Abstract

Luminescent nanocomposite films, containing SrF2:Ho up-conversion particles, were prepared by two different protocols from aqueous dispersions of TEMPO-oxidized cellulose nanofibrils (TOCNF) functionalized with 3-aminopropyltriethoxysilane (APS) without the use of organic solvents at pH = 4.0–4.5 and 9.0–9.5, respectively. Proposed synthetic protocols included the formation of the films by drying the dispersions containing pre-hydrolyzed APS adsorbed onto TOCNF and SrF2:Ho particles followed by heating at 105 °C. Hydrophobic (water contact angle 101 ± 2°), strong, and translucent TOCNF/SrF2:Ho-APS films were prepared by casting from a solution at pH = 4.0–4.5. Scanning electron microscopy, energy-dispersive X-ray spectroscopy with element mapping, Fourier-transform infrared spectroscopy, X-ray diffraction methods confirmed homogeneous distribution of up-conversion particles in TOCNF matrices as well as the grafting of linear polysiloxanes via the condensation of silanol groups and OH-groups on the surface of TOCNF. Differential scanning calorimetry and thermogravimetry data confirmed an increase in thermal stability of the APS modified nanocomposite films obtained at pH = 4.0–4.5. Hydrophobic TOCNF/SrF2:Ho-APS nanocomposite films exhibited an intense red luminescence in the visible spectrum range (5I7 level excitation of Ho3+ ions with 1912 nm laser irradiation) as well as two-times higher laser damage threshold compared to unmodified TOCNF/SrF2:Ho films. TOCNF/SrF2:Ho-APS films can be used for visualization 2 μm laser radiation in medicine and long-distance atmosphere monitoring.

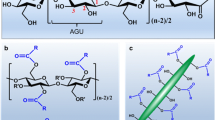

Graphic abstract

Similar content being viewed by others

References

Andresen M, Johansson LS, Tanem BS, Stenius P (2006) Properties and characterization of hydrophobized microfibrillated cellulose. Cellulose 13:665–677. https://doi.org/10.1007/s10570-006-9072

Auzel F (2004) Upconversion and anti-Stokes processes with f and d ions in solids. Chem Rev 104(1):139–174. https://doi.org/10.1021/cr020357g

Beari F, Brand M, Jenkner P, Lehnert R, Metternich HJ, Monkiewicz J, Siesler HW (2001) Organofunctional alkoxysilanes in dilute aqueous solution: new accounts on the dynamic structural mutability. J Organomet Chem 625(2):208–216. https://doi.org/10.1016/S0022-328X(01)00650-7

Belyaev AN, Chabushkin AN, Khrushchalina SA, Kuznetsova OA, Lyapin AA, Romanov KN, Ryabochkina PA (2016) Investigation of endovenous laser ablation of varicose veins in vitro using 1.885 μm laser radiation. Lasers Med Sci 31:503–510. https://doi.org/10.1007/s10103-016-1877-z

Brites CDS, Kuznetsov SV, Konyushkin VA, Nakladov AN, Fedorov PP, Carlos LD (2020) Simultaneous measurement of the emission quantum yield and local temperature: the illustrative example of SrF2:Yb3+/Er3+ single crystals. Eur J Inorg Chem 17:1555–1561. https://doi.org/10.1002/ejic.202000113

Culler SR, Ishida H, Koenig JL (1985) Structure of silane coupling agents adsorbed on silicon powder. J Colloid Interface Sci 106(2):334–346. https://doi.org/10.1016/s0021-9797(85)80007-2

Dai L, Wang Y, Zou X, Chen Z, Liu H, Ni Y (2020) Ultrasensitive physical, bio, and chemical sensors derived from 1-, 2-, and 3-D Nanocellulosic materials. Small 16(13):1906567. https://doi.org/10.1002/smll.201906567

