Abstract

A process was developed combining two natural-based products to obtain bio-based films. Industrial cellulose pulp was dissolved and mixed with epoxidized soybean oil (ESBO), which acts as an internal plasticizer. A distillable and recyclable ionic liquid-based solvent was used to dissolve the cellulose. Appropriate distribution of the cellulose/ESBO solution on glass surfaces and careful regeneration of the cellulose enabled the development of solvent-free and flexible cellulose films. Fourier transform infrared spectroscopy revealed the presence of the triglyceride structure and the absence of the epoxide ring in the films, confirming the chemical reaction between the hydroxyl and epoxide groups of cellulose. The resulting films were further characterized by scanning electron microscopy, dynamic scanning calorimetry, thermogravimetry, and mechanical tensile tests. The films were also evaluated by contact angle measurement, swelling ability, in vitro degradability and cytotoxicity. The results showed that the presence of ESBO can adjust both the flexibility and hydrophilicity of the cellulose films, resulting in materials suitable for a variety of applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, interest in biopolymer-based films has increased (Rakhshaei and Namazi 2017; Sahana and Rekha 2018; Wilpiszewska et al. 2020). Cellulose, a linear homopolymer of β-1, 4-linked glucopyranose units, is the most abundant biopolymer on Earth. Given the concern about environmental sustainability, the properties of cellulose, such as its abundance, low cost, biodegradability, biocompatibility and thermal properties, make cellulose a desirable candidate as a base material for use in various fields (Klemm et al. 2005; Sahana and Rekha 2018).

However, despite the unique properties of cellulose, the insolubility of this biopolymer in all common solvents (especially water and organic solvents) due to the strong inter- and intramolecular hydrogen bonds great limits its use. Moreover, for some practical applications, such as biomedical or tissue engineering applications, it is necessary to better tune the properties of the crude cellulose (Galiano et al. 2018). However, it is highly desirable that such modifications can take place in a homogeneous medium, without the use of toxic chemicals, making the process more sustainable and offering the possibility to easily control the degree of modification of the cellulose (Onwukamike et al. 2019). Solubilization of cellulose has been extensively studied (Striegel 1997; Cai and Zhang 2005; King et al. 2011; Medronho and Lindman 2014). Despite the possibility of using different solvents such as NaOH/urea, N-methylmorpholine-N-oxide (NMMO), N,N-dimethylacetamide/lithium chloride (DMAc/LiCl), or ionic liquids (ILs) (Sayyed et al. 2019), the recently emerged acid-base conjugated ionic liquids (ABILs) have increased the potential to develop a new type of cellulose-based materials due to their chemical and thermal stability, low volatility, high solvation capacity, and recyclability (King et al. 2011; Onwukamike et al. 2019). The dissolution process in ILs and ABILs has been discussed in detail elsewhere (Meenatchi et al. 2017; Kostag et al. 2018; Berga et al. 2020). It is well known that dissolution of cellulose implies the disruption of inter- and intramolecular hydrogen bonds between the hydroxyl groups of cellulose. In the case of ABILs, this disruption is caused by the ability of the carboxylate anion to form hydrogen bonds with the hydroxyl groups of the anhydroglucose units, resulting in the disruption of the H-bonds of the cellulose chains and the development of a negative charge on the cellulose. The cations begin to "condense" to maintain electrical charge neutrality, increasing the repulsion of the negatively charged cellulose-carboxylate complex (Xu et al. 2013; Li et al. 2016; El Seoud et al. 2019). Also, the addition of a co-solvent such as DMSO accelerates mass transfer by decreasing the viscosity of the system and increasing the solvation of ABIL and free ions interacting with the cellulose hydrogen network (Xu et al. 2013; Kasprzak et al. 2019). Several papers have been published based on these solvents as homogeneous reaction media to optimize cellulose processing properties (Parviainen et al. 2015; Kakko et al. 2017; Ribeiro et al. 2021).

Regenerated cellulose films usually have low flexibility and are brittle, which limits their applications. The presence of solvent contributes to flexibility (Haq et al. 2019) and to improve their processability, flexibility, and thermal stability, various types of plasticizers can be used. In the past, typical plasticizers were based on esters of phthalic acid (di (2-ethylhexyl) phthalate (DEHP), diisodecyl phthalate (DIDP)) (Crawford and Esmerian 1971) or esters of chloroacetic acid (Koenig et al. 2012). More recently, more environmentally friendly options have been tested, such as water, polyols, citrates, vegetable oils, and deep eutectic solvents (Vieira et al. 2011; Sirvioe et al. 2018; Pour-Esmaeil et al. 2020). Even if these plasticizers were effective, they are usually only physically linked to the cellulose, which under certain conditions can lead to migration with consequent changes in cellulose properties, but more importantly to environmental contamination or undesirable interactions with biological systems. One way to overcome this limitation is to dissolve the cellulose followed by a chemical crosslinking step (Pour-Esmaeil et al. 2020).

Considering their natural origin, biodegradability, and low toxicity, vegetable oils represent a promising alternative for the production of bio-plasticizers (Jia et al. 2018). Among them, epoxidized soybean oil (ESBO), a bio-based, low-cost, and non-toxic oil with high thermal and oxidative stability and high content of reactive oxirane rings, has opened a wide range of possibilities for various applications (Chua et al. 2012; Frias et al. 2021). Moreover, epoxides can react with the hydroxyl groups of cellulose via an epoxy-hydroxyl reaction to form a chemically cross-linked network (Shen et al. 2016; Zainal et al. 2021). Moreover, ESBO is already produced on an industrial scale and used in various applications, such as lubricant formulations (Adhvaryu and Erhan 2002), coatings (Yang et al. 2022), and plasticizers (Yang et al. 2014) for synthetic polymeric materials such as polyvinyl chloride (PVC) (Bueno-Ferrer et al. 2010). In this work, the internal plasticization of cellulose pulp using ESBO is studied and a conjugate acid-base as solvent. The chemical crosslinking of cellulose with ESBO is evaluated, as well as the relationship between amount of plasticizer and the hydrophilicity, flexibility, and cytotoxicity of the final cellulose films. The resulting films were chemically, physically, thermally, and mechanically characterized. Preliminary results of cell viability tests with cellulose-based films open a new perspective for healthcare applications, especially when greater flexibility is required.

Experimental part

Materials

Industrial cellulose pulp (bleached eucalyptus kraft pulp, BEKP, DP \(\approx\) 1100) was kindly supplied by Celtejo S.A. cellulose company and used without further purification. ESBO was purchased from Hobum, Oleo Chemicals. 1,1,3,3-Tetramethylguanidine (TMG, TCI, 99%), acetic acid (HOAc, TCI, > 99.5%), dimethyl sulfoxide (DMSO, Fisher Sci, 99.9%), chloroform (CHCl3, Fisher Sci, 99.8%) dimethylformamide (DMF, Fisher Sci, HPLC grade ≥ 99.5%) and deuterium oxide (D2O, Eurisotop, 99.9% deuterium) were used as received. Deionized water was obtained by reverse osmosis.

