Abstract

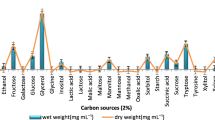

The extraordinary nature of the bacterial cellulose (BC) biopolymer gives it potential for diverse applications; however, the low BC yield of many indigenous cellulose-producing bacteria is a persistent problem in its synthesis. In this study, the BC yield of Komactobacter intermedius (BCRC 910677) was optimized by modifying culture media. The optimal culture period, type of carbon, and nitrogen sources were evaluated using the one-factor-at-a-time approach prior to the optimization study. The optimization was done by using the response surface methodology (RSM). In RSM optimization study, a Box–Behnken design with three parameters is applied; the three parameters include fructose concentrations (X1), peptone concentrations (X2), and pH values (X3). Our optimal culture media combined 41 g/L of fructose, 38 g/L peptone, and a pH of 5.2. The predicted BC yield from the RSM model is 4.012 g/L, while BC yield of 3.906 g/L is obtained from the experiment using the optimized medium; that is only 2.64% difference. An increase in BC production of 3.82-fold (compared to the culture in HS medium) was obtained after 6-days culture. The K. intermedius investigated in this study show great potential for commercial BC productions and as feedstock. The RSM can be a promising approach to enhance BC yield since the parameters were well correlated.

Similar content being viewed by others

References

Adachi O, Yakushi T (2016) Membrane-bound dehydrogenases of acetic acid bacteria. In: Matsushita K, Toyama H, Tonouchi N, Okamoto-Kainuma A (eds) Acetic acid bacteria: ecology and physiology. Springer, Tokyo, pp 273–297

Bae S, Shoda M (2005) Statistical optimization of culture conditions for bacterial cellulose production using Box–Behnken design. Biotechnol Bioeng 90:20–28

Basu A, Vadanan SV, Lim S (2019) Rational design of a scalable bioprocess platform for bacterial cellulose production. Carb Polym 207:684–693

Box GEP, Hunter JS, Hunter WG (2005) Statistics for experimenters, 2nd edn. Wiley, New York

Brown AJ (1886) XLIII—on an acetic ferment which forms cellulose. J Chem Soc Faraday Trans 49:432–439

Cheng KC, Catchmark JM, Demirci A (2009) Enhanced production of bacterial cellulose by using biofilm reactor and its material property analysis. J Biol Eng 3:12

Fan X, Gao Y, He W, Hu H, Tian M, Wang K, Pan S (2016) Production of nano bacterial cellulose from beverage industrial waste of citrus peel and pomace using Komagataeibacter xylinus. Carbohydr Polym 151:1068–1072

Fernández J, Morena AG, Valenzuela SV, Pastor FIJ, Díaz P, Martínez J (2019) Microbial Cellulose from a Komagataeibacter intermedius Strain Isolated from Commercial Wine Vinegar. J Polym Environ 27:956–967

Ferreira SLC, Bruns RE, Ferreira HS, Matos GD, David JM, Brandão GC, da Silva EGP, Portugal LA, dos Reis PS, Souza AS, dos Santos WNL (2007) Box–Behnken design: an alternative for the optimization of analytical methods. Anal Chim Acta 597:179–186

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21(2):885–896

Gullo M, China SL, Petroni G, Gregorio SD, Giudici P (2019) Exploring K2G30 genome: a high bacterial cellulose producing strain in glucose and mannitol based media. Front Microbiol 10:58

Hassan E, Hassan M, Abouzeid R, Berglund L, Oksman K (2017) Use of bacterial cellulose and crosslinked cellulose nanofibers membranes for removal of oil from oil-in-water emulsions. Polymers 9:388

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum: preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58:345–352

Iguchi M, Yamanaka S, Budhiono A (2000) Bacterial cellulose—a masterpiece of nature’s arts. J Mater Sci 35:261–270

Irving BA, Weltman JY, Brock DW, Davis CK, Gaesser GA, Weltman A (2007) NIH ImageJ and Slice-O-Matic computed tomography imaging software to quantify soft tissue. Obesity 15:370–376