De France K, Zeng Z, Wu T, Nyström G (2020) Functional materials from nanocellulose: utilizing structure-property relationships in bottom-up fabrication. Adv Mater. https://doi.org/10.1002/adma.202000657

Delone NB (1993) Basics of interaction of laser radiation with matter. Editions Frontières, France

Dias OAT, Konar S, Leão AL, Yang W, Tjong J, Sain M (2020) Current state of applications of nanocellulose in flexible energy and electronic devices. Front Chem 8:420. https://doi.org/10.1002/smll.201906567

Dong H, Sun L-D, Yan C-H (2013) Basic understanding of the lanthanide related upconversion emissions. Nanoscale 5:5703–5714. https://doi.org/10.1039/C3NR34069D

Eichhorn SJ (2018) Cellulose nanofibres for photonics and plasmonics. Current Opin Green Sustain Chem 12:1–7. https://doi.org/10.1016/j.cogsc.2018.03.010

Emmert LA, Rudolph W (2014) Femtosecond laser-induced damage in dielectric materials. In: Ristau D (ed) Laser-induced damage in optical materials. Taylor & Francis Group, Milton Park, pp 127–152

Fedorov PP, Luginina AA, Kuznetsov SV, Osiko VV (2011) Nanofluorides. J Fluor Chem 132:1012–1039. https://doi.org/10.1016/j.jfluchem.2011.06.025

Fedorov PP, Luginina AA, Rozhnova YA, Kuznetsov SV, Voronov VV, Uvarov OV, Pynenkov AA, Nishchev KN (2017) Preparation of nanodispersed fluorite-type Sr1-xRxF2+x (R= Er, Yb, Ho) phases from citrate solutions. J Fluor Chem 194:8–15. https://doi.org/10.1016/j.jfluchem.2016.12.003

Fedorov PP, Luginina AA, Kuznetsov SV, Voronov VV, Lyapin AA, Ermakov AS, Pominova DV, Yapryntsev AD, Ivanov VK, Pynenkov AA, Nishchev KN (2019) Composite up-conversion luminescent films containing a nanocellulose and SrF2: Ho particle. Cellulose 26:2403–2423. https://doi.org/10.1007/s10570-018-2194-4

Fedorov PP, Luginina AA, Kuznetsov SV, Voronov VV, Yapryntsev AD, Lyapin AA, Pynenkov AA, Nishchev KN, Chernova EV, Petukhov DI, Kuryakov VN, Gainutdinov RV, Ivanov VK (2020) Hydrophobic up-conversion carboxylated nanocellulose/fluoride phosphor composite films modified with alkyl ketene dimer. Carbohyd Polym 250:116866. https://doi.org/10.1016/j.carbpol.2020.116866

Fischer S, Ivaturi A, Jakob P, Kramer KW, Martin-Rodriguez R, Mejerink A et al (2018) Upconversion solar cell measurements under real sunlight. Opt Mater 84:389–395. https://doi.org/10.1016/j.optmat.2018.05.072

Fukuzumi H, Saito T, Okita Y, Isogai A (2010) Thermal stabilization of TEMPO-oxidized cellulose. Polym Degrad Stab 95(9):1502–1508. https://doi.org/10.1016/j.polymdegradstab.2010.06.015

Guan Q, Song R, Wu W et al (2018) Fluorescent CdTe-QD-encoded nanocellulose microspheres by green spraying method. Cellulose 25:7017–7029. https://doi.org/10.1007/s10570-018-2065-z

Habibi Y, Chanzy H, Vignon MR (2006) TEMPO-mediated surface oxidation of cellulose whiskers. Cellulose 13(6):679–687. https://doi.org/10.1007/s10570-006-9075-y

Hai J, Li T, Su J, Liu W, Ju Y, Wang B, Hou Y (2018) Reversible response of luminescent terbium(III)-nanocellulose hydrogels to anions for latent fingerprint detection and encryption. Angew Chem Int Ed 57(23):6786–6790. https://doi.org/10.1002/anie.201800119

