Abstract

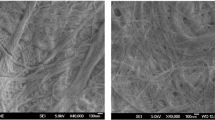

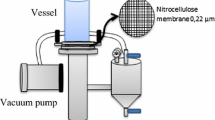

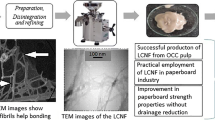

The aim of this work was to study the feasibility of using orange tree pruning to obtain lignocellulose nanofibers (LCNFs) and their application in paperboard recycling process. The orange tree pruning was treated with an environmentally friendly process (13% NaOH on dry matter, at liquid/solid ratio of 8, 170 °C and 40 min). The cellulosic pulp obtained was used for the isolation of LCNFs by means of two different pretreatments, 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO)-mediated (TO-LCNFs) and mechanical refining (Mec-LCNFs), followed by high-pressure homogenization treatment. The reinforcement effect produced by the LCNF addition on paperboard recycled fiber was compared with other conventional industrial techniques such as chemical addition and mechanical beating. It was shown that TEMPO-mediated oxidation produces a greater delamination in fiber during its nanofibrillation, obtaining smaller width nanofibers with greater specific surface. The LCNF addition, especially TO-LCNFs, presents reinforcement effects comparable to those achieved by mechanical beating for the different mechanical properties, with the advantage of not modifying the fiber physically and increasing the numbers of recycling cycles. The economic analysis of both treatments shows that despite the Mec-LCNF cost is slightly higher, it is presented as an alternative to mechanical beating for use in paperboard recycling process.

Similar content being viewed by others

References

Anastas PT, Warner JC (1998) Green chemistry: theory and practice. Oxford University Press, New York, p 30

Arola S, Malho JN, Laaksonen P, Lille M, Linder MB (2013) The role of hemicellulose in nanofibrillated cellulose networks. Soft Matter 9:1319–1326. https://doi.org/10.1039/C2SM26932E

Besbes I, Alila S, Boufi S (2011) Nanofibrillated cellulose from TEMPO-oxidized eucalyptus fibers: effect of the carboxyl content. Carbohydr Polym 84(3):975–983. https://doi.org/10.1016/j.carbpol.2010.12.052

Boufi S, González I, Delgado-Aguilar M, Tarrés Q, Pèlach MA, Mutjé P (2016) Nanofibrillated cellulose as an additive in papermaking process: a review. Carbohydr Polym 154:151–166. https://doi.org/10.1016/j.carbpol.2016.07.117

Brodin FW, Gregersen OW, Syverud K (2014) Cellulose nanofibrils: challenges and possibilities as a paper additive or coating material—a review. Nord Pulp Pap Res J 29(1):156–166. https://doi.org/10.3183/npprj-2014-29-01-p156-166

Chaker A, Alila S, Mutjé P, Vilar MR, Boufi S (2013) Key role of the hemicellulose content and the cell morphology on the nanofibrillation effectiveness of cellulose pulps. Cellulose 20:2863–2875. https://doi.org/10.1007/s10570-013-0036-y

Chen M, Ma Q, Zhu JY, Alonso DM, Runge T (2019) GVL pulping facilitates nanocellulose production from woody biomass. Green Chem 21:5316–5325. https://doi.org/10.1039/C9GC01490J

Dai H, Ou S, Huang Y, Huang H (2018) Utilization of pineapple peel for production of nanocellulose and film application. Cellulose 25:1743–1756. https://doi.org/10.1007/s10570-018-1671-0

Delgado-Aguilar M, González I, Pèlach MA, de la Fuente E, Negro C, Mutjé P (2015a) Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 22(1):789–802. https://doi.org/10.1007/s10570-014-0473-2

Delgado-Aguilar M, Tarrés Q, Pèlach MA, Mutjé P, Fullana-i-Palmer P (2015b) Are cellulose nanofibers a solution for a more circular economy of paper products? Environ Sci Technol 49:12206–12213. https://doi.org/10.1021/acs.est.5b02676

Domínguez-Robles J, Espinosa E, Savy D, Rosal A, Rodríguez A (2016) Biorefinery process combining specel® process and selective lignin precipitation using mineral acids. BioResources 11:7061–7077