Procedures

Dissolution of industrial cellulose pulp

The following procedures were based on our previously reported work (Ribeiro et al. 2021). Raw BEKP was ground in a coffee grinder and stored at T = 50 °C. The acid-base ionic liquid solvent (ABIL) was obtained by acid-base neutralization. It is prepared by adding the first TMG (14 mL, 0.11 mol) to a round bottom flask heated at T = 90 °C. Then, acetic acid was slowly added under stirring to TMG, to achieve a 1:1 molar ratio mixture. To reduce the viscosity, 10 mL of DMSO were added to the mixture as co-solvent. After, the cellulose-ground pulp (~ 610 mg) was slowly added to the mixture solvent under vigorous stirring and left for 2 h at T = 90 °C, to obtain a 2 wt% cellulose solution (Online Resource, section S1).

Preparation of cellulose/ESBO films

After dissolution, ESBO was added to cellulose solution and left to react overnight at T = 90 °C. To study the effect of ESBO on film properties, three different amounts were added to cellulose solutions (0.5, 1 and 2 g). Then, cellulose/ESBO films are obtained by regeneration against water and oven-drying. To obtain the regenerated material, solutions were dropped on a glass plate and spread with a micrometric film applicator (1000 µm, Zehntner, ZUA 2000 series) and then placed into distilled water (cellulose/ESBO solution: water = 1:10 (v/v)), washed 3 times, 30 min each washing. Control experiments were done with only cellulose or with only ESBO. Films were formed only when cellulose was present. Finally, gels were dried in a conventional oven at T = 60 °C for 12 h to obtain cellulose based films.

Ionic liquid quantification

The amount of ionic liquid retained in films was calculated by a method developed in our previous work. (Ribeiro et al. 2021) Briefly, films were extracted with deuterium oxide, for 24 h, with slow stirring (150 rpm) at room temperature. The resulting solution was analyzed by 1H-NMR, using an internal standard (DMF) and the amount of ionic liquid present was calculated by a calibration curve.

Cellulose-ESBO chemical crosslink

To confirm cellulose/ESBO chemical crosslink through the reaction of ESBO epoxy groups and cellulose hydroxyl groups, a similar procedure to the one used for ionic liquid quantification was performed but instead of water the dried films were extracted with chloroform, for 24 h, to remove ESBO. After drying films were analyzed by FTIR and 1H-NMR.

Characterizations

Fourier-transform infrared spectroscopy (FTIR)

Films were characterized by FTIR in ATR mode using an Agilent Technologies Carey 630 spectrometer equipped with a Golden Gate Single Reflection Diamond ATR in the 4000–750 cm−1 range at room temperature. Spectra were collected with 4 cm−1 spectral resolution and 64 accumulations. ACD/Curve Manager software was used to analyze spectra.

Proton nuclear magnetic resonance ( 1 H-NMR)

1H-NMR spectra were recorded on a Bruker Avance III 400 MHz spectrometer, with a 5 mm TIX triple resonance detection probe, at T = 25 °C. Solvent characteristic peaks were used as an internal reference. For films characterization purpose, to confirm the presence of ESBO, films were dissolved into ABIL solvent and DMSO-d6, in same proportion than the solvent for cellulose. The residual DMSO peak was used as reference.

Morphology

To investigate film surface morphology, samples were examined by scanning electron microscopy (SEM). The surfaces were coated with gold and analyzed in a field emission scanning electron microscope (FESEM), ZEISS MERLIN Compact/VPCompact, Gemini II.

Crystallinity

To evaluate the crystallinity of cellulose pulp and regenerated cellulose films, X-ray diffraction (XRD) was performed using an X-ray diffraction instrument (X’PERT MPD, Philips). The XRD patterns with cobalt anode, CoKα radiation consists of Kα1 (1.78897 Å) and Kα2 (1.79285 Å) components at 40 kV and 35 mA were collected in the 2θ range from 4° to 50° at a scanning rate of 1.0° min−1. The crystallinity index (CrI, %) was estimated using deconvolution method of Gaussian model, by the ratio between crystalline peaks area and pattern total area (Park et al. 2010; Yao et al. 2020),

After subtracting the background signal of the substrate, measured without any sample. The presented spectra were firstly smoothed using a Savitzky-Golay method by 5th order polynomial function, and the corresponding deconvolution using Gaussian functions were processed using Origin Lab® software.

Thermal studies

The thermal stability of films was studied by thermogravimetric analysis (TGA) that was conducted using NETZSCH STA 44F5 (Netzsch, Germany). Samples were heated in a temperature range of 20–500 °C at a heating rate of 10 °C·min−1 under nitrogen purge flow. Also, thermal behavior was evaluated by differential scanning calorimetry (DSC) made in a NETZSCH DSC 204 F1 Phoenix model (Netzsch, Germany). All samples were analyzed in an aluminum pan with an ordinarily closed aluminum lid. The samples were cooled from room temperature to -50 °C and followed a heating cycle to 200 °C. A heating/cooling rate of 10 °C·min−1 was used. A dry nitrogen environment with a purge flow was applied. Important to refer that all samples were dried in a vacuum oven at 40 °C, overnight before analysis. All the values were collected from the heat flux curve.

Tensile testing

Tensile tests were performed on an Instron 5944 mechanical tester equipped with a 250 N load cell. Cellulose film rectangular-shaped specimens (50 mm; 10 mm; 0.05–0.1 mm) were presented to tension at a rate of 5 mm·min−1 until failure. The thickness of films was measured with a digital micrometer screw gauge (precision 1 µm) and measurement was taken at three different locations on each film, and the mean value was used in the calculus of the mechanical test results. Samples were dried in a vacuum oven at 40 °C for 24 h, before testing. The present values are an average of five valid tests.

Swelling capacity

The swelling capacity of cellulose/ESBO films was investigated. Dried films were immersed in distilled water at room temperature. The films were weighted at specific periods, and excess surface water was gently removed with absorbent paper.

The swelling ratio (Q) was calculated by:

where, \({W}_{t}\) is the film weight at a specific time and \({W}_{0}\) is the initial dried weight of the film.

The swelling capacity of films in phosphate-buffered saline (PBS) solution (pH 7.4, 0.01 M), incubated in vitro at 37 °C, was also evaluated. Both presented results are an average of three measured samples.

Degradation evaluation

In vitro, preliminary hydrolytic degradation tests of dried cellulose-based films were performed in phosphate-buffered saline solution (PBS, pH = 7.4, 0.01 M), at 37 °C, for 2 weeks. After, the samples were recovered, and dried under vacuum into a desiccator, at room temperature, for 48 h. Degradability was considered through the weight remaining (WR) of samples, calculated by:

where, \({W}_{2}\) is the film weight after incubation for 2 weeks and \({W}_{0}\) is the initial dried weight.

