Abstract

Construction of biomass-based wearable aerogel heater with enhanced thermal insulation property plays a significant role in preventing heat loss for personal thermal management. Inspired by natural creatures’ utilization own hollow microstructures to resist the extremely cold surroundings, we report an eco-friendly strategy to construct calcium alginate (CA) /kapok fiber (KF)/carbon nanotubes (CNTs) active-cum-passive aerogel heater with desired economic feasibility, sustainability and efficient thermal insulation performance. The renewable cellulose hollow KF disrupts the heat transfer pathway and enabled CA/KF/CNT lower thermal conductivity (0.024 W/m·K) and ultralight density (0.027 g/cm3). The CNTs in the aerogel heater not only provided excellent conductivity for realizing Joule-heating but also enhanced the photothermal conversion capability from solar irradiation, ensuring extra self-heating ability without power supply. According to energy-saving analysis, the total energy saved in China per year was 6.03 × 109 kWh when using the developed aerogel heater instead of the traditional heating method. This developed biomass aerogel heater in this work exhibits great potential to be applicable in the fields of wearable personal thermal management to enhance the adaptability of human body in cold environment. Our work may inspire the study of biomass-derived wearable heaters for solving global energy issues.

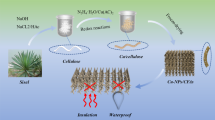

Graphical abstract

Similar content being viewed by others

Data availability

All data included in this study are available upon request by contact with the corresponding author.

References

Cao Y-M, Zheng M, Li Y-F, Zhai WY, Yuan G-T, Zheng M, Zhuo M-P, Wang Z-S, Liao L-S (2021) Smart textiles based on mos2 hollow nanospheres for personal thermal management. ACS Appl Mater Interfaces 13:48988–48996. https://doi.org/10.1021/acsami.1c13269

Cui Y, Gong HX, Wang YJ, Li DW, Bai HA (2018) Thermally insulating textile inspired by polar bear hair. Adv Mater 30:1706807. https://doi.org/10.1002/adma.201706807

Du A, Wang HQ, Zhou B, Zhang C, Wu XL, Ge YT, Niu TT, Ji XJ, Zhang T, Zhang ZH, Wu GM, Shen J (2018) Multifunctional silica nanotube aerogels inspired by polar bear hair for light management and thermal insulation. Chem Mater 30:6849–6857. https://doi.org/10.1021/acs.chemmater.8b02926

Faruk MD, Ahmed A, Jalil MA, Islam MT, Shamim A, Adak B, Hossain MM, Mukhopadhyay S (2021a) Functional textiles and composite based wearable thermal devices for Joule heating: progress and perspectives. Appl Mater Today 23:101025. https://doi.org/10.1016/j.apmt.2021.101025

Fu RR, Ren YF, Fang KJ, Sun YN, Zhang ZC, Luo AQ (2021) Preparation, characterization and biocompatibility of chitosan/TEMPO-oxidized bacterial cellulose composite film for potential wound dressing applications. Fibers Polym 22(7):1790–1799. https://doi.org/10.1007/s12221-021-0854-8

Gu B, Huang XY, Qin FX, Yang DY, Zhang T (2020) Laminated cellulose hybrid membranes with triple thermal insulation functions for personal thermal management application. ACS Sustainable Chem Eng J 8:15936–15945. https://doi.org/10.1021/acssuschemeng.0c05465

Guo Y, Dun CC, Xu JW, Mu JK, Li PY, Gu LW, Hou CY, Hewitt CA, Zhang QH, Li YG, Carroll DL, Wang HZ (2017) Ultrathin, washable, and large-area graphene papers for personal thermal management. Small 13:1702645. https://doi.org/10.1002/smll.201702645

Guo ZG, Sun C, Wang J, Cai ZS, Ge FY (2021) High-performance laminated fabric with enhanced photothermal conversion and joule heating effect for personal thermal management. ACS Appl Mater Interfaces 13:8851–8862. https://doi.org/10.1021/acsami.0c23123

Hazarika A, Deka BK, Kim D, Jeong HE, Park YB, Park HW (2018) Woven kevlar fiber /polydimethylsiloxane /reduced graphene oxide composite-based personal thermal management with freestanding cu−ni core−shell nanowires. Nano Lett 18:6731–6739. https://doi.org/10.1021/acs.nanolett.8b02408

