Abstract

Ni catalysts impregnated on CaO–Al2O3 with various Al/Ca molar ratios were synthesized, and employed in the glycerol steam reforming process to investigate the effect of calcium content on the catalyst efficiency. The prepared catalysts were characterized by XRD, BET, H2-TPR, CO2-TPD and SEM analyses. According to the preliminary tests, the characteristic features of the catalysts were directly affected by the Al/Ca molar ratio. The specific surface area and total pore volume increased with increasing in Al2O3 content. Meanwhile, the higher CaO content increased the catalyst reducibility and also the concentration of basic sites. The sample with Al/Ca of 2 had the best performance with glycerol conversion of 99.4% and H2 yield of 99.9% at 700 °C. Moreover, the results revealed that the catalyst calcined at 500 °C, and reduced at 700 °C possessed a glycerol conversion of 99.4% and this catalyst was selected as the best sample among the studied catalysts.

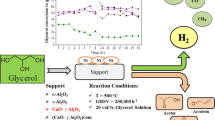

Graphical Abstract

Similar content being viewed by others

References

Akbari E, Alavi SM, Rezaei M, Larimi AS (2022) Preparation and evaluation of A/BaO-MnOx catalysts (A: Rh, Pt, Pd, Ru) in lean methane catalytic combustion at low temperature. Int J Energy Res 46(5):6292–6313.

Akbari E, Alavi SM, Rezaei M, Larimi AS (2022) CeO2-promoted BaO-MnOx catalyst for lean methane catalytic combustion at low temperatures: Improved catalytic efficiency and light-off temperature. Int J Hydrog Energy 47:13004–13021.

Dawood F, Anda M, Shafiullah GM (2020) Hydrogen production for energy: an overview. Int J Hydrogen Energy 45:3847–3869

Kaviani M, Rezaei M, Alavi SM, Akbari E (2022) High coke resistance Ni-SiO2@SiO2 core-shell catalyst for biogas dry reforming: Effects of Ni loading and calcination temperature. Fuel 330:125609–125628.

Meshkani F, Rezaei M (2015) Preparation of nanocrystalline metal (Cr, Al, Mn, Ce, Ni, Co and Cu) modified ferrite catalysts for the high temperature water gas shift reaction. Renewable Energy 74:588–598

Xiao Z, Li L, Wu C, Li G, Liu G, Wang L (2016) Ceria-promoted Ni–Co/Al2O3 catalysts for n-dodecane steam reforming. Catal Lett 146:1780–1791

Abatzoglou N, Fauteux-Lefebvre C (2016) Review of catalytic syngas production through steam or dry reforming and partial oxidation of studied liquid compounds. WIREs Energy Environ 5:169–187

Men Y, Kolb G, Zapf R, Hessel V, Löwe H (2007) Ethanol steam reforming in a microchannel reactor. Process Saf Environ Prot 85:413–418

Gu Y, Jerome F (2010) Glycerol as a sustainable solvent for green chemistry. Green Chem 12:1127–1138

Senseni AZ, Rezaei M, Meshkani F (2017) Glycerol steam reforming over noble metal nano catalysts. Chem Eng Res Des 123:360–366

Schwengber CA, Alves HJ, Schaffner RA, Silva FAD, Sequinel R, Bach VR, Ferracin RJ (2016) Overview of glycerol reforming for hydrogen production. Renew Sustain Energy Rev 58:259–266

Yus M, Soler J, Herguido J, Menéndez M (2017) Glycerol steam reforming with low steam/glycerol ratio in a two-zone fluidized bed reactor. Catal Today 229:317–327

Saeidabad NG, Noh YS, Eslami AA, Song HT, Kim HD, Fazeli A, Moon DJ (2020) A review on catalysts development for steam reforming of biodiesel derived glycerol. Promot Supports Catal 10:910

Wang Y, Li Y, Yang L, Fan X, Chu L (2022) Revealing the effects of Ni on sorption-enhanced water-gas shift reaction of CaO for H2 production by density functional theory. Process Saf Environ Prot 157:254–265

Bepari S, Kuila D (2019) Steam reforming of methanol, ethanol and glycerol over nickel-based catalysts-a review. Int J Hydrogen Energy 45:18090–18113

Dahdah E, Estephane J, Gennequin C, Aboukaïs A, Abi-Aad E, Aouad S (2020) Zirconia supported nickel catalysts for glycerol steam reforming: Effect of zirconia structure on the catalytic performance. Int J Hydrogen Energy 45:4457–4467

Gharahshiran VS, Yousefpour M, Amini V (2020) A comparative study of zirconia and yttria promoted mesoporous carbon-nickel-cobalt catalysts in steam reforming of ethanol for hydrogen production. Mol Catal 484:110767

Vaidya PD, Rodrigues AE (2009) Glycerol reforming for hydrogen production: a review. Chem Eng Technol 32:1463–1469

Carrero A, Calles J, Moreno LG, Vizcaíno A (2017) Production of renewable hydrogen from glycerol steam reforming over bimetallic Ni- (Cu Co, Cr) catalysts supported on SBA-15 silica. Catalysts 7:55–59