Contact angle

The contact angle was determined by the sessile drop technique, using an Optical Tensiometer Theta Flex (Biolin Scientific, Manchester, UK) with an image resolution of 1984 × 1264 pixels, 3009 fps maximum measuring speed and ± 0.1° accuracy. The water drop volume was 4.0 μL, and measurements were performed at a controlled temperature ambient (25 °C). Then, the drop profile was analyzed following the Young–Laplace equation and all angles were calculated after 1 s and 5 s of drop.

Transmittance

UV–Vis studies for films were performed with a Jasco V-530 spectrophotometer. The analyses were conducted in the 800–300 nm range, at room temperature. The presented values are only from visible light wavelengths.

Cell culture and cell viability assays

Mouse fibroblast cells (NIH3T3, passages 17–25) were used to determine the cytotoxicity of the cellulose-based films through a direct contact test, according to the ISO 10993–5 standard. NIH3T3 cells were cultured in Dulbecco’s Modified Eagle’s Medium/F-12 (DME/F-12 1:1, 2.50 mM L-glutamine, 15.0 mM HEPES buffer, HyClone™, GE Healthcare Life Sciences, South Logan, Utah) supplemented with 10% fetal bovine serum (FBS, South America, Biowest), 100 μg/mL streptomycin and 100 U/mL penicillin. Cells were kept at 37 ºC in a humidified atmosphere containing 5% CO2 and subcultured at 80–90% confluence. Subculture involved removing the culture medium every 2 days, washing with sterile PBS, and detachment of cell monolayers with 0.25% trypsin, 1x (Corning, Manassas, USA) at 37 ºC. Cellulose-based films were cut into a circular shape that fit into 96-well plates and sterilized under UV light for 30 min. The cultured NIH3T3 fibroblast cells were placed in direct contact with the materials at a density of 10,000 cells/well in 96-well culture plates. Cells were incubated in a 5% CO2 incubator at 37 ºC and the culture medium was removed and replaced every 2 days. On the day of the test (days 1, 3, and 7), the culture medium was removed and replaced with a mixture of 90 μL of DME/F-12 medium and 10 μL of AlamarBlue™ HS Cell Viability reagent (Invitrogen), according to the manufacturer´s instructions. After 4 h of incubation at 37 ºC in a humidified environment with 5% CO2, 100 μL of the supernatant solution of each well was then transferred to a new 96-well plate, and the absorbance was measured at 570 nm, using 600 nm as the reference wavelength (normalized to the value of 600 nm). All experiments were performed in quadruplicate (n = 4) for each film, each with three technical replicates. Two controls were performed: a negative control (K−, untreated NIH3T3 cells, i.e., cells without the material present) and positive control (K+, 70% ethanol-treated cells). Cell viability was calculated as a percentage relative to the untreated NIH3T3 cells, which were considered 100% viable.

Cell adhesion

To investigate cell adhesion, NIH3T3 cells (at a cell density of 1 × 104 cells per well) were seeded on the surface of the films and cultured for 2 days at 37 °C in a humidified air atmosphere with 5% CO2. For cell fixation, cell-seeded films were incubated with paraformaldehyde (4%) for 2 h at RT. Subsequently, the fixed cells were dehydrated through a series of graded ethanol/PBS mixtures (ethanol concentrations of 30, 50, 75, 85, 95 and 100%) for 15 min/time. The dried cell-seeded films were sputter-coated with a gold layer and observed by SEM. SEM images were acquired with different magnifications, at an acceleration voltage of 10 kV, using a High-resolution field emission scanning electron microscope, with EDS, WDS (STEM ZEISS, Merlin).

Statistical analysis

All quantitative data are expressed as mean ± standard deviations (S.D.). For statistical analysis, viability assay data were obtained from four individual experiments. To determine statistically significant differences between each group, a Tukey’s multiple comparisons test was performed using GraphPad Prism version 7 software (GraphPad Software Inc., La Jolla, CA, USA). A p-value < 0.0001 was considered statistically significant.

Results and discussion

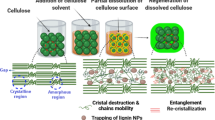

Cellulose-based films with ESBO

ESBO is currently used as a plasticizer in industry. The presence of reactive epoxy groups prompts us to use this compound to improve the properties of cellulose films. The cellulose/ESBO films were prepared following our previously reported procedure in an ABIL solvent (Ribeiro et al. 2021) with some improvements related to the regeneration step. To understand whether the reaction conditions are crucial for the reaction between the epoxide ring of ESBO and the hydroxyl groups of cellulose, a physical mixture of cellulose pulp and ESBO was prepared and analyzed by FTIR (Fig. S2). Only under the conditions of solubilization was there evidence of the disappearance of the epoxide groups and the resulting chemical crosslinking. In dissolved form, cellulose can be present in alkoxy form, which is a good nucleophilic reagent that can react with the epoxide groups of ESBO (Scheme 1), chemically binding to them (Liu et al. 2016; Pour-Esmaeil et al. 2020). In addition, the unbound epoxide groups of ESBO can react with water in regeneration/washing steps to form hydroxyl groups (Wai et al. 2019). It is worth noting that a similar reaction of cellulose and ESBO to prepare scaffolds was recently reported but using an NMMO-based solvent which is known to be thermally unstable (Onwukamike et al. 2019) and requires the addition of a base catalyst (Pour-Esmaeil et al. 2020). In our case, the epoxy-hydroxyl reaction occurs through a simpler process, through catalysis of the acid/base system of ABIL (Teng and Soucek 2000; Dhakshinamoorthy et al. 2010).

The presence of solvents in the final cellulose films is an issue that is not addressed in many articles. However, for certain practical applications, their absence is mandatory due to environment toxicity which severely limits the scope of application. In our case, extending the washing time (3 × 30 min) resulted in an extremely effective removal of ABIL. In addition, the use of a micrometer film deposition allows a thinner film thickness and consequently a more efficient regeneration and washability of the films. Thus, the finished films have a thickness between 50 and 100 µm. Visual inspection shows that the films become more flexible with increasing amounts of ESBO. However, some transparency is lost, and a yellowish color appears (characteristic of soybean oil).

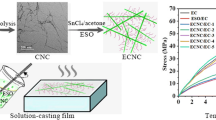

The films were labelled according to the quantity of added ESBO, i.e., a film labelled “Cel-ESBO1.0” is a film that results from cellulose reaction with 1.0 g of ESBO. The amount of cellulose used was always the same, 610 mg. A control sample (Cel-film) with only cellulose was also prepared. Figure 1 presents a schematic representation of the films’ preparation.

