Abstract

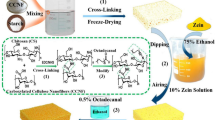

Oil gelling agent serves as potential materials in the treatment of marine oil pollution. However, the reported oil gelling agents have some limitations in practical applications, such as the high cost, complex synthesis, secondary pollution, and the lack of enough storage space for the inorganic oil gelling agents. Here, a novel powdery oil gelling agent with a hierarchical porous structure was developed and used in remediating oil pollution on the water surface. Based on the three-dimensional (3D) network of cellulose nanofibrils/silicon dioxide (CNFs/SiO2), it was found that GO acted as a larger skeleton and formed a double skeleton 3D network with CNFs to successfully construct the oil gelling agent (S/GO/CNFs/SiO2, SGCS) with hierarchical porous structure and selective wettability. SGCS can efficiently solidify various oil independent of environmental factors (temperature and pH), especially the accessibility of the large pores and the capillary action of the small pores contribute to the faster solidifying of crude oil. Resulting from the photothermal conversion function of GO, it shows the ability to recovery oil from the solidified state to achieve higher economic benefits. This study overcomes to a certain extent the current limitations of oil gelling agents and will provide powerful support for the application of oil gelling agents in practical marine oil spills.

Graphical abstract

Double skeleton powdery oil gelling agent constructed by cellulose nanofibrils and graphene oxide was successfully fabricated and utilized to effectively remove marine oil spill.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Alea C, Ruiz CI, Yap JB, Molina EF, Saballa AJ, Ñuneza JS, Bacharo KBB (2022) An investigation of aquatic oil spills in the Philippines from 2000 to 2021. Mar Pollut Bull 185:114241. https://doi.org/10.1016/j.marpolbul.2022.114241

Andrade A, Henríquez-Gallegos S, Albornoz-Palma G, Pereira M (2021) Effect of the chemical and structural characteristics of pulps of Eucalyptus and Pinus on the deconstruction of the cell wall during the production of cellulose nanofibrils. Cellulose 28:5387–5399. https://doi.org/10.1007/s10570-021-03848-0

Basak S, Nanda J, Banerjee A (2012) A new aromatic amino acid based organogel for oil spill recovery. J Mater Chem 22:11658. https://doi.org/10.1039/C2JM30711A

Carrier G, Fendell F, Mitchell J (1992) In situ burning via towed boom of oil spilled at sea. Combust Flame 90:295–306. https://doi.org/10.1016/0010-2180(92)90091-3

Çaykara T, Demirci S, Eroğlu MS, Güven O (2005) Poly(ethylene oxide) and its blends with sodium alginate. Polymer 46:10750–10757. https://doi.org/10.1016/j.polymer.2005.09.041

Chen J, Shen X, Wang R, Zhang R, Liu Z, Hao R, Su H (2020) Preparation and thermal decomposition behaviorof energetic functionalized graphene oxide and its catalytic effectonthe thermal decomposition of ap. Chin J Explos Propellants 43:180–187. https://doi.org/10.14077/j.issn.1007-7812.201909010

Chen X, Yang Y, Li Y, Bao M, Zhang D, Wang Z (2021) Integrated asymmetric superwetting Janus membrane for the efficient separation of various surfactant-stabilized oil–water emulsions. Environ Sci Nano 8:2235–2248. https://doi.org/10.1039/D1EN00335F

Copenhaver K, Li K, Wang L, Lamm M, Zhao X, Korey M, Neivandt D, Dixon B, Sultana S et al (2022) Pretreatment of lignocellulosic feedstocks for cellulose nanofibril production. Cellulose 29:4835–4876. https://doi.org/10.1007/s10570-022-04580-z

Dhaka A, Chattopadhyay P (2021) A review on physical remediation techniques for treatment of marine oil spills. J Environ Manag 288:112428. https://doi.org/10.1016/j.jenvman.2021.112428

Duan J, Gong S, Gao Y, Xie X, Jiang L, Cheng Q (2016) Bioinspired ternary artificial nacre nanocomposites based on reduced graphene oxide and nanofibrillar cellulose. ACS Appl Mater Interfaces 8:10545–10550. https://doi.org/10.1021/acsami.6b02156

Fan T, Su Y, Fan Q, Li Z, Cui W, Yu M, Ning X, Ramakrishna S, Long Y (2021) Robust graphene@pps fibrous membrane for harsh environmental oil/water separation and all-weather cleanup of crude oil spill by joule heat and photothermal effect. ACS Appl Mater Interfaces 13:19377–19386. https://doi.org/10.1021/acsami.1c04066

Ganesh Kumar A, Nivedha Rajan N, Kirubagaran R, Dharani G (2019) Biodegradation of crude oil using self-immobilized hydrocarbonoclastic deep sea bacterial consortium. Mar Pollut Bull 146:741–750. https://doi.org/10.1016/j.marpolbul.2019.07.006

