Abstract

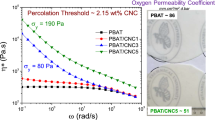

Cellulose nanocrystals (CNCs) were dispersed via solution casting in amorphous (A) and semi-crystalline (SC) poly (lactic acid) (PLA) and poly (butylene adipate-co-terephthalate) (PBAT). The protocol, optimized following the Hansen solubility parameter theory, relies on binary mixtures of tetrahydrofuran and dimethyl sulfoxide for the polymers and CNCs, respectively. First highlighted through atomic force microscopy, good filler dispersion and distribution were confirmed by a decrease of the linear viscoelastic region and significant increases of the complex viscosity, storage modulus, and apparent yield stress of the nanocomposites with CNC content, specifically at low frequencies. CNC percolation thresholds of 1, 0.3, and 0.3 wt% were determined in A-PLA, SC-PLA, and PBAT, respectively. These are the lowest to be reported in the literature until now. While PLA retained solvent traces, leading to a significant plasticizing effect, solvent removal was complete in PBAT. It was attributed to the crystallization of PBAT at the drying temperature (70 °C).

Similar content being viewed by others

References

Abbasi S, Carreau PJ, Derdouri A, Moan M (2009) Rheological properties and percolation in suspensions of multiwalled carbon nanotubes in polycarbonate. Rheol Acta 48:943–959. https://doi.org/10.1007/s00397-009-0375-7

Abbott SJ, Hansen CM, Yamamoto H (2018) Hansen solubility parameters in practice software, ebook, datasets. http://www.hansen-solubility.com. Accessed 03 July 2018

Andrady AL, Neal MA (2009) Applications and societal benefits of plastics. Philos Trans R Soc B Biol Sci 364:1977–1984. https://doi.org/10.1098/rstb.2008.0304

Arias A, Heuzey M-C, Huneault MA, Ausias G, Bendahou A (2015) Enhanced dispersion of cellulose nanocrystals in melt-processed polylactide-based nanocomposites. Cellulose 22:483–498. https://doi.org/10.1007/s10570-014-0476-z

Bagheriasl D, Carreau PJ (2019) Polymer-cellulose nanocrystal (CNC) nanocomposites. In: Processing of polymer nanocomposites. pp 371–393. https://doi.org/10.3139/9781569906361.013

Bagheriasl D, Carreau PJ, Riedl B, Dubois C, Hamad WY (2016) Shear rheology of polylactide (PLA)-cellulose nanocrystal (CNC) nanocomposites. Cellulose 23:1885–1897. https://doi.org/10.1007/s10570-016-0914-1

Bagheriasl D, Carreau PJ, Riedl B, Dubois C (2018) Enhanced properties of polylactide by incorporating cellulose nanocrystals. Polym Compos 39:2685–2694. https://doi.org/10.1002/pc.24259

Bagheriasl D, Safdari F, Carreau PJ, Dubois C, Riedl B (2019) Development of cellulose nanocrystal-reinforced polylactide: a comparative study on different preparation methods. Polym Compos 40:E342–E349. https://doi.org/10.1002/pc.24676

Beuguel Q, Bagheriasl D, Bruel C, Tavares JR, Carreau PJ, Heuzey M-C (2018) Comportement rhéologique à l’état fondu de nanocomposites à base de nanocristaux de cellulose (CNCs). Rhéologie 34:10–16

Bruel C, Beuguel Q, Tavares JR, Carreau PJ, Heuzey M-C (2018) The apparent structural hydrophobicity of cellulose nanocrystals. J Sci Technol For Prod Process 7:13–23

Bruel C, Tavares JR, Carreau PJ, Heuzey M (2019a) Impact of colloidal stability on cellulose nanocrystals self-ordering in thin films. TechConnect Briefs, pp 61–64. https://briefs.techconnect.org/papers/impact-of-colloidal-stability-on-cellulose-nanocrystals-self-ordering-inthin-films/

Bruel C, Tavares JR, Carreau PJ, Heuzey MC (2019b) The structural amphiphilicity of cellulose nanocrystals characterized from their cohesion parameters. Carbohydr Polym 205:184–191. https://doi.org/10.1016/j.carbpol.2018.10.026

Bruel C, Davies TS, Carreau PJ, Tavares JR, Heuzey M-C (2020) Self-assembly behaviors of colloidal cellulose nanocrystals: a tale of stabilization mechanisms. J Colloid Interface Sci 574:399–409. https://doi.org/10.1016/j.jcis.2020.04.049

