Abstract

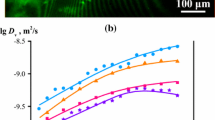

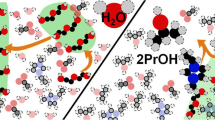

The diffusion dynamics of 1-Butyl-3-methylimidazolium chloride ([BMIM]Cl) during coagulation process of cellulose filaments with H2O as non-solvent were investigated in detail. The diffusion coefficients of [BMIM]Cl was calculated based on the Fick’s second law of diffusion according to the experimental data. Several factors which affect the coagulation process including polymer concentration, concentration and temperature of coagulation bath were discussed respectively. It is found that the diffusion rate of [BMIM]Cl decreased with the increasing polymer content in the spinning solutions and the initial concentration of [BMIM]Cl in the coagulation bath, while the diffusion coefficients increased largely with the coagulation temperature becoming higher. The diffusion coefficients of [BMIM]Cl is relatively lower, in contrast with the conventional solvent in the solution spinning process, which is coordinate with the result of polyacrylonitrile [BMIM]Cl system by Zhang et al. (Polym Eng Sci 48(1):184–190, 2008). Compared with the diffusion process of N-methylmorpholine-N-oxide (NMMO) from cellulose filament, the diffusion coefficients of [BMIM]Cl is lower, which suggested a stronger coagulation and washing conditions should be taken to produce regenerated cellulose fiber with [BMIM]Cl as solvent.

Similar content being viewed by others

References

Biganska O, Navard P (2005) Kinetics of precipitation of cellulose from cellulose-NMMO-water solutions. Biomacromolecules 6(4):1948–1953

Biganska O, Navard P (2009) Morphology of cellulose objects regenerated from cellulose–N-methylmorpholine N-oxide–water solutions. Cellulose 16(2):179–188

Cai J, Zhang L (2005) Rapid dissolution of cellulose in LiOH/urea and NaOH/urea aqueous solutions. Macromol Biosci 5:539–548

Csihony S, Fischmeister C, Bruneau C, Horváth IT, Dixneuf PH (2002) First ring-opening metathesis polymerization in an ionic liquid. Efficient recycling of a catalyst generated from a cationic ruthenium allenylidene complex. New J Chem 26(11):1667–1670

Cuissinat C, Navard P, Heinze T (2008) Swelling and dissolution of cellulose. Part IV: free floating cotton and wood fibres in ionic liquids. Carbohydr Polym 72:590–596

Fink H, Weigel P, Purz H, Ganster J (2001) Structure formation of regenerated cellulose materials from NMMO-solutions. Prog Polym Sci 26:1473–1524

Fukaya Y, Sugimoto A, Ohno H (2006) Superior solubility of polysaccharides in low viscosity, polar, and halogen-free 1, 3-Dialkylimidazolium formates. Biomacromolecules 7:3295–3297

Gavillon R, Budtova T (2007) Kinetics of cellulose regeneration from cellulose-NaOH-water gels and comparison with cellulose-N-methylmorpholine-N-oxide-water solutions. Biomacromolecules 8(2):424–432

Heinze T, Liebert T (2001) Unconventional methods in cellulose functionalization. Prog Polym Sci 26:1689–1762

Heinze T, Schwikal K, Barthel S (2005) Ionic liquids as reaction medium in cellulose functionalization. Macromol Biosci 5:520–525

Hermanutz F, Gähr F, Uerdingen E, Meister F, Kosan B (2008) New developments in dissolving and processing of cellulose in ionic liquids. Macromol Symp 262:23–27

Kosan B, Michels C, Meister F (2008) Dissolution and forming of cellulose with ionic liquids. Cellulose 15:59–66

Liu RG, Hu XC (2006) Precipitation kinetics of cellulose in the Lyocell spinning process. Ind Eng Chem Res 45(8):2840–2844

Sammons R, Collier J, Rials T, Petrovan S (2008) Rheology of 1-Butyl-3-methylimidazolium chloride cellulose solutions. I. shear rheology. J Appl Polym Sci 110:1175–1181

Sun N, Swatloski RP, Maxim ML, Rahman M, Harland AG, Haque A, Spear SK, Daly DT, Rogers RD (2007) Magnetite-embedded cellulose fibers prepared from ionic liquid. J Mater Chem 18:283–290

Swatloski R, Spear S, Holbrey J, Rogers R (2002) Dissolution of cellulose with ionic liquids. J Am Chem Soc 124(18):4974–4975

Terbojevich M, Cosani A, Conio G, Ciferri A, Bianchi E (1985) Mesophase formation and chain rigidity in cellulose and derivatives. 3. Aggregation of cellulose in N, N-dimethylacetamide-lithium chloride. Macromolecules 18:640–646

Zhang H, Wu J, Zhang J, He J (2005) 1-Allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277

Zhang H, Wang Z, Zhang Z, Wu J, Zhang J, He J (2007) Regenerated cellulose/multiwalled-carbon-nanotube composite fibers with enhanced mechanical properties prepared with the ionic liquid 1-Allyl-3-methylimidazolium chloride. Adv Mater 19:698–704

Zhang Y, Tu X, Liu W, Wang H (2008) Diffusion dynamics of ionic liquids during the coagulation of solution spinning for acrylic fibers. Polym Eng Sci 48(1):184–190

Acknowledgments

The work was supported by a grant from National Natural Science Foundation of China (50873025), Shanghai Leading Academic Discipline Project, and Project Number: B603 and the Innovation Funds for PhD Students (Jiang Guansen) of Donghua University. Meanwhile, we thank Shandong Helon Co., Ltd, China for the providing of cotton linter pulp.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, G., Huang, W., Zhu, T. et al. Diffusion dynamics of 1-Butyl-3-methylimidazolium chloride from cellulose filament during coagulation process. Cellulose 18, 921–928 (2011). https://doi.org/10.1007/s10570-011-9551-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-011-9551-x