Abstract

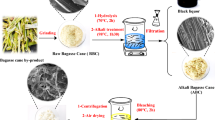

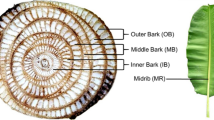

The main aspect of this study is to develop water hyacinth (WN) and sugarcane bagasse (SN) nonwovens by applying an economic solution of wet-laid web formation by utilizing plant wastes. To improve the mechanical properties, the fibers were pre-treated with NaOH at 5, 10 and 15 (v/w) %, and to increase the hydrophobicity, the nonwovens were post-treated with water repellent (WR) chemicals at 1, 5, 10, 15 and 20 (v/v) %. SEM micrographs revealed the rougher fiber surface after alkali treatment and thin layers on the fiber surface after WR treatment. EDX and FTIR analysis proved the removal of impurities after alkali treatment and the appearance of fluorine compound after WR treatment. XRD patterns confirmed the crystallinity of WN was higher than that of SN nonwovens, and the crystallinity was increased after alkali and WR treatment. Untreated WN nonwovens exhibited about twice the tensile strength (TS) and tensile modulus (TM) but 2.47% lower elongation at break (Eb%) than untreated SN nonwovens. TS increased significantly by 89% and 2.5 times, TM was increased by 60 and 87%, Eb% was decreased by 25 and 35% for WN and SN nonwovens, respectively, when treated with 10% NaOH compared to untreated nonwovens. Hydrophobicity improved considerably with increasing WR concentration. For example, at 10% WR, a drop of water showed an initial contact angle of 143.3° and took 5.11 h to be completely absorbed by the WN nonwoven. However, the mechanical properties decreased when the concentration of WR and NaOH increased. Therefore, 10% WR and 10% NaOH were considered the optimum concentrations for the surface treatment of the fibers.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Abd El-Baky MA, Megahed M, El-Saqqa HH, Alshorbagy AE (2019) Mechanical properties evaluation of sugarcane bagasse-glass/polyester composites. J Nat Fibers 18:1163–1180. https://doi.org/10.1080/15440478.2019.1687069

Abral H, Dalimunthe MH, Hartono J et al (2018) Characterization of tapioca starch biopolymer composites reinforced with micro scale water hyacinth fibers. Starch-Stärke 70:7–8. https://doi.org/10.1002/star.201700287

Ajithram A, Jappes JTW, Brintha NC (2021) Water hyacinth (Eichhornia crassipes) natural composite extraction methods and properties—a review. Mater Today Proc 45:1626–1632. https://doi.org/10.1016/J.MATPR.2020.08.472

Asrofi M, Abral H, Putra YK et al (2018) Effect of duration of sonication during gelatinization on properties of tapioca starch water hyacinth fiber biocomposite. Int J Biol Macromol 108:167–176. https://doi.org/10.1016/J.IJBIOMAC.2017.11.165

Bae GY, Min BG, Jeong YG et al (2009) Superhydrophobicity of cotton fabrics treated with silica nanoparticles and water-repellent agent. J Colloid Interface Sci 337:170–175. https://doi.org/10.1016/j.jcis.2009.04.066

Barreto ACH, Costa MM, Sombra ASB et al (2010) Chemically modified banana fiber: structure, dielectrical properties and biodegradability. J Polym Environ 18:523–531. https://doi.org/10.1007/S10924-010-0216-X

Bhuvaneshwari M, Sangeetha K (2017a) Development of water hyacinth Nonwoven fabrics for thermal insulation. i-Manager’s J Future Eng Technol 13:22. https://doi.org/10.26634/JFET.13.1.13759

Chonsakorn S, Srivorradatpaisan S, Mongkholrattanasit R (2018) Effects of different extraction methods on some properties of water hyacinth fiber. J Nat Fibers 16:1015–1025. https://doi.org/10.1080/15440478.2018.1448316

Chowdhury KP (2018) Impact of different water repellent finishes on cotton double Jersey fabrics. J Text Sci Technol 04:85–99. https://doi.org/10.4236/jtst.2018.43006

Corrales RCNR, Mendes FMT, Perrone CC et al (2012) Structural evaluation of sugar cane bagasse steam pretreated in the presence of CO2 and SO2. Biotechnol Biofuels 5:1–8. https://doi.org/10.1186/1754-6834-5-36/TABLES/4

Cullity BD (1978) Elements of X-ray diffraction, 2nd edn. Addison-Wesley Publishing Company Inc., Reading

da Luz FS, Candido VS, da Silva ACR, Monteiro SN (2018) Thermal behavior of polyester composites reinforced with green sugarcane bagasse fiber. JOM 70(10):1965–1971. https://doi.org/10.1007/S11837-018-3086-7

