Abstract

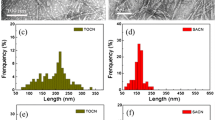

Highly transparent films with excellent gas barriers are very attractive materials for electronic devices. However, gas barrier properties of conventional cellulose nanofibril films tend to degrade under humid conditions. It is a great challenge to obtain nanocellulose films that simultaneously have very low gas permeability, high transparency, and high moisture and water resistance. In this study, free-standing, highly transparent films with excellent oxygen barrier properties were prepared from cellulose nanofibrils (CNF), followed by post-thermal treatment. Also, reducing agent was introduced to reduce discoloration during heating. CNF films showed high transparency (85–90% at 600 nm). SEM images indicated the loss of porous structure after thermal treatment, resulting in higher gas barriers and lower water retention values. Film showed extremely low oxygen permeability value of 0.007 ml μm kPa−1 m−2 day−1 at 23 °C and 50% relative humidity (RH) after treatment at 145 °C. Even at 80% RH, the oxygen permeability is only 0.584 ml μm kPa−1 m−2 day−1, which is 100 times lower than most plastic films such as poly(ethylene terephthalate) and poly(vinyl chloride).

Similar content being viewed by others

References

Aulin C, Gällstedt M, Lindström T (2010) Oxygen and oil barrier properties of icrofibrillated cellulose films and coatings. Cellulose 17:559–574. https://doi.org/10.1007/s10570-009-9393-y

Aulin C, Salazar-Alvarez G, Lindström T (2012) High strength, flexible and transparent nanofibrillated cellulose–nanoclay biohybrid films with tunable oxygen and water vapor permeability. Nanoscale 4:6622–6628. https://doi.org/10.1039/c2nr31726e

Bayer IS et al (2011) Water-repellent cellulose fiber networks with multifunctional properties. ACS Appl Mater Interfaces 3:4024–4031. https://doi.org/10.1021/am200891f

Belbekhouche S et al (2011) Water sorption behavior and gas barrier properties of cellulose whiskers and microfibrils films. Carbohydr Polym 83:1740–1748. https://doi.org/10.1016/j.carbpol.2010.10.036

Benhamou K, Kaddami H, Magnin A, Dufresne A, Ahmad A (2015) Bio-based polyurethane reinforced with cellulose nanofibers: a comprehensive investigation on the effect of interface. Carbohydr Polym 122:202–211. https://doi.org/10.1016/j.carbpol.2014.12.081

Bhuiyan MTR, Hirai N, Sobue N (2000) Changes of crystallinity in wood cellulose by heat treatment under dried and moist conditions. J Wood Sci 46:431–436. https://doi.org/10.1007/bf00765800

Brancato A, Walsh FL, Sabo R, Banerjee S (2007) Effect of recycling on the properties of paper surfaces. Ind Eng Chem Res 46:9103–9106. https://doi.org/10.1021/ie070826a

Charton C, Schiller N, Fahland M, Holländer A, Wedel A, Noller K (2006) Development of high barrier films on flexible polymer substrates. Thin Solid Films 502:99–103. https://doi.org/10.1016/j.tsf.2005.07.253

Chen Y, Wang Y, Wan J, Ma Y (2010) Crystal and pore structure of wheat straw cellulose fiber during recycling. Cellulose 17:329–338. https://doi.org/10.1007/s10570-009-9368-z

Chen Y-M, Wan J-Q, Huang M-Z, Ma Y-W, Wang Y, Lv H-L, Yang J (2011) Influence of drying temperature and duration on fiber properties of unbleached wheat straw pulp Carbohydrate polymers 85:759–764. https://doi.org/10.1016/j.carbpol.2011.03.041

Diniz JF, Gil M, Castro J (2004) Hornification—its origin and interpretation in wood pulps. Wood Sci Technol 37:489–494. https://doi.org/10.1007/s00226-003-0216-2

Fang Z et al (2014) Novel nanostructured paper with ultrahigh transparency and ultrahigh haze for solar cells. Nano Lett 14:765–773. https://doi.org/10.1021/nl404101p

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Hu L et al (2013) Transparent and conductive paper from nanocellulose fibers. Energy Environ Sci 6:513–518. https://doi.org/10.1039/c2ee23635d