Du F, Scogna RC, Zhou W, Brand S, Fischer JE, Winey KI (2004) Nanotube networks in polymer nanocomposites: rheology and electrical conductivity. Macromolecules 37:9048–9055. https://doi.org/10.1021/ma049164g

Dufresne A (2017) Cellulose nanomaterial reinforced polymer nanocomposites. Curr Opin Colloid Interface Sci 29:1–8. https://doi.org/10.1016/j.cocis.2017.01.004

Dufresne A (2018) Cellulose nanomaterials as green nanoreinforcements for polymer nanocomposites. Philos Trans R Soc A 376:20170040. https://doi.org/10.1098/rsta.2017.0040

Ferreira FV, Dufresne A, Pinheiro IF, Souza DHS, Gouveia RF, Mei LHI, Lona LMF (2018) How do cellulose nanocrystals affect the overall properties of biodegradable polymer nanocomposites: a comprehensive review. Eur Polym J 108:274–285. https://doi.org/10.1016/j.eurpolymj.2018.08.045

Ferreira FV, Cividanes LS, Gouveia RF, Lona LMF (2019a) An overview on properties and applications of poly(butylene adipate- co -terephthalate)-PBAT based composites. Polym Eng Sci 59:E7–E15. https://doi.org/10.1002/pen.24770

Ferreira FV, Mariano M, Pinheiro IF, Cazalini EM, Souza DHS, Lepesqueur LSS, Koga-Ito CY, Gouveia RF, Lona LMF (2019b) Cellulose nanocrystal-based poly(butylene adipate-co-terephthalate) nanocomposites covered with antimicrobial silver thin films. Polym Eng Sci 59:E356–E365. https://doi.org/10.1002/pen.25066

Galgali G, Ramesh C, Lele A (2001) Rheological study on the kinetics of hybrid formation in polypropylene nanocomposites. Macromolecules 34:852–858. https://doi.org/10.1021/ma000565f

Goffin AL, Raquez JM, Duquesne E, Siqueira G, Habibi Y, Dufresne A, Dubois P (2011) From interfacial ring-opening polymerization to melt processing of cellulose nanowhisker-filled polylactide-based nanocomposites. Biomacromol 12:2456–2465. https://doi.org/10.1021/bm200581h

Gois GDS, De Andrade MF, Garcia SMS, Vinhas GM, Santos ASF, Medeiros ES, Oliveira JE, De Almeida YMB (2017) Soil biodegradation of PLA/CNW nanocomposites modified with ethylene oxide derivatives. Mater Res 20:899–904. https://doi.org/10.1590/1980-5373-MR-2016-0960

Gupta A, Simmons W, Schueneman GT, Hylton D, Mintz EA (2017) Rheological and thermo-mechanical properties of poly(lactic acid)/lignin-coated cellulose nanocrystal composites. ACS Sustain Chem Eng 5:1711–1720. https://doi.org/10.1021/acssuschemeng.6b02458

Hamad WY, Hu TQ (2010) Structure-process-yield interrelations in nanocrystalline cellulose extraction. Can J Chem Eng 88:392–402. https://doi.org/10.1002/cjce.20298

Hansen CM (1967) The three dimensional solubility parameter and solvent diffusion coefficient. J Paint Technol 39:104–117

Hansen CM (2007) Hansen solubility parameters. CRC Press, Boca Raton

Heshmati V, Kamal MR, Favis BD (2018a) Tuning the localization of finely dispersed cellulose nanocrystal in poly (lactic acid)/bio-polyamide11 blends. J Polym Sci Part B Polym Phys 56:576–587. https://doi.org/10.1002/polb.24563

Heshmati V, Kamal MR, Favis BD (2018b) Cellulose nanocrystal in poly(lactic acid)/polyamide11 blends: Preparation, morphology and co-continuity. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2017.10.027

Hu G, Zhao C, Zhang S, Yang M, Wang Z (2006) Low percolation thresholds of electrical conductivity and rheology in poly(ethylene terephthalate) through the networks of multi-walled carbon nanotubes. Polymer (Guildf) 47:480–488. https://doi.org/10.1016/j.polymer.2005.11.028

Jeddi J, Yousefzade O, Babaei A, Ghanbar S, Rostami A (2017) Morphology, microstructure and rheological properties of SAN (styrene-acrylonitrile)/EPDM (ethylene-propylene-diene monomer) nanocomposites: Investigating the role of organoclay type and order of mixing. Mater Chem Phys 187:191–202. https://doi.org/10.1016/j.matchemphys.2016.12.001

