Abstract

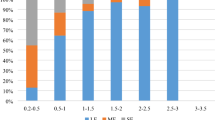

The changes in crystal structure and pore size of wheat straw fiber after repeated recycling were studied by means of X-ray diffraction, Fourier transform infrared spectrophotometry, and transmission electron microscopy. The results showed that in unbleached wheat straw cellulose crystallinity increased and the water retention value decreased with increasing rounds of recycling. After five rounds, the crystallinity increased by 14.6% compared with fiber never used for papermaking. The width of the crystallite in a 002 lattice plane (L002) increased after each round of recycling, which indicated co-crystallization during the recycling process. The pore-size distribution of wheat straw fiber consisted of numerous micropores and mesopores but few macropores. The pore volumes of pulp micropores and mesopores decreased after two rounds of recycling, but subsequent rounds scarcely affected the pore-volume distribution. The average pore size and specific surface area of the fiber decreased after recycling. In addition, after recycling and rewetting, the fiber lumen became irreversibly collapsed and distorted, with numerous pleats that changed the shapes and size of the pores.

Similar content being viewed by others

References

Aggerbrandt LG, Samuelsson O (1964) Penetration of water-soluble polymers into cellulose fibres. J Appl Poly Sci 8:2801–2812

Andreasson B (2003) The porous structure of pulp fibres with different yields and influence on paper strength. Cellulose 10:111–123

Berthold J, Salmén L (1997) Inverse size exclusion chromatography (ISEC) for determining the relative pore size distribution of wood pulps. Holzforschung 51(4):361–368

Bobalek JF, Chaturvedi M (1989) The effects of recycling on the recycling on pulp properties. Tappi J 72(6):146–151

Böttger J, Thi L, Krause T (1983) Untersuchungen zur Porenstruktur von Zellstoffasern. Das Papier 37(10A):V14–V21

Bouchard J, Douek M (1994) The effects of recycling on the chemical properties of pulps. J Pulp Pap Sci 20(5):131–136

Bovin A, Hartler N, Teder A (1972) Changes in pulp quality due to repeated papermaking. Pap Technol 5:261–265

Bugajer S (1976) O efeito de recicalgem de fibras secundárias sobre as propriedades do papel kraft. Papel 12:108–112

Daniel T (2002) Changes of cellulose fiber wall structure during drying investigated using NMR self diffusion and relaxation experiments. Cellulose 9:139–147

Forsstrom J (2005) Influence of pore structure and water retaining ability of fibres the strength of papers from unbleached kraft fibres. Nordic Pulp Pap Res J 20(2):176–185

Gregg SJ, Sing KSW (1982) Adsorption surface area and porosity [M], 2nd edn. Academic Press, London

Gu MD (1999) Expanding wastepaper recycling to develop China paper industry. World Pulp Pap 18(5):1–3

Gu MD (2001) A further discussion on the extension of waste paper reutilization. China Pulp Pap Ind 22(10):9–12

Gu MD (2002) Suggestions on the expansion of waste paper reclamation. China Pulp Pap Ind 24(5):17–19

Häggkvist M, Li T-Q, Ödberg L (1998) Effects of drying and pressing on the pore structure in the cellulose fibre wall studied by 1H and 2H NMR relaxation. Cellulose 5:33–49

Horn RA (1975) What are the effects of recycling on fibre and paper properties? Pap Trade J 159(7/24):78–82

Hu BL, Che Y, Yang Q, Liu DM, Huang WH (2003) Analyses on cryogenic nitrogen isothermal adsorption characteristics of coal reservoirs in the Ordos Basin, coal geology and exploration. Coal Geol Explor 31(2):20–23

Hult EL, Larsson PT, Iversen T (2001) Cellulose fibril aggregation—an inherent property of kraft pulps. Polymer 42:3309–3314

Jayme G (1958) Properties of wood cellulose II. Determination of and significance of water retention value. Tappi 41:180

Klungness JH, Caulfield DF (1982) Mechanisms affecting fibre bonding during drying and aging of pulps. Tappi J 65(12):94–98

Kontturi E, Vuorinen T (2009) Indirect evidence of supramolecular changes within cellulose microfibrils of chemical pulp fibers upon drying. Cellulose 16:65–74

