Abstract

The removal of residual dyes in coloured textile wastewaters is mandatory, and a significant portion of the dyes used are cationic. Textile factories mainly process cotton yarns, and 8 % of this virgin feedstock is lost as cotton dust waste (CDW). Using factorial experimental design, this dust was derivatised with monochloroacetic acid (MCAA) to produce a partially carboxymethylated cellulose (CM−-CDW) with NaOH, MCAA and isopropanol for the retention of Basic Blue 41 dye (BB 41) (column and batch), and biodegradability was investigated. The dye retention efficiency was examined with additional experiments varying the initial concentration, contact time and addition of salts. Heteronuclear multiple bonding correlation-nuclear magnetic resonance confirmed the covalent insertion of CM− groups in the cellulosic fibres. The selected matrix provided a dye sorption of 58.33 (column) and 64.50 mg/g (batch). The Langmuir isotherm was a good fit to the sorption data. The efficiency of uptake of BB 41 was predominantly dictated by the concentration of alkali in the matrix synthesis. Biodegradability by cellulases was similar when using uncharged and dye-charged matrices. The latter were fully regenerated by washing in dilute acid. Retention was proportional to the initial dye concentration and the contact time required to reach equilibrium, which was longer for higher dye concentrations. The addition of 10 mmol/l NaCl decreased BB 41 retention by 50 %. Therefore, CM−-CDW proved effective for the removal of the cationic dye BB 41 and thus represents an important alternative in the treatment of coloured textile effluents.

Similar content being viewed by others

Introduction

The textile industry is among the most intensive global enterprises, with Brazil ranked 6th in the world. Cotton yarn is reported as the main textile feedstock, thus surpassing other fibres such as polyester and wool. Cotton fibres accept both anionic and cationic dyes (Cegarra 2000), and the staining losses are usually significantly high, in the range of 15–50 % in wastewater; this generates a serious environmental problem and hence the need for a local solution given the severe penalties imposed by environmental legislation. Coloured textile wastewaters block the transmission of light in rivers and lakes, and in doing so, they threaten the normal life and reproduction of both micro- and macro-biota (Robinson et al. 2001), in addition to preventing the use of these sources as drinking water for human and animal consumption. Several recent studies have made use of ligno(hemi)cellulosic [l(h)c] models like sugar cane bagasse for chemical derivatisation and then for the capture of textile dyes (Gurgel and Gil 2009; Kamel et al. 2012; Nada and Hassan 2006; Racz and Borsa 1997; Simkovic and Laszlo 1997; Tahir et al. 2012). Bagasse and related native materials from secondary or residual phytobiomasses are composed of cellulose: hemicelluloses: lignin in a roughly 50: 30: 20 proportion, and chemical derivatisation methods such as carboxymethylation require the previous mercerisation of the native fibres through strong alkaline conditions (e.g., NaOH ≥ 20 % w/v), causing high losses in the hemicellulose and lignin fractions since both are mostly alkali-solubilised (Gurgel and Gil 2009; Jiang et al. 2012). These losses may be somewhat reduced by exploring a supplemental chemical step, namely, the previous cross-linking of the polymeric triplet by forming a bridge between its ether and epichlorohydrin, again in a strongly alkaline reaction medium. In both cases, a parallel problem is generated, and the overall loss may be conveniently addressed before water disposal or reutilisation. In our laboratory experience, hemicellulose (heteroxylan) loss may account for 15–30 % of its original amount, depending on the severity of reaction parameters like NaOH concentration and temperature. Both alkaline extracts following filtration and centrifugation had the pH adjusted to 5.0 with glacial acetic acid (O’Dwyer 1939) followed by the addition of five vol of ethanol to ensure complete precipitation of hemicellulose and solubilisation of lignin and its fragments.

All of these facts prompted us to select a more appropriate initial cellulosic feedstock, in this case, cotton dust waste (CDW) from a textile factory, given its multiple advantages as indicated in Table 1, with an emphasis on the absence of both hemicellulose and lignin in it.

Materials and methods

Feedstock for derivatisation

Döhler S/A, a large textile factory in Joinville-SC (200,000 m2; 3,200 employees), a state in southern Brazil, provided CDW, a cellulosic residue generated during the spinning and weaving of cotton fibres and mostly corresponding to the smaller or shorter fibres that accumulate around textile machines and their surroundings. CDW is collected through sweeping and air aspirators, thus incorporating some ground dust and oil mist. All other chemicals were purchased from Sigma-Aldrich, St. Louis, MO, USA. The same factory provided Basic Blue 41 as well other reference dyes.

Carboxymethylation of cotton dust waste (CDW)

To achieve the partial carboxymethylation of CDW, we followed the general procedure previously published for sago waste (Pushpamalar et al. 2006) but adopted a 33−1 factorial design with a centre point in triplicate. The experimental variables included sodium hydroxide concentration [10 (−), 20 (0) and 30 (+) %, w/v], isopropanol (iPrOH) additive volume [0 (−20 (0) and 40 (+) ml)] and the amount of the derivatising agent monochloroacetic acid (MCAA) added [1 (−1), 2 (0) and 3 (+) g].