He HL, Liu JR, Wang YS, Zhao YH, Qin Y, Zhu ZY, Yu ZC, Wang JF (2022) An ultralight self-powered fire alarme-textile based on conductive aerogel fiber with repeatable temperature monitoring performance used in firefighting clothing. ACS Nano 16(2):2953–2967. https://doi.org/10.1021/acsnano.1c10144

He HL, Qin Y, Liu JR, Wang YS, Wang JF, Zhao YH, Zhu ZY, Jiang Q, Wan YH, Qu XR, Yu ZC (2023) A wearable self-powered fire warning e-textile enabled by aramid nanofibers/MXene/silver nanowires aerogel fiber for fire protection used in firefighting clothing. Chem Eng J 460:141661. https://doi.org/10.1016/j.cej.2023.141661

Hsu PC, Liu XG, Liu C, Xie X, Lee HR, Welch AJ, Zhao T, Cui Y (2015) Personal thermal management by metallic nanowire-coated textile. Nano Lett 15:365–371. https://doi.org/10.1021/nl5036572

Hu PY, Lyu J, Fu C, Gong WB, Liao JH, Lu WB, Chen YP, Zhang XT (2020) Multifunctional aramid nanofiber/carbon nanotube hybrid aerogel films. ACS Nano 14:688–697. https://doi.org/10.1021/acsnano.9b07459

Jin HR, Zhou XY, Xu TT, Dai CY, Gu YW, Yun S, Hu T, Guan GF, Chen J (2020) Ultralight and hydrophobic palygorskite-based aerogels with prominent thermal insulation and flame retardancy. ACS Appl Mater Interfaces 12:11815–11824. https://doi.org/10.1021/acsami.9b20923

Kong Y, Dan HB, Kong WJ, Gao Y, Shang YN, Ji KD, Yue QY, Gao BY (2020) Self-floating maize straw/graphene aerogel synthesis based on microbubble and ice crystal templates for efficient solar-driven interfacial water evaporation. J Mater Chem A 8:24734–24742. https://doi.org/10.1039/d0ta07576k

Li XQ, Xie WR, Sui CX, Hsu P-C (2020) Multispectral thermal management designs for net-zero energy buildings. ACS Mater Lett 2:1624–1643. https://doi.org/10.1021/acsmaterialslett.0c00322

Li L, Liu WD, Liu QF, Chen ZG (2022a) Multifunctional wearable thermoelectrics for personal thermal management. Adv Funct Mater 32:2200548. https://doi.org/10.1002/adfm.202200548

Li QH, Yuan ZH, Zhang C, Hu SQ, Chen ZM, Wu YZ, Chen P, Qi HS, Ye DD (2022b) Tough, highly oriented, super thermal insulating regenerated all-cellulose sponge-aerogel fibers integrating a graded aligned nanostructure. Nano Lett 22:3516–3524. https://doi.org/10.1021/acs.nanolett.1c03943

Li Y, Cui YG, Zhang MJ, Li XD, Li R, Si WY, Sun QH, Yu LM, Huang CS (2022c) Ultrasensitive pressure sensor sponge using liquid metal modulated nitrogen-doped graphene nanosheets. Nano Lett 22:2817–2858. https://doi.org/10.1021/acs.nanolett.1c04976

Liao HH, Chen WH, Liu Y, Wang Q (2020) A phase change material encapsulated in a mechanically strong graphene aerogel with high thermal conductivity and excellent shape stability. Compos Sci Technol 189:108010. https://doi.org/10.1016/j.compscitech.2020.108010

Lu D, Su L, Wang HJ, Niu M, Xu L, Ma MB, Gao HF, Cai ZX, Fan XY (2019) Scalable fabrication of resilient sic nanowires aerogels with exceptional high-temperature stability. ACS Appl Mater Interfaces 11:45338–45344. https://doi.org/10.1021/acsami.9b16811

Luo H, Li Q, Du KK, Xu ZQ, Zhu HZ, Liu DL, Cai L, Ghosh P, Qiu M (2019) An ultra-thin colored textile with simultaneous solar and passive heating abilities. Nano Energ 65:103998. https://doi.org/10.1016/j.nanoen.2019.103998

Luo H, Zhu YN, Xu ZQ, Hong Y, Ghosh PT, Kaur S, Wu MB, Yang CY, Qiu M, Li Q (2021) Outdoor personal thermal management with simultaneous electricity generation. Nano Lett 21:3879–3886. https://doi.org/10.1021/acs.nanolett.1c00400