Jian J, Xiangbin Z, Xianbo H (2020) An overview on synthesis, properties and applications of poly(butylene-adipate-co-terephthalate)–PBAT. Adv Ind Eng Polym Res 3:19–26. https://doi.org/10.1016/j.aiepr.2020.01.001

Kamal MR, Khoshkava V (2015) Effect of cellulose nanocrystals (CNC) on rheological and mechanical properties and crystallization behavior of PLA/CNC nanocomposites. Carbohydr Polym 123:105–114. https://doi.org/10.1016/j.carbpol.2015.01.012

Khoshkava V, Kamal MR (2013) Effect of surface energy on dispersion and mechanical properties of polymer/nanocrystalline cellulose nanocomposites. Biomacromol 14:3155–3163. https://doi.org/10.1021/bm400784j

Khoshkava V, Kamal MR (2014) Effect of cellulose nanocrystals (CNC) particle morphology on dispersion and rheological and mechanical properties of polypropylene/CNC nanocomposites. ACS Appl Mater Interfaces 6:8146–8157. https://doi.org/10.1021/am500577e

Krishnamoorti R, Giannelis EP (1997) Rheology of end-tethered polymer layered silicate nanocomposites. Macromolecules 30:4097–4102. https://doi.org/10.1021/ma960550a

Mathew AP, Oksman K, Sain M (2005) Mechanical properties of biodegradable composites from poly lactic acid (PLA) and microcrystalline cellulose (MCC). J Appl Polym Sci 97:2014–2025. https://doi.org/10.1002/app.21779

Miao C, Hamad WY (2019) Critical insights into the reinforcement potential of cellulose nanocrystals in polymer nanocomposites. Curr Opin Solid State Mater Sci 23:100761. https://doi.org/10.1016/j.cossms.2019.06.005

Mohanty S, Nayak SK (2012) Biodegradable nanocomposites of poly(butylene adipate-co-terephthalate) (PBAT) and organically modified layered silicates. Springer 20:195–207. https://doi.org/10.1007/s10924-011-0408-z

Morelli CL, Belgacem MN, Branciforti MC, Bretas RES, Crisci A, Bras J (2016a) Supramolecular aromatic interactions to enhance biodegradable film properties through incorporation of functionalized cellulose nanocrystals. Compos Part A Appl Sci Manuf 83:80–88. https://doi.org/10.1016/j.compositesa.2015.10.038

Morelli CL, Belgacem MN, Branciforti MC, Salon CB, Bras J, Bretas RES (2016b) Nanocomposites of PBAT and cellulose nanocrystals modified by in situ polymerization and melt extrusion. Polym Eng Sci 56:1339–1348. https://doi.org/10.1002/pen.24367

Morelli CL, Belgacem N, Bretas RES, Bras J (2016c) Melt extruded nanocomposites of polybutylene adipate- co -terephthalate (PBAT) with phenylbutyl isocyanate modified cellulose nanocrystals. J Appl Polym Sci. https://doi.org/10.1002/app.43678

Mukherjee T, Tobin MJ, Puskar L, Sani MA, Kao N, Gupta RK, Pannirselvam M, Quazi N, Bhattacharya S (2017) Chemically imaging the interaction of acetylated nanocrystalline cellulose (NCC) with a polylactic acid (PLA) polymer matrix. Cellulose 24:1717–1729. https://doi.org/10.1007/s10570-017-1217-x

Nofar M, Sacligil D, Carreau PJ, Kamal MR, Heuzey M-C (2018) Poly (lactic acid) blends: processing, properties and applications. Int J Biol Macromol 125:307–360. https://doi.org/10.1016/j.ijbiomac.2018.12.002

Oksman K, Aitomäki Y, Mathew AP, Siqueira G, Zhou Q, Butylina S, Tanpichai S, Zhou X, Hooshmand S (2016) Review of the recent developments in cellulose nanocomposite processing. Compos Part A Appl Sci Manuf 83:2–18. https://doi.org/10.1016/j.compositesa.2015.10.041

Pal N, Dubey P, Gopinath P, Pal K (2017) Combined effect of cellulose nanocrystal and reduced graphene oxide into poly-lactic acid matrix nanocomposite as a scaffold and its anti-bacterial activity. Int J Biol Macromol 95:94–105. https://doi.org/10.1016/j.ijbiomac.2016.11.041