Assays were carried out in Erlenmeyer flasks (125 ml) in which 2 g of CDW was mercerised with 80 ml of NaOH and a given volume of iPrOH for 1 h. MCAA was then added, and the reaction was allowed to proceed for 1 h more. The entire experiment was conducted under agitation (200 rpm) in a Gyratory Water Bath Shaker (Newbrunswick, model G76) at 35 °C. The reaction media was filtered through fritted glass (40–100 µm) under vacuum, and the CM−-CDW cation exchange matrix was washed with water until reaching a neutral point; lyophylisation was the last step, using a FreeZone apparatus from LabConco. Other control samples were processed in parallel to assess the influence of each parameter in the preparation of CM−-CDW: this included the individual addition of H2O, NaOH, iPrOH or MCAA to the original cellulosic material, as well as some mixtures of their pairs (e.g., MCAA with NaOH or iPrOH).

Analysis of dye retention in CM −-CDW anion exchange cellulosic matrices in column and batch modes

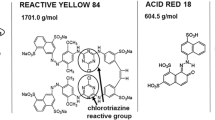

The dye assayed here as a model textile waste by product representing the environmental problem (C.I. Basic Blue 41, or BB 41), was obtained from the company DyStar® and donated by Döhler S/A. It is a cationic (basic; a quaternary amine) dye (Fig. 1) and it was selected due to its intensive use in cotton, wool and synthetic fibers dyeing.(Abbasi and Asl 2008; Fraga and Zanoni 2009; Roulia and Vassiliadis 2005). For instance, at Dohler S/A, the use of Astrazon Blue-like cationic dye (also computing de Red and Yellow variants) corresponds to around 5 % of all basic textile dyes and its main use is for polyacrylonitrile and anionized ethylene polytereftalate (PES−) dyeing. BB 41 has the following properties: maximum solubility in water of 40 g/l at 20 °C, octanol/water partition coefficient (Kow) of 0.007 and ε (molar absorbance coefficient) = 19,975, as determined at LQBB—Biomass Chemo/Biotechnology. The same textile factory also furnished other dye standards and some samples of coloured textile waste waters under in loco remediation. Thin layer chromatography (TLC) of these dyes was carried out on silica gel 60 chromatoplates (Merck) using a mix of chloroform: methanol: ethyl acetate: acetic acid: water (60: 20: 5: 1: 1) as the mobile phase.

Previously reported guidelines for Congo Red and Eosin Y (Ansari et al. 2012; Jiang et al. 2012) were followed to monitor the retention efficiency of the selected dye, cationic BB 41, from an aqueous stock solution of 500 mg/l at pH 6.8 on the anion exchange matrices (CM−-CDW series). Experiments were carried out in triplicate in both column and batch modes, including a comparison with a commercial sample of CM Cellulose (Sigma C-2883). The columns used were 1 ml transparent plastic pipette tips that had been filled with 0.1 g of CM− -CDW, receiving successive 1-ml dye loadings until reaching matrix saturation or the first light-coloured eluate. Batch experiments were carried out at 25 °C until reaching an equilibrium time of 24 h in agitated glass flasks containing 0.05 g of each kind of ionic matrix and 10 ml of dye solution.

The maximum absorbance value for BB 41, 601 nm, was obtained by scanning diluted BB 41 solutions in a Shimadzu UV-1659 PC spectrophotometer. The BB 41 dye concentration was calculated from a calibration curve ranging from 1 to 40 mg/l (y = 45.82 × and R2 = 0.999) using Excel software. For spectrophotometric readings, quartz cuvettes were used with a 1 cm path length and 1 ml volume. Any reading exceeding the absorbance value was repeated in appropriate dilutions with reverse osmosis water to improve accuracy. The total dye retained/g of derivatised CDW matrix was determined by using these measured dye concentrations and the exact amount of dye initially added to each matrix. The dye retention at equilibrium (q e ) was calculated using Equation 1:

where C i is the initial dye concentration (mg/l), C e is the final (residual) concentration of the dye (supernatant) after reaching equilibrium, V is the volume of the experimental solution put in contact with each ionic exchange matrix and W is the employed mass of each matrix. The result qe is expressed in mg/g.

Once the best CM−-CDW matrix was selected, the effect of varying dye concentrations (100, 200, 300, 400 and 500 mg/l) was evaluated in batch mode. Nine samples of supernatant were collected, from 30 to 1,440 min, to determine the needed time for equilibration (bound versus unbound dye).

Adsorption is usually described with an isotherm. The adsorption isotherm indicates how the adsorbed molecules are distributed between the liquid phase and solid phase when the adsorption process reaches an equilibrium state (Nwabanne and Igbokwe 2008). Freundlich and Langmuir isotherms are used in adsorption to understand the extent and degree of favourability of adsorption (Ding et al. 2008). Five dye solutions from 100 to 500 mg/l were assayed against normalised 0.05 g parcels of the selected CM−-CDW matrix, and the resulting data were then used to draw both types of isotherms according to their respective formulas (Jiang et al. 2012).

