Abstract

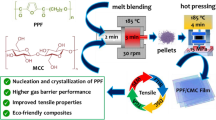

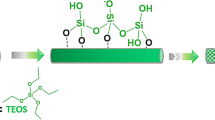

Nanocomposites of polyamides with cellulose whiskers are difficult to obtain by conventional processing of extrusion and injection molding because of the low thermal stability of the cellulosic nanostructures and the relatively high processing temperature of polyamides, which is higher than the temperature of thermal degradation of cellulose whiskers. Thus, in this study cellulose whiskers were coated with polyamide 6 (PA6) in order to increase their thermal stability and prevent the formation of agglomerates. This coating on cellulose whiskers allows their application to obtain nanocomposites with polyamides, whose processing temperatures are relatively high, around 250 °C. Cellulose whiskers (CWs) were obtained from cotton fibers by acid hydrolysis. The freeze-dried CWs were coated with PA6 by dispersing them in formic acid; PA6 was solubilized in this suspension. The cellulose-coated whiskers (CCWs) were characterized by X-ray diffraction, differential scanning calorimetry (DSC), thermogravimetry (TG), scanning electron microscopy (SEM-FEG) and infrared spectroscopy. SEM-FEG and TG results showed that the PA6 coating on CWs prevented high agglomeration of dried CWs and promoted an increase in their thermal stability from 180 to 280 °C, allowing the use of CCWs to obtain nanocomposites with PA6 using conventional processing routes, such as extrusion and injection molding, at appropriate processing temperatures. In this way, 1 wt% CCWs was used to prepare nanocomposites with PA6. The PA6 + 1CW nanocomposites were compared to neat PA6 without CWs. The samples were characterized by tensile tests and DSC, and the results showed that the PA6 coating on CWs was effective in raising the thermal stability of CWs, improving the dispersion of CWs in the matrix of PA6, resulting in a 45 % increase in the elastic modulus of the nanocomposite with only 1 wt% of coated cellulose whiskers in comparison to neat PA6.

Similar content being viewed by others

References

Azouz KB, Ramires EC, Van den Fonteyne W, El Kissi N, Dufresne A (2012) Simple method for the melt extrusion of a cellulose nanocrystal reinforced hydrophobic polymer. ACS Macro Lett 1(1):236–240

Bittencourt PRS (2008) Náilon 6 e 6,6 em blendas com lignina Kraft modificada por ácido fórmico: caracterização e efeito de radiação UV. PhD Thesis. University of Maringa, Brazil

Borysiak S, Garbarczyk J (2003) Applying the WAXS method to estimate the supermolecular structure of cellulose fibres after mercerization. Fibres Text East Eur 11, 5(44):104–106

Corrêa AC, Teixeira EM, Pessan LA, Mattoso LHC (2010) Cellulose nanofibers from curaua fibers. Cellulose 17:1183–1192

Dufresne A (2006) Comparing the mechanical properties of high performances polymer nanocomposites from biological sources. J Nanosci Nanotechnol 6:322–330

Eichhorn SJ (2011) Cellulose nanowhiskers: promising materials for advanced applications. Soft Matter 7:303–315

Evora MC, Gonçalez OL, Dutra RCL, Diniz MF, Wiebeck H, Silva LGA (2002) Comparação de Técnicas FTIR de Transmissão, Reflexão e Fotoacústica na Análise de Poliamida-6, Reciclada e Irradiada. Polímeros: Ciência e Tecnologia 12(1):60–68

French AD (2013) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose. doi:10.1007/s10570-013-0030-4

Hubbe MA, Rojas OJ, Lucia LA, Sain M (2008) Cellulosic nanocomposites: a review. BioResources 3(3):929–980

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85

Kataoka Y, Kondo T (1998) FT-IR microscopic analysis of changing cellulose crystalline structure during wood cell wall formation. Macromolecules 31(3):760–764

Khanna YP, Kuhn WP (1997) Measurement of crystalline index in nylons by DSC: complexities and recommendations. J Polym Sci B Polym Phys 35(14):2219–2231

