Abstract

The response surface methodology was used for the optimization of different submerged fermentation conditions for the production of recombinant laccase Lcc1 in Pichia pastoris KM71H. The initial screening of production parameters was performed using a Plackett–Burman design, and the variables with significant effects on laccase production were identified as follows: medium initial pH, methanol additive amount and liquid volume. These variables were selected for further optimization studies using a Box-Behnken design. The results indicated that the optimum fermentation conditions were as follows: medium optimal initial pH value of 7.01, methanol additive amount of 0.63% (v/v) per 24 h and liquid volume of 19.50% (v/v). These conditions provided the highest laccase enzyme activity of 12,491 U/L, resulting in a 3-fold increase in the production of recombinant laccase. Using industrial basic salt as culture medium, the maximum enzyme activity of Lcc1 was 22,594 U/L after high-density fermentation, which was 1.8-fold increase by shake flask optimization. Furthermore, partially purified laccase was used for the degradation of the octyl phenol and 4-tert-octylphenol, which displayed excellent degradation capacity. After 24 h, the degradation rate of 200 mg/L of 4-tert-octylphenol at 40 °C, pH 4.5 using 50 mM tartaric acid buffer with 1500 U/L purified laccase enzyme in L/A (laccase/ABTS) system was 97.2%. For octyl phenol, the degradation rate was 93.1%. All of the results suggested that the laccase Lcc1 significantly reduced or eliminated the toxicity of octyl phenol and 4-tert-octylphenol, which may be suitable for typical phenolic pollutants in the environment.

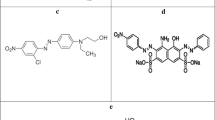

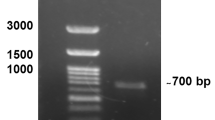

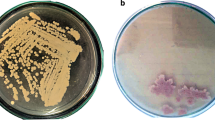

Graphical