Abstract

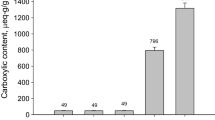

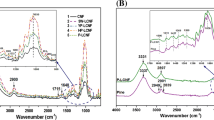

In this work, three different lignocellulosic nanofibers (LCNF) were produced from unbleached wheat straw soda pulp by using different pre-treatments: mechanical, enzymatic, and TEMPO [(2,2,6,6-tetramethylpiperidin-1-yl) oxy radical]-mediated oxidation processes. The different LCNF were characterized and studied by their chemical composition (FTIR), crystal structure (XRD), thermal degradation behaviour (TGA), morphological (TEM), and their reinforcement effect on papermaking slurries. The pre-treatment used to obtain LCNF showed significant differences on the nanofibrillation yield (37–95%), carboxyl content (74–362 µmol g−1), cationic demand (428–1116 µeq g−1), and on its dimensions (7–14 nm), thermal stability, and structure. Regarding application as reinforcement on papermaking slurries, LCNF obtained by TEMPO-mediated oxidation produced a greater reinforcing effect than the other LCNF. Nevertheless, the obtained LCNF from mechanical process produce a similar increase in the mechanical properties of the papersheets due to its high length, compared with LCNF obtained by TEMPO-mediated oxidation.

Similar content being viewed by others

References

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polym 87:963–979

Afra E, Yousefi H, Hadilam MH, Nishino T (2013) Comparative effect of mechanical beating and nanofibrillation on paper properties made from bagasse and softwood pulps. Carbohydr Polym 97:725–730

Alcalá M, González I, Boufi S, Vilaseca F, Mutjé P (2013) All-cellulose composites from unbleached hardwood kraft pulp reinforced with nanofibrillated cellulose. Cellulose 20:2909–2921

Benhamou K, Dufresne A, Magnin A, Mortha G, Kaddami H (2014) Control of size and viscoelastic properties of nanofibrillated cellulose from palm tree by varying the TEMPO-mediated oxidation. Carbohydr Polym 99:74–83

Besbes I, Alila S, Boufi S (2011a) Nanofibrillated cellulose from TEMPO-oxidized eucalyptus fibers: effect of the carboxyl content. Carbohydr Polym 84(3):975–983

Besbes I, Vilar MR, Boufi S (2011b) Nanofibrillated cellulose from Alfa, Eucalyptus and Pine fibers: preparation, characteristics and reinforcing potential. Carbohydr Polym 84:1198–1206

Bettaieb F, Khiari R, Dufresne A, Mhenni MF, Belgacem MN (2015) Mechanical and thermal properties of Posidonia ocenica cellulose nanocrystal reinforced polymer. Carbohydr Polym 123:99–104

Boufi S, González I, Delgado-Aguilar M, Tarrés Q, Pèlach MA, Mutjé P (2016) Nanofibrillated cellulose as an additive in papermaking process: a review. Carbohydr Polym 154:151–166

Carrasco F, Mutjé P, Pelàch MA (1998) Control of retention in paper-making by colloid titration and zeta potential techniques. Wood Sci Technol 32(2):145–155

Cereal Supply and Demand Brief. Food and Agriculture Organization of the United Nation (FAO) (2016) http://www.fao.org/worldfoodsituation/csdb/en/. Accessed 30 May 2016

Chacker A, Mutje P, Vilar MR, Boufi S (2014) Agriculture crop residues as a source for the production of nanofibrillated cellulose with low energy demand. Cellulose 21:4247–4259

Chandra CS, Neena G, Sunil KN (2016) Isolation and characterization of cellulose nanofibrils from arecanut husk fiber. Carbohydr Polym 142:158–166

Chirayil CJ, Joy J, Mathew L, Mozetic M, Koetz J, Thomsa S (2014) Isolation and characterization of cellulose nanofibrils from Helicteres isora plant. Ind Crop Prod 59:27–37

Delgado-Aguilar M, González I, Pelàch MA, De la Fuente E, Negro C, Mutjé P (2014) Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 22(1):789–802