Mu P, Bai W, Fan YK, Zhang Z, Sun HX, Zhu ZQ, Liang WD, Li A (2019) Conductive hollow kapok fiber-PPy monolithic aerogels with excellent mechanical robustness for efficient solar steam generation. J Mater Chem A 7:9673–9679. https://doi.org/10.1039/c8ta12243a

Peng H, Xie RY, Fang KJ, Cao CG, Qi Y, Ren YF, Chen WC (2021) Effect of diethylene glycol on the inkjet printability of reactive dye solution for cotton fabrics. Langmuir 37:1493–1500. https://doi.org/10.1021/acs.langmuir.0c03016

Qi JL, Xie YJ, Liang HW, Wang YS, Ge TT, Song YM, Wang MZ, Li Q, Yu HP, Fan ZJ, Liu SX, Wang QW, Liu YX, Li J, Lu P, Chen WS (2019) Lightweight, flexible, thermally-stable, and thermally-insulating aerogels derived from cotton nanofibrillated cellulose. ACS Sustainable Chem Eng 10:9202–9210. https://doi.org/10.1021/acssuschemeng.8b06851

Qian X, Zhou JW, Chen G (2021) Phonon-engineered extreme thermal conductivity materials. Nat Mater 20:1188–1202. https://doi.org/10.1038/s41563-021-00918-3

Rabha DK (2021) Performance investigation of a passive-cum-active dryer with a biomass-fired heater integrated with a plate heat exchanger. Renew Energ 169:598–607. https://doi.org/10.1016/j.renene.2020.12.126

Ren YF, Fang L, Liu YJ, Shen CM, Wu LL, Zheng XH, Fang KJ (2022) Warming performance of far infrared lights electrogenerated by carbon nanotubes composite fabrics. Mater Lett 319:132220. https://doi.org/10.1016/j.matlet.2022.132220

Si Y, Wang XQ, Yan CC, Yang L, Yu JY, Ding B (2016) Ultralight biomass-derived carbonaceous nanofibrous aerogels with superelasticity and high pressure-sensitivity. Adv Mater 28(43):9512–9518. https://doi.org/10.1002/adma.201603143

Song P, Cui JW, Di J, Liu DB, Xu MZ, Tang BJ, Zeng QS, Xiong J, Wang CD, He Q, Kang LX, Zhou JD, Duan RH, Chen BB, Guo SS, Liu FC, Shen J, Liu Z (2020) Carbon microtube aerogel derived from kapok fiber: an efficient and recyclable sorbent for oils and organic solvents. ACS Nano 14:595–602. https://doi.org/10.1021/acsnano.9b07063

Sun JM, Wu ZW, An B, Ma CH, Xu LF, Zhang ZS, Luo S, Li W, Liu SX (2021a) Thermal-insulating, flame-retardant and mechanically resistant aerogel based on bio-inspired tubular cellulose. Compos Part B 22:108997. https://doi.org/10.1016/j.compositesb.2021.108997

Sun KY, Dong HS, Kou Y, Yang HN, Liu HQ, Li YG, Shi Q (2021b) Flexible graphene aerogel-based phase change film for solar-thermal energy conversion and storage in personal thermal management applications. Chem Eng J 419:129637. https://doi.org/10.1016/j.cej.2021.129637

Sun Y, Li DP, Kim JU, Li B, Cho S-H, Kim T-I, Nam J-D, Ci LJ, Suhr J (2021c) Carbon aerogel reinforced PDMS nanocomposites with controllable and hierarchical microstructures for multifunctional wearable devices. Carbon 171:758–767. https://doi.org/10.1016/j.carbon.2020.09073

Tao Z, Yang M, Wu LM, Yan JM, Yang F, Lin J, Wang JJ, Wang G (2021) Phase change material based on polypyrrole/Fe3O4- functionalized hollow kapok fiber aerogel matrix for solar /magnetic- thermal energy conversion and storage. Chem Eng J 423:130180. https://doi.org/10.1016/j.cej.2021.130180

Wang ZQ, Yang HW, Li Y, Zheng XH (2020) Robust silk fibroin/graphene oxide aerogel fiber for radiative heating textiles. ACS Appl Mater Interfaces 12:15726–15736

Wang M, Li N, Wang G-D, Shao WL, Qi DZ, Xi LL (2021) High-sensitive flexural sensors for health monitoring of composite materials using embedded carbon nanotube (CNT) buckypaper. Compos Struct 261:113280. https://doi.org/10.1016/j.compstruct.2020.113280