Pinheiro IF, Ferreira FV, Souza DHS, Gouveia RF, Lona LMF, Morales AR, Mei LHI (2017) Mechanical, rheological and degradation properties of PBAT nanocomposites reinforced by functionalized cellulose nanocrystals. Eur Polym J 97:356–365. https://doi.org/10.1016/j.eurpolymj.2017.10.026

Pinheiro IF, Ferreira FV, Alves GF, Rodolfo A, Morales AR, Mei LHI (2019) Biodegradable PBAT-based nanocomposites reinforced with functionalized cellulose nanocrystals from Pseudobombax munguba: rheological, thermal, mechanical and biodegradability properties. J Polym Environ 27:757–766. https://doi.org/10.1007/s10924-019-01389-z

Raquez J-M, Habibi Y, Murariu M, Dubois P (2013) Polylactide (PLA)-based nanocomposites. Prog Polym Sci 38:1504–1542. https://doi.org/10.1016/j.progpolymsci.2013.05.014

Rol F, Belgacem MN, Gandini A, Bras J (2019) Recent advances in surface-modified cellulose nanofibrils. Prog Polym Sci 88:241–264

Rujnić-Sokele M, Pilipović A (2017) Challenges and opportunities of biodegradable plastics: a mini review. Waste Manag Res 35:132–140. https://doi.org/10.1177/0734242X16683272

Safdari F, Bagheriasl D, Carreau PJ, Heuzey MC, Kamal MR (2018) Rheological, mechanical, and thermal properties of polylactide/cellulose nanofiber biocomposites. Polym Compos 39:1752–1762. https://doi.org/10.1002/pc.24127

Shojaeiarani J, Bajwa DS, Stark NM (2018) Spin-coating: a new approach for improving dispersion of cellulose nanocrystals and mechanical properties of poly (lactic acid) composites. Carbohydr Polym 190:139–147. https://doi.org/10.1016/j.carbpol.2018.02.069

Solomon MJ, Almusallam AS, Seefeldt KF, Somwangthanaroj A, Varadan P (2001) Rheology of polypropylene/clay hybrid materials. Macromolecules 34:1864–1872. https://doi.org/10.1021/ma001122e

Tokiwa Y, Calabia BP (2006) Biodegradability and biodegradation of poly(lactide). Appl Microbiol Biotechnol 72:244–251. https://doi.org/10.1007/s00253-006-0488-1

Tokiwa Y, Calabia B, Ugwu C, Aiba S (2009) Biodegradability of plastics. Int J Mol Sci 10:3722–3742. https://doi.org/10.3390/ijms10093722

Trifol J, Plackett D, Sillard C, Hassager O, Daugaard AE, Bras J, Szabo P (2016) A comparison of partially acetylated nanocellulose, nanocrystalline cellulose, and nanoclay as fillers for high-performance polylactide nanocomposites. J Appl Polym Sci. https://doi.org/10.1002/app.43257

Vatansever E, Arslan D, Nofar M (2019) Polylactide cellulose-based nanocomposites. Int J Biol Macromol 137:912–938. https://doi.org/10.1016/j.ijbiomac.2019.06.205

Vatansever E, Arslan D, Sarul DS, Kahraman Y, Nofar M (2020) Effects of molecular weight and crystallizability of polylactide on the cellulose nanocrystal dispersion quality in their nanocomposites. Int J Biol Macromol 154:276–290. https://doi.org/10.1016/j.ijbiomac.2020.03.115

Wu C, Zhang X, Wang X, Gao Q, Li X (2019) Surface modification of cellulose nanocrystal using succinic anhydride and its effects on poly(butylene succinate) based composites. Cellulose 26:3167–3181. https://doi.org/10.1007/s10570-019-02292-5

Acknowledgments

Financial support from the Natural Science and Engineering Research Council (NSERC) of Canada is gratefully acknowledged. The authors are also grateful to FPInnovations for providing the CNCs. The Fond de Recherche du Québec - Nature et Technologies (FRQNT) kindly provided a scholarship to C. Bruel. The authors also wish to acknowledge the help of Dr. Helia Sojoudiasli and Mr. Matthieu Gauthier for the material preparation and processing. Finally, we wish to thank Mr. Jed Randall from NatureWorks for providing one of the PLA samples.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohammadi, M., Bruel, C., Heuzey, MC. et al. CNC dispersion in PLA and PBAT using two solvents: morphological and rheological properties. Cellulose 27, 9877–9892 (2020). https://doi.org/10.1007/s10570-020-03460-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03460-8