Since textile dyeing is usually carried out in the presence of salts and/or mordants, the influence of NaCl (0–100 mmol/l) on dye retention (500 mg/l) was estimated using the selected CM−-CDW matrix (0.05 g) in batch mode after an equilibration time of 6 h.

Biodegradability assay and chemical analyses of cellulolytic enzymatic fragments

Hundred-mg samples of each matrix were buffered with 5 ml of 50 mmol/l Na citrate–phosphate at pH 5.0, and then 2 µl of Cellic-2 cellulase and the same volume of β-glucosidase was added. Incubations were carried out at 50 °C for 72 h. Clean supernatants collected during the reaction period were analysed in triplicate for reducing and total sugars by the standard dinitrosalycilate (DNS) method (Miller 1959). The same enzymatic analytical approach was applied after saturation of the selected CM–-CDW matrix with the dye BB 41.

The released free sugars were also analysed by TLC using a silica gel 60 chromatoplate (Merck), using iProH: ethyl acetate : water (70: 1: 2) as the mobile phase and a spray of 0.5 % orcinol in sulphuric acid: methanol (10: 90) as the chromogenic reagent at 110 °C for a few minutes.

The same clean hydrolysates were analysed using 1H and 13C nuclear magnetic resonance (NMR) spectroscopy to determine their derived HMBC (heteronuclear multiple bond correlation) values, following our previously published method (Tiboni et al. 2012) designed for azure bacterial cellulose following its extensive depolymerisation by industrial cellulases.

CM−-CDW matrix regeneration/recycling

Following the recommended factory protocol for the regeneration of carboxymethylated resins (Sigma 1997), a representative sample of the utilised and fully coloured CM–-CDW matrix was cleaned of the dye BB 41 through several brief washings with 0.1 mol/l HCl, followed by single washings with 0.1 mol/l and 1.0 mol/l NaOH.

Statistical analysis

The results of all studied parameters were analysed through the Kolmogorov–Smirnov statistical method in order to evaluate the normality of the data distribution, which was expressed as mean ± standard deviation. Differences were tested by the two-tailed Student’s t test, ANOVA and the Tukey test. Values for which p < 0.05 were considered statistically significant. All statistical analyses were performed with the Statistica program (Statsoft Inc., USA).

Results and discussion

Experimental response from the factorial design

The experimental responses resulting from the fractionary factorial design for BB 41 retention on CM-CDW matrices and their biodegradability, compared with controls, are depicted in Table 2. Superscripted letters represent statistically different analysis groups according to Tukey’s test

Differences amongst the retention runs were clearly indicated by the Tukey statistical analyses. The CM−-CDW matrices 1 through 3, those synthesised with the lower NaOH concentrations, displayed reduced dye retention capacities, with average values of 5 and 20.51 mg/g in batch mode and in columns, respectively. Matrices from CM−-CDW 4 to 8, either with an increased NaOH concentration (20 and 30 %) or with the addition of iPrOH in the derivatisation step, corresponded to increased dye retention, improving from 16.67 to 32.22 mg/g in column mode and from 32.68 to 41.36 mg/g in batch mode. Once know the saturation limit of the column bed through the spectrophotometric measurement of the first coloured eluate, the experiment was repeated now feeding the column with equal successive smaller and normalized volume loadings of the same dye solution. This resulted, sometimes, in similar concentration of non retained dye in the eluate fractions following column saturation (e.g., CDW-CM− 1, 2 and 3).

Accordingly, the best retention results from all experiments, 88.33 and 60.93 mg/g in the column and batch modes, respectively, were obtained using matrix CM−-CDW 9, whose synthesis used the highest concentrations of carboxymethylation reagent, alkali and organosolvent additive. The latter value was three times greater than that average from the three runs performed with the lowest NaOH concentration, thus confirming the paramount role of the alkali concentration in the preparation of CM− matrices with improved dye binding capacity. More importantly, in the batch case, the addition of the largest volume of iPrOH led to a non-significant gain since the respective control (in the absence of the organosolvent) had already yielded a retention value of 64.50 mg/g. Therefore, the inclusion of iPrOH was no longer considered for the optimised carboxymethylation procedure since an additional environmental problem was avoided. The inclusion of the cosolvent iPrOH has been quoted by some authors as a useful aid when full carboxymethylation (three CM- groups/one anhydroglucose unit) is intended, compared with other organosolvents (methanol, ethanol, acetone and DMSO) (Pushpamalar et al. 2006; Tijsen et al. 2001). Table 2 also shows that the comparison between the column sorption (most preferred than the batch mode) of BB 41 by native cotton dust waste and the partially carboxymethylated derivative of the same matrix, the second proved to be 17.7 times more efficient than the former. This capacity could be better still explored through a somewhat higher degree of carboxymethylation although not reaching the inconvenient degree of substitution (DS) where the CM- derivative turns to a gelling state.