Hokkanen S, Repo E, Suopajärvi T et al (2014) Adsorption of Ni(II), Cu(II) and Cd(II) from aqueous solutions by amino modified nanostructured microfibrillated cellulose. Cellulose 21:1471–1487. https://doi.org/10.1007/s10570-014-0240-4

Indarti E, Marwan RR, Wanrosli WD (2019) Silylation of TEMPO oxidized nanocellulose from oil palm empty fruit bunch by 3-aminopropyltriethoxysilane. Int J Biol Macromol 135:106–112. https://doi.org/10.1016/j.ijbiomac.2019.05.161

Ishida H, Chiang C, Koenig JL (1982) The structure of aminofunctional silane coupling agents: 1. γ-Aminopropyltriethoxysilane and its analogues. Polymer 23(2):251–257. https://doi.org/10.1016/0032-3861(82)90310-x

Jiang F, Han S, Hsieh YL (2013) Controlled defibrillation of rice straw cellulose and selfassembly of cellulose nanofibrils into highly crystalline fibrous materials. RSC Adv 3(30):12366–12375. https://doi.org/10.1039/c3ra41646a

Jiang H, Zhou D, Qu D, Chu G, Xu W, Song H, Xu Y (2016) Self-organized helical superstructure of photonic cellulose loaded with upconversion nanoparticles showing modulated luminescence. RSC Adv 6:76231–76236. https://doi.org/10.1039/C6RA13894B

Johansson LS, Tammelin T, Campbell JM, Setälä H, Österberg M (2011) Experimental evidence on medium driven cellulose surface adaptation demonstrated using nanofibrillated cellulose. Soft Matter 7:10917–10924. https://doi.org/10.1039/C1SM06073B

Khanjanadeh H, Behrooz R, Bahramifar N, Gindl-Altmutter W, Bacher M, Edler M, Griesser T (2018) Surface chemical functionalization of cellulose nanocrystals by 3-aminopropyltriethoxysilane. Int J Biol Macromol 106:1288–1296. https://doi.org/10.1016/j.ijbiomac.2017.08.136

Kim J, Holing GJ, Somorjai GA (2011) Curing induced structural reorganization and enhanced reactivity of amino-terminated organic thin films on solid substrates: observations of two types of chemically and structurally unique amino groups on the surface. Langmuir 27:5171–5175. https://doi.org/10.1021/la2007205

Kontturi E, Laaksonen P, Linder MB, Nonappa GAH, Rojas OJ, Ikkala O (2018) Advanced materials through assembly of nanocelluloses. Adv Mater 30(24):1703779. https://doi.org/10.1002/adma.201703779

Li XM, Reinhoudt D, Crego-Calama M (2007) What do we need for a superhydrophobic surface? A review on the recent progress in the preparation of superhydrophobic surfaces. Chem Soc Rev 36(8):1350–1368. https://doi.org/10.1039/B602486F

Li X, Hu Y (2019) Luminescent films functionalized with cellulose nanofibrils/CdTe quantum dots for anti-counterfeiting applications. Carbohyd Polym 203:167–175. https://doi.org/10.1016/j.carbpol.2018.09.028

Li X, Zou L, Wu G, Shen J (2014) Laser-induced damage on ordered and amorphous sol-gel silica coatings. Opt Mater Exp 4(12):2478–2484. https://doi.org/10.1364/ome.4.002478

Liang L, Qin X, Zheng K, Liu X (2019) Energy flux manipulation in upconversion nanosystems. Acc Chem Res 52(1):228–236. https://doi.org/10.1021/acs.accounts.8b00469

Lichtenstein K, Lavoine N (2017) Toward a deeper understanding of the thermal degradation mechanism of nanocellulose. Polym Degrad Stab 146:53–60. https://doi.org/10.1016/j.polymdegradstab.2017.09.018