Solvent content in films

The water used in the washing step promotes cellulose regeneration by displacing the solvent [TMG] [OAc]. To quantify the amount of solvent remaining in the final films, an extraction method followed by NMR analysis was used. The TMG-based quantification of the solvent is shown in Table 1 (see online resource, section S3). The results show that a residual amount of IL remains in the films from this extraction step and that it is independent of the amount of ESBO used in the reaction.

Replacing cellulose-solvent bonds with cellulose-ESBO bonds promotes efficient release of IL for water. It is important to emphasize that in our previous work, the resulting films had a much higher amount (45–95 wt%) of retained solvent, as in other reported work (Haq et al. 2019; Ribeiro et al. 2021). Improving solvent extraction from films is very important when the resulting films are composed of only biobased materials and have no solvent contamination, as they can serve as new materials for novel biomedical applications.

Fourier-Transform Infrared spectroscopy

FTIR analysis was performed to analyze the chemical composition of the films and the degree of interaction between cellulose and ESBO. In Fig. 2, the signal at 3300 cm−1 corresponds to the stretching vibrations of the hydroxyl group (−OH) of water absorbed by cellulose, which is common in cellulose regenerates (Pang et al. 2013). The peaks at 2920 and 2851 cm−1 correspond to the characteristic absorption of the asymmetric -CH2 stretching and the symmetric -CH3 stretching, whose transmittance increases proportionally to the ESBO concentration in the films. The same is true for the peak at 1742 cm−1, which represents the stretching of the ESBO C = O group (Yang et al. 2014). The peaks at 845 and 822 cm−1 correspond to the epoxide groups of ESBO that disappeared in cellulose films plasticized with ESBO, indicating a ring-opening reaction of the epoxide groups with the hydroxyl groups of cellulose (Petrović 2008; Pour-Esmaeil et al. 2020). Also, the isolated characteristic peak of the ABIL solvent at 1545 cm−1 (Ribeiro et al. 2021) is not present in the FTIR spectra of the films, supporting the absence of this material in films.

To further confirm the chemical cross-linking of cellulose and ESBO, extraction tests were performed with chloroform to remove any free ESBO, and the resulting films were analyzed again by FTIR (Fig. S3). The presence of the typical ESBO peaks and the absence of the epoxy group peaks confirmed that the plasticizer was still present in the films, indicating chemical crosslinking with cellulose chains. The presence of ESBO in films was also proved by acquisition of an 1H-NMR of the films in the same dissolution mixture but using DMSO-d6 (Fig S7).

Scanning Electronic Microscopy

The morphology of the cellulose-based films was analyzed using SEM. Like the control sample (Fig. 3A), the films prepared with 0.5 g ESBO (Fig. 3B) had a smooth surface, indicating good miscibility of ESBO and cellulose and their uniform distribution in the films. As the amount of ESBO increases (0.5 to 2.0 g), the surface becomes less homogeneous and exhibits unevenness. In the films with 2.0 g ESBO (Fig. 3D), the surfaces lost some homogeneity and unevenness appeared, probably because ESBO (which is hydrophobic) tended to aggregate in water during the regeneration step and promoted partial phase separation (Yang et al. 2014).

Crystallinity (XRD)

XRD is currently used to investigate the crystallinity of cellulose. The several aspects that contribute to crystallinity and to the process of the analysis of the crystallinity are already highlighted (French and Santiago Cintrón 2013; French 2014, 2020). For cellulose pulp, the diffraction peak at 18.6° despite seeming to be only one peak is the superimposition of the two peaks at 2θ = 17.8° and 19.6° (Figure S6) that are indexed as (1–10), (110) diffraction planes, while at 2θ = 26.1° and 40.4° are form the (200) and (004) planes from Miller indices, respectively (French 2014) (Fig. 4A). Using deconvolution of the signal (Online Resource, S4) the crystallinity of cellulose pulp was estimated to be 61% consistent with other works. (Park et al. 2010; Yao et al. 2020).

In case of cellulose films, during the process of dissolution and regeneration is expected to change the cellulose crystallinity and reduces it significantly. In all film samples the signals are very broad without the evidence of sharp peaks and (004) plane peak (Fig. 4B). Hence, by comparison with amorphous cellulose samples obtained by exhaustive ball-milling (Yao et al. 2020), our samples seem to be practically constituted by an amorphous cellulose structure, also observed by other authors. (Pour-Esmaeil et al. 2020; Xu et al. 2019).

Thermal Properties

The thermal behavior and stability of the films were investigated by DSC and TGA, respectively (Fig. 5). The DSC thermogram of ESBO (Fig. 5A-a) shows endothermic peaks before 0 °C, which could be attributed to crystalline polymorphism characteristic of some vegetable oils (Guo et al. 2000; Bueno-Ferrer et al. 2010). This phenomenon was seen in the DSC curve of pure ESBO as a crystallization event before melting, with two endothermic peaks around − 13 °C and − 7 °C.

As expected, the cellulose films showed no thermal transitions (Fig. 5A-b). In the case of the ESBO- containing films, the DSC thermograms showed the very distinct characteristic peaks of crystalline polymorphism of ESBO (< 0 °C), with the peak temperature slightly increasing with increasing ESBO content. The thermograms also show a glass transition which must correspond to cellulose (Tg ~ 55 °C) caused by the cellulose-ESBO reaction. The crosslinking between cellulose and ESBO produced a new amorphous phase in the sample, which led to the appearance of this glass transition. The values obtained (Table 2) are much lower compared to cellulose ester derivatives which corresponds to the forms of known plasticized cellulose (Lee and Shiraishi 2001; Boulven et al. 2019). The Tg values of the films also decreased with increasing ESBO content, indicating an increasing degree of plasticization of the cellulose. This effect of plasticization will further manifest in the mechanical properties of the films.

The thermal stability of ESBO and cellulose/ESBO films was also evaluated (Fig. 5B). The cellulose-based samples showed a small dehydration step below 100 °C. All samples showed a one-step thermal decomposition between 257 and 400 °C. ESBO exhibited higher thermal stability than the control cellulose film (Fig. 5B-a, b). Incorporation of ESBO increased the thermal stability of the cellulose films to a significant extent in the Cel-ESBO1.0 and 2.0 samples, due to the presence of higher ESBO content in these films. The same behavior is seen in the analysis of the residual weight, where the samples Cel-ESBO1.0 and Cel-ESBO2.0 show lower values compared to Cel-ESBO0.5 and even more than the control sample.

Mechanical Properties

Figure 6 shows the typical stress–strain curves of the samples to understand the effects of different amounts of ESBO on the mechanical properties of the films. The absence of the ionic liquid in cellulose films results in a material with an increased strength of 100 MPa for the maximum stress (Ribeiro et al. 2021). This is an interesting value for cellulose films that could compete with commercial polyolefins (Fig. 6a) (Wang et al. 2013).

Between the samples with ESBO, the elongation of films increases ten times (Table S2) with increasing the amount of ESBO used, from 2% for Cel-ESBO0.5 to 20% for Cel-ESBO2.0, revealing the plasticization effect of ESBO.