Kiziltas A, Gardner DJ, Han Y, Yang HS (2011) Dynamic mechanical behavior and thermal properties of microcrystalline cellulose (MCC)-filled nylon 6 composites. Thermochim Acta 519:38–43

Kiziltas A, Nazari B, Gardner DJ, Bousfield DW (2013) Polyamide 6–cellulose composites: effect of cellulose composition on melt rheology and crystallization behavior. Polym Eng Sci. doi:10.1002/pen.23603

Leite AMD, Araújo EM, Lira HL, Barbosa R, Ito EM (2009) Obtenção de Membranas Microporosas a partir de Nanocompósitos de Poliamida 6/Argila Nacional. Parte 1: Influência da Presença da Argila na Morfologia das Membranas. Polímeros: Ciência e Tecnologia 19(4):271–277

Lin N, Dufresne A (2013) Physical and/or chemical compatibilization of extruded cellulose nanocrystal reinforced polystyrene nanocomposites. Macromolecules 46(14):5570–5583

Marcilla A, Menargues AGS (2005) TG/FTIR study of the thermal pyrolysis of EVA copolymers. J Anal Appl Pyrolysis 74:224–230

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Oliveira MFL, Oliveira MG, Leite MCAM (2011) Nanocompósitos de poliamida 6 e argila organofílica: estudo da cristalinidade e propriedades mecânicas. Polímeros 21(1):78–82

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941

Qua EH, Hornsby PR (2011) Preparation and characterization of nanocellulose reinforced polyamide-6. Plast Rubber Compos 40(6/7):300–306

Roman M, Winter WT (2004) Effect of sulfate groups from sulfuric acid hydrolysis on the thermal degradation behavior of bacterial cellulose. Biomacromolecules 5:1671–1677

Roy D, Semsarilar M, Guthrie JT, Perrier S (2009) Cellulose modification by polymer grafting: a review. Chem Soc Rev 38:2046–2064

Silva R, Haraguchi SK, Muniz EC, Rubira AF (2009) Aplicações de fibras lignocelulósicas na química de polímeros e em compósitos. Quim Nova 32(3):661–671

Silverstein RM, Bassler GC, Morril TC (1979) Identificação espectrométrica de compostos orgânicos. Ed. Guanabara II, Rio de Janeiro

Spinacé MAS, Lambert CS, Fermoselli KKG, De Paoli MA (2009) Characterization of lignocellulosic curaua fibres. Carbohydr Polym 77:47–53

Teixeira EM, Corrêa AC, Manzoli A, Leite FL, Oliveira CR, Mattoso LHC (2010) Cellulose nanofibers from white and naturally colored cotton fibers. Cellulose 17:595–606

Teixeira EM, Bondancia TJ, Teodoro KBR, Correa AC, Marconcini JM, Mattoso LHC (2011) Sugarcane bagasse whiskers: extraction and characterizations. Ind Crops Prod 33:63–66

Tonoli GHD, Teixeira EM, Corrêa AC, Marconcini JM, Caixeta LA, Pereira-da-Silva MA, Mattoso LHC (2012) Cellulose micro/nanofibres from Eucalyptus kraft pulp: preparation and properties. Carbohydr Polym 89:80–88

Wang N, Ding E, Cheng R (2007) Thermal degradation behaviors of spherical cellulose nanocrystals with sulfate groups. Polymer 48:3486–3493

Zuluaga R, Putaux JL, Restrepo A, Mondragon I, Gañán P (2007) Cellulose microfibrils from banana farming residues: isolation and characterization. Cellulose 14:585–592

Acknowledgments

The authors gratefully acknowledge the financial support provided by FAPESP (process no. 08/03606-9), CAPES, FINEP and EMBRAPA.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Corrêa, A.C., de Morais Teixeira, E., Carmona, V.B. et al. Obtaining nanocomposites of polyamide 6 and cellulose whiskers via extrusion and injection molding. Cellulose 21, 311–322 (2014). https://doi.org/10.1007/s10570-013-0132-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-0132-z