Lizundia E, Puglia D, Nguyen T-D, Armentano I (2020) Cellulose nanocrystal based multifunctional nanohybrids. Prog Mater Sci 112:100668. https://doi.org/10.1016/j.pmatsci.2020.100668

Lyapin AA, Kuznetsov SV, Ryabochkina PA, Merculov AP, Chernov MV, Ermakova YA, Luginina AA, Fedorov PP (2017) Upconversion luminescence of Ca1-xHoxF2+x and Sr0.98-xEr0.02HoxF2.02+x powders upon excitation by an infrared laser. Laser Phys Lett 14:076003. https://doi.org/10.1088/1612-202X/aa7418

Masmoudi M, Rahal C, Abdelmouleh M, Abdelhedi R (2013) Hydrolysis process of γ-APS and characterization of silane film formed on copper in different conditions. Appl Surf Sci 286:71–77. https://doi.org/10.1016/j.apsusc.2013.09.018

Nguyen TD, Hamad WY, MacLachlan MJ (2017) Near-IR-sensitive upconverting nanostructured photonic cellulose films. Adv Opt Mater 5:1600514. https://doi.org/10.1002/adom.201600514

Okita Y, Saito T, Isogai A (2010) Entire surface oxidation of various cellulose microfibrils by TEMPO-mediated oxidation. Biomacromol 11(6):1696–1700. https://doi.org/10.1021/bm100214b

Orsolini P, Antonini C, Stojanovic A, Malfait WJ, Caseri WR, Zimmermann T (2018) Superhydrophobicity of nanofibrillated cellulose materials through polysiloxane nanofilaments. Cellulose 25:1127–1146. https://doi.org/10.1007/s10570-017-1636-8

Ovsyankin VV, Feofilov PP (1966) Mechanism of summation of electronic excitations in activated crystals. JETP Lett 3:322–323

Pavia DL, Lampman GM, Kriz GS, Vyvyan JR (2009) Introduction to Spectroscopy. 4th edn. Belmont, USA

Peña-Alonso R, Rubio F, Rubio J (2005) The role of γ -Aminopropyltriethoxysilane (γ -APS) on thermal stability of TEOS-PDMS ormosils. J Sol-Gel Sci Technol 36:77–85. https://doi.org/10.1007/s10971-005-3408-4

Pereira ALS, Feitosa JPA, Morais JPS, Rosa MF (2020) Bacterial cellulose aerogels: influence of oxidation and silanization on mechanical and absorption properties. Carbohydr Polym 250:116927. https://doi.org/10.1016/j.carbpol.2020.116927

Peresin MS, Kammiovirta K, Heikkinen H, Johansson LS, Vartiainen J, Setälä H, Österberg M, Tammelin T (2017) Understanding the mechanisms of oxygen diffusion through surface functionalized nanocellulose films. Carbohydr Polym 174:309–317. https://doi.org/10.1016/j.carbpol.2017.06.066

Qiao B, Wang T-J, Gao H, Jin Y (2015) High density silanization of nano-silica particles using γ-aminopropyltriethoxysilane (APTES). Appl Surf Sci 351:646–654. https://doi.org/10.1016/j.apsusc.2015.05.174

Qin X, Liu X, Huang W, Bettinelli M, Liu X (2017) Lanthanide activated phosphors based on 4f–5d optical transitions: theoretical and experimental aspects. Chem Rev 117:4488–4527. https://doi.org/10.1021/acs.chemrev.6b00691

Rachini A, Le Troedec M, Peyratout C, Smith A (2012) Chemical modification of hemp fibers by silane coupling agents. J Appl Polym Sci 123(1):601–610. https://doi.org/10.1002/app.34530

Reig DS, Grauel B, Konyushkin VA, Nakladov AN, Fedorov PP, Busko D, Howard IA, Richards BS, Resch-Genger U, Kuznetsov SV, Turshatov A, Würth C (2020) Upconversion properties of SrF2:Yb3+, Er3+ single crystals. J Mater Chem C 8:4093–4101. https://doi.org/10.1039/C9TC06591A

