Abstract

Photocatalytic nitrate removal to produce recyclable netrogen (N2) without using chemical reductants is regarded as an environmentally friendly and effective technology for denitrification. However, the sluggish cathode reaction kinetics severely hampered the efficiency of nitrate reduction reaction (NO3RR). Developing high performance photocatalyst is highly pursued for boosting NO3RR. In this study, Bi2MoO6 nanosheets with massive oxygen vacancies are fabricated through hydrothermal reaction and subsequent plasma modification. Maximal nitrate conversion yield of 38% with the high N2 selectivity of 80.0% is achieved for photocatalytic NO3RR. The underlying photocatalytic mechanism is systemically investigated through comprehensive approaches. The enhanced nitrate conversion efficiency is mainly attributed to the synergistic effect between deliberately generated oxygen vacancies and Mo active sites, capturing O and N atoms of nitrate, respectively, thus promoting the adsorption of nitrate and cleavage of N–O bond. Furthermore, the H “repulsion” effect of Bi efficiently suppresses hydrogenation reaction, resulting in greatly enhanced N2 selectivity.

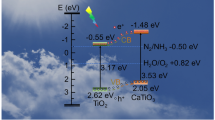

Graphical Abstract

The generation of oxygen vacancy leads to the cleavage of N-O bond in NO3-, which also enhances the adsorption of nitrate. The specific adsorption of nitrogen on active Mo site is enhanced, and the repulsion of element Bi to protons enhances the selectivity of N2 in the product.

Similar content being viewed by others

References

Anjana SU, Iqbal M (2007) Agron. Sustainable Dev 27:45–57

Garcia-Segura S, Lanzarini-Lopes M, Hristovski K et al (2018) Appl Catal, B 236:546–568

Saravanakumar D, Song J, Lee S et al (2017) Chemsuschem 10:3999–4003

Ensie B, Samad S (2014) Desalination 347:1–9

Su JF, Ruzybayev I, Shah I et al (2016) Appl Catal, B 180:199–209

Tałałaj IA, Biedka P, Bartkowska I (2019) Environ Chem Lett 17:1177–1193

Liu C, Dermody D, Harris K et al (2017) ACS Comb Sci 19:422–436

Sposob M, Bakke R, Dinamarca C (2017) Bioresour Technol 233:209–215

Ma J, Yang Q, Wang S et al (2010) J Hazard Mater 175:518–523

Fessenden RW, Meisel D, Camaioni DM (2000) J Am Chem Soc 122:3773–3774

Bems B, Jentoft FC, Schlögl R (1999) Appl Catal, B 20:155–163

Cook AR, Dimitrijevic N, Dreyfus BW et al (2001) J Phys Chem A 105:3658–3666

Chen F, Yang Q, Wang Y et al (2017) Appl Catal, B 205:133–147

Li H, Shang J, Ai Z et al (2015) J Am Chem Soc 137:6393–6399

Di J, Zhao X, Lian C et al (2019) Nano Energy 61:54–59

Guo Q, Zhou C, Ma Z et al (2016) Chem Soc Rev 45:3701–3730

Li H, Li J, Ai Z et al (2018) Angew Chem Int Ed 57:122–138

Serpone N (2006) J Phys Chem B 110:24287–24293

Li H, Sun B, Xu Y et al (2018) J Colloid Interface Sci 531:664–671

Dou S, Tao L, Wang R et al (2018) Adv Mater 30:1705850

Zhao J, Chen Z (2017) J Am Chem Soc 139:12480–12487

Geng J, Ji S, Xu H et al (2021) Inorg Chem Front 8:5209–5213

Greeley J, Jaramillo TF, Bonde J et al (2006) Nat Mater 5:909–913

Wu S, Xiong J, Sun J et al (2017) ACS Appl Mater Interfaces 9:16620–16626

Zhang N, Jalil A, Wu D et al (2018) J Am Chem Soc 140:9434–9443

Dai W, Long J, Yang L et al (2021) J Energy Chem 61:281–289

Li Y, Go YK, Ooka H et al (2020) Angew Chem Int Ed 59:9744–9750

Chen Y, Yang W, Gao S et al (2018) ACS Appl Nano Mater 1:3565–3578

Kongmark C, Coulter R, Cristol S et al (2012) Cryst Growth Des 12:5994–6003

Li G, Yang W, Gao S et al (2021) Chem Eng J 404:127115

Loyalka SK, Riggs CA (1995) Appl Spectrosc 49:1107–1110

Yandulov DV, Schrock RR (2003) Science 301:76–78

Li H, Li W, Gu S et al (2017) J Mol Catal 433:301–312

Liu G, Yang HG, Wang X et al (2009) J Phys Chem C 113:21784–21788

Wang S, Ding X, Yang N et al (2020) Appl Catal B 265:118585

He D, Li Y, Ooka H et al (2018) J Am Chem Soc 140:2012–2015

Hao Y-C, Guo Y, Chen L-W et al (2019) Nat Catal 2:448–456

Trasatti S (1972) J Electroanal Chem Interfacial Electrochem 39:163–184

Marković NM, Ross PN (2002) Surf Sci Rep 45:117–229

Acknowledgements

This work was supported by the Natural Science Foundation of China (No. 52101279), Natural Science Foundation of Hunan Provience (No. 2020JJ5688), Science Research Initiation Fund of Central South University (No. 202045012), Jiangsu Key Laboratory for Carbon-Based Functional Materials & Devices, Soochow University.

Author information

Authors and Affiliations

Contributions

Y K: Investigation, Methodology, Writing—original draft. Z Z: Formal analysis. X W: Data Curation. X C: Writing—review & editing. S J: Resources, Conceptualization& supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kang, Y., Zhao, Z., Wu, X. et al. Plasma Engraved Bi2MoO6 for Enhanced Photocatalytic Nitrate Reduction Reaction. Catal Lett 153, 432–440 (2023). https://doi.org/10.1007/s10562-022-03987-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-022-03987-4