Hult E-L, Larsson P, Iversen T (2001) Cellulose fibril aggregation—an inherent property of kraft pulps. Polymer 42:3309–3314. https://doi.org/10.1016/s0032-3861(00)00774-6

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85. https://doi.org/10.1039/c0nr00583e

Jonoobi M, Harun J, Mathew AP, Hussein MZB, Oksman K (2010) Preparation of cellulose nanofibers with hydrophobic surface characteristics. Cellulose 17:299–307. https://doi.org/10.1007/s10570-009-9387-9

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature based materials. Angew Chem Int Ed 50:5438–5466. https://doi.org/10.1002/anie.201001273

Lange J, Wyser Y (2003) Recent innovations in barrier technologies for plastic packaging—a review. Pack Technol Sci 16:149–158. https://doi.org/10.1002/pts.621

Le D, Kongparakul S, Samart C, Phanthong P, Karnjanakom S, Abudula A, Guan G (2016) Preparing hydrophobic nanocellulose-silica film by a facile one-pot method. Carbohydr Polym 153:266–274. https://doi.org/10.1016/j.carbpol.2016.07.112

Lu T, Li Q, Chen W, Yu H (2014) Composite aerogels based on dialdehyde nanocellulose and collagen for potential applications as wound dressing and tissue engineering scaffold. Compos Sci Technol 94:132–138. https://doi.org/10.1016/j.compscitech.2014.01.020

Missoum K, Martoïa F, Belgacem MN, Bras J (2013) Effect of chemically modified nanofibrillated cellulose addition on the properties of fiber-based materials. Ind Crops Prod 48:98–105. https://doi.org/10.1016/j.indcrop.2013.04.013

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994. https://doi.org/10.1039/c0cs00108b

Mulyadi A, Deng Y (2016) Surface modification of cellulose nanofibrils by maleated styrene block copolymer and their composite reinforcement application. Cellulose 23:519–528. https://doi.org/10.1007/s10570-015-0787-8

Nishiyama Y (2009) Structure and properties of the cellulose microfibril. J Wood Sci 55:241–249. https://doi.org/10.1007/s10086-009-1029-1

Noack M, Schneider M, Dittmar A, Georgi G, Caro J (2009) The change of the unit cell dimension of different zeolite types by heating and its influence on supported membrane layers. Microporous Mesoporous Mater 117:10–21. https://doi.org/10.1016/j.micromeso.2008.05.013

Okahisa Y, Yoshida A, Miyaguchi S, Yano H (2009) Optically transparent wood–cellulose nanocomposite as a base substrate for flexible organic light-emitting diode displays. Compos Sci Technol 69:1958–1961. https://doi.org/10.1016/j.compscitech.2009.04.017

Österberg M, Vartiainen J, Lucenius J, Hippi U, Seppälä J, Serimaa R, Laine J (2013) A fast method to produce strong NFC films as a platform for barrier and functional materials. ACS Appl Mater Interfaces 5:4640–4647. https://doi.org/10.1021/am401046x

Östlund Å, Köhnke T, Nordstierna L, Nydén M (2010) NMR cryoporometry to study the fiber wall structure and the effect of drying. Cellulose 17:321–328. https://doi.org/10.1007/s10570-009-9383-0

Park S, Venditti RA, Jameel H, Pawlak JJ (2006) Changes in pore size distribution during the drying of cellulose fibers as measured by differential scanning calorimetry. Carbohydr Polym 66:97–103. https://doi.org/10.1016/j.carbpol.2006.02.026

Rodionova G, Lenes M, Eriksen Ø, Gregersen Ø (2011) Surface chemical modification of microfibrillated cellulose: improvement of barrier properties for packaging applications. Cellulose 18:127–134. https://doi.org/10.1007/s10570-010-9474-y

Saito T, Nishiyama Y, Putaux J-L, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7:1687–1691. https://doi.org/10.1021/bm060154s

Sehaqui H, Zimmermann T, Tingaut P (2014) Hydrophobic cellulose nanopaper through a mild esterification procedure. Cellulose 21:367–382. https://doi.org/10.1007/s10570-013-0110-5