Robles E, Csóka L, Labidi J (2018) Effect of reaction conditions on the surface modification of cellulose nanofibrils with aminopropyl triethoxysilane. Coatings 8(4):139. https://doi.org/10.3390/coatings8040139

Rol F, Belgacem MN, Gandini A, Bras J (2019) Recent advances in surface-modified cellulose nanofibrils. Prog Polym Sci 88:241–264. https://doi.org/10.1016/j.progpolymsci.2018.09.002

Sai H, Fu R, Xing L, Xiang J, Li Z, Li F, Zhang T (2015) Surface modification of bacterial cellulose aerogels’ web-like skeleton for oil/water separation. ACS Appl Mater Interfaces 7(13):7373–7381. https://doi.org/10.1021/acsami.5b00846

Salon M-CB, Gerbaud G, Abdelmouleh M, Bruzzese C, Boufi S, Belgacem MN (2007) Studies of interactions between silane coupling agents and cellulose fibers with liquid and solid-state NMR. Magn Reson Chem 45(6):473–483. https://doi.org/10.1002/mrc.1994

Salon M-CB, Belgacem MN (2010) Competition between hydrolysis and condensation reactions of trialkoxysilanes, as a function of the amount of water and the nature of the organic group. Colloids Surf A Physicochem Eng Asp 366:147–154. https://doi.org/10.1016/j.colsurfa.2010.06.002

Scholle K, Lamrini S, Koopmann P, Fuhrberg P (2010) 2 µm laser sources and their possible applications. In: Pal B (ed) Frontiers in guided wave optics and optoelectronics. InTech, London, pp 471–500

Tan Y, Liu Y, Chen W, Liu Y, Wang Q, Li J, Yu H (2016) Homogeneous dispersion of cellulose nanofibers in waterborne acrylic coatings with improved properties and unreduced transparency. ACS Sustain Chem Eng 4(7):3766–3772. https://doi.org/10.1021/acssuschemeng.6b00415

Thomas B, Raj MC, Athira KB, Rubiyah MH, Joy J, Moores A, Drisko GL, Sanchez C (2018) Nanocellulose, a versatile green platform: from biosources to materials and their applications. Chem Rev 118(24):11575–11625. https://doi.org/10.1021/acs.chemrev.7b00627

Vandenberg ET, Bertilsson L, Liedberg B, Uvdal K, Erlandsson R, Elwing H, Lundström I (1991) Structure of 3-aminopropyl triethoxy silane on silicon oxide. J Colloid Interface Sci 147(1):103–118. https://doi.org/10.1016/0021-9797(91)90139-y

Verber CM, Grieser DR, Jones WH (1971) Cooperative and sequential excitation of red fluorescence of Ho3+ in CaF2. J Appl Phys 42(7):2767–2769. https://doi.org/10.1063/1.1660621

Vicente AT, Araújo A, Mendes MJ, Nunes D, Oliveira MJ, Sanchez-Sobrado O, Ferreira MP, Águas H, Fortunato E, Martins R (2018) Multifunctional cellulose-paper for light harvesting and smart sensing applications. J Mater Chem C 6:3143–3181. https://doi.org/10.1039/C7TC05271E

Voronova MI, Surov OV, Kraev AS, Isaeva DA, Mityukhina IS, Zakharov AG (2017) Template synthesis of mesoporous silicas with the use of nanocrystalline cellulose. Colloid J 79:18–25. https://doi.org/10.1134/S1061933X17010148

Wang H, Pei Y, Qian X, An X (2020) Eu-metal organic framework@TEMPO-oxidized cellulose nanofibrils photoluminescence film for detecting copper ions. Carbohyd Polym 236:116030. https://doi.org/10.1016/j.carbpol.2020.116030

Wenzel RN (1936) Resistance of solid surfaces to wetting by water. Ind Eng Chem 28(8):988–994. https://doi.org/10.1021/ie50320a024