Jahan F, Kumar V, Rawat G, Saxena RK (2012) Production of microbial cellulose by a bacterium isolated from fruit. Appl Biochem Biotechnol 167:1157–1171

Johnson DT, Taconi KA (2007) The glycerin glut: options for the value-added conversion of crude glycerol resulting from biodiesel production. Environ Prog 26:338–348

Jung H-I, Jeong J-H, Lee O-M, Park G-T, Kim K-K, Park H-C, Lee S-M, Kim Y-G, Son H-J (2010) Influence of glycerol on production and structural–physical properties of cellulose from Acetobacter sp. V6 cultured in shake flasks. Bioresour Technol 101:3602–3608

Kurosumi A, Sasaki C, Yamashita Y, Nakamura Y (2009) Utilization of various fruit juices as carbon source for production of bacterial cellulose by Acetobacter xylinum NBRC 13693. Carbohydr Polym 76:333–335

Li Z, Wang L, Hua J, Jia S, Zhang J, Liu H (2015) Production of nano bacterial cellulose from waste water of candied jujube-processing industry using Acetobacter xylinum. Carbohydr Polym 120:115–119

Lin S-P, Calva LL, Catchmark JM, Liu J-R, Demirci A, Cheng K-C (2013) Biosynthesis, production and applications of bacterial cellulose. Cellulose 20:2191–2219

Lin D, Lopez-Sanchez P, Li R, Li Z (2014) Production of bacterial cellulose by Gluconacetobacter hansenii CGMCC 3917 using only waste beer yeast as nutrient source. Bioresour Technol 151:113–119

Lin S-P, Huang Y-H, Hsu K-D, Lai Y-J, Chen Y-K, Cheng K-C (2016) Isolation and identification of cellulose-producing strain Komagataeibacter intermedius from fermented fruit juice. Carbohydr Polym 151:827–833

Lin S-P, Kung H-N, Tsai Y-S, Tseng T-N, Hsu K-D, Cheng K-C (2017) Novel dextran modified bacterial cellulose hydrogel accelerating cutaneous wound healing. Cellulose 24:4927–4937

Liu M, Zhing C, Wu X-Y, Wei Y-Q, Bo T, Han P-P, Jia S-R (2015) Metabolomic profiling coupled with metabolic network reveals differences in Gluconacetobacter xylinus from static and agitated cultures. Biochem Eng J 101:85–98

Lo K-Y, Tseng T-N, Lin S-P, Liu J-M, Shih T-Y, Cheng K-C (2019) PVA/Dextran/Chitosan hydrogel with antimicrobial and biocompatible abilities in wound dressing. Cell Polym 38:15–30

López-Meza J, Araíz-Hernández D, Carrillo-Cocom LM, López-Pacheco F, Rocha-Pizaña MdR, Alvarez MM (2016) Using simple models to describe the kinetics of growth, glucose consumption, and monoclonal antibody formation in naive and infliximab producer CHO cells. Cytotechnology 68:1287–1300

Lu Z, Zhang Y, Chi Y, Xu N, Yao W, Sun B (2011) Effects of alcohols on bacterial cellulose production by Acetobacter xylinum 186. World J Microbiol Biotechnol 27:2281–2285

Mamlouk D, Gullo M (2013) Acetic acid bacteria: physiology and carbon sources oxidation. Indian J Microbiol 53:377–384

Masaoka S, Ohe T, Sakota N (1993) Production of cellulose from glucose by Acetobacter xylinum. J Biosci Bioeng 75:18–22

Mohammadkazemi F, Azin M, Ashori A (2015) Production of bacterial cellulose using different carbon sources and culture media. Carbohydr Polym 117:518–523

Mohite BV, Salunke BK, Patil SV (2013) Enhanced production of bacterial cellulose by using Gluconacetobacter hansenii NCIM 2529 strain under shaking conditions. Appl Biochem Biotechnol 169:1497–1511

