Abstract

Cotton, a commonly used textile material, tends to burn easily. For some specific end-uses, flame-retardant (FR) properties are required. However, this kind of finish tends to worsen the hand feel and strength of the fabric. This study explored the feasibility of applying softener and wetting agent during flame-retardant treatment of cotton fabrics to improve their comfort and mechanical properties. Here, flame-retardant agent Pyrovatex CP New, crosslinking agent Knittex CHN, and phosphoric acid were combined with various softeners and wetting agent, and applied to the fabrics using a pad–dry–cure process. Fabric combustibility was evaluated by 45° flammability test. The thermal decomposition behavior and chemical structure of the samples were characterized by thermogravimetric analysis and Fourier-transform infrared spectroscopy, respectively. The thermophysiological comfort properties, hand, and mechanical properties of the fabrics were additionally measured. The results demonstrated that FR-treated cotton specimens had lower strength and poor fabric hand and wettability, which might be caused by formation of crosslinks due to the acidic reaction condition and high curing temperature. Meanwhile, softener addition could compensate for these drawbacks and remarkably improve fabric hand and strength. On the other hand, addition of wetting agents could improve the flame resistance of the FR-treated fabrics.

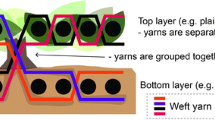

[reprinted with permission from Poon and Kan (2015), Elsevier, license no. 3990280994351]

Similar content being viewed by others

Abbreviations

- FR:

-

Flame retardant

- PA:

-

Phosphoric acid

- CPNew:

-

Pyrovatex CP New

- CHN:

-

Knittex CHN

- FSA:

-

Ultratex FSA New

- ACN:

-

Turpex ACN New

- FH:

-

Ultratex FH New

- DCW:

-

Ultraphil DCW New

- PBN:

-

Invadine PBN

- KES-F:

-

Kawabata Evaluation System for Fabrics

- FTIR:

-

Fourier-transform infrared

- ATR:

-

Attenuated total reflection

- TGA:

-

Thermogravimetric analysis

- ANOVA:

-

Analysis of variance

- B :

-

Bending rigidity

- G :

-

Shear stiffness

- SMD:

-

Surface roughness

- MIU:

-

Coefficient of friction

- WT:

-

Tensile energy

- RT:

-

Tensile resilience

References

Adanur S, Tewari A (1997) An overview of military textiles. Indian J Fibre Text Res 22:348–352

Chen Y, Frendi A, Tewari S, Sibulkin M (1991) Combustion properties of pure and fire-retarded cellulose. Combust Flame 84:121–140

Chen Q, Fan JT, Sarkar M, Jiang GM (2010) Biomimetics of plant structure in knitted fabrics to improve the liquid water transport properties. Text Res J 80:568–576

Ebrahimi I, Kiumarsi A, Gashti MP, Rashidian R, Norouzi HM (2011) Atmospheric-air plasma enhances coating of different lubricating agents on polyester fiber. Eur Phys J Appl Phys 56:10801

Flambard X, Bourbigot S, Kozlowski R, Muzyczek M, Mieleniak B, Ferreira M, Vermeulen B, Poutch F (2005) Progress in safety, flame retardant textiles and flexible fire barriers for seats in transportation. Polym Degrad Stab 88:98–105. http://www.sciencedirect.com/science/article/pii/S014139100400326X

Gaan S, Sun G (2007) Effect of phosphorus and nitrogen on flame retardant cellulose: a study of phosphorus compounds. J Anal Appl Pyrol 78:371–377

Gaan S, Sun G (2009) Effect of nitrogen additives on thermal decomposition of cotton. J Anal Appl Pyrol 84:108–115

Gashti MP, Adibzadeh H (2014) Ultrasound for efficient emulsification and uniform coating of an anionic lubricant on cotton. Fibers Polym 15:65–70

Gashti MP, Navid MY, Rahimi MH (2012) Coating of macroemulsion and microemulsion silicones on poly (ethylene terephthalate) fibers: evaluation of the thermal properties and flammability. J Appl Polym Sci 125:1430–1438