Regarding the maximum tensile strength (TS), the presence of ESBO causes a decrease relatively to the cellulose control sample (a). This decrease could be related to the more difficult alignment of the cellulose chains and the resulting lower intermolecular interactions between the cellulose chains that occur during regeneration and water evaporation (Zheng et al. 2019). A similar explanation was given for the influence of temperature and time in the regeneration process from the cellulose gel state to film state (Wang et al. 2019; Wei et al. 2020). The formation of new interfaces between cellulose chains and ESBO with low binding degree could explain the decrease of this mechanical property (Pang et al. 2013). However, with increasing amount of ESBO, the maximum TS is maintained, which is about 30 MPa. The maintenance of the maximum tensile strength could be due to the formation of covalent bonds between cellulose and ESBO, leading to new interactions and stacking between cellulose and ESBO chains (Ma et al. 2011). In addition, the mechanical properties of cellulose-ESBO films are very similar to those of cellulose films for packaging (Zhao et al. 2019), show more flexibility than cellulose-based films for wound dressing (Rakhshaei and Namazi 2017) and have better properties than regenerated cellulose-zinc oxide nanocomposite films for biomedical applications (Ul-Islam et al. 2014) or cellulose membranes for tissue engineering (Rambo et al. 2008).

Transparency and UV–Vis transmittance

For certain applications, such as packaging or biomedical applications, the transparency of films is particularly important. Therefore, the light transmission of cellulose/ESBO films was measured by UV–vis spectroscopy; the results are shown in Table S4. The regenerated cellulose film exhibited high transparency and transmittance (70–80%) in the range VIS, which is consistent with our previous results (Ribeiro et al. 2021). However, with increasing ESBO content, a yellowish coloration appears, which reduces the light transmission of the films.

Nevertheless, these values of transmittance could suggest that cellulose/ESBO films became non-transparent and very opaque. The photographs (Fig. 7) comparing all cellulose films prove their transparency and their vision through capacity.

Contact angle

The water contact angle test of films was measured, after 1 s and 5 s after drop fall, in order to analyze the influence of ESBO content on film hydrophilicity. The results are shown in Fig. 8.

The control film (Fig. 8a) formed a low angle value between the water droplet and the film (24°), which was expected due to the hydrophilic property of cellulose films. With the presence of ESBO, the films became less hydrophilic, and the contact angle increased from 24° to 62° with only the smallest amount of ESBO added. Due to the hydrophobic portion of ESBO, the water contact angle value increased significantly with increasing amount, from 62° to 97° for Cel-ESBO0.5 and Cel-ESBO2.0, respectively.

This contact angle is one of the highest values for a cellulose film comparable to cellulose ester derivatives (Crépy et al. 2009; Huang et al. 2019) and could be an important aspect for future applications (Qing et al. 2015). Also, after 5 s whereas cellulose film rapidly decreased its contact angle due to high swelling capacity of cellulose, with the increasing ESBO content, the decrease in contact angle is lower and film surface maintains its hydrophobic characteristics, especially for Cel-ESBO2.0.

Swelling capacity

The water absorption capacity of the cellulose/ESBO films was evaluated. The films absorbed water rapidly and reached an equilibrium state after about 30 min (Fig. 9). The kinetic profile of swelling is similar for all films, but the maximum swelling varies depending on the amount of ESBO added. After only 5 min, the control cellulose film (Cel-film) had swelled to 200% of its dry weight, making it the most hydrophilic film. Increasing the amount of ESBO added resulted in a decrease in maximum swelling due to the presence of the hydrophobic portion. Cel-ESBO2.0 absorbed almost four times less water than the control cellulosic film. The reversibility of the swelling capacity was also evaluated. For this purpose, the films were dried in a vacuum oven at 60 °C for 12 h after the first swelling cycle. The original mass of the films was maintained, as was their original structure, with only minor weaknesses in the control samples. In a further swelling test, the films showed similar swelling kinetics and maximum swelling capacity as the original films.

In addition, the water uptake capacity was investigated using a PBS buffer (0.01 M, pH = 7.4) at 37 °C (Fig. 10). Compared to distilled water, the swelling capacity decreased for all films, ranging from 42% for Cel-film to 24% for Cel-ESBO2.0, the highest and lowest swelling capacity, respectively. The tendency for the water absorption capacity to decrease with increasing amounts of ESBO also remained. Thinking about healthy applications of these materials, the observed swelling capacities are much higher than those of carboxymethylcellulose hydrogel for wound dressings (Rakhshaei and Namazi 2017) and a similar swelling compared to cellulose membranes for tissue engineering (Rambo et al. 2008) or polymer hydrogel for wound dressings (Paula et al. 2021). Depending on the application, the high swelling capacity could also be a disadvantage. Nevertheless, incorporation of ESBO resulted in a significant reduction in swelling, indicating improved hydrophobicity compared to cellulose-based hydrophobic ester mats (Saraiva et al. 2021).

Degradability evaluation

Preliminary in vitro degradability of cellulose-based films was studied in PBS saline (pH = 7.4) at 37 °C for 2 weeks (Fig. 11). All cellulose-based films maintained their initial weight, in some cases with a slight increase. This slight increase could be due to the absorption of the salts of the PBS solution. The cellulose/ESBO-based films were more flexible but had excellent structural integrity compared to the control cellulose-based films, showing that the presence of ESBO does not alter the main cellulose structure. This stability was also observed in other recent work with cellulose derivative mats, where weight loss after 30 days was negligible (Saraiva et al. 2021), and in cellulose-based scaffolds for tissue engineering (Pour-Esmaeil et al. 2020). This structural stability of cellulose films is very important to avoid the premature loss of properties that is characteristic of cellulose fibre-based materials when they are exposed to humid environment.

Cell viability analysis

The possible application of these types of materials in health science requires the knowledge of their cytotoxicity. The cytotoxicity of the synthesized cellulose-based materials was investigated by determining the cell viability of NIH3T3 fibroblast cells grown on unmodified (Cel film) and modified (Cel-ESBO0.5, Cel-ESBO1.0, Cel-ESBO2.0) films. Figure 12 shows the results of cell viability after 1, 3 and 7 days of cell culture on the films compared to the control (untreated cells corresponding to 100%). The results of the AlamarBlue™ HS cell viability assay on NIH3T3 cells with one-day treatment showed high viability for (un)modified samples-Cel film (86.30 ± 5.87%), Cel-ESBO0.5 (94.32 ± 6.19%), Cel-ESBO1.0 (84.74 ± 4.38%), and Cel-ESBO2.0 (91.94 ± 2.57%)-compared to control. As can be seen in Fig. 12, all films showed better cell proliferation after 3 days of cell culture compared with day 1. The pattern for cells grown in the presence of Cel-ESBO1.0 (90.40 ± 2.61%), Cel-ESBO2.0 (93.01 ± 5.75%), and Cel film (88.27 ± 5.44%) was similar, but viable cells on Cel-ESBO0.5 were 102.23 ± 4.55%.