The increase of the reaction temperature from 25 to 50 °C has also been shown to be useful, as a previous study showed that dye binding on bituminous shale (not a cellulose derivative) increased from 55 to 118 mg/g (Müftüoglu et al. 2003). Furthermore, the last control matrix (CDW + NaOH + MCAA; 64.50 mg/g) was twice as effective as the commercial CM Cellulose brand (32.56 mg/g).

Linseed cake has also been evaluated for the same purpose, and its outstanding binding capacity for BB 41 (Liversidge et al. 1997) may be partially explained by the presence of some residual triacylglycerols (polyunsaturated fatty acids—PUFAs) in the L(h)C material and also by its surplus binding capacity toward the hydrophobic segments of cationic dye molecules.

Two dyes often used in cytochemical procedures, methylene blue (Basic Blue 9) and rhodamine G, yielded retentions of 185.63 and 118.21 mg/g, respectively, when assayed in highly carboxymethylated samples from garment workshops (Tian et al. 2014).

Statistical analyses yielded a linear model with R2 = 0.97 (adjusted R2 = 0.96) for both the column and batch experiments. ANOVA was significant for all secondary interactions and for isolated variables, as confirmed by values of F1.24 > 5.72, with particular emphasis on the NaOH concentration variable with F = 1,278.96 for column mode and F = 522.34 for batch mode, far greater than the other variables and interactions. The only exception to this was the interaction between iPrOH and MCAA in the column experiments. Higher F values are indicative of a marked difference in the retention results when the value of the NaOH factor shifts from (−) to (+) levels.

For all effects, the significance was calculated from the standard deviation from the primary effects, 1.13 (column) and 1.11 (batch), and second orders, 1.70 (column) and 1.67 (batch), then multiplied by the value ttab0,95.24 = 2.064, thus resulting in values of 2.33 and 2.29 (primary) and 3.51 and 3.45 mg/g (secondary), respectively. Based on these calculations, it may be observed from Fig. 2b that all effects were significant for batch experiments; the most important factor for the improved retention of a basic dye in CDW-carboxymethylated matrices was the concentration of NaOH used in the derivatisation procedure. The net retention enhancement from the proposed (−) to (+) levels was 25.41 mg/g. Conversely, the interaction between the cosolvent and the derivatisation reagent (MCAA) resulted in a net reduction in dye retention. The conclusions are the same for the corresponding column experiments, except for the interaction between iPrOH and MCAA, which was not significant (Fig. 2a).

In other studies using various L(h)Cs feedstocks for the capture of the cationic dye BB 9 (methylene blue), retention varied between 20.35 and 59.17 mg/g (Annadurai et al. 2002; Ferrero 2007; Hassan et al.). Our best result in column mode (88.33 mg/g) was between 4.3 and 1.5 times more efficient than these values, although BB 9 and BB 41 display some structural differences; both, however, have a representative positive charge attributed to the quaternary amine group.

Figure 3 shows the comparative efficiencies of the cation exchange matrices (0.05 g each) used in the factorial design for the synthesis of the CM−-CDW series. The equilibration time was 24 h. It can be observed that the simply mercerised CDW-OH− (C) led to negligible dye sequestration given 10 ml of dye solution at 50 mg/l (Fig. 3a). The commercial CM Cellulose performed better (Fig. 3b), and the most efficient retention corresponded to the CM−-CDW matrix (Fig. 3d). The commercial CM Cellulose and CM−-CDW matrices differ substantially in their physical aspects, the former being a fine powder, while the second is a fluffy fibrous material; this may explain the difference in retention even given the higher DS of the former.

Concerning the biodegradability of the carboxymethylated matrices and related polysaccharides, as shown in Table 2, native CDW and commercial CM Cellulose were minimally hydrolysed (<20 %), for different reasons: the former, because it is a native cellulosic architecture and very crystalline; the latter, because it is heavily carboxymethylated. CDW once mercerised and the somewhat similar product from drastic pulping, Whatman no 1 filter paper, displayed improved hydrolysis in the 62–69 % range. These figures further increased to 75 and 80 %, respectively, in samples CDW + NaOH + MCAA and CM−-CDW 9, both equally mercerised with the strongest alkali concentration (30 %) but differing in the presence of iPrOH. The hydrolysis of the remaining samples (CM−-CDW 1 through 7) varied from 57 to 85 %, depending on the synthesis parameters. The most likely reason for the highest biodegradability, observed in sample CM−-CDW 8 (91 %), may be that this sample had the lowest concentration of MCAA, and hence a lower DS was attained.

Statistical analyses also yielded a linear model with R2 = 0.88 (adjusted R2 = 0.86) for the biodegradability assay. ANOVA was also significant for all isolated variables and secondary interactions, except for the interaction between NaOH and iPrOH. The significance was confirmed with values of F1.24 > 5.72, with particular emphasis on the NaOH concentration variable with F = 791.51, far greater than the other variables and interactions. Higher F values are indicative of a marked difference in retention results when value of the NaOH factor shifts from (−) to (+). The significance was also calculated from the standard deviation from the primary effects (0.79) and second orders (1.20), then multiplied by the value ttab 0,95.24 = 2.064, thus resulting in values of 1.63 and 2.48 %, respectively. Based on these calculations, and as shown in Fig. 2c, the concentration of NaOH in the derivatisation procedure was the most important factor affecting the hydrolysis of CDW-carboxymethylated matrices. The net enhancement in retention upon shifting from the proposed (−) to (+) levels was 22.43 %.