Georgakilas V, Tiwari JN, Kemp KC, Perman JA, Bourlinos AB, Kim KS, Zboril R (2016) Noncovalent functionalization of graphene and graphene oxide for energy materials, biosensing, catalytic, and biomedical applications. Chem Rev 116:5464–5519. https://doi.org/10.1021/acs.chemrev.5b00620

Han X, Guo Z (2021) Graphene and its derivative composite materials with special wettability: potential application in oil-water separation. Carbon 172:647–681. https://doi.org/10.1016/j.carbon.2020.10.060

Hou Y, Zhong X, Ding Y, Zhang S, Shi F, Hu J (2020) Alginate-based aerogels with double catalytic activity sites and high mechanical strength. Carbohydr Polym 245:116490. https://doi.org/10.1016/j.carbpol.2020.116490

Kang W, Cui Y, Qin L, Yang Y, Zhao Z, Wang X, Liu X (2020) A novel robust adsorbent for efficient oil/water separation: magnetic carbon nanospheres/graphene composite aerogel. J Hazard Mater 392:122499. https://doi.org/10.1016/j.jhazmat.2020.122499

Kuznetsova A, Wovchko EA, Yates JTJ (1997) FTIR study of the adsorption and thermal behavior of vinyl triethoxysilane chemisorbed on γ-Al2O3. Langmuir 13:5322–5328. https://doi.org/10.1021/la9702401

Li Y-S, Wright PB, Puritt R, Tran T (2004) Vibrational spectroscopic studies of vinyltriethoxysilane sol–gel and its coating. Spectrochim Acta A 60:2759–2766. https://doi.org/10.1016/j.saa.2003.12.047

Li P, Cai Q, Lin W, Chen B, Zhang B (2016a) Offshore oil spill response practices and emerging challenges. Mar Pollut Bull 110:6–27. https://doi.org/10.1016/j.marpolbul.2016.06.020

Li Y, Zhang Z, Ge B, Men X, Xue Q (2016b) One-pot, template-free synthesis of a robust superhydrophobic polymer monolith with an adjustable hierarchical porous structure. Green Chem 18:5266–5272. https://doi.org/10.1039/c6gc01171c

Li J, Huo Y, Liu M, Zeng H (2017) Phase-selective organogelators for oil spill treatment. Prog Chem 29:617–627. https://doi.org/10.7536/PC170234

Liao CY, Lin JJ (2016) Recyclability of organically modified clays for oil absorption and recovery. RSC Adv 6:93081–93085. https://doi.org/10.1039/c6ra11992a

Lv D, Du H, Che X, Wu M, Zhang Y, Liu C, Nie S, Zhang X, Li B (2019) Tailored and integrated production of functional cellulose nanocrystals and cellulose nanofibrils via sustainable formic acid hydrolysis: kinetic study and characterization. ACS Sustain Chem Eng 7:9449–9463. https://doi.org/10.1021/acssuschemeng.9b00714

Marcano DC, Kosynkin DV, Berlin JM, Sinitskii A, Sun Z, Slesarev A, Alemany LB, Lu W, Tour JM (2010) Improved synthesis of graphene oxide. ACS Nano 4:4806–4814. https://doi.org/10.1021/nn1006368

Motta FL, Stoyanov SR, Soares JBP (2018) Application of solidifiers for oil spill containment: a review. Chemosphere 194:837–846. https://doi.org/10.1016/j.chemosphere.2017.11.103

Okesola BO, Smith DK (2016) Applying low-molecular weight supramolecular gelators in an environmental setting-self-assembled gels as smart materials for pollutant removal. Chem Soc Rev 45:4226–4251. https://doi.org/10.1039/c6cs00124f

Prathap A, Sureshan KM (2017) Organogelator-cellulose composite for practical and eco-friendly marine oil-spill recovery. Angew Chem Int Edit 56:9405–9409. https://doi.org/10.1002/anie.201704699

Prendergast DP, Gschwend PM (2014) Assessing the performance and cost of oil spill remediation technologies. J Clean Prod 78:233–242. https://doi.org/10.1016/j.jclepro.2014.04.054

Shen Y, Li B, Chen X, Wang S, Guan Y, Li Y (2022) Phase-selective cellulose nanofibril-based oil gelling agent for oil spill recovery. Environ Sci Nano 9:489–498. https://doi.org/10.1039/d1en00816a

Vibhute AM, Muvvala V, Sureshan KM (2016) A sugar-based gelator for marine oil-spill recovery. Angew Chem Int Edit 55:7782–7785. https://doi.org/10.1002/anie.201510308

Wang A, Li Y, Yang X, Bao M, Cheng H (2017) The enhanced stability and biodegradation of dispersed crude oil droplets by Xanthan Gum as an additive of chemical dispersant. Mar Pollut Bull 118:275–280. https://doi.org/10.1016/j.marpolbul.2017.03.001

Wang M, Zhang T, Mao D, Yao Y, Zeng X, Ren L, Cai Q, Mateti S, Li LH et al (2019) Highly compressive boron nitride nanotube aerogels reinforced with reduced graphene oxide. ACS Nano 13:7402–7409. https://doi.org/10.1021/acsnano.9b03225

