Abstract

Microcrystalline cellulose (MCC) is a promising bio-based filler for lightweight yet mechanically high-performance eco-polymer composites because of its low density and high biocompatibility. However, intermolecular hydrogen bonding among MCC is stronger than the polymer–filler interactions, which deteriorate the mechanical properties of the composites. Herein, we investigated the effects of functional groups on the mechanical properties of composites by scrutinizing chemically modified microcrystalline methyl cellulose (m-MMC) with three different substitution levels of hydroxyl group to hydroxypropyl (HP) group: no-, low-, and high-level substitution (HP-0, HP-low, and HP-high). The degree of HP substitution of m-MMC was quantitatively measured by CP/MAS NMR analysis. The relatively bulky HP groups interrupted the filler–filler intermolecular interactions and reduced the crystallinity and density of m-MMC, as evident from X-ray diffractometer and pycnometer data, respectively. For scalable production of the composites, the m-MMC were compounded with thermoplastic polyurethane (TPU) by a twin-screw extruder at concentrations between 0.5 and 10 wt%. Despite its low filler concentration, the toughness of m-MMC/TPU composites was remarkably enhanced, up to 28% (229.2 to 294.4 MJ/m3) at 0.5 wt% loading of HP-low, owing to the enhanced polymer–filler interactions. The fundamental understanding on structure–property relationships will provide insights for designing of mechanically robust yet eco-friendly polymer composites.

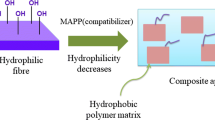

Graphical abstract

Similar content being viewed by others

References

Ago M, Endo T, Hirotsu T (2004) Crystalline transformation of native cellulose from cellulose I to cellulose II polymorph by a ball-milling method with a specific amount of water. Cellulose 11:163–167. https://doi.org/10.1023/B:CELL.0000025423.32330.fa

Ahn K, Zaccaron S, Zwirchmayr NS et al (2019) Yellowing and brightness reversion of celluloses: CO or COOH, who is the culprit? Cellulose 26:429–444. https://doi.org/10.1007/s10570-018-2200-x

Alves P, Cardoso R, Correia TR et al (2014) Surface modification of polyurethane films by plasma and ultraviolet light to improve haemocompatibility for artificial heart valves. Colloids Surf B Biointerfaces 113:25–32. https://doi.org/10.1016/j.colsurfb.2013.08.039

Annandarajah C, Langhorst A, Kiziltas A et al (2019) Hybrid cellulose-glass fiber composites for automotive applications. Mater (Basel) 12:1–11. https://doi.org/10.3390/ma12193189

Arun Kumar R, Sivashanmugam A, Deepthi S et al (2015) Injectable chitin-poly(ε-caprolactone)/nanohydroxyapatite composite microgels prepared by simple regeneration technique for bone tissue engineering. ACS Appl Mater Interfaces 7:9399–9409. https://doi.org/10.1021/acsami.5b02685

Avolio R, Bonadies I, Capitani D et al (2012) A multitechnique approach to assess the effect of ball milling on cellulose. Carbohydr Polym 87:265–273. https://doi.org/10.1016/j.carbpol.2011.07.047

Beardsmore GR, Cull JP (2010) Thermal conductivity. Crustal Heat Flow. https://doi.org/10.1017/cbo9780511606021.005

Blaine RL, Hahn BK (1998) Obtaining kinetic parameters by modulated thermogravimetry. J Therm Anal Calorim 54:695–704. https://doi.org/10.1023/A:1010171315715

Candau N, Stoclet G, Tahon JF et al (2021) Mechanical reinforcement and memory effect of strain-induced soft segment crystals in thermoplastic polyurethane-urea elastomers. Polym (Guildf) 223:123708. https://doi.org/10.1016/j.polymer.2021.123708

Chabros A, Gawdzik B, Podkościelna B et al (2020) Composites of unsaturated polyester resins with microcrystalline cellulose and its derivatives. Materials 13:62