Wood R (2014) Laser-induced damage by thermal effects. Laser-Induced damage in optical materials. In: Ristau D (ed) Laser-induced damage in optical materials. CRC Press, Taylor & Francis Group, Boca Raton, pp 9–24

Xiong R, Yu S, Smith MJ, Zhou J, Krecker M, Zhang L, Nepal D, Bunning TJ, Tsukruk VV (2019) Self-assembly of emissive nanocellulose/quantum dots nanostructures for chiral fluorescent materials. ACS Nano 13(8):9074–9081. https://doi.org/10.1021/acsnano.9b03305

Xue B, Zhang Z, Sun Y, Wang J, Jiang H, Du M, Chi C, Li X (2018) Near-infrared emissive lanthanide hybridized nanofibrillated cellulose nanopaper as ultraviolet filter. Carbohyd Polym 186:176–183. https://doi.org/10.1016/j.carbpol.2017.12.088

Yang Q, Zhang C, Shi Z, Wang J, Xiong C, Saito T, Isogai A (2018) Luminescent and transparent nanocellulose films containing europium carboxylate groups as flexible dielectric materials. ACS Appl Nano Mater 1(9):4972–4979. https://doi.org/10.1021/acsanm.8b01112

Zhang S, Liu G, Chang H, Li X, Zhang Z (2019) Optical haze nanopaper enhanced ultraviolet harvesting for direct soft-fluorescent emission based on lanthanide complex assembly and oxidized cellulose nanofibrils. ACS Sustain Chem Eng 7(11):9966–9975. https://doi.org/10.1021/acssuschemeng.9b00970

Zhang Z, Chang H, Xue B, Han Q, Lü X, Zhang S, Li X, Zhu X, Wong W, Li K (2017) New transparent flexible nanopaper as ultraviolet filter based on red emissive Eu(III) nanofibrillated cellulose. Opt Mater 73:747–753. https://doi.org/10.1016/j.optmat.2017.09.039

Zhang Z, Chang H, Xue B, Zhang S, Li X, Wong WK, Li K, Zhu X (2018) Near-infrared and visible dual emissive transparent nanopaper based on Yb(III)–carbon quantum dots grafted oxidized nanofibrillated cellulose for anticounterfeiting applications. Cellulose 25:377–389. https://doi.org/10.1007/s10570-017-1594-1

Zhao J, Wei Z, Feng X, Miao M, Sun L, Cao S, Shi L, Fang J (2014) Luminescent and transparent nanopaper based on rare-earth up-converting nanoparticles grafted nanofibrillated cellulose derived from garlic skin. ACS Appl Mater Interfaces 6:14945–14951. https://doi.org/10.1021/am5026352

Zhou J, Liu Q, Feng W, Sun Y, Li F (2015) Upconversion luminescent materials: advances and applications. Chem Rev 115(1):395–465. https://doi.org/10.1021/cr400478f

Acknowledgements

This work was supported by the Ministry of Science and Higher Education within the State assignment to Prokhorov General Physics Institute of the Russian Academy of Sciences and FSRC Crystallography and Photonics RAS. The equipment of the Shared Research Center supported by the Ministry of Science and Higher Education (RFMEFI62114X0005) was used in experiments. Authors express their sincere gratitude to Dr. Arthur I. Popov for his most kind assistance in the preparation of the present manuscript and Dr. Vladimir N. Kuryakov for zeta potential measurements.

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Human and animals rights

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

The authors have no statements about informed consent as this research does not involve human participants.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Luginina, A.A., Kuznetsov, S.V., Ivanov, V.K. et al. Laser damage threshold of hydrophobic up-conversion carboxylated nanocellulose/SrF2:Ho composite films functionalized with 3-aminopropyltriethoxysilane. Cellulose 28, 10841–10862 (2021). https://doi.org/10.1007/s10570-021-04198-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-04198-7