Abstract

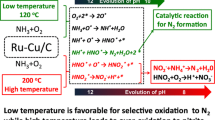

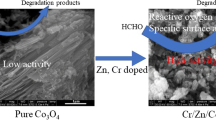

Formaldehyde-water-trioxane (HCHO–H2O–TOX) tends to form a stable azeotrope and the HCHO solution can also produce multiple by-products, making it challenging to refine and obtain high-purity TOX, resulting in increased energy consumption. Formic acid (FA) is the most easily generated and undesirable main byproduct of HCHO, which has strong corrosiveness to production equipment. However, the negative impact of HCHO mentioned above is often overlooked because of its low concentration. In this study, the CuO/ZnO–AlN catalyst was synthesized using a simple deposition precipitation method. The catalyst demonstrated a high removal rate of HCHO and inhibition of FA, along with excellent hydrothermal stability. Aluminum nitride (AlN) can form a layer of Al(OH)3 coating, acting as a physical barrier against H2O during the reaction process and releasing trace OH− to facilitate the formation of Cannizaro intermediates. It can then catalyze HCHO dehydrogenation under alkaline-free conditions to form H2 and an intermediate (HCOO−), which is further converted to H2 and CO2 under the influence of Cu0. The relevant characterization results showed that Cu0 is the active site. The strong interaction between AlN and copper refines the particle size of CuO and promotes the reduction of CuO to Cu0. In addition, an H2 atmosphere can more effectively inhibit the oxidation of Cu0 compared to an N2 atmosphere, resulting in a higher HCHO removal rate. This rate can reach 100% at 105 ℃ and 4 MPa H2 and almost no FA can be detected in the product. Cycling tests proved that the prepared catalyst could be recycled and reused three times without a noticeable reduction in catalytic activity, demonstrating its good application potential.

Graphical Abstract

Similar content being viewed by others

References

Liu H, Wang J, Jiang P, Yan F (2020) Durability of fiber-reinforced polyoxymethylene composites under the high hydrostatic pressure in the deep sea. J Appl Polym Sci 137:48686

Penick K, Solchaga LA, Berilla JA, Welter JFM (2010) Performance of polyoxymethylene plastic (POM) as a component of a tissue engineering bioreactor. J Biomed Mater Res A 75:168–174

Gao H, Zhang J, Wang R, Wang M (2015) Highly efficient hydrogen production and formaldehyde degradation by Cu2O microcrystals. Appl Catal B Environ 172:1–6

Gao Y, Sun S, He Y, Wang X, Wu D (2011) Effect of poly(ethylene oxide) on tribological performance and impact fracture behavior of polyoxymethylene/polytetrafluoroethylene fiber composites. Compos B 42:1945–1955

Wang X, Duan Z, Wei R, Lei Q, Chen H (2023) Production of trioxane from formaldehyde via hierarchical beta zeolite synthesized using a cationic polymer. Catal Lett. https://doi.org/10.1007/s10562-022-04265-z

Curioni A, Sprik M, Andreoni W (1997) Density functional theory-based molecular dynamics simulation of acid-catalyzed chemical reactions in liquid trioxane. J Am Chem Soc 119:7218–7229

Tanaka M, Ogino K (2006) Study of trioxane production process with super-or subcritical fluid as solvent and extractant. Synth Commun 36:1927–1932

Grützner T, Hasse H, Lang N, Siegert M, Ströfer E (2007) Development of a new industrial process for trioxane production. Chem Eng Sci 62:5613–5620

Martin R (1954) The mechanism of the Cannizzaro reaction of formaldehyde. Aust J Chem 7:335–347

Osada M, Watanabe M, Sue K, Adschiri T, Arai K (2004) Water density dependence of formaldehyde reaction in supercritical water. J Supercrit Fluids 28:219–224

Popova GY, Andrushkevich TV, Chesalov YA, Parmon VN (2007) Transient response study of the formaldehyde oxidation to formic acid on V-Ti–O catalyst: FTIR and pulse study. J Mol Catal A 268:251–256

Shen Y, Ning F, Bai C, Zhan Y, Li S, Huang Y, Zhou X (2018) Hydrogen generation from s-trioxane and water catalytic reforming: a solid organic hydrogen carrier. ACS Appl Energy Mater 1:4860–4866

Ken-ichi M, Michio E (1985) Formaldehyde electro-oxidation on copper metal and copper-based amorphous alloys in alkaline media. Bull Chem Soc Jpn 58:2043–2050

Jin Z, Jacobsen N, Li P, Liu G (2013) Enhancing catalytic formaldehyde oxidation on CuO-Ag2O nanowires for gas sensing and hydrogen evolution. J Mater Chem A 1:14736–14743

Bi Y, Lu G (2008) Nano-Cu catalyze hydrogen production from formaldehyde solution at room temperature. Int J Hydrogen Energy 33:2225–2232

Du L, Qian K, Zhu X, Yan X, Kobayashi H, Liu Z, Lou Y, Li R (2019) Interface engineering of palladium and zinc oxide nanorods with strong metal–support interactions for enhanced hydrogen production from base-free formaldehyde solution. J Mater Chem A 7:8855–8864