Strong alkaline pretreatment of cellulosic materials causes drastic alterations in the architecture of the native polysaccharide chains. An inversion occurs as the parallel β-1,4-linked chains (allomorph I) become antiparallel chains (allomorph II). The hydrogen bond arrangement is also affected, as well as the crystalline index. Despite the primary C6-OH group of each anhydroglucopyranose ring being the most reactive because it has less steric hindrance (Sidley Chemical 2013), the covalent entry of substituents (e.g., CM−) is preferential at C2-OH (Heydarzadeh et al. 2009). When carboxymethylation goes to completion (C2, C6 and C3), the β-glucan backbone is then a less susceptible option for the binding and hydrolytic scission of the glucosidic linkages by cellulases. These considerations are in accordance with the high degree of hydrolysis displayed by our CM−-CDW matrix using the selected ratio, intended to restrict the average carboxymethylation just to one R-OH amongst the three available/anhydroglucose residue. The opposite effectively occurred with the commercial and highly substituted CM Cellulose, which was confirmed by the negative effect caused by an increase of MCAA content in the derivatisation medium (e.g., Fig. 2c; −8.43 % when MCAA was raised from 1 to 3 g). Even given the positive effect of the NaOH concentration, care should be taken since higher concentrations lead to the cogeneration of sodium glycolate (Tijsen et al. 2001).

The DS we have attained kept the original matrix as completely insoluble and fully prone to settle material thus facilitating its managing by simple filtration or centrifugation. Higher DS(s) and the consequent matrix gelation would turn the cation exchanger matrices more difficult to manage and recycle.

A subsequent unforeseen and fruitful parallel result was that the selected CM−-CDW matrix experienced only a 4.1 % decrease in the cellulolysis assay when it was previously fully charged with BB 41 dye.

Chemical and enzymatic characterisation of the CM−-CDW matrix

As previously explained, the CM−-CDW matrices were designed to result in partial (theoretically 33 %) carboxymethylation. A higher DS would result in a matrix with increased gelling behaviour, thus hampering the flowability of the cation exchange matrix.

Despite the limited DS (complete = 3; herein attained ≤1.0) of carboxymethyl groups, a TLC chromatographic inspection of the released carbohydrate fragments from CM−-CDW or commercial CM Cellulose and simply mercerised CDW, following extensive cellulolysis with cellulose + β-glucosidase, should show some distinctive features in their respective chromatographic profiles. This was indeed attained, as shown in Fig. 4.

As expected, given an appropriate load of the enzyme and other optimised kinetic conditions (temperature and incubation time), mercerised CDW resulted in the almost complete recovery of a single product, glucose (Rf = 0.69). Conversely and accordingly, both CM−-CDW and its related polysaccharide, a commercial sample of CM Cellulose, effectively released trace amounts of cellobiose (Rf = 0.59) in addition to glucose, as well as a larger oligosaccharide (Rf = 0.46) and minor amounts of even larger oligosaccharides, as a natural consequence of the insertion of carboxymethyl substituents, which created a steric barrier for more efficient enzyme action.

The clean supernatants of the previously described cellulolytic assays were examined by 1H and 13C-NMR in a liquid state (Fig. 5a) instead of as whole solid samples since the latter resulted in less intense signals. Figure 5b and c display these HMBC correlations for CM−-CDW as amplified images. From the derived HMBC spectrum in Fig. 5b, a clear correlation can be observed between the hydrogen atoms from α-carbonyl CH2 at 4.01–4.33 ppm (multiplet) and two carbonyls at 180.6 and 180.0 ppm. These last duplications may be explained by the partial carboxymethylation of two different -CH2–OH/–HCH–OH groups at the carbohydrate chain. The first multiplet (α-CH2 C=O) also correlates with carbons at 72.2 and 85.0 ppm (Fig. 5c), these belonging to the anhydropyranose ring of cellulose or its enzymatic fragments. This confirms the covalent linkage between the carboxymethyl substituent and a carbohydrate receptor.

NMR 13C assessment of carboxymethylation of cellulose is well marked when DS is 1.5 but scarcely visible when DS is reduced to 0.5. In the case of our more efficient matrix it resulted easier to detected the specific low field signal of the carboxymethyl group when the matrix was completely cellulolysed with industrial cellulases instead of performing the spectroscopy of the fibrous CM− polysaccharide (Fig. 5a, b).

Dye concentration and contact time for batch sorption and derived isotherms

The corresponding Langmuir isotherm for the sorption of BB 41 dye on a CDW-CM− sample (number 9) was obtained assaying five progressive dye concentrations (from 100 till 500 mg/l) as depicted in Fig. 6.