Guan JP, Chen GQ (2006) Flame retardancy finish with an organophosphorus retardant on silk fabrics. Fire Mater 30:415–424

Guin T, Krecker M, Milhorn A, Grunlan JC (2014) Maintaining hand and improving fire resistance of cotton fabric through ultrasonication rinsing of multilayer nanocoating. Cellulose 21:3023–3030

Guo J (2003) The effects of household fabric softeners on the thermal comfort and flammability of cotton and polyester fabrics. Dissertation, Virginia Polytechnic Institute and State University

Hasani H (2010) Effect of different processing stages on mechanical and surface properties of cotton knitted fabrics. Indian J Fibre Text Res 35:139–144

Horridge P, Timmons M (1979) Blend for children’s sleepwear incorporating inherently flame-retardant fiber. J Consum Prod Flammabil 6:218–227

Horrocks AR, Nazaré S, Kandola B (2004) The particular flammability hazards of nightwear. Fire Saf J 39:259–276

Hsieh YL (1995) Liquid transport in fabric structures. Text Res J 65:299–307

Kamath M, Bhat G, Parikh D, Condon B (2009) Processing and characterization of flame retardant cotton blend nonwovens for soft furnishings to meet federal flammability standards. J Ind Text 38:251–262

Kandola BK, Horrocks S, Horrocks AR (1997) Evidence of interaction in flame-retardant fibre-intumescent combinations by thermal analytical techniques. Thermochim Acta 294:113–125

Kang IS, Yang CQ, Wei W, Lickfield GC (1998) Mechanical strength of durable press finished cotton fabrics: part I: effects of acid degradation and crosslinking of cellulose by polycarboxylic acids. Text Res J 68:865–870

Kawabata S, Niwa M, Yamashita Y (2002) Recent developments in the evaluation technology of fiber and textiles: toward the engineered design of textile performance. J Appl Polym Sci 83:687–702

Lam YL, Kan CW, Yuen CWM (2011a) Effect of titanium dioxide on the flame-retardant finishing of cotton fabric. J Appl Polym Sci 121:267–278

Lam YL, Kan CW, Yuen CWM (2011b) Flame-retardant finishing in cotton fabrics using zinc oxide co-catalyst. J Appl Polym Sci 121:612–621

Lam YL, Kan CW, Yuen CWM (2011c) Effect of oxygen plasma pretreatment and titanium dioxide overlay coating on flame retardant finished cotton fabrics. BioResources 6:1454–1474

Lam YL, Kan CW, Yuen CWM, Au CH (2011d) Low stress mechanical properties of plasma-treated cotton fabric subjected to titanium dioxide coating. Text Res J 81:1008–1013

Lam YL, Kan CW, Yuen CWM (2014) Objective measurement of hand properties of plasma pre-treated cotton fabrics subjected to flame-retardant finishing catalyzed by zinc oxide. Fibers Polym 15:1880–1886

Lau L, Fan JT, Siu T, Siu LYC (2002) Effects of repeated laundering on the performance of garments with wrinkle-free treatment. Text Res J 72:931–937

Lecoeur E, Vroman I, Bourbigot S, Lam T, Delobel R (2001) Flame retardant formulations for cotton. Polym Degrad Stab 74:487–492

Lessan F, Montazer M, Moghadam M (2011) A novel durable flame-retardant cotton fabric using sodium hypophosphite, nano TiO2 and maleic acid. Thermochim Acta 520:48–54

Parvinzadeh M (2009) Ultrasonic assisted finishing of cotton with nonionic softener. Tenside Surfactants Deterg 46:335–339

Parvinzadeh M, Hajiraissi R (2008) Effect of nano and micro emulsion silicone softeners on properties of polyester fibers. Tenside Surfactants Deterg 45:254–257

Paul R (2014) Functional finishes for textiles: improving comfort, performance and protection. Woodhead, Cambridge

Poon CK, Kan CW (2015) Effects of TiO2 and curing temperatures on flame retardant finishing of cotton. Carbohydr Polym 121:457–467

