Abstract

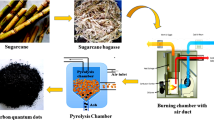

Natural fibers such as those from sugarcane bagasse may be obtained as industrial waste products. These fibers have recently been investigated as low-cost reinforcements in composites for engineering applications, some of which may require exposure to temperatures above ambient. In the present work, fibers extracted from sugarcane bagasse were used at up to 30 vol.% as reinforcement in polyester-matrix composites. The thermal behavior of these composites was investigated by thermogravimetric analysis (TGA) and derivative thermogravimetry (DTG) as well as dynamic mechanical analysis (DMA) and differential scanning calorimetry (DSC). TGA/DTG results indicated similar limits of thermal stability at about 200°C for the neat polyester and the bagasse fiber composites. The thermal degradation peak at around 370°C was also similar, being attributed mainly to polyester. DSC analysis revealed that bagasse fiber incorporation caused only a minor change in the glass-transition temperature. On the contrary, DMA parameters revealed notable changes attributed to effect of the bagasse fibers on the viscous stiffness and damping capacity of the polyester.

Similar content being viewed by others

References

K.G. Satyanarayana, J.L. Guimarães, and F. Wypych, Compos. Part A 38, 1694 (2007).

J. Crocker, Mater. Technol. 2–3, 174 (2008).

M.J. John and S. Thomas, Carbohydr. Polym. 71, 343 (2008).

S.N. Monteiro, F.P.D. Lopes, A.S. Ferreira, and D.C.O. Nascimento, JOM 61 (1), 17 (2009).

S.N. Monteiro, F.P.D. Lopes, A.P. Barbosa, A.B. Bevitori, I.L.A. da Silva, and L.L. da Costa, Metall. Mater. Trans. A 42, 2963 (2011).

O. Faruk, A.K. Bledzki, H.P. Fink, and M. Sain, Progr. Polym. Sci. 37, 1555 (2012).

V.K. Thakur, M.K. Thakur, and R.K. Gupta, Int. J. Polym Anal. Charact. 19, 256 (2014).

O. Güven, S.N. Monteiro, E.A.B. Moura, and J.W. Drelich, Polym. Rev. 56, 702 (2016).

K.L. Pickering, M.G.A. Efendy, and T.M. Le, Compos. Part A 83, 98 (2016).

J. Holbery and D. Houston, JOM 58 (11), 80 (2006).

R. Zah, R. Hischier, A.L. Leão, and I. Braun, J. Clean. Prod. 15, 1032 (2007).

N. Thomas, S.A. Paul, L.A. Pothan, and B. Deepa, Natural fibers: structure, properties and application.Cellulose Fibers: Bio- and Nano-Polymer Composites, ed. S. Kalia, B.S. Kaith, and I. Kaur (Berlin: Springer, 2011), p. 3.

P. Wambua, J. Ivens, and I. Verpoest, Compos. Sci. Technol. 63, 1259 (2003).

S.V. Joshi, L.T. Drzal, A.K. Mohanty, and S. Arora, Compos. Part A 35, 371 (2004).

N.O.R. Maciel, J. Ferreira, J.S. Vieira, C.G.D. Ribeiro, F.P.D. Lopes, F.M. Margem, and S.N. Monteiro, J. Mater Res. Technol. (2018) accepted for publication.

Z. Benzait and L. Trabzon, J. Compos. Mater. (2018). https://doi.org/10.1177/0021998318764002.

N.H. Ravindranath, P. Balachandra, S. Dasappa, and R.K. Usha, Biomass Bioenergy 30, 826 (2006).

Y. Lei, Q. Wu, F. Yao, and Y. Xu, Compos. Part A 38, 1664 (2007).

Y. Habibi, W.K. El-Zawawy, M.M. Ibrahim, and A. Dufresne, Compos. Sci. Technol. 68, 1877 (2008).

V. Vilay, M. Mariatti, R. Mattaib, and M. Todo, Compos. Sci. Technol. 68, 631 (2008).

D.R. Mulinari, H.J.C. Voorwald, M.A.H. Cioffi, M.L.C.P. Silva, and S.M. Luz, Carbohydr. Polym. 75, 317 (2009).

M.A.S. Spinacé, C.S. Lambert, K.K.G. Fermoselli, and M. De Paoli, Carbohydr. Polym. 77, 47 (2009).

S.M. Luz, A. Caldeira-Pires, and P.M.C. Ferrão, Resour. Conserv. Recycl. 54, 1135 (2010).

E.F. Cerqueira, C.A.R.P. Baptista, and D.R. Mulinari, Eng. Proc. 10, 2046 (2011).

D. Verma, P.C. Gope, M.K. Maheshwari, and R.K. Sharma, J. Mater. Environ. Sci. 3, 1079 (2012).

A. Moubarik, N. Grimi, and N. Boussetta, Compos. Part B. 52, 233 (2013).

S.N. Monteiro, V.S. Candido, F.O. Braga, L.T. Bolzan, R.P. Weber, and J.W. Drelich, Eur. Polym. J. 78, 173 (2016).

G. Odian, Principles of Polymerization (New York: Wiley, 1991).

E.M.S. Sanchez, C.A.C. Zavaglia, and M.I. Felisberti, Polymer 41, 765 (2000).

L.U. Devi, S.S. Bhagawan, and S. Thomas, Polym. Compos. 32, 1741 (2011).

N. Venkateshwaran, A.E. Perumal, and R.H.A. Raj, J. Polym. Environ. 20, 565 (2012).

N. Venkateshwaran, A.E. Perumal, and D. Arunsundaranayagam, Mater. Des. 47, 151 (2013).

S.M.S. Kumar, D. Duraibabu, and K. Subramaniann, Mater. Des. 59, 63 (2014).

A. Etaati, S. Pather, Z. Fang, and H. Wang, Compos. Part B 62, 19 (2014).

C.S.M.F. Costa, A.C. Fonseca, A.C. Serra, and J.F.J. Coelho, Polym. Rev. 56, 362 (2016).

R.E. Wetton, Developments in Polymer Characterization, ed. J.V. Dawkins (London: Elsevier, 1986), p. 179.

W. Shlesing, M. Buhk, and M. Osterhold, Prog. Org. Coat. 49, 197 (2004).

M.T. Shaw and W.J. MacKnight, Introduction to Polymer Viscoelasticity (Hoboken, NJ: Wiley, 2005).

S. Mohanty, S.K. Verma, and S.K. Nayak, Compos. Sci. Technol. 66, 538 (2006).

Acknowledgements

The authors thank the Brazilian agencies CNPq, FAPERJ, and CAPES for support of this investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

da Luz, F.S., Candido, V.S., da Silva, A.C.R. et al. Thermal Behavior of Polyester Composites Reinforced with Green Sugarcane Bagasse Fiber. JOM 70, 1965–1971 (2018). https://doi.org/10.1007/s11837-018-3086-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3086-7