Domínguez-Robles J, Sánchez R, Díaz-Carrasco P, Espinosa E, García-Domínguez MT, Rodríguez A (2017) Isolation and characterization of lignins from wheat straw: application as binder in lithium batteries. Int J Biol Macromol 104:909–918. https://doi.org/10.1016/j.ijbiomac.2017.07.015

Domínguez-Robles J, Larrañeta E, Fong ML, Martin NK, Irwin NJ, Mutjé P, Tarrés Q, Delgado-Aguilar M (2020) Lignin/poly(butylene succinate) composites with antioxidant and antibacterial properties for potential biomedical applications. Int J Biol Macromol 145:92–99. https://doi.org/10.1016/j.ijbiomac.2019.12.146

Du X, Zhang Z, Liu W, Deng Y (2017) Nanocellulose-based conductive materials and their emerging applications in energy devices—a review. Nano Energy 35:299–320. https://doi.org/10.1016/j.nanoen.2017.04.001

Dufresne A (2013) Nanocellulose: a new ageless bionanomaterial. Mater Today 16:220–227. https://doi.org/10.1016/j.mattod.2013.06.004

Espinosa E, Tarrés Q, Delgado-Aguilar M, González I, Mutjé P, Rodríguez A (2016) Suitability of wheat straw semichemical pulp for the fabrication of lignocellulosic nanofibres and their application to papermaking slurries. Cellulose 23:837–852. https://doi.org/10.1007/s10570-015-0807-8

Espinosa E, Sánchez R, Otero R, Domínguez-Robles J, Rodríguez A (2017a) A comparative study of the suitability of different cereal straws for lignocellulose nanofibers isolation. Int J Biol Macromol 103:990–999. https://doi.org/10.1016/j.ijbiomac.2017.05.156

Espinosa E, Sánchez R, González Z, Domínguez-Robles J, Ferrari B, Rodríguez A (2017b) Rapidly growing vegetables as new sources for lignocellulose nanofibre isolation: physicochemical, thermal and rheological characterization. Carbohydr Polym 175:27–37. https://doi.org/10.1016/j.carbpol.2017.07.055

Espinosa E, Tarrés Q, Domínguez-Robles J, Delgado-Aguilar M, Mutjé P, Rodríguez A (2018) Recycled fibers for fluting production: the role of lignocellulosic micro/nanofibers of banana leaves. J Clean Prod 172:233–238. https://doi.org/10.1016/j.jclepro.2017.10.174

Espinosa E, Bascón-Villegas I, Rosal A, Pérez-Rodríguez F, Chinga-Carrasco G, Rodríguez A (2019) PVA/(ligno)nanocellulose biocomposite films. Effect of residual lignin content on structural, mechanical, barrier and antioxidant properties. Int J Biol Macromol 141:197–206. https://doi.org/10.1016/j.ijbiomac.2019.08.262

Espinosa E, Rol F, Bras J, Rodríguez A (2020) Use of multi-factorial analysis to determine the quality of cellulose nanofibers: effect of nanofibrillation treatment and residual lignin content. Cellulose. https://doi.org/10.1007/s10570-020-03136-3

European Union (2018) European regional development fund (ERDMF) http://ec.europa.eu/regional_policy/es/policy/themes/rural-development/. Acceded Sept 2019

Ferrer A, Filpponen I, Rodríguez A, Laine J, Rojas OJ (2012) Valorization of residual empty palm fruit bunch fibers (EPFBF) by microfluidization: production of nanofibrillated cellulose and EPFBF nanopaper. Bioresour Technol 125:249–255. https://doi.org/10.1016/j.biortech.2012.08.108

Fillat U, Wicklein B, Martín-Sampedro R, Ibarra D, Ruiz-Hitzky E, Valencia C, Sarrión A, Castro E, Eugenio ME (2018) Assessing cellulose nanofiber production from olive tree pruning residue. Carbohydr Polym 179:252–261. https://doi.org/10.1016/j.carbpol.2017.09.072