Penner S (2017) Reforming Catalysts. Catalysts 7:334

Chimentao RJ, Miranda BC, Szanyi J, Sepulveda C, Santos JBO, Correa JVS, Llorca J, Medina F (2017) Sources of deactivation during glycerol conversion on Ni/-Al2O3. Mol Catal 435:49–57

Zamzuri NH, Mat R, Amin NAS, Kiakalaieh AT (2016) Hydrogen production from catalytic steam reforming of glycerol over various supported nickel catalysts. Int J Hydrogen Energy 42:9087–9098

Padmakar D, Surendar M, Chandrashekar P, Lingaiah N (2020) A highly stable and efficient Co–Mg–Sr mixed oxide catalysts for hydrogen production from glycerol steam reforming. Catal Lett 150:2734–2743

Menezes J, Jácome F, Manfro R, Souza M (2019) Effect of CaO addition on nickel catalysts supported on alumina for glycerol steam reforming. Catal Lett 149:1991–2003

Inokawa H, Nishimoto S, Kameshima Y, Miyake M (2011) Promotion of H2 production from ethanol steam reforming by zeolite basicity. Int J Hydrogen Energy 36:15195–15202

Feng P, Huang K, Xu Q, Qi W (2020) Ni supported on the CaO modified attapulgite as catalysts for hydrogen production from glycerol steam reforming. Int J Hydrogen Energy 45:8223–8233

Senseni AZ, Meshkani F, Rezaei M (2016) Steam reforming of glycerol on mesoporous nanocrystalline Ni/Al2O3 catalysts for H2 production. Int J Hydrogen Energy 41:20137–20146

Gallo A, Pirovano C, Ferrini P, Marelli M, Psaro R, Santangelo S, Faggio G, Santo VD (2012) Influence of reaction parameters on the activity of ruthenium based catalysts for glycerol steam reforming. Appl Catal B 121:40–49

Siew KW, Lee HC, Gimbun J, Chin SY, Khan MR, Taufiq-Yap YH, Cheng CK (2015) Syngas production from glycerol-dry (CO2) reforming over La-promoted Ni/Al2O3 catalyst. Renewable Energy 74:441–447

Naeem MA, Armutlulu A, Kierzkowska A, Müller CR (2017) Development of High-performance CaO-based CO2 Sorbents Stabilized with Al2O3 or MgO. Energy Procedia 114:158–166

Xu L, Miao Z, Song H, Chen W, Chou LJ (2015) Significant roles of mesostructure and basic modifier for ordered mesoporous Ni/CaO–Al2O3 catalyst towards CO2 reforming of CH4. Catal Sci Technol 4:1759–1770

Haryanto A, Fernando SD, Murali N, Adhikari S (2005) Current status of hydrogen production techniques by steam reforming of ethanol: a review. Energy Fuels 19:2098–2106

Xu L, Song H, Chou L (2012) One-Pot synthesis of ordered mesoporous NiO−CaO−al2o3composite oxides for catalyzing CO2 reforming of CH4. ACS Catal 2:1331–1342

Varbar M, Alavi SM, Rezaei M, Akbari E (2022) Cobalt promoted Ni/MgAl2O4 catalyst in lean methane catalytic oxidation. Res Chem Intermed 48:1129–1150.

Jing J, Zhang Z, Wang S, Li W (2018) Influence of calcination temperature on the structure and catalytic reforming performance of Ni/CaO-Al2O3 catalyst. J Fuel Chem Technol 46:673–679

Jing J, Wang S, Zhang X, Li Q, Li W (2017) Influence of Ca/Al molar ratio on structure and catalytic reforming performance of Ni/CaO-Al2O3 catalyst. J Fuel Chem Technol 45:956–962

Kazemi S, Alavi SM, Rezaei M (2022) Hydrogen production from COx Free thermocatalytic decomposition of methane over the mesoporous iron aluminate spinel (FeAl2O4) nanopowder supported nickel catalysts. Int J Hydrog Energy 47:18370–18383.

Charisiou ND, Papageridis KN, Tzounis L, Sebastian V, Hinder SJ, Baker MA, AlKetbi M, Polychronopoulou K, Goula MA (2018) Ni supported on CaO-MgO-Al2O3 as a highly selective and stable catalyst for H2 production via the glycerol steam reforming reaction. Int J Hydrogen Energy 44(1):256–273

Kitamura S, Su-enaga T, Ikenaga N, Miyake T, Suzuki T (2011) Steam reforming of glycerin using ni-based catalysts loaded on CaO–ZrO2 solid solution. Catal Lett 141:498–905

Acknowledgements

The authors gratefully acknowledge the support received from the Iran National Science Foundation (INSF) with grant number of 97017638.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sabokmalek, S., Alavi, S.M., Rezaei, M. et al. Hydrogen Production by Glycerol Steam Reforming on the Ni/CaO-Al2O3 Catalysts: The Study of Synergistic Effect Between CaO and Al2O3. Catal Lett 153, 3698–3711 (2023). https://doi.org/10.1007/s10562-022-04247-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-022-04247-1