The initial dye concentration is a remarkable force pushing mass transfer from the liquid medium to the ion exchange matrix. In a previous study, peanut shells pretreated with HCl and immobilised on sodium alginate allowed the increased removal of Drimarine Black CL-B dye from 10 (control) to 200 mg/l not going beyond even when the dye concentration was raised to 600 mg/l (Noreen et al. 2013; Sadaf and Bhatti 2014). Similar results have been reported by others (Tan et al. 2008; Auta and Hameed 2013).

The adsorption isotherm data were fitted to the Langmuir isotherm equation, with a coefficient of determination value of 0.9717. The Langmuir parameter, qm, represents monolayer saturation at equilibrium when the surface is fully covered with dye molecules; the value obtained in this study was 76.92 mg/g. The other Langmuir constant, KL, indicates the affinity for BB 41 binding, with a value of 0.044 l/mg. The values of the dimensionless parameter RL were calculated according to RL = 1/1 + KL Co, and they fell in the range of 0 < RL < 1, between 0.185 to 0.029, depending on the initial concentration of the aqueous dye solution (100–500 mg/l), which confirmed a favourable adsorption process for BB 41 removal using CM−-CDW. It is apparent that derivatised CDW is a suitable sorbent for the removal of BB 41 from aqueous solution within the conditions used in this study. At all concentrations tested, saturation was observed, and the equilibrium state was reached and maintained.

Effect of salt and pH on dye retention

The inclusion of electrolytes (such as salts or mordants) during textile dyeing is a routine procedure. Hence, wastewaters usually contain additional contamination. The presence of these salts in textile effluents is one of the factors that control the electrostatic and non-electrostatic interactions between the surface of an ion exchange matrix and the dye molecules and therefore affect the retention capacity (Sadaf and Bhatti 2014). The influence of common salt (NaCl at concentrations up to 100 mmol/l = 0.59 %) was investigated with respect to its influence on BB 41 sorption on the CM−-CDW cation exchange matrix, as displayed in Fig. 7. The presence of salt at 10 mmol/l (ca. 0.06 %) reduced the sorption process by 50 %, which further increased to 85 % at 50 mmol/l; this same loss in sorption was maintained even at 100 mmol/l NaCl (no statistical difference between these two more elevated salt concentrations). It is interesting to note the salt concentration of approximately 20 mmol/l in the effluent wastewater of Döhler S/A. Doubtless, salt inclusion in the assayed dye solution implies in a competing ion exchange mechanism (BB41 + vs Na+) for the available anionic CM− counter-ions of the exchanger matrix.

The pH(s) of the model dye BB 41 solution was 7.5 and that of the virgin CDW-CM− (just suspended in water) was 8.1. BB 41 does not experience neither significant colour/hue variation nor retention efficiency variation around the best pH range of cation exchange, this determined by the specific pKa = 4.7 of the strategic CM− groups. The referred assayed range was either 1 pH unit above or 1 unit below such as pKa value. Whenever needed, the pH value of the dye solution or any correspondent coloured wastewater can be adjusted with minimum amounts of the less expensive NaOH or HCl solutions.

BB 41 chromatographic profile and CM−-CDW regeneration/recycling

TLC indicated that the dye BB 41, as opposed to three other industrial reactive textile dyes, is a relatively pure substance, as shown in Fig. 8a as an almost pure single spot (Rf = 0.95); the composition of the other examined industrial dyes such as Reactive Red 239 and Reactive Black 5 is heterogeneous.

a TLC profile of BB 41 and other textile dyes. (1) Reactive Black 5; (2) BB 41; (3) Reactive Red 239; (4) Basic Red 18:1. b Regeneration time course of a BB 41- saturated column. Fractions 1–5 came from column elution with 0.1 mol/l HCl followed by 0.1 mol/l and 1.0 mol/l NaOH (fractions 6 and 7, respectively)

Using the recommended protocol for the regeneration of carboxymethylated insoluble polysaccharides published by the manufacturer, namely, diluted mineral acid and alkali (0.1 mol/l) washings, CM−-CDW proved to be satisfactorily regenerated and reusable as shown in Fig. 8b. Most (>75 %) of the bound dye BB 41 was eluted in the first washing with 1 ml of 0.1 mol/l HCl (fraction 2) just after the void volume, then regeneration approached completion in the next 3–5 fractions with the same eluent. The minor coloured fractions in fractions six and seven may correspond to minor contaminants of BB 41 indicated earlier by the higher Rf(s) in the TLC plate from Fig. 8a.

Our best cationic exchanger matrix could allow the sorption and then the concentration of BB 41 from a coloured textile waste stream by a factor of 100× or more. Since the matrix can be recycled and reused, the retained dye can be further eluted by 0.1 mmol/l HCl as a fast and ultraconcetrated eluate. Disconsidering a second reuse of this dye solution, its chemical or microbiological degradations could be addressed, respectively, either by ultrasonication coupled to nanoTiO2 and H2O2 or by Pseudomonas putida (Abbasi and Asl 2008; Khan et al. 2013).