Delgado-Aguilar M, González I, Tarrés Q, Alcalá M, Pèlach MA, Mutjé P (2015) Approaching a low-cost production of cellulose nanofibers for papermaking applications. BioResources 10(3):5345–5355

Delgado-Aguilar M, González I, Tarrés Q, Pèlach MA, Alcalá M, Mutjé P (2016) The key role of lignin in the production of low-cost lignocellulosic nanofibers for papermaking applications. Ind Crops Prod 86:295–300

Espinosa E, Tarrés Q, Delgado-Aguilar M, González I, Mutjé P, Rodríguez A (2016) Suitability of wheat straw semichemical pulp for the fabrication of lignocellulosic nanofibers and their application to papermaking slurries. Cellulose 23:837–852

Feria JM, Alfaro A, López F, Pérez A, García JC, Rivera A (2012) Integral valorization of Leucaena diversifolia by hydrothermal and pulping processing. Bioresour Technol 103:381–388

González I, Boufi S, Pelách MA, Alcalá M, Vilaseca F, Mutjé P (2012) Nanofibrillated cellulose as paper additive in eucalyptus pulps. BioResources 7(4):5167–5180

González I, Alcalá M, Arbat G, Vilaseca F, Mutjé P (2013) Suitability of rapeseed chemithermomechanical pulp as raw material in papermaking. BioResources 8(2):1697–1708

González I, Alcalá M, Chinga-Carrasco G, Vilaseca F, Boufi S, Mutjé P (2014) From paper to nanopaper: evolution of mechanical and physical properties. Cellulose 21(4):2599–2609

Henriksson M, Henriksson G, Berglund LA, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibes. Eur Polym J 43(8):3434–3441

Ibrahim MM, El-Zawawy WK, Juttke Y, Koschella A, Heinze T (2013) Cellulose and microcrystaline cellulose from rice straw and banana plant waste—preparation and characterization. Cellulose 20:2403–2416

Iwamoto S, Nakagaito A, Yano H (2007) Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl Phys A Mater Sci Process 89:461–466

Iwamoto S, Abe K, Yano H (2008) The effect of hemicellulose on wood pulp nanofibrillation and nanofiber network characteristics. Biomacromolecules 9(3):1022–1026

Jiang F, Hsieh YL (2013) Chemically and mechanically isolated nanocellulose and their self-assembled structures. Carbohydr Polym 95(1):32–40

Kajanto I, Kosonen M (2012) The potential use of micro- and nanofibrillated cellulose as a reinforcing element in paper. J For 2(6):42–48

Lu Y, Tekinalp HL, Eberle CC, Peter W, Naskar AK, Ozcan S (2014) Nanocellulose in polymer composites and biomedical applications. Tappi J 13(6):47–54

Marx-Figini M (1987) The acid-catalyzed degradation of cellulose linters in distinct ranges of degree of polymerization. J Appl Polym Sci 33(6):2097–2105

Meng Q, Fu S, Lucia LA (2016) The role of heteropolysaccharides in developing oxidized cellulose nanofibrils. Carbohydr Polym 144:187–195

Mohammadkazemi F, Doosthoseini K, Ganjian E, Azin M (2009) Manufacturing of bacterial nano-cellulose reinforced fiber-cement composites. Constr Build Mater 101:958–964

Moran JL, Alvarez VA, Cyras VP, Vazquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15:149–159

Nair SS, Yan N (2015) Effect of high residual lignin on the thermal stability of nanofibrils and its enhanced mechanical performance in aqueous environments. Cellulose 22:3137–3150

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941

Puangsin B, Yanga Q, Saito T, Isogai A (2013) Comparative characterization of TEMPO-oxidized cellulose nanofibril films prepared from non-wood resource. Int J Biol Macromol 59:208–213

Quiévy N, Jacquet N, Sclavons M, Deroanne C, Paquot M, Devaux J (2010) Influence of homogenization and drying on the thermal stability of microfibrillated cellulose. Polym Degrad Stab 95:165–188

Rodríguez A, Sánchez R, Requejo A, Ferrer A (2010) Feasibility of rice straw as a raw material for the production of soda cellulose pulp. J Clean Prod 18:1084–1091