Laivins GV, Scallan AM (1993) The mechanism of hornification of wood pulps. In: Baker CF (ed) Products of papermaking, vol 2. Pira International, Leatherhead, pp 1235–1260

Law LN, Valade JL, Quan J (1996a) Effects of recycling on papermaking properties of mechanical and high yield pulps, part 1: hardwood. Tappi J 79(3):167–173

Law LN, Valade JL, Li Z (1996b) Recycling behaviour of thermomechanical pulp: effects of refining energy. Tappi J 79(10):181–185

Li TQ, Eriksson U (1994) Kaolin-based coating layer studied by 2H and 1H NMR relaxation method. Langmuir 10:4624–4629

Li TQ, Henriksson U (1993) Determination of pore sizes in wood cellulose fibers by 2H and 1H. Nordic Pulp Pap Res J 8(3):326–330

Lindstöm T, Carlsson G (1982) The effect of carboxyl groups and their ionic form during drying on the hornification of cellulose fibers. Sven Papperstidn 85(15):146–151

Liu H, Wu SH, Jiang XM (2005) The configuration analysis of the adsorption isotherm of nitrogen in low temperature with the lignite char produced under fast pyrolysis. J China Coal Soc 30(4):507–510

Lu J, Shi SL, Yang RN, Niu MH, Song WJ (2005) Modification of reed cellulose microstructure and IT change in enzymatic hydrolysis of reed pulp. Trans China Pulp Pap 20(2):85–90

Maloney TC (1999) The formation of pores in the cell wall. J Pulp Pap Sci 25(12):430–436

Maloney TC, Li TQ, Weise U, Paulapuro H (1997) Intra- and inter-fibre pore closure in wet pressing. Appita J 50(4):301–306

Matsuda Y, Isogai A, Onabe F (1994) Effects of thermal and hydrothermal treatments on the reswelling capabilities of pulps and papersheets. J Pulp Pap Sci 20(11):323–327

Mckee RC (1971) Effects of repulping on sheet properties and fibre characteristics. Pap Trade J 155(21):34–39

Newman RH (2004) Carbon-13 NMR evidence for cocrystallization of cellulose as a mechanism for hornification of bleached kraft pulp. Cellulose 11:45–52

Rebuzzi FD, Evtuguin V (2006) Effect of glucuronoxylan on the hornification of Eucalyptus globulus bleached pulps. Macromol Symp 232:121–128

Ren GP, Zhang CQ, Jiang XM, Yu LJ (2007) Analysis of surface area and pore structure of datong coal. Combust Sci Technol 13(3):265–268

Scallan AM, Tigeström AC (1992) Elasticity of the wet fibre wall: effect of pulping and recycling. J Pulp Pap Sci 18:188–192

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Shao SY (2001) Recycled properties of straw pulp. Hubei Pap 4:11–14

Stone JE, Scallan AM (1965) Effects of component removal upon the porous structure of the cell wall of wood. Polym Sci Part C 69(6):13–25

Stone JE, Scallan AM (1968) The effect of component removal upon the porous structure of the cell wall of wood. Part III. A comparison between the sulphite and kraft processes. Pulp Pap Mag Can T288:69–74

Wijnman CF (1954) Influence of heavy beating of cotton fibers on molecular length and crystallinity. Tappi 37:96–99

Wistara N, Yong RA (1999) Properties and treatments of pulps from recycled paper. Part I: physical and chemical properties of pulps. Cellulose 6:291–324

Yamagishi Y, Oye R (1981) Influence of recycling on wood pulp fibres-changes in properties of wood pulp fibres with recycling. Jpn Tappi J 35(9):33–36

Yang TZ, Luo SZ, Xu YS (2006) Characterization of pore structure on N2 adsorption applied to porous materials. Carbon 1:17–22

Acknowledgments

This work was supported by the National Technology Research and Development of China (863 Program) (No. 2007AA03Z433), Science and Technology Key Project of Guangdong Province, China (No. 2008A0302008) and Science and Technology Plan Project of Guangdong Province, China (No. 2008B030302035).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Y., Wang , Y., Wan, J. et al. Crystal and pore structure of wheat straw cellulose fiber during recycling. Cellulose 17, 329–338 (2010). https://doi.org/10.1007/s10570-009-9368-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-009-9368-z