Duman MN, Kocak ED, Merdan N, Mistik I (2017) Nonwoven production from agricultural okra wastes and investigation of their thermal conductivities. IOP Conf Ser Mater Sci Eng 254:192007. https://doi.org/10.1088/1757-899X/254/19/192007

El-Wakil AEA, Abd-Elbasseer M, El-Basheer TM (2021) Mechanical and acoustical properties of Eichhornia crassipes (water hyacinth) fiber-reinforced styrene butadiene rubber. Polym Compos 42:3732–3745. https://doi.org/10.1002/PC.26088

Halder P, Paul N, Khan I et al (2014) Agricultura residue potential for electricity generation in Bangladesh. IOSR J Mech Civ Eng (IOSR-JMCE) 11:89–95

Herlina Sari N, Wardana ING, Irawan YS, Siswanto E (2017) Characterization of the chemical, physical, and mechanical properties of NaOH-treated natural cellulosic fibers from corn husks. J Nat Fibers 15:545–558. https://doi.org/10.1080/15440478.2017.1349707

Jirawattanasomkul T, Minakawa H, Likitlersuang S et al (2021) Use of water hyacinth waste to produce fibre-reinforced polymer composites for concrete confinement: mechanical performance and environmental assessment. J Clean Prod 292:126041. https://doi.org/10.1016/J.JCLEPRO.2021.126041

Kalia S, Kaith BS, Kaur I (2009) Pretreatments of natural fibers and their application as reinforcing material in polymer composites—a review. Polym Eng Sci 49:1253–1272. https://doi.org/10.1002/PEN.21328

Kerni L, Singh S, Patnaik A, Kumar N (2020) A review on natural fiber reinforced composites. Mater Today Proc 28:1616–1621. https://doi.org/10.1016/j.matpr.2020.04.851

Keya KN, Kona NA, Koly FA et al (2019) Natural fiber reinforced polymer composites: history, types, advantages, and applications. Mater Eng Res 1:69–87. https://doi.org/10.25082/mer.2019.02.006

Kumar Basak S, Mohammad Ali M, Shafiqul Islam M, Raj Shaha P (2015) Aquatic weeds of Haor area in Kishoregonj district, Bangladesh: availability, threats and management approaches. Int J Fish Aquat Stud 2:151–156

Le Phuong HA, Ayob NAI, Blanford CF et al (2019) Nonwoven membrane supports from renewable resources: bamboo fiber reinforced poly (lactic acid) composites. ACS Sustain Chem Eng 7:11885–11893. https://doi.org/10.1021/ACSSUSCHEMENG.9B02516

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33. https://doi.org/10.1007/s10924-006-0042-3

Liu H, He H, Peng X et al (2019) Three-dimensional printing of poly(lactic acid) bio-based composites with sugarcane bagasse fiber: effect of printing orientation on tensile performance. Polym Adv Technol 30:910–922. https://doi.org/10.1002/PAT.4524

Manimaran P, Pillai GP, Vignesh V, Prithiviraj M (2020) Characterization of natural cellulosic fibers from Nendran Banana Peduncle plants. Int J Biol Macromol 162:1807–1815. https://doi.org/10.1016/J.IJBIOMAC.2020.08.111

Martinez-Hernandez E, Amezcua-Allieri MA, Sadhukhan J, Anell JA (2017) Sugarcane bagasse valorization strategies for bioethanol and energy production. In: Sugarcane—technology and research. IntechOpen. https://doi.org/10.5772/INTECHOPEN.72237

Mccusker LB, von Dreele RB, Cox DE et al (1999) Rietveld refinement guidelines. J Appl Crystallogr 32:36–50. https://doi.org/10.1107/S0021889898009856

Milani MDY, Samarawickrama DS, Dharmasiri GPCA, Kottegoda IRM (2016) Study the structure, morphology, and thermal behavior of banana fiber and its charcoal derivative from selected banana varieties. J Nat Fibers 13:332–342. https://doi.org/10.1080/15440478.2015.1029195

Miskat MI, Ahmed A, Chowdhury H et al (2020) Assessing the theoretical prospects of bioethanol production as a biofuel from agricultural residues in Bangladesh: a review. Sustainability 12:8583. https://doi.org/10.3390/SU12208583

Mohamed A, el Halwany M, Hassan M, Aly H (2021) Environmental fresh-cut fruits or vegetables packages from Nonwoven bagasse fibers. J Des Sci Appl Arts 2:86–95. https://doi.org/10.21608/jdsaa.2021.32753.1065

Mohamed AL, Hassabo AG, Nada AA, Abou-Zeid NY (2017) Properties of cellulosic fabrics treated by water-repellent emulsions. Indian J Fibre Text Res 42:223–229