Fleur R, Karakashov B, Nechyporchuk O, Terrien M, Meyer V, Dufresne A, Belgacem MN, Bras J (2017) Pilot-scale twin screw extrusion and chemical pretreatment as an energy-efficient method for the production of nanofibrillated cellulose at high solid content. ACS Sustain Chem Eng 5:6524–6531. https://doi.org/10.1021/acssuschemeng.7b00630

Food and Agricultural Organization of the United Nations (2018) FAOSTAT 2018. www.fao.org/faostat/en/#data. Acceded May 2020

French A (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Gharehkhani S, Sadeghinezhad E, Kazi SN, Yarmand H, Badarudin A, Safei MR, Zubir MNM (2015) Basic effects of pulp refining on fiber properties—a review. Carbohydr Polym 115:785–803. https://doi.org/10.1016/j.carbpol.2014.08.047

González Z, Rosal A, Requejo A, Rodríguez A (2011) Production of pulp and energy using orange tree prunings. Bioresour Technol 102:9330–9334. https://doi.org/10.1016/j.biortech.2011.07.088

González Z, Vargas F, Jiménez L, Rodríguez A (2013) Orange tree prunings as raw material for the cellulose production by Kraft process. Cell Chem Technol 47:603–611

Hetemäki S, Hanewinkel M, Muys B, Ollikainen M, Palahí M, Trasobares A (2017) Leading the way to a European circular bioeconomy strategy. From Science to Policy 5. European Forest Institute

Ibrahim MM, El-Zawawy WK, Juttke Y, Koschella A, Heinze T (2013) Cellulose and microcrystalline cellulose from rice straw and banana plant waste-preparation and characterization. Cellulose 20:2403–2416. https://doi.org/10.1007/s10570-013-9992-5

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85. https://doi.org/10.1039/C0NR00583E

Iwamoto S, Abe K, Yano H (2008) The effect of hemicelluloses on wood pulp nanofibrillation and nanofiber network characteristics. Biomacromolecules 9:1022–1026. https://doi.org/10.1021/bm701157n

Jayme G (1994) Micro-swelling measurement in cellulosic pulp. Wochenbl Papierfabr 6:187–194

Jiang F, Hsieh YL (2013) Chemically and mechanically isolated nanocellulose and their self-assembled structures. Carbohydr Polym 95:32–40. https://doi.org/10.1016/j.carbpol.2013.02.022

Jiménez L, Rodríguez A, Díaz MJ, López F, Ariza J (2004) Organosolv pulping of olive tree trimmings by use of ethylene glycol/soda/water mixtures. Holzforschung 58:122–128. https://doi.org/10.1515/HF.2004.017

Jiménez L, Rodríguez A, Pérez A, Moral A, Serrano L (2008) Alternative raw materials and pulping process using clean technologies. Ind Crop Prod 28:11–16. https://doi.org/10.1016/j.indcrop.2007.12.005

Jonoobi M, Oladi R, Kavoudpour Y, Oksman K, Dufresne A, Hamzeh Y, Davoodi R (2015) Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: a review. Cellulose 22:935–969. https://doi.org/10.1007/s10570-015-0551-0

Kassab Z, Kassem I, Hannache H, Bouhfid R, Qaiss AEK, Achabi ME (2020) Tomato plant residue as new renewable source for cellulose production: extraction of cellulose nanocrystals with different surface functionalities. Cellulose 27:4288–4303. https://doi.org/10.1007/s10570-020-03097-7

Khiari R, Mhenni M, Belgacem M, Mauret E (2010) Chemical composition and pulping of date palm rachis and Posidonia oceanica—a comparison with other wood and non-wood fibre sources. Bioresour Technol 101:775–780. https://doi.org/10.1016/j.biortech.2009.08.079

Lahtinen P, Liukkonen S, Pere J, Sneck A, Kangas H (2014) A comparative study of fibrillated fibers from different mechanical and chemical pulps. BioResources 9:2115–2127

Liu J, Yang R, Yang F (2015) Effect of the starch source on the performance of cationic starches having similar degree of substitution for papermaking using deinked pulp. BioResources 10:922–931