In turn, after 7 days in culture, Cel-ESBO1.0 (41.61 ± 3.47%) and Cel-ESBO2.0 (38.36 ± 4.35%) have a significantly decreased cell viability, however proliferation of NIH3T3 cells in Cel-ESBO0.5 (77.01 ± 5.04%), is comparable with the control Cel-film (87.71 ± 3.93%),. This means that the introduction of ESBO0.5 had no significant cytotoxic effect, even after 7 days. According to p values, there is a significant difference between the Cel-ESBO0.5 and Cel-ESBO1.0, and Cel-film on days 1, 3 and 7. Furthermore, the viability results indicate that for 7 days test, the Cel-ESBO0.5 films are cytocompatible and nontoxic for NIH3T3 cells and showed greater ability for growth and proliferation after 7 days of incubation.

Cell attachment analysis

Considering the viability results, the Cell-ESBO0.5 films seeded with NIH3T3 cells were observed using SEM to visualize the adhesion, proliferation, and morphology of the cells on the material surface. As shown in the micrographs from SEM (Fig. 13), NIH3T3 cells adhered to and spread on the film surface after 2 days of incubation, demonstrating the interaction of fibroblast cells with the film surface. Fibroblast cells were observed in a flat, elongated (cytoplasmic extensions), and rounded morphology with a monolayer-like structure on the film surface. These results can be explained by the particular structure of the film surface due to the presence of functional groups that can promote stronger cell adhesion, proliferation, and bioactivity on rough surfaces (Kunzler et al. 2007). The results indicate that Cel-ESBO0.5 films support adhesion/fixation and cell proliferation and therefore, they are suitable for tissue engineering applications.

Conclusions

In this work, cross-linked cellulose ESBO films were prepared and extensively characterized in terms of their morphology, thermal behavior, and physical and biological properties. The cellulose-ESBO reaction was carried out in an acid-base conjugated ionic liquid, one of the most environmentally friendly cellulose solvents nowadays, serving both as a medium and a catalyst, which is one of the main advantages of this system. The FTIR and extraction methods confirmed the chemical crosslinking between cellulose and ESBO. The solvent remaining in the films is in a residual amount, which increases the potential applications of these type of materials. The resulting films exhibited adjustable swelling and flexibility properties as well as transparency, depending on the amount of ESBO initially added. The cellulose-based films also showed structural stability in PBS buffer for 2 weeks and retained their physical structure. In terms of their biological performance, the cellulose/ESBO films proved to be biocompatible as well asnoncytotoxic, and promoted adhesion and proliferation of NIH3T3 fibroblasts, at least for 3 days. After 7 days test, only Cel-ESBO0.5 showed to be an interesting bioplasticizer for adjusting properties of cellulose films.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article and its supplementary materials.

References

Adhvaryu A, Erhan SZ (2002) Epoxidized soybean oil as a potential source of high-temperature lubricants. Ind Crops Prod 15(3):247–254. https://doi.org/10.1016/S0926-6690(01)00120-0

Airong X, Zhang Y, Zhao Y, Wang J (2013) Cellulose dissolution at ambient temperature: role of preferential solvation of cations of ionic liquids by a cosolvent. Carbohydr Polym 92(1):540–544. https://doi.org/10.1016/j.carbpol.2012.09.028

Berga L, Bruce I, Nicol TWJ et al (2020) Cellulose dissolution and regeneration using a non-aqueous, non-stoichiometric protic ionic liquid system. Cellulose 27:9593–9603. https://doi.org/10.1007/s10570-020-03444-8

Boulven M, Quintard G, Cottaz A, Joly C, Charlot A, Fleury E (2019) Homogeneous acylation of Cellulose diacetate: Towards bioplastics with tuneable thermal and water transport properties. Carbohydr Polym 206:674–684. https://doi.org/10.1016/j.carbpol.2018.11.030

Bueno-Ferrer C, Garrigós MC, Jiménez A (2010) Characterization and thermal stability of poly(vinyl chloride) plasticized with epoxidized soybean oil for food packaging. Polym Degrad Stab 95(11):2207–2212. https://doi.org/10.1016/j.polymdegradstab.2010.01.027

Cai J, Zhang L (2005) Rapid dissolution of cellulose in LiOH/urea and NaOH/urea aqueous solutions. Macromol Biosci 5:539–548. https://doi.org/10.1002/mabi.200400222

Chua S-C, Xuebing X, Guo Z (2012) Emerging sustainable technology for epoxidation directed toward plant oil-based plasticizers. Proc Biochem 47(10):1439–1451. https://doi.org/10.1016/j.procbio.2012.05.025

Crawford RR, Esmerian OK (1971) Effect of plasticizers on some physical properties of cellulose acetate phthalate films. J Pharm Sci 60(2):312–314. https://doi.org/10.1002/jps.2600600238

Crépy L, Chaveriat L, Banoub J, Martin P, Joly N (2009) Synthesis of cellulose fatty esters as plastics-influence of the degree of substitution and the fatty chain length on mechanical properties. Chemsuschem 2(2):165–170. https://doi.org/10.1002/cssc.200800171

Dhakshinamoorthy A, Alvaro M, Garcia H (2010) Metal-organic frameworks as efficient heterogeneous catalysts for the regioselective ring opening of epoxides. Chem A Europ J 16(28):8530–8536. https://doi.org/10.1002/chem.201000588

El Seoud OA, Kostag M, Jedvert K, Malek NI (2019) Cellulose in ionic liquids and alkaline solutions: advances in the mechanisms of biopolymer dissolution and regeneration. Polymers 11:1–28. https://doi.org/10.3390/polym11121917

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

French AD (2020) Increment in evolution of cellulose crystallinity analysis. Cellulose 27:5445–5448. https://doi.org/10.1007/s10570-020-03172-z

French AD, Santiago Cintrón M (2013) Cellulose polymorphy, crystallite size, and the segal crystallinity index. Cellulose 20:583–588. https://doi.org/10.1007/s10570-012-9833-y

Frias CF, Fonseca AC, Coelho JFJ, Serra AC (2021) Straightforward synthesis of amido polyols from epoxidized soybean oil for polyurethane films. Macromol Mater Eng 306(11):2100453. https://doi.org/10.1002/mame.202100453

Galiano F, Briceño K, Marino T, Molino A, Christensen KV, Figoli A (2018) Advances in biopolymer-based membrane preparation and applications. J Membr Sci 564:562–586. https://doi.org/10.1016/j.memsci.2018.07.059