Conclusions

Cotton dust waste, which is inexpensive and readily available in loco in textile factories, was revealed as an attractive feedstock compared with a ligno(hemi)cellulosic model, native cane bagasse, for the chemical synthesis of an anionic partially carboxymethylated derivative as an ion exchange matrix for the removal of the cationic dye Basic Blue 41.

Factorial designs exploring the concentrations of the anionic reagent MCAA and of the strong alkaline catalyst NaOH, as well the addition or absence of the cosolvent iPrOH, allowed the synthesis of improved dye-sequestering matrices: higher reagent concentrations led to better matrices. In batch mode experiments, the selected CM−-CDW matrix retained 64.50 mg/g of the cationic dye Basic Blue 41. The experimental sorption data fit well in a Langmuir isotherm (76.92 mg/g) with R2 = 0.9717. The presence of salts in conjunction with residual basic dye in the wastewater diminishes the ion exchange capacity of CM−-CDW by 50–85 %. Advantageously, the dye-saturated CM−-CDW ion exchange matrix could be quickly regenerated and then reutilised after simple washings with a very diluted hydrochloric acid solution. Advantageously, the dye-saturated CM−-CDW ion exchange matrix could be quickly regenerated taking advantage of the affinity constant and then reutilised after simple washings with a very diluted hydrochloric acid solution.

Considering the low if not the negative material cost for the cellulosic feedstock, as well as the international prices for MCAA (in the range of US$ 590–620/metric ton, taking into account China’s current offers for this reagent) (Alibaba 2014), the chemical procedure and the obtained high dye sorption performance make the optimised CM− matrix very attractive for scaled-up experiments of the remediation of dye-coloured wastewater in the textile factory industry.

References

Abbasi M, Asl NR (2008) Sonochemical degradation of Basic Blue 41 dye assisted by nanoTiO2 and H2O2. J Hazard Mater 153:942–947. doi:10.1016/j.jhazmat.2007.09.045

Alibaba (2014) Henan Xinxiang Zhongyuan Chemical Co., Ltd. Monocloroacetic acid cotation. http://hnzyyjhg.en.alibaba.com/product/556257370-213473867/monochloroacetic_acid_97_5_price.html. Accessed 10 Jan 2014

Annadurai G, Juang R-S, Lee D-J (2002) Use of cellulose-based wastes for adsorption of dyes from aqueous solutions. J Hazard Mater 92:263–274. doi:10.1016/S0304-3894(02)00017-1

Ansari R, Seyghali B, Mohammad-khah A, Zanjanchi MA (2012) Highly efficient adsorption of anionic dyes from aqueous solutions using sawdust modified by cationic surfactant of cetyltrimethylammonium bromide. J Surfactants Deterg 15:557–565. doi:10.1007/s11743-012-1334-3

Auta M, Hameed BH (2013) Coalesced chitosan activated carbon composite for batch and fixed-bed adsorption of cationic and anionic dyes. Colloids Surf B 105:199–206

Cegarra J (2000) Biotecnologia aplicada aos processos de química têxtil. Química Têxtil 58:5–14

Ding C, Li Z, Yan J, Jin J (2008) Adsorption behavior of p-chlorophenol on the reed wetland soils. J Environ Sci Technol 1:169–174

Ferrero F (2007) Dye removal by low cost adsorbents: Hazelnut shells in comparison with wood sawdust. J Hazard Mater 142:144–152. doi:10.1016/j.jhazmat.2006.07.072

Fraga LE, Zanoni MVB (2009) Photoelectrocatalytical degradation of Basic Blue 41 dye using nanoporous semiconductor Ti/TiO2. Eclet Quim 34:27–36

Gurgel LVA, Gil LF (2009) Adsorption of Cu(II), Cd(II) and Pb(II) from aqueous single metal solutions by succinylated twice-mercerized sugarcane bagasse functionalized with triethylenetetramine. Water Res 43:4479–4488. doi:10.1016/j.watres.2009.07.017

Hassan W, Farooq U, Ahmad M, Athar M, Khan MA Potential biosorbent, Haloxylon recurvum plant stems, for the removal of methylene blue dye Arabian. J Chem. doi:10.1016/j.arabjc.2013.05.002

Heydarzadeh HD, Najafpour GD, Nazari-Moghaddam AA (2009) Catalyst-free conversion of alkali cellulose to fine carboxymethyl cellulose at mild conditions. World Appl Sci J 6:564–569

Jiang G-B, Lin Z-T, Huang X-Y, Zheng Y-Q, Ren C-C, Huang C-K, Huang Z-J (2012) Potential biosorbent based on sugarcane bagasse modified with tetraethylenepentamine for removal of eosin Y. Int J Biol Macromol 50:707–712. doi:10.1016/j.ijbiomac.2011.12.030

Kamel S, Abou-Yousef H, Yousef M, El-Sakhawy M (2012) Potential use of bagasse and modified bagasse for removing of iron and phenol from water. Carbohydr Polym 88:250–256. doi:10.1016/j.carbpol.2011.11.090