Ludwicka K, Jedrzejczak-Krzepkowska M, Kubiak K, Kolodziejczyk M, Pankiewicz T, Bielecki S (2016) Medical and cosmetic applications of bacterial nanocellulose. In: Gama M et al (eds) Bacterial nanocellulose. Elsevier, Amsterdam, pp 145–165. https://doi.org/10.1016/B978-0-444-63458-0.00009-3

Mahfoudhi N, Boufi S (2017) Nanocellulose as a novel nanostructured adsorbent for environmental remediation: a review. Cellulose 24:1171–1197. https://doi.org/10.1007/s10570-017-1194-0

Marx-Figini M (1987) The acid-catalyzed degradation of cellulose linters in distinct ranges of degree of polymerization. J Appl Polym Sci 33(6):2097–2105. https://doi.org/10.1002/app.1987.070330621

Meng Q, Li H, Fu S, Lucia LA (2014) The non-trivial role of native xylans on the preparation of TEMPO-oxidized cellulose nanofibrils. React Funct Polym 85:142–150. https://doi.org/10.1016/j.reactfunctpolym.2014.07.021

Merayo N, Balea A, de la Fuente E, Blanco A, Negro C (2017) Synergies between cellulose nanofibers and retention additives to improve recycled paper properties and the drainage process. Cellulose 24:2987–3000. https://doi.org/10.1007/s10570-017-1302-1

Moohan J, Stewart SA, Espinosa E, Rosal A, Rodríguez A, Larrañeta E, Donnelly RF, Domínguez-Robles J (2020) Cellulose nanofibers and other biopolymers for biomedical applications. A review. Appl Sci 10:65. https://doi.org/10.3390/app10010065

Nair SS, Yan N (2015) Bark derived submicron-sized and nano-sized cellulose fibers: from industrial waste to high performance materials. Carbohydr Polym 134:258–266. https://doi.org/10.1016/j.carbpol.2015.07.080

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941. https://doi.org/10.1021/bm061215p

Pääkkönen T, Dimic-Misic K, Orelma H, Pönni R, Vuorinen T, Maloney T (2016) Effect of xylan in hardwood pulp on the reaction rate of TEMPO-mediated oxidation and the rheology of the final nanofibrillated cellulose gel. Cellulose 23:277–293. https://doi.org/10.1007/s10570-015-0824-7

Puangsin B, Yanga Q, Saito T, Isogai A (2013) Comparative characterization of TEMPO-oxidized cellulose nanofibril films prepared from non-wood resource. Int J Biol Macromol 59:208–213. https://doi.org/10.1016/j.ijbiomac.2013.04.016

Rambabu N, Panthapulakkal S, Sain M, Dalai AK (2016) Production of nanocellulose fibers from pinecone biomass: evaluation and optimization of chemical and mechanical treatment conditions on mechanical properties of nanocellulose films. Ind Crop Prod 83:746–754. https://doi.org/10.1016/j.indcrop.2015.11.083

Rodríguez A, Sánchez R, Requejo A, Ferrer A (2010) Feasibility of rice straw as a raw material for the production of soda cellulose pulp. J Clean Prod 18:1084–1091. https://doi.org/10.1016/j.jclepro.2010.03.011

Rojo E, Peresin MS, Sampson WW, Hoeger IC, Vartiainen J, Laine J, Rojas OJ (2015) Comprehensive elucidation of the effect of residual lignin on the physical, barrier, mechanical and surface properties of nanocellulose films. Green Chem 17:1853–1866. https://doi.org/10.1039/C4GC02398F

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibres prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491. https://doi.org/10.1021/bm0703970

Sánchez R, Espinosa E, Domínguez-Robles J, Loaiza JM, Rodríguez A (2016) Isolation and characterization of lignocellulose nanofibers from different wheat straw pulps. Int J Biol Macromol 92:1025–1033. https://doi.org/10.1016/j.ijbiomac.2016.08.019

Sarasini E, Fiore V (2018) A systematic literature review on less common natural fibres and their biocomposites. J Clean Prod 195:240–267. https://doi.org/10.1016/j.jclepro.2018.05.197

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using X-ray diffractometer. Text Res J 29:786–974