Chang S, Han CD (1996) Effect of bulky pendent side groups on the structure of mesophase in a thermotropic main-chain liquid-crystalline polymer. Macromolecules 29:2103–2112. https://doi.org/10.1021/ma950913r

Chen H, Ginzburg VV, Yang J et al (2016) Thermal conductivity of polymer-based composites: fundamentals and applications. Prog Polym Sci 59:41–85. https://doi.org/10.1016/j.progpolymsci.2016.03.001

Dorigato A, Dzenis Y, Pegoretti A (2013) Filler aggregation as a reinforcement mechanism in polymer nanocomposites. Mech Mater 61:79–90. https://doi.org/10.1016/j.mechmat.2013.02.004

Filho GR, de Assunção RMN, Vieira JG et al (2007) Characterization of methylcellulose produced from sugar cane bagasse cellulose: crystallinity and thermal properties. Polym Degrad Stab 92:205–210. https://doi.org/10.1016/j.polymdegradstab.2006.11.008

Gallu R, Méchin F, Gérard JF, Dalmas F (2022) Influence of the chain extender of a segmented polyurethane on the properties of polyurethane-modified asphalt blends. Constr Build Mater 328:127061. https://doi.org/10.1016/j.conbuildmat.2022.127061

Graninger G, Kumar S, Garrett G, Falzon BG (2020) Effect of shear forces on dispersion-related properties of microcrystalline cellulose-reinforced EVOH composites for advanced applications. Compos Part A Appl Sci Manuf 139:106103. https://doi.org/10.1016/j.compositesa.2020.106103

Hospodiuk-Karwowski M, Bokhari SMQ, Chi K et al (2022) Dual-charge bacterial cellulose as a potential 3D printable material for soft tissue engineering. Compos Part B Eng 231:109598. https://doi.org/10.1016/j.compositesb.2021.109598

Hou X, Sun L, Wei W et al (2022) Structure and performance control of high-damping bio-based thermoplastic polyurethane. J Appl Polym Sci 139:52059. https://doi.org/10.1002/app.52059

Jin J, Ding J, Klett A et al (2018) Carbon fibers derived from fractionated-solvated lignin precursors for enhanced mechanical performance. ACS Sustain Chem Eng 6:14135–14142. https://doi.org/10.1021/acssuschemeng.8b02697

Kargarzadeh H, Huang J, Lin N et al (2018) Recent developments in nanocellulose-based biodegradable polymers, thermoplastic polymers, and porous nanocomposites. Prog Polym Sci 87:197–227. https://doi.org/10.1016/j.progpolymsci.2018.07.008

Khalid S, Yu L, Feng M et al (2018) Development and characterization of biodegradable antimicrobial packaging films based on polycaprolactone, starch and pomegranate rind hybrids. Food Packag Shelf Life 18:71–79. https://doi.org/10.1016/j.fpsl.2018.08.008

Krimm S, Tobolsky AV (1951) Quantitative X-ray studies of Order in amorphous and crystalline polymers. Text Res J 21:805–822. https://doi.org/10.1177/004051755102101106

Lee HJ, Ryu YS, Kim IS, Kim SH (2020) Pretreatment of microfibrillated cellulose on polylactide composites. Macromol Res 28:110–117. https://doi.org/10.1007/s13233-020-8016-1

Liang W, Xu Y, Li X et al (2019) Transparent polyurethane nanofiber air filter for high-efficiency PM2.5 capture. Nanoscale Res Lett 14:361. https://doi.org/10.1186/s11671-019-3199-0

Liu W, Fei M, Ban Y et al (2017) Preparation and evaluation of green composites from microcrystalline cellulose and a soybean-oil derivative. Polymers (Basel). https://doi.org/10.3390/polym9100541

Liu C, Wu W, Shi Y et al (2020a) Creating MXene/reduced graphene oxide hybrid towards highly fire safe thermoplastic polyurethane nanocomposites. Compos Part B Eng 203:108486. https://doi.org/10.1016/j.compositesb.2020.108486