Ashby EC, Doctorovich F, Liotta CL, Neumann HM, Barefield EK, Konda A, Zhang K, Hurley J, Siemer DD (1993) Concerning the formation of hydrogen in nuclear waste. Quantitative generation of hydrogen via a Cannizzaro intermediate. J Am Chem Soc 115:1171–1173

Liu Y, Max M, David M, Alonso JA (2015) Effects of water on the copper-catalyzed conversion of hydroxymethylfurfural in tetrahydrofuran. ChemSusChem 8:3983–3986

Kocjan A, Dakskobler A, Krnel K, Kosma T (2011) The course of the hydrolysis and the reaction kinetics of AlN powder in diluted aqueous suspensions. J Eur Ceram Soc 31:815–823

Kosmac̆ T, Novak S, Sajko M (1997) Hydrolysis-assisted solidification (HAS): a new setting concept for ceramic net-shaping. J Eur Ceram Soc 17:427–432

Novak S, Kosma T, Krnel K, Drai G (2002) Principles of the hydrolysis assisted solidification (HAS) process for forming ceramic bodies from aqueous suspension. J Eur Ceram Soc 22:289–295

Krnel K, Kocjan A, Kosmac T (2010) A simple method for the preparation of nanostructured aluminate coatings. J Am Chem Soc 92:2451–2454

Fukumoto S, Hookabe T, Tsubakino H (2000) Hydrolysis behavior of aluminum nitride in various solutions. J Mater Sci 35:2743–2748

Krnel K, Kosmac T (2004) Reactivity of AlN powder in an aqueous environment. Key Eng Mater 264–268:29–32

Bowen P, Highfield JG, Mocellin A, Ring TA (1990) Degradation of aluminum nitride powder in an aqueous environmet. J Am Ceram Soc 73:724–728

Paul MA (2002) A kinetic salt effect on the acid-catalyzed decomposition of trioxane. J Am Chem Soc 74:141–143

Wyatt VT, Gary DS, Alberto N (2010) The Lewis acid-catalyzed synthesis of hyperbranched oligo(glycerol–diacid)s in aprotic polar media. J Am Oil Chem Soc 87:1359–1369

Chen Z, Ge H, Wang P, Sun J, Chen J (2020) Insight into the deactivation mechanism of water on active Cu species for ester hydrogenation: experimental and theoretical study. Mol Catal 488:110919

Shi R, Zhao J, Quan Y, Pei Y, Wang X, Li Z, Ren J (2021) Carbon-supported nitrogen-doped graphene-wrapped copper nanoparticles: an effective catalyst for the oxidative carbonylation of methanol. Ind Eng Chem Res 60:2944–2953

Jingren Y, Deqian Z, Hongfei Z, Qingshui X, Jian H, Lang X, Dongliang P (2018) 3D graphene encapsulated ZnO-NiO-CuO double-shelled hollow microspheres with enhanced lithium storage properties. J Alloy Compd 765:1158–1166

Zhou M, Li J, Wang K (2017) Selective conversion of furfural to cyclopentanone over CNT-supported Cu based catalysts: model reaction for upgrading of bio-oil. Fuel 202:1–11

Gao P, Li F, Xiao F, Zhao N, Wei W, Zhong L, Sun Y (2012) Effect of hydrotalcite-containing precursors on the performance of Cu/Zn/Al/Zr catalysts for CO2 hydrogenation: introduction of Cu2+ at different formation stages of precursors. Catal Today 194:9–15

Mccue AJ, Mcritchie CJ, Shepherd AM, Anderson JA (2014) Cu/Al2O3 catalysts modified with Pd for selective acetylene hydrogenation. J Catal 319:127–135

Fu T, Wang X, Zheng H, Li Z (2017) Effect of Cu location and dispersion on carbon sphere supported Cu catalysts for oxidative carbonylation of methanol to dimethyl carbonate. J Carbon 115:363–374

Hong ZS, Cao Y, Deng JF, Fan KN (2002) CO2 hydrogenation to methanol over Cu/ZnO/Al2O3 catalysts prepared by a novel gel-network-coprecipitation method. Catal Lett 82:37–44

Boyce AL, Graville SR, Sermon PA (1991) Reduction of CuO-containing catalysts, CuO: I: TPR and TGA. React Kinet Catal Lett 44:309

Leilei D, Kaicheng Q, Xiaohui Z, Xiaoqing Y, Kobayashi H, Zhiqi L, Yupeng L, Renhong L (2019) Interface engineering of palladium and zinc oxide nanorods with strong metal-support interactions for enhanced hydrogen production from base-free formaldehyde solution. J Mater Chem A 7(15):8855–8864

Funding

This work was supported by Sichuan Science and Technology Program (2023YFG0104).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors state that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, R., Lei, Q., Deng, C. et al. Improving Catalytic Performance and Stability of Copper-Zinc Based Catalyst on Aluminum Nitride for Formaldehyde Removal from Crude Trioxane. Catal Lett (2024). https://doi.org/10.1007/s10562-024-04592-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10562-024-04592-3