Rouger J, Mutjé P (1984) Correlation between the cellulose fibers beating and the fixation of a soluble cationic polymer. Br Polym J 16(2):83–86

Saito T, Isogai A (2004) TEMPO-mediated oxidation of native cellulose. The effect of oxidation conditions on chemical and crystal structures of the water-insoluble fractions. Biomacromol 5(5):1983–1989

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491

Sánchez R, Espinosa E, Domínguez-Robles J, Loaiza JM, Rodríguez A (2016) Isolation and characterization of lignocellulose nanofibers from different wheat straw pulps. Int J Biol Macromol 92:1025–1033

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using X-ray diffractometer. Text Res J 29:786–794

Sharma PR, Varma AJ (2014) Thermal stability of cellulose and their nanoparticles: effect of incremental increases in carboxyl and aldehyde groups. Carbohydr Polym 114:339–343

Soni B, Hassan EB, Mahmoud B (2015) Chemical isolation and characterization of different cellulose nanofibers from cotton stalks. Carbohydr Polym 134:581–589

Taipale T, Österberg M, Nykänen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020

Tanaka R, Saito T, Isogai A (2012) Cellulose nanofibrils prepared from softwood cellulose by TEMPO/NaClO/NaClO2 systems in water at pH 4.8 or 6.8. Int J Biol Macromol 51(3):228–234

Tanaka R, Saito T, Ishii D, Isogai A (2014) Determination of nanocellulose fibril length by shear viscosity measurement. Cellulose 21:1581–1589

Tarrés Q, Saguer E, Pèlach MA, Alcalá M, Delgado-Aguilar M, Mutjé P (2016) The feasibility of incorporating cellulose micro/nanofibers in papermaking processes: the relevance of enzymatic hydrolyisis. Cellulose 23(2):1433–1445

Tian C, Yi J, Wu Y, Wu Q, Qing Y, Wang L (2016) Preparation of highly charged cellulose nanofibrils using high-pressure homogenization coupled with strong acid hydrolysis pretreatments. Carbohydr Polym 136:485–492

Turbak A, Snyder F, Sandberg K (1983) Microfibrillated cellulose: a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci Appl Polym Symp 37:815–827

Vallejos ME, Felissia FE, Area MC, Ehman NV, Tarrés Q, Mutje P (2016) Nanofibrillated cellulose (CNF) from eucalyptus sawdust as a dry strength agent of unrefined eucalyptus handsheets. Carbohydr Polym 139:99–105

Vargas F, González Z, Sánchez R, Jiménez L, Rodríguez A (2012) Cellulosic pulps of cereal straws as raw material for the manufacture of ecological packaging. BioResources 7(3):4161–4170

Xiang Z, Gao W, Chen L, Lan W, Zhu JY, Runge T (2016) A comparison of cellulose nanofibrils produced from Cladophora glomerata algae and bleached eucalyptus pulp. Cellulose 23:493–503

Xu Q, Gao Y, Qin M, Wu K, Fu Y, Zhao Y (2013) Nanocrystalline cellulose from aspen kraft pulp and its application in deinked pulp. Int J Biol Macromol 60:241–243

Yousefi H, Faezipour M, Nishino T, Shakeri A, Ebrahimi G (2011) All-cellulose composite and nanocomposite made from partially dissolved micro and nanofibers of canola straw. Polym J 43:559–564

Acknowledgments

The authors are grateful to Spain’s DGICyT, MICINN for funding this research within the framework of the Projects CTQ2013-46804-C2-2-R and supported by the Spanish Ministry of Science and Education through the National Program FPU (Grant Number FPU14/02278), and also to the staff of the Central Service for Research Support (SCAI) at the University of Córdoba.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Espinosa, E., Domínguez-Robles, J., Sánchez, R. et al. The effect of pre-treatment on the production of lignocellulosic nanofibers and their application as a reinforcing agent in paper. Cellulose 24, 2605–2618 (2017). https://doi.org/10.1007/s10570-017-1281-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1281-2