Liu Z, Zhang S, He B et al (2020b) Temperature-responsive hydroxypropyl methylcellulose-N-isopropylacrylamide aerogels for drug delivery systems. Cellulose 27:9493–9504. https://doi.org/10.1007/s10570-020-03426-w

Maharjan B, Park J, Kaliannagounder VK et al (2021) Regenerated cellulose nanofiber reinforced chitosan hydrogel scaffolds for bone tissue engineering. Carbohydr Polym 251:117023. https://doi.org/10.1016/j.carbpol.2020.117023

Mattonai M, Pawcenis D, del Seppia S et al (2018) Effect of ball-milling on crystallinity index, degree of polymerization and thermal stability of cellulose. Bioresour Technol 270:270–277. https://doi.org/10.1016/j.biortech.2018.09.029

Miao C, Hamad WY (2013) Cellulose reinforced polymer composites and nanocomposites: a critical review. Cellulose 20:2221–2262. https://doi.org/10.1007/s10570-013-0007-3

Mohamad Haafiz MK, Eichhorn SJ, Hassan A, Jawaid M (2013) Isolation and characterization of microcrystalline cellulose from oil palm biomass residue. Carbohydr Polym 93:628–634. https://doi.org/10.1016/j.carbpol.2013.01.035

Nguyen Dang L, Le Hoang S, Malin M et al (2016) Synthesis and characterization of castor oil-segmented thermoplastic polyurethane with controlled mechanical properties. Eur Polym J 81:129–137. https://doi.org/10.1016/j.eurpolymj.2016.05.024

Omran AAB, Mohammed AABA, Sapuan SM et al (2021) Micro-and nanocellulose in polymer composite materials: a review. Polymers (Basel) 13:1–30. https://doi.org/10.3390/polym13020231

Parandeh S, Kharaziha M, Karimzadeh F (2019) An eco-friendly triboelectric hybrid nanogenerators based on graphene oxide incorporated polycaprolactone fibers and cellulose paper. Nano Energy 59:412–421. https://doi.org/10.1016/j.nanoen.2019.02.058

Pei A, Malho JM, Ruokolainen J et al (2011) Strong nanocomposite reinforcement effects in polyurethane elastomer with low volume fraction of cellulose nanocrystals. Macromolecules 44:4422–4427. https://doi.org/10.1021/ma200318k

Ramezani M, Monroe MBB (2022) Biostable segmented thermoplastic polyurethane shape memory polymers for smart biomedical applications. ACS Appl Polym Mater 4:1956–1965. https://doi.org/10.1021/acsapm.1c01808

Rangappa SM, Siengchin S, Parameswaranpillai J et al (2022) Lignocellulosic fiber reinforced composites: progress, performance, properties, applications, and future perspectives. Polym Compos 43:645–691. https://doi.org/10.1002/pc.26413

Rasheed M, Jawaid M, Parveez B et al (2021) Morphology, structural, thermal, and tensile properties of bamboo microcrystalline cellulose/poly(lactic acid)/poly(butylene succinate) composites. Polymers (Basel) 13:1–15. https://doi.org/10.3390/polym13030465

Rebouillat S, Pla F (2013) State of the art manufacturing and engineering of nanocellulose: a review of available data and industrial applications. J Biomater Nanobiotechnol 04:165–188. https://doi.org/10.4236/jbnb.2013.42022

Sakellariou P, Rowe RC (1995) Interactions in cellulose derivative films for oral drug delivery. Prog Polym Sci 20:889–942. https://doi.org/10.1016/0079-6700(95)00008-4

Shen R, Xue S, Xu Y et al (2020) Research progress and development demand of nanocellulose reinforced polymer composites. Polymers 12:2113

Sheng N, Zhang M, Song Q et al (2022) Enhanced salinity gradient energy harvesting with oppositely charged bacterial cellulose-based composite membranes. Nano Energy 101:107548. https://doi.org/10.1016/j.nanoen.2022.107548