Sharma PR, Varma AJ (2014) Thermal stability of cellulose and their nanoparticles: effect of incremental increases in carboxyl and aldehyde groups. Carbohydr Polym 114:339–343. https://doi.org/10.1016/j.carbpol.2014.08.032

Sharma S, Zhang X, Nair SS, Ragauskas A, Zhu J, Deng Y (2014) Thermally enhanced high performance cellulose nano fibril barrier membranes. RSC Adv 4:45136–45142. https://doi.org/10.1039/c4ra07469f

Shimizu M, Saito T, Fukuzumi H, Isogai A (2014) Hydrophobic, ductile, and transparent nanocellulose films with quaternary alkylammonium carboxylates on nanofibril surfaces. Biomacromolecules 15:4320–4325. https://doi.org/10.1021/bm501329v

Shimizu M, Saito T, Isogai A (2016) Water-resistant and high oxygen-barrier nanocellulose films with interfibrillar cross-linkages formed through multivalent metal ions. J Membr Sci 500:1–7. https://doi.org/10.1016/j.memsci.2015.11.002

Shinoda R, Saito T, Okita Y, Isogai A (2012) Relationship between length and degree of polymerization of TEMPO-oxidized cellulose nanofibrils. Biomacromolecules 13:842–849. https://doi.org/10.1021/bm2017542

Sirviö JA, Kolehmainen A, Visanko M, Liimatainen H, Niinimäki J, Hormi OE (2014) Strong, self-standing oxygen barrier films from nanocelluloses modified with regioselective oxidative treatments. ACS Appl Mater Interfaces 6:14384–14390. https://doi.org/10.1021/am503659j

Song Z, Xiao H, Zhao Y (2014) Hydrophobic-modified nano-cellulose fiber/PLA biodegradable composites for lowering water vapor transmission rate (WVTR) of paper. Carbohydr Polym 111:442–448. https://doi.org/10.1016/j.carbpol.2014.04.049

Stanssens D, Van den Abbeele H, Vonck L, Schoukens G, Deconinck M, Samyn P (2011) Creating water-repellent and super-hydrophobic cellulose substrates by deposition of organic nanoparticles. Mater Lett 65:1781–1784. https://doi.org/10.1016/j.matlet.2011.03.057

Takaichi S, Saito T, Tanaka R, Isogai A (2014) Improvement of nanodispersibility of oven-dried TEMPO-oxidized celluloses in water. Cellulose 21:4093–4103. https://doi.org/10.1007/s10570-014-0444-7

Urbina L et al (2016) Biodegradable composites with improved barrier properties and transparency from the impregnation of PLA to bacterial cellulose membranes. J Appl Polym Sci 133. https://doi.org/10.1002/app.43669

Wu J, Zheng Y, Yang Z, Lin Q, Qiao K, Chen X, Peng Y (2013) Influence of dialdehyde bacterial cellulose with the nonlinear elasticity and topology structure of ECM on cell adhesion and proliferation. RSC Adv 4:3998–4009. https://doi.org/10.1039/c3ra45407

Yagyu H, Saito T, Isogai A, Koga H, Nogi M (2015) Chemical modification of cellulose nanofibers for the production of highly thermal resistant and optically transparent nanopaper for paper devices. ACS Appl Mater Interfaces 7:22012–22017. https://doi.org/10.1021/acsami.5b06915

Yang Q, Saito T, Isogai A (2012) Facile fabrication of transparent cellulose films with high water repellency and gas barrier properties. Cellulose 19:1913–1921. https://doi.org/10.1007/s10570-012-9790-5

Acknowledgments

Jianyu Xia would like to thank the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), the Doctorate Fellowship Foundation of Nanjing Forestry University and National Natural Science Foundation of China (No. 31670597) for the financial support. And the work was supported by Dr. Deng’s group from RBI at Georgia Tech.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, J., Zhang, Z., Liu, W. et al. Highly transparent 100% cellulose nanofibril films with extremely high oxygen barriers in high relative humidity. Cellulose 25, 4057–4066 (2018). https://doi.org/10.1007/s10570-018-1843-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1843-y