Wang X, Liu Z, Liu X, Su Y, Wang J, Fan T, Ning X, Ramakrishn S, Long Y-Z (2022) Ultralight and multifunctional PVDF/SiO2@GO nanofibrous aerogel for efficient harsh environmental oil-water separation and crude oil absorption. Carbon 193:77–87. https://doi.org/10.1016/j.carbon.2022.03.028

Wu Y, Jia S, Qing Y, Luo S, Liu M (2016) A versatile and efficient method to fabricate durable superhydrophobic surfaces on wood, lignocellulosic fiber, glass, and metal substrates. J Mater Chem A 4:14111–14121. https://doi.org/10.1039/c6ta05259b

Wu W, Du M, Shi H, Zheng Q, Bai Z (2023) Application of graphene aerogels in oil spill recovery: a review. Sci Total Environ 856:159107. https://doi.org/10.1016/j.scitotenv.2022.159107

Ye R, Tour JM (2019) Graphene at fifteen. ACS Nano 13:10872–10878. https://doi.org/10.1021/acsnano.9b06778

Yi S, Su Y, Wan Y (2010) Preparation and characterization of vinyltriethoxysilane (VTES) modified silicalite-1/PDMS hybrid pervaporation membrane and its application in ethanol separation from dilute aqueous solution. J Membr Sci 360:341–351. https://doi.org/10.1016/j.memsci.2010.05.028

Yu L, Hao G, Liang Q, Jiang W (2015) Fabrication of magnetic porous silica submicroparticles for oil removal from water. Ind Eng Chem Res 54:9440–9449. https://doi.org/10.1021/acs.iecr.5b02428

Yu M, Zhang H, Yang F (2017) Hydrophilic and compressible aerogel: a novel draw agent in forward osmosis. ACS Appl Mater Interfaces 9:33948–33955. https://doi.org/10.1021/acsami.7b10229

Zeng J, Hu F, Cheng Z, Wang B, Chen K (2021) Isolation and rheological characterization of cellulose nanofibrils (CNFs) produced by microfluidic homogenization, ball-milling, grinding and refining. Cellulose 28:3389–3408. https://doi.org/10.1007/s10570-021-03702-3

Zhang J, Zhang F, Song J, Liu L, Si Y, Yu J, Ding B (2019) Electrospun flexible nanofibrous membranes for oil/water separation. J Mater Chem A 7:20075–20102. https://doi.org/10.1039/c9ta07296a

Zhou L, Xu Z (2020) Ultralight, highly compressible, hydrophobic and anisotropic lamellar carbon aerogels from graphene/polyvinyl alcohol/cellulose nanofiber aerogel as oil removing absorbents. J Hazard Mater 388:121804. https://doi.org/10.1016/j.jhazmat.2019.121804

Acknowledgments

Authors acknowledge funding by National Natural Science Foundation of China (22172149) and Taishan Scholars Foundation of Shandong Province.

Funding

This research is financially supported by National Natural Science Foundation of China (22172149) and Taishan Scholars Foundation of Shandong Province (tsqn202211053). This is MCTL contribution No.296.

Author information

Authors and Affiliations

Contributions

YS: Conceptualization, investigation, writing–original draft. BL: Resources, supervision. MW: Validation, visualization. XC: Supervision, writing–review and editing. YG: Visualization, writing–review and editing. SW: Visualization, writing–review and editing. YL: Supervision, writing–review and editing, funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics approval and consent to participate

All authors have consented to participate on the manuscript.

Consent for publication

All authors have approved the final version of the manuscript.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Movie S1: Crude oil was solidified by SGCS and removed from the seawater surface by a stainless steel mesh. (MP4 21193 KB)

Movie S2: Diesel was solidified by SGCS and removed from the water surface by a stainless steel mesh. (MP4 19134 KB)

Movie S3: Partial recovery of crude oil from solidified oil under simulated sunlight. (MP4 13411 KB)

10570_2023_5338_MOESM4_ESM.docx

SEM images of GCS and SGCS (Fig. S1). SEM images of SGCS prepared by different amounts of GO and TEOS (Fig. S2). Comparison of SGCS and SCS solidification capacity for different types of oil (Fig. S3). Photographs of different oil phases before and after solidification (Fig. S4). Stress sweep experiment of the solidified diesel and crude oil by SCS at a constant frequency (Fig. S5). Viscosity-temperature curve of crude oil (Fig. S6). The exploration of the dosage of each reagent in the preparation of SGCS (Table S1). Maximum oil solidification capacity of SGCS for different oil phases (Table S2). Comparison of solidification capability capacity with inorganic gelling agent. (Table S3). (MP4 9152 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shen, Y., Li, B., Wu, M. et al. Double skeleton network structure constructed by cellulose nanofibrils and graphene oxide as efficient oil gelling agent. Cellulose 30, 7763–7777 (2023). https://doi.org/10.1007/s10570-023-05338-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05338-x