratti E, Capocefalo A, Brasili F, Mosca Conte A, Missori M, Angelini R, Sennato S, Mazzuca C, Zaccarelli E (2023) Molecular origin of the two-step mechanism of gellan aggregation. Sci Adv 9:eadg4392. https://doi.org/10.1126/sciadv.adg4392

Uchida Y, Masamitsu I, Takayashu K (2007) Evaluation of aqueous washing methods of paper by the measurement of organic acid extraction. Restaurator 28:169–184. https://doi.org/10.1515/REST.2007.169

Vanbeek M, Jones L, Sheardown H (2008) Hyaluronic acid containing hydrogels for the reduction of protein adsorption. Biomaterials 29:780–789. https://doi.org/10.1016/j.biomaterials.2007.10.039

Vereshchagin AG, Novitskaya GV (1965) The triglyceride composition of linseed oil. J Am Oil Chem Soc 42:970–974. https://doi.org/10.1007/BF02632457

Vieira S, da Silva MA, Garet E, Silva-Correia J, Reis RL, González-Fernández Á, Oliveira JM (2019) Self-mineralizing Ca-enriched methacrylated gellan gum beads for bone tissue engineering. Acta Biomater 93:74–85. https://doi.org/10.1016/j.actbio.2019.01.053

Wahba WN, Shoshah NM, Nasr HE, Abdel-Maksoud G (2022) The use of different techniques for removal of pressure sensitive tapes from historical paper documents: a review. Egypt J Chem 65(131):1019–1031

Warda J, Brückle I, Bezúr A, Kushel D (2007) Analysis of agarose, carbopol, and laponite gel poultices in paper conservation. J Am Inst Conserv 46:263–279. https://doi.org/10.1179/019713607806112260

Zidan Y, El-Shafei A, Noshy W, Salim E (2017) A comparative study to evaluate conventional and nonconventional cleaning treatments of cellulosic paper supports. Mediterr Archaeol Archaeometr. https://doi.org/10.5281/ZENODO.1005538

Acknowledgments

C.M. and L.M. acknowledge Giulia Zanasi for support in HPLC measurements; all authors acknowledge the conservator Carola Gottscher for useful suggestions and interesting discussions. Authors acknowledge financial support from ERC POC project MICROTECH (grant agreement no.101066434).

Funding

Open access funding provided by Università degli Studi di Roma Tor Vergata within the CRUI-CARE Agreement. The authors acknowledge Regione Lazio through L.R. 13/08 Progetto Gruppo di Ricerca MICROARTE n. prot. A0375-2020-36515. C.M., M.M. and L.M. acknowledge funding from the National Research Council of Italy under the Project n. B86C19000230005 of the Joint Bilateral Agreement CNR/CACH Biennial Programme 2019–2021.

Author information

Authors and Affiliations

Contributions

CM, EZ supervised the research. LS experimental investigation, data analysis and interpretation. MB, MC performed the NMR measurements. SF, RA performed the rheology measurements. SS performed the AFM measurements. LT, EC, MM, BR planning experiments and revision of the article. LM performed the HPLC measurements.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Consent for publication

All authors have given their explicit consent to submit and have obtained consent from the responsible authorities at the institute and organisations where the work was carried out.

Ethical approval

No results of studies involving humans or animals are reported.

Ethical standards

This study was carried out based on Compliance with Ethical Standards.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Severini, L., Tavagnacco, L., Angelini, R. et al. Methacrylated gellan gum hydrogel: a smart tool to face complex problems in the cleaning of paper materials. Cellulose 30, 10469–10485 (2023). https://doi.org/10.1007/s10570-023-05479-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05479-z