Khan SS, Arunarani A, Chandran P (2013) Biodegradation of Basic Violet 3 and Acid Blue 93 by Pseudomonas putida. Clean Soil Air Water 41:1–6

Liversidge RM, Lloyd GJ, Wase DAJ, Forster CF (1997) Removal of Basic Blue 41 dye from aqueous solution by linseed cake. Process Biochem 32:473–477. doi:10.1016/S0032-9592(96)00107-0

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Müftüoglu A, Karakelle B, Ergin M, Erkol A, Yilmaz F (2003) The removal of Basic Blue 41 dye from aqueous solutions by bituminous shale. Adsorpt Sci Technol 21:751–760. doi:10.1260/026361703773581803

Nada AA, Hassan ML (2006) Ion exchange properties of carboxylated bagasse. J Appl Polym Sci 102:1399–1404. doi:10.1002/app.24255

Noreen S, Bhatti HN, Nausheen S, Sadaf S, Ashfaq M (2013) Batch and fixed bed adsorption study for the removal of Drimarine Black CL-B dye from aqueous solution using a lignocellulosic waste: A cost affective adsorbent. Ind Crops Prod 50:568–579. doi:10.1016/j.indcrop.2013.07.065

Nwabanne JT, Igbokwe PK (2008) Kinetics and equilibrium modeling of nickel adsorption by cassava peel. J Eng Appl Sci 3:829–834

O’Dwyer MH (1939) The hemicelluloses of the wood of English oak. Biochem J 33:713–717

Pushpamalar V, Langford SJ, Ahmad M, Lim YY (2006) Optimization of reaction conditions for preparing carboxymethyl cellulose from sago waste. Carbohydr Polym 64:312–318. doi:10.1016/j.carbpol.2005.12.003

Racz I, Borsa J (1997) Swelling of carboxymethylated cellulose fibres. Cellulose 4:293–303. doi:10.1023/a:1018400226052

Robinson T, McMullan G, Marchant R, Nigam P (2001) Remediation of dyes in textile effluent: a critical review on current treatment technologies with a proposed alternative. Bioresour Technol 77:247–255. doi:10.1016/S0960-8524(00)00080-8

Roulia M, Vassiliadis AA (2005) Interactions between C.I. Basic Blue 41 and aluminosilicate sorbents. J Colloid Interface Sc 291:37–44. doi:10.1016/j.jcis.2005.04.085

Sadaf S, Bhatti HN (2014) Batch and fixed bed column studies for the removal of Indosol Yellow BG dye by peanut husk. J Taiwan Inst Chem Eng 45:541–553. doi:10.1016/j.jtice.2013.05.004

Sidley Chemical (2013) Enzymatic Properties of Hydroxy Ethyl Cellulose. http://celluloseether.com/enzymatic-hydroxy-ethyl-cellulose/. Accessed 28 de dez. de 2013

Sigma (1997) Regeneration of CM Cellulose. https://www.sigmaaldrich.com/content/dam/sigma-aldrich/docs/Sigma/Product_Information_Sheet/c4146pis.pdf

Simkovic I, Laszlo JA (1997) Preparation of ion exchangers from bagasse by crosslinking with epichlorohydrin–NH4OH or epichlorohydrin-imidazole. J Appl Polym Sci 64:2561–2565

Tahir H, Sultan M, Akhtar N, Hameed U, Abid T (2012) Application of natural and modified sugar cane bagasse for the removal of dye from aqueous solution. J Saudi Chem Soc. doi:10.1016/j.jscs.2012.09.007

Tan IAW, Ahmad AL, Hameed BH (2008) Adsorption of basic dye on high-surface-area activated carbon prepared from coconut husk: equilibrium, kinetic and thermodynamic studies. J Hazard Mater 154(1–3):337–346. doi:10.1016/j.jhazmat.2007.10.031

Tian D, Zhang X, Lu C, Yuan G, Zhang W, Zhou Z (2014) Solvent-free synthesis of carboxylate-functionalized cellulose from waste cotton fabrics for the removal of cationic dyes from aqueous solutions. Cellulose 21:473–484

Tiboni M et al (2012) The use of dyed bacterial cellulose to monitor cellulase complex activity. Cellulose 19:1867–1877. doi:10.1007/s10570-012-9787-0

Tijsen CJ, Kolk HJ, Stamhuis EJ, Beenackers AACM (2001) An experimental study on the carboxymethylation of granular potato starch in non-aqueous media. Carbohydr Polym 45:219–226. doi:10.1016/S0144-8617(00)00243-5

Acknowledgments

The authors would like to thank the National Council for Scientific and Technological Development (CNPq), Coordination for the Improvement of Higher Education Personnel (CAPES) and the Araucaria Foundation from SETI-PR.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baldo, G.R., Döhler, L., Grzybowski, A. et al. Partially carboxymethylated cotton dust waste for sorption of textile wastewater coloured with the cationic dye Basic Blue 41 as a model: synthesis, regeneration and biodegradability. Cellulose 21, 3041–3053 (2014). https://doi.org/10.1007/s10570-014-0304-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0304-5