Serra A, González I, Oliver-Ortega H, Tarrés Q, Delgado-Aguilar M, Mutjé P (2017) Reducing the amount of catalyst in TEMPO-Oxidized cellulose nanofibers: effect on properties and cost. Polymers 9:557. https://doi.org/10.3390/polym9110557

Shao Y, Guizani C, Grosseau P, Chaussy D, Beneventi D (2018) Use of lignocellulosic materials and 3D printing for the development of structured monolithic carbon materials. Compos Part B Eng 149:206–215. https://doi.org/10.1016/j.compositesb.2018.05.035

Shinoda R, Saito T, Okita Y, Isogai A (2012) Relationship between length and degree of polymerization of TEMPO-oxidized cellulose nanofibrils. Biomacromolecules 13:842–849. https://doi.org/10.1021/bm2017542

Simair AA, Qureshi AS, Simair SP, Khushk I, Klykov SP, Ali CH, Lu CR (2018) An integrated bioprocess for xylanase production from agriculture waste under open non-sterilized conditions: biofabrication as fermentation tool. J Clean Prod 193:194–205. https://doi.org/10.1016/j.jclepro.2018.05.020

Solala I, Iglesias MC, Peresin MS (2020) On the potential of lignin-containing cellulose nanofibrils (LCNFs): a review on properties and applications. Cellulose 6:1–25. https://doi.org/10.1007/s10570-019-02899-8

Sun X, Wu Q, Ren S, Lei T (2015) Comparison of highly transparent all-cellulose nanopaper prepared using sulfuric acid and TEMPO-mediated oxidation methods. Cellulose 22:1123–1133. https://doi.org/10.1007/s10570-015-0574-6

Tarrés Q, Espinosa E, Domínguez-Robles J, Rodríguez A, Mutjé P, Delgado-Aguilar M (2017a) The suitability of banana leaf residue as raw material for the production of high lignin content micro/nano fibers: from residue to value-added products. Ind Crop Prod 99:27–33. https://doi.org/10.1016/j.indcrop.2017.01.021

Tarrés Q, Ehman NV, Vallejos ME, Area MC, Delgado-Aguilar M, Mutjé P (2017b) Lignocellulosic nanofibers from triticale straw: the influence of hemicelluloses and lignin in their production and properties. Carbohydr Polym 163:20–27. https://doi.org/10.1016/j.carbpol.2017.01.017

Tarrés Q, Oliver-Ortega H, Alcalá M, Merayo N, Balea A, Blanco A, Mutjé P, Delgado-Aguilar M (2018) Combined effect of sodium carboxymethyl cellulose, cellulose nanofibers and drainage aids in recycled paper production process. Carbohydr Polym 183:201–206. https://doi.org/10.1016/j.carbpol.2017.12.027

Tayeb P, Tayeb AH (2019) Nanocellulose applications in sustainable electrochemical and piezoelectric systems: a review. Cabohydr Polym 224:115149. https://doi.org/10.1016/j.carbpol.2019.115149

Vargas F, González Z, Sánchez R, Jiménez L, Rodríguez A (2012) Cellulosic pulps of cereal straws as raw material for the manufacture of ecological packaging. BioResources 7(3):4161–4170

Wang YH, Wei XY, Li JH, Wang F, Wang QH, Zhang YD, Kong LX (2017) Homogeneous isolation of nanocellulose from eucalyptus pulp by high pressure homogenization. Ind Crop Prod 104:237–241. https://doi.org/10.1016/j.indcrop.2017.04.032

Weise U (1998) Hornification: mechanisms and terminology. Pap Puu-pap 80:110–115

Acknowledgments

The authors are grateful to Spain’s DGICyT, MICINN for funding this research within the framework of the Projects CTQ2016-78729-R and supported by the Spanish Ministry of Science and Education through the National Program FPU (Grant Number FPU14/02278), to the staff of the Central Service for Research Support (SCAI) at the University of Córdoba, and also to Smurfit Kappa Container S.L.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Espinosa, E., Arrebola, R.I., Bascón-Villegas, I. et al. Industrial application of orange tree nanocellulose as papermaking reinforcement agent. Cellulose 27, 10781–10797 (2020). https://doi.org/10.1007/s10570-020-03353-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03353-w