Song Y, Wu T, Bao J et al (2022) Porous cellulose composite aerogel films with super piezoelectric properties for energy harvesting. Carbohydr Polym 288:119407. https://doi.org/10.1016/j.carbpol.2022.119407

Thanomchat S, Srikulkit K, Suksut B, Schlarb AK (2014) Morphology and crystallization of polypropylene/microfibrillated cellulose composites. Appl Sci Eng Prog 7:23–34

Wang X, Luo X, Wang X (2005) Study on blends of thermoplastic polyurethane and aliphatic polyester: morphology, rheology, and properties as moisture vapor permeable films. Polym Test 24:18–24. https://doi.org/10.1016/j.polymertesting.2004.08.003

Wang H, Qiao H, Guo J et al (2020) Preparation of cobalt-based metal organic framework and its application as synergistic flame retardant in thermoplastic polyurethane (TPU). Compos Part B Eng 182:107498. https://doi.org/10.1016/j.compositesb.2019.107498

Włoch M, Landowska P (2022) Preparation and properties of thermoplastic polyurethane composites filled with powdered buckwheat husks. Mater (Basel). https://doi.org/10.3390/ma15010356

Xie Y, Pan Y, Cai P (2022) Cellulose-based antimicrobial films incroporated with ZnO nanopillars on surface as biodegradable and antimicrobial packaging. Food Chem 368:130784. https://doi.org/10.1016/j.foodchem.2021.130784

Xu J, Li X, Liu R et al (2020) Dialdehyde modified cellulose nanofibers enhanced the physical properties of decorative paper impregnated by aldehyde-free adhesive. Carbohydr Polym 250:116941. https://doi.org/10.1016/j.carbpol.2020.116941

Yao X, Qi X, He Y et al (2014) Simultaneous reinforcing and toughening of polyurethane via grafting on the surface of microfibrillated cellulose. ACS Appl Mater Interfaces 6:2497–2507. https://doi.org/10.1021/am4056694

Acknowledgments

This work was supported by the Technology Innovation Program (No. 20011362, Development of Eco-friendly Solid Insulation Materials and Core Parts for High Voltage Switchgear) funded by the Ministry of Trade, Industry & Energy (MOTIE) and the Korea Evaluation Institute of Industrial Technology (KEIT) of the Republic of Korea, by the X-mind Corps program of the National Research Foundation (NRF) of the republic of Korea funded by the Ministry of Science, ICT (NRF-2017H1D8A1032288), and by the Ministry of Trade, Industry & Energy (MOTIE) of the Republic of Korea under the Fostering Global Talents for Innovative Growth Program (No. P0017303) supervised by the Korea Institute for Advancement of Technology (KIAT) in part by the NRF. Oak Ridge National Laboratory is managed by UT-Battelle, LLC under Contract DE-AC05-00OR22725 with the U.S. Department of Energy (DOE). The views and opinions of the authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, expressed or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights.

Funding

Funding is provided by National Research Foundation of the Republic of Korea (Grant No. NRF-2017H1D8A1032288), Ministry of Trade, Industry and Energy of the Republic of Korea (Grant Nos. 20011362, P0017303), U.S. Department of Energy (Grant No. DE-AC05-00OR22725).

Author information

Authors and Affiliations

Contributions

SJ: Investigation, formal analysis, data curation, visualization, and writing of the original draft. WC: Investigation, formal analysis, data curation, visualization, writing of the original draft. SKL: Investigation, validation, and data curation. ARY: Investigation and data curation. JGL: Validation. KJ: Resources. YP: Formal analysis and data curation. CGY: Methodology and writing–review and editing. JJW: Conceptualization, methodology, supervision, resources, writing–review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jhang, S., Cho, W., Lee, S.K. et al. Functional group effect of chemically modified microcrystalline methyl cellulose on thermoplastic polyurethane composites. Cellulose 30, 6917–6931 (2023). https://doi.org/10.1007/s10570-023-05335-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05335-0