Guo A, Cho Y, Petrović ZS (2000) Structure and properties of halogenated and nonhalogenated soy-based polyols. J Polym Sci Part A Polym Chem 38:3900–3910. https://doi.org/10.1002/1099-0518(20001101)38:21%3c3900::AID-POLA70%3e3.0.CO;2-E

Haq MA, Habu Y, Yamamoto K et al (2019) Ionic liquid induces flexibility and thermoplasticity in cellulose film. Carbohydr Polym 223:6. https://doi.org/10.1016/j.carbpol.2019.115058

Huang L, Wu Q, Wang Q, Wolcott M (2019) One-step activation and surface fatty acylation of cellulose fibers in a solvent-free condition. ACS Sustain Chem Eng 7:15920–15927. https://doi.org/10.1021/acssuschemeng.9b01974

Jia P, Xia H, Tang K, Zhou Y (2018) Plasticizers derived from biomass resources: a short review. Polymers. https://doi.org/10.3390/polym10121303

Kakko T, King AWT, Kilpeläinen I (2017) Homogenous esterification of cellulose pulp in [DBNH] [OAc]. Cellulose 24:5341–5354. https://doi.org/10.1007/s10570-017-1521-5

Kasprzak D, Krystkowiak E, Stępniak I, Galiński M (2019) Dissolution of cellulose in novel carboxylate-based ionic liquids and dimethyl sulfoxide mixed solvents. Europ Polym J 113:89–97. https://doi.org/10.1016/j.eurpolymj.2019.01.053

King AWT, Asikkala J, Mutikainen I et al (2011) Distillable acid-base conjugate ionic liquids for cellulose dissolution and processing. Angew Chemie Int Ed 50:6301–6305. https://doi.org/10.1002/anie.201100274

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chemie Int Ed 44:3358–3393. https://doi.org/10.1002/anie.200460587

Koenig G, Lohmar E, Rupprich N, et al (2012) Chloroacetic acids. In: Ullmann’s encyclopedia of industrial chemistry. Wiley, Germany

Kostag M, Jedvert K, Achtel C et al (2018) Recent advances in solvents for the dissolution, shaping and derivatization of cellulose: quaternary ammonium electrolytes and their solutions in water and molecular solvents. Molecules 23:1–39. https://doi.org/10.3390/molecules23030511

Kunzler TP, Drobek T, Schuler M, Spencer ND (2007) Systematic study of osteoblast and fibroblast response to roughness by means of surface-morphology gradients. Biomaterials 28(13):2175–2182. https://doi.org/10.1016/j.biomaterials.2007.01.019

Lee S-H, Shiraishi N (2001) Plasticization of cellulose diacetate by reaction with maleic anhydride, glycerol, and citrate esters during melt processing. J Appl Polym Sci 81(1):243–250. https://doi.org/10.1002/app.1435

Li X, Zhang Y, Tang J et al (2016) Efficient preparation of high concentration cellulose solution with complex DMSO/ILs solvent. J Polym Res 23:32. https://doi.org/10.1007/s10965-016-0922-8

Liu H, Wang A, Xu X et al (2016) Porous aerogels prepared by crosslinking of cellulose with 1{,}4-butanediol diglycidyl ether in NaOH/urea solution. RSC Adv 6:42854–42862. https://doi.org/10.1039/C6RA07464B

Ma H, Zhou B, Li H-S, Li Y-Q, Shi-Yi O (2011) Green composite films composed of nanocrystalline cellulose and a cellulose matrix regenerated from functionalized ionic liquid solution. Carbohydr Polym 84(1):383–389. https://doi.org/10.1016/j.carbpol.2010.11.050

Medronho B, Lindman B (2014) Competing forces during cellulose dissolution: from solvents to mechanisms. Curr Opin Colloid Interface Sci 19:32–40. https://doi.org/10.1016/j.cocis.2013.12.001

Meenatchi B, Renuga V, Manikandan A (2017) Cellulose dissolution and regeneration using various imidazolium based protic ionic liquids. J Mol Liq 238:582–588. https://doi.org/10.1016/j.molliq.2016.05.008

Onwukamike KN, Grelier S, Grau E et al (2019) Critical review on sustainable homogeneous cellulose modification: why renewability is not enough. ACS Sustain Chem Eng 7:1826–1840. https://doi.org/10.1021/acssuschemeng.8b04990

Pang J, Liu X, Zhang X et al (2013) Fabrication of cellulose film with enhanced mechanical properties in ionic liquid 1-allyl-3-methylimidaxolium chloride (AmimCl). Materials 6:1270–1284. https://doi.org/10.3390/ma6041270

Park S, Baker JO, Himmel ME et al (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:10. https://doi.org/10.1186/1754-6834-3-10

Parviainen A, Wahlström R, Liimatainen U et al (2015) Sustainability of cellulose dissolution and regeneration in 1,5-diazabicyclo[4.3.0]non-5-enium acetate: a batch simulation of the IONCELL-F process. RSC Adv 5:69728–69737. https://doi.org/10.1039/C5RA12386K

Paula CTB, Pereira P, Coelho JFJ, Fonseca AC, Serra AC (2021) Development of light-degradable poly(urethane-urea) hydrogel films. Mater Sci Eng C 131:112520. https://doi.org/10.1016/j.msec.2021.112520

Petrović ZS (2008) Polyurethanes from vegetable oils. Polym Rev 48:109–155. https://doi.org/10.1080/15583720701834224

Pour-Esmaeil S, Sharifi-Sanjani N, Khoee S, Taheri-Qazvini N (2020) Biocompatible chemical network of α-cellulose-ESBO (epoxidized soybean oil) scaffold for tissue engineering application. Carbohydr Polym 241:116322. https://doi.org/10.1016/j.carbpol.2020.116322

Qing Y, Cai Z, Yiqiang W, Yao C, Qinglin W, Li X (2015) Facile preparation of optically transparent and hydrophobic cellulose nanofibril composite films. Ind Crops Prod 77:13–20. https://doi.org/10.1016/j.indcrop.2015.08.016

Rakhshaei R, Namazi H (2017) A potential bioactive wound dressing based on carboxymethyl cellulose/ZnO impregnated MCM-41 nanocomposite hydrogel. Mater Sci Eng C 73:456–464. https://doi.org/10.1016/j.msec.2016.12.097

Rambo CR, Recouvreux DOS, Carminatti CA, Pitlovanciv AK, Antônio RV, Porto LM (2008) Template assisted synthesis of porous nanofibrous cellulose membranes for tissue engineering. Mater Sci Eng, C 28(4):549–554. https://doi.org/10.1016/j.msec.2007.11.011

Ribeiro DCM, Rebelo RC, De Bon F et al (2021) Process development for flexible films of industrial cellulose pulp using superbase ionic liquids. Polymers. https://doi.org/10.3390/polym13111767

Sahana TG, Rekha PD (2018) Biopolymers: applications in wound healing and skin tissue engineering. Mol Biol Rep 45:2857–2867. https://doi.org/10.1007/s11033-018-4296-3