Wang YS, Liu JR, Zhao YH, Qin Y, Zhu ZY, Yu ZC, He HL (2022) Temperature-triggered fire warning PEG@wood powder/carbon nanotube/calcium alginate composite aerogel and the application for firefighting clothing. Compos Part B-Eng 247:110348. https://doi.org/10.1016/j.compositesb.2022.110348

Xia D, Li H, Mannering J, Huang P, Zheng XR, Kulak A, Baker D, Iruretagoyena D, Menzel R (2020) Electrically heatable graphene aerogels as nanoparticle supports in adsorptive desulfurization and high-pressure CO(2)capture. Adv Funct Mater 30:2002788. https://doi.org/10.1002/adfm.202002788

Yang F, Zhao XY, Xue TT, Yuan SJ, Huang YP, Fan W, Liu TX (2020) Superhydrophobic polyvinylidene fluoride/polyimide nanofiber composite aerogels for thermal insulation under extremely humid and hot environment. Sci China Mater 64:1267–1277. https://doi.org/10.1007/s40843-020-1518-4

Ye D-D, Wang T, Liao W, Wang H, Zhao H-B, Wang Y-T, Xu SM, Wang Y-Z (2019) Ultrahigh-temperature insulating and fire-resistant aerogels from cationic amylopectin and clay via a facile route. ACS Sustainable Chem Eng 7:11582–11592. https://doi.org/10.1021/acssuschemeng.9b0

Yu ZC, Zhao YH, Liu JR, Wang YS, Qin Y, Zhu ZY, Wu C, Peng JC, He HL (2022) Advancement in cellulose-based multifunctional high conductive PNIPAAm/PPy hydrogel/cotton composites for EMI shielding. Cellulose. https://doi.org/10.1007/s10570-022-04698-0

Yue XJ, He MY, Zhang T, Yang DY, Qu FX (2020) Laminated fibrous membrane inspired by polar bear pelt for outdoor personal radiation management. ACS Appl Mater Interfaces 12:12285–12293. https://doi.org/10.1021/acsami.9b20865

Zhan H-J, Wu K-J, Hu Y-L, Liu J-W, Li H, Guo X, Xu J, Yang Y, Yu Z-L, Gao H-L, Luo X-S, Chen J-F, Ni Y, Yu S-H (2019) Biomimetic carbon tube aerogel enables super-elasticity and thermal insulation. Chem 5:1871–1882. https://doi.org/10.1016/j.chempr.2019.04.025

Zhang Q, Zhang X, Cheng W, Li Z, Li Q (2020) In situ-synthesis of calcium alginate nano-silver phosphate hybrid material with high flame retardant and antibacterial properties. Int J Biol Macromol 165:1615–1625. https://doi.org/10.1016/j.ijbiomac.2020

Zhou B, Li QT, Xu PH, Feng YZ, Ma JM, Liu CT, Shen CY (2021b) An asymmetric sandwich structural cellulose-based film with self-supported MXene and AgNW layers for flexible electromagnetic interference shielding and thermal management. Nanoscale 13:2378–2388. https://doi.org/10.1039/d0nr07840a

Acknowledgements

Not applicable.

Funding

This work was financial support by the Opening Project of Hubei Key Laboratory of Biomass Fibers and Eco-dyeing & Finishing (STRZ202214), Opening Project of National Local Joint Laboratory for Advanced Textile Processing and Clean Production (FX2022006), Guiding Project of Natural Science Foundation of Hubei province (2022CFC072), Guiding Project of Scientific Research Plan of Education Department of Hubei Province (B2022081), Shenghong Key Scientific Research Project of Emergency Support and Public Safety Fiber Materials and Products (2022-rw0101), and Science and Technology Guidance Program of China National Textile and Apparel Council (2022002).

Author information

Authors and Affiliations

Contributions

HH and YW have contributed equally to this work. HH: Writing–original draft, Data curation, Experimental investigation. YW: Writing–original draft, Experimental investigation. JL: Formal analysis. YZ: Data collection. QJ: Investigation. XZ: Experimental investigation. JW: Methodology. HW: Experimental investigation. ZY: Conceptualization, Methodology, Writing—review & editing, Supervision, and Funding acquisition. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Consent for publication

All authors agreed to the publication in the submitted form.

Ethical approval.

Not applicable.

Informed consent

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, H., Wang, Y., Liu, J. et al. Biomass based active-cum-passive aerogel heater with enhanced thermal insulation property derived from hollow cellulose kapok fiber for personal thermal management. Cellulose 30, 7031–7045 (2023). https://doi.org/10.1007/s10570-023-05310-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05310-9