Montgomery DC (1991) Design and analysis of experiments. Wiley, New York

Müller T, Walter B, Wirtz A, Burkovski A (2006) Ammonium toxicity in bacteria. Curr Microbiol 52:400–406. https://doi.org/10.1007/s00284-005-0370-x

Ohrem HL, Schornick E, Kalivoda A, Ognibene R (2013) Why is mannitol becoming more and more popular as a pharmaceutical excipient in solid dosage forms? Pharm Dev Technol 19:257–262

Panesar PS, Chavan Y, Chopra HK, Kennedy JF (2012) Production of microbial cellulose: response surface methodology approach. Carbohydr Polym 87:930–934

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3(1):1

Pourramezan GZ, Poayaei AM, Qezelbash QR (2009) Optimization of culture conditions for bacterial cellulose production by Acetobacter sp. Biotechnology 8:150–154

Ramana KV, Tomar A, Singh L (2000) Effect of various carbon and nitrogen sources on cellulose synthesis by Acetobacter xylinum. World J Microbiol Biotechnol 16:245–248

Rani MU, Rastogi NK, Appaiah KA (2011) Statistical optimization of medium composition for bacterial cellulose production by Gluconacetobacter hansenii UAC09 using coffee cherry husk extract–an agro-industry waste. J Microbiol Biotechnol 21:739–745

Ruka DR, Simon GP, Dean KM (2012) Altering the growth conditions of Gluconacetobacter xylinus to maximize the yield of bacterial cellulose. Carbohydr Polym 89:613–622

Santoso SP, Kurniawan A, Soetaredjo FE, Cheng K-C, Putro JN, Ismadji S, Ju Y-H (2019) Eco-friendly cellulose–bentonite porous composite hydrogels for adsorptive removal of azo dye and soilless culture. Cellulose 16:3339–3358

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH Image to ImageJ: 25 years of image analysis. Nat Methods 9:671–675

Son H-J, Kim M-S, Kim Y-G, Lee S-J (2001) Optimization of fermentation conditions for the production of bacterial cellulose by a newly isolated Acetobacter. Biotechnol Appl Biochem 33:1–5

Toda K, Asakura T, Fukaya M, Entani E, Kawamura Y (1997) Cellulose production by acetic acid-resistant Acetobacter xylinum. J Biosci Bioeng 84:228–231

Trovatti E, Serafim LS, Freire CSR, Silvestre AJD, Neto CP (2011) Gluconacetobacter sacchari: an efficient bacterial cellulose cell-factory. Carbohydr Polym 86:1417–1420

Wu C-N, Cheng K-C (2016) Strong, thermal-stable, flexible, and transparent films by self-assembled TEMPO-oxidized bacterial cellulose nanofibers. Cellulose 24:269–283

Wu J-M, Liu R-H (2012) Thin stillage supplementation greatly enhances bacterial cellulose production by Gluconacetobacter xylinus. Carbohydr Polym 90:116–121

Wu C-N, Fuh S-C, Lin S-P, Lin Y-Y, Chen H-Y, Liu J-M, Cheng K-C (2018) TEMPO-oxidized bacterial cellulose pellicle with silver nanoparticles for wound dressing. Biomacromol 19:544–554

Yalkowsky SH, Dannenfelser RM (1992) The AQUASOL database of aqueous solubility, 5th edn. University of Arizona College of Pharmacy, Tucson

Zhong C, Zhang G-C, Liu M, Zheng X-T, Han P-P, Jia S-R (2013) Metabolic flux analysis of Gluconacetobacter xylinus for bacterial cellulose production. Appl Microbiol Biotechnol 97:6189–6199

Acknowledgments

This study was partly funded by the Ministry of Science and Technology, Taiwan, under Contract No. 106-2628-E-002-009-MY3.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Santoso, S.P., Chou, CC., Lin, SP. et al. Enhanced production of bacterial cellulose by Komactobacter intermedius using statistical modeling. Cellulose 27, 2497–2509 (2020). https://doi.org/10.1007/s10570-019-02961-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02961-5