Mohammad S, Reza S, Islam S (2019) Utilization potential of waste from sugarcane factory of Bangladesh as partial replacement of cement in concrete. J Environ Treat Tech 7:109–112

Mukhtar I, Leman Z, Ishak M, Zainudin ES (2016) Sugar palm fibre and its composites: a review of recent developments. BioResources 11:10756–10782

Nayak SY, Sultan MTH, Shenoy SB et al (2020) Potential of natural fibers in composites for ballistic applications—a review. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1787919

Prasad N, Agarwal VK, Sinha S (2016) Banana fiber reinforced low-density polyethylene composites: effect of chemical treatment and compatibilizer addition. Iran Polym J 25:229–241. https://doi.org/10.1007/S13726-016-0416-X

Rani MJ, Murugan M, Subramaniam P, Subramanian E (2014) A study on water hyacinth Eichhornia crassipes as oil sorbent. J Appl Nat Sci 6:134–138. https://doi.org/10.31018/JANS.V6I1.389

Rawal A, Sayeed MMA (2014) Tailoring the structure and properties of jute blended nonwoven geotextiles via alkali treatment of jute fibers. Mater Des 53:701–705. https://doi.org/10.1016/J.MATDES.2013.07.073

Salas-Ruiz A, del Mar Barbero-Barrera M (2019) Performance assessment of water hyacinth–cement composite. Constr Build Mater 211:395–407. https://doi.org/10.1016/J.CONBUILDMAT.2019.03.217

Samyn P (2013) Wetting and hydrophobic modification of cellulose surfaces for paper applications. J Mater Sci 48:6455–6498. https://doi.org/10.1007/S10853-013-7519-Y

Santhanam V, Dhanaraj R, Chandrasekaran M et al (2020) Experimental investigation on the mechanical properties of woven hybrid fiber reinforced epoxy composite. In: Mater Today: Proc. Elsevier Ltd, pp 1850–1853

Schindler WD, Hauser PJ (2004) Chemical finishing of textiles. Woodhead, Cambridge, England

Sumrith N, Techawinyutham L, Sanjay MR et al (2020) Characterization of Alkaline and Silane treated fibers of ‘water hyacinth plants’ and reinforcement of ‘water hyacinth fibers’ with bioepoxy to develop fully biobased sustainable ecofriendly composites. J Polym Environ 28(10):2749–2760. https://doi.org/10.1007/S10924-020-01810-Y

Supri AG, Ismail H (2010) The effect of NCO-polyol on the properties of low-density polyethylene/water hyacinth fiber (Eichhornia crassiper) composites. Polym Plast Technol Eng 49:766–771. https://doi.org/10.1080/03602551003749569

Suryanto H, Marsyahyo E, Irawan YS, Soenoko R (2014) Morphology, structure, and mechanical properties of natural cellulose fiber from Mendong Grass (Fimbristylis globulosa). J Nat Fibers 11:333–351. https://doi.org/10.1080/15440478.2013.879087

Tan SJ, Supri AG (2015) Properties of low-density polyethylene/natural rubber/water hyacinth fiber composites: the effect of alkaline treatment. Polym Bull 73(2):539–557. https://doi.org/10.1007/S00289-015-1508-Z

Vidyashri V, Lewis H, Narayanasamy P et al (2019) Preparation of chemically treated sugarcane bagasse fiber reinforced epoxy composites and their characterization. Cogent Eng 6–1:1708644. https://doi.org/10.1080/23311916.2019.1708644

Zahid M, Heredia-Guerrero JA, Athanassiou A, Bayer IS (2017) Robust water repellent treatment for woven cotton fabrics with eco-friendly polymers. Chem Eng J 319:321–332. https://doi.org/10.1016/J.CEJ.2017.03.006

Zakaria MS, Musa L, Nordin RM, Halim KAA (2020) Sugarcane bagasse reinforced polyester composites: effects of fiber surface treatment and fiber loading on the tensile and flexural properties. IOP Conf Ser Mater Sci Eng 957:012032. https://doi.org/10.1088/1757-899X/957/1/012032

Zhao T, Zheng J, Sun G (2012) Synthesis and applications of vegetable oil-based fluorocarbon water repellent agents on cotton fabrics. Carbohydr Polym 89:193–198. https://doi.org/10.1016/J.CARBPOL.2012.02.070

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Motaleb, K.Z.M.A., Abakevičienė, B. & Milašius, R. Prospective utilization of water hyacinth and sugarcane plant wastes into a promising nonwoven biomaterial: development and improvement of their physico-mechanical properties. Cellulose 30, 3297–3316 (2023). https://doi.org/10.1007/s10570-023-05066-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05066-2