Saraiva S, Pereira P, Paula CT, Rebelo RC, Coelho JFJ, Serra AC, Fonseca AC (2021) Development of electrospun mats based on hydrophobic hydroxypropyl cellulose derivatives. Mater Sci Eng C 131:112498. https://doi.org/10.1016/j.msec.2021.112498

Sayyed AJ, Deshmukh NA, Pinjari DV (2019) A critical review of manufacturing processes used in regenerated cellulosic fibres: viscose, cellulose acetate, cuprammonium, LiCl/DMAc, ionic liquids, and NMMO based lyocell. Cellulose 26:2913–2940. https://doi.org/10.1007/s10570-019-02318-y

Shen X, Shamshina JL, Berton P et al (2016) Hydrogels based on cellulose and chitin: fabrication, properties, and applications. Green Chem 18:53–75. https://doi.org/10.1039/C5GC02396C

Sirviö JA, Visanko M, Ukkola J, Liimatainen H (2018) Effect of plasticizers on the mechanical and thermomechanical properties of cellulose-based biocomposite films. Ind Crops Prod 122:513–521. https://doi.org/10.1016/j.indcrop.2018.06.039

Striegel AM (1997) Theory and applications of DMAC/LICL in the analysis of polysaccharides. Carbohydr Polym 34:267–274. https://doi.org/10.1016/s0144-8617(97)00101-x

Teng G, Soucek MD (2000) Epoxidized soybean oil-based ceramer coatings. J Am Oil Chem Soc 77(4):381–387. https://doi.org/10.1007/s11746-000-0062-0

Ul-Islam M, Khattak WA, Ullah MW et al (2014) Synthesis of regenerated bacterial cellulose-zinc oxide nanocomposite films for biomedical applications. Cellulose 21:433–447. https://doi.org/10.1007/s10570-013-0109-y

Vieira MGA, da Silva MA, dos Santos LO, Beppu MM (2011) Natural-based plasticizers and biopolymer films: a review. Europ Polym J 47(3):254–263. https://doi.org/10.1016/j.eurpolymj.2010.12.011

Wai PT, Jiang P, Shen Y et al (2019) Catalytic developments in the epoxidation of vegetable oils and the analysis methods of epoxidized products. RSC Adv 9:38119–38136. https://doi.org/10.1039/C9RA05943A

Wang Q, Cai J, Zhang L et al (2013) A bioplastic with high strength constructed from a cellulose hydrogel by changing the aggregated structure. J Mater Chem A 1:6678–6686. https://doi.org/10.1039/C3TA11130J

Wang Y, Yuan L, Tian H, Zhang L, Ang L (2019) Strong, transparent cellulose film as gas barrier constructed via water evaporation induced dense packing. J Membr Sci 585:99–108. https://doi.org/10.1016/j.memsci.2019.04.059

Wei Q-Y, Lin H, Yang B et al (2020) Structure and properties of all-cellulose composites prepared by controlling the dissolution temperature of a NaOH/urea solvent. Ind Eng Chem Res 59:10428–10435. https://doi.org/10.1021/acs.iecr.9b07075

Wilpiszewska K, Antosik AK, Schmidt B et al (2020) Hydrophilic films based on carboxymethylated derivatives of starch and cellulose. Polymers. https://doi.org/10.3390/polym12112447

Xu A, Wang Y, Gao J, Wang J (2019) Facile fabrication of a homogeneous cellulose/polylactic acid composite film with improved biocompatibility, biodegradability and mechanical properties. Green Chem 21:4449–4456. https://doi.org/10.1039/c9gc01918a

Yang D, Peng X, Zhong L et al (2014) Green films from renewable resources: properties of epoxidized soybean oil plasticized ethyl cellulose films. Carbohydr Polym 103:198–206. https://doi.org/10.1016/j.carbpol.2013.12.043

Yang X, Cheng F, Fan Y, Song Y, He N, Lai G, Gong Z, Shen J (2022) Highly transparent acrylate epoxidized soybean oil based UV–curable silicone–modified coatings with good thermal stability and flame retardancy. Prog Organ Coat 165:106769. https://doi.org/10.1016/j.porgcoat.2022.106769

Yao W, Weng Y, Catchmark JM (2020) Improved cellulose X-ray diffraction analysis using fourier series modeling. Cellulose 27:5563–5579. https://doi.org/10.1007/s10570-020-03177-8

Zainal SH, Mohd NH, Suhaili N, Anuar FH, Lazim AM, Othaman R (2021) Preparation of cellulose-based hydrogel: a review. J Mater Res Technol 10:935–952. https://doi.org/10.1016/j.jmrt.2020.12.012

Zhao G, Lyu X, Lee J, Cui X, Chen W-N (2019) Biodegradable and transparent cellulose film prepared eco-friendly from durian rind for packaging application. Food Packag Shelf Life 21:100345. https://doi.org/10.1016/j.fpsl.2019.100345

Zheng X, Huang F, Chen L et al (2019) Preparation of transparent film via cellulose regeneration: correlations between ionic liquid and film properties. Carbohydr Polym 203:214–218. https://doi.org/10.1016/j.carbpol.2018.09.060

Acknowledgments

The authors acknowledge to Dr. Alfred French and Dr.ª Denise Petri for the provided Mercury calculated XRD pattern of cellulose Iß to CoKα radiation.

Funding

Open access funding provided by FCT|FCCN (b-on). This research was supported by FEDER funds through the program COMPETE–Programa Operacional Factores de Competitividade–and by national funds through FCT–Fundação para a Ciência e a Tecnologia, under the project UID/EMS/00285/2020. FCT also supported the project POCI-01–0145-FEDER-029742 (POLYCEL). NMR data were collected at the UC-NMR facility which is supported in part by FEDER – European Regional Fund through the COMPETE Programme (Operational Programme for Competitiveness) and by National Funds through FCT – Fundação para a Ciência e a Tecnologia (Portuguese Foundation for Science and Technology) through grants REEQ/481/QUI/2006-RECI/QEQ-QFI/0168/2012, CENTRO-07-CT62-FEDER-002012, and Rede Nacional de Ressonância Magnética Nuclear (RNRRMN).

Author information

Authors and Affiliations

Contributions

All authors of this manuscript contributed to the development of this work. RR and DR contributed equally to this work: methodology, validation, investigation, data curation and writing original and review. P. P. and FDB: formal analysis, investigation, supervision, and writing original and review. JC and AS: conceptualization, methodology, resources, writing-review and editing, project administration and funding acquisition. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Consent for publication

All authors have read and agreed to the published version of the manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rebelo, R.C., Ribeiro, D.C.M., Pereira, P. et al. Cellulose-based films with internal plasticization with epoxidized soybean oil. Cellulose 30, 1823–1840 (2023). https://doi.org/10.1007/s10570-022-04997-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04997-6