Poon CK, Kan CW (2016) Relationship between curing temperature and low stress mechanical properties of titanium dioxide catalyzed flame retardant finished cotton fabric. Fibers Polym 17:380–388

Prezant DJ, Kelly KJ, Malley KS, Karwa ML, McLaughlin MT, Hirschorn R, Brown A (1999) Impact of a modern firefighting protective uniform on the incidence and severity of burn injuries in New York City firefighters. J Occup Environ Med 41:469–479

Rahimi M, Parvinzadeh M, Navid M, Ahmadi S (2011) Thermal characterization and flammability of polyester fiber coated with nonionic and cationic softeners. J Surfactants Deterg 14:595–603

Saville BP (1999) Physical testing of textiles. Woodhead, Cambridge

Schindler WD, Hauser PJ (2004) Chemical finishing of textiles. Woodhead, Cambridge

Siriviriyanun A, O’Rear EA, Yanumet N (2008) Self-extinguishing cotton fabric with minimal phosphorus deposition. Cellulose 15:731–737

Stegmaier T, Mavely J, Schneider P (2005) High performance and high functional fibres and textiles. In: Shishoo RL (ed) Textiles in sport. Woodhead, Cambridge, pp 89–119

Sun D, Stylios GK (2005) Investigating the plasma modification of natural fiber fabrics—the effect on fabric surface and mechanical properties. Text Res J 75:639–644

Weil ED, Levchik SV (2008) Flame retardants in commercial use or development for textiles. J Fire Sci 26:243–281

Wu W, Yang CQ (2006) Comparison of different reactive organophosphorus flame retardant agents for cotton: part I. The bonding of the flame retardant agents to cotton. Polym Degrad Stab 91:2541–2548

Wu X, Yang CQ (2008) Flame retardant finishing of cotton fleece fabric: part III—the combination of maleic acid and sodium hypophosphite. J Fire Sci 26:351–368

Wu X, Yang CQ (2009) Flame retardant finishing of cotton fleece fabric: part IV—bifunctional carboxylic acids. J Fire Sci 27:431–446

Yang H, Yang CQ (2007) Nonformaldehyde flame retardant finishing of the nomex/cotton blend fabric using a hydroxy-functional organophosphorus oligomer. J Fire Sci 25:425–446

Yang CQ, Wei W, Lickfield GC (2000) Mechanical strength of durable press finished cotton fabric—part II: comparison of crosslinking agents with different molecular structures and reactivity. Text Res J 70:143–147

Yang CQ, Wu W, Xu Y (2005) The combination of a hydroxy-functional organophosphorus oligomer and melamine-formaldehyde as a flame retarding finishing system for cotton. Fire Mater 29:109–120

Yang CQ, He Q, Lyon RE, Hu Y (2010) Investigation of the flammability of different textile fabrics using micro-scale combustion calorimetry. Polym Degrad Stab 95:108–115

Yang Z, Fei B, Wang X, Xin JH (2012a) A novel halogen-free and formaldehyde-free flame retardant for cotton fabrics. Fire Mater 36:31–39

Yang Z, Wang X, Lei D, Fei B, Xin JH (2012b) A durable flame retardant for cellulosic fabrics. Polym Degrad Stab 97:2467–2472

Zhu P, Sui S, Wang B, Sun K, Sun G (2004) A study of pyrolysis and pyrolysis products of flame-retardant cotton fabrics by DSC, TGA, and PY–GC–MS. J Anal Appl Pyrol 71:645–655

Acknowledgments

This work was supported by a research studentship from The Hong Kong Polytechnic University granted to Dr. Ka-po Maggie Tang (RPPU). This work is part of a final-year project submitted by Sai-leung Tso in partial fulfilment of the requirements for a BA (Hons) degree at the Institute of Textiles and Clothing, The Hong Kong Polytechnic University. Thanks are also due to Huntsman for sponsoring of chemicals.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, Kp.M., Kan, Cw., Fan, Jt. et al. Effect of softener and wetting agent on improving the flammability, comfort, and mechanical properties of flame-retardant finished cotton fabric. Cellulose 24, 2619–2634 (2017). https://doi.org/10.1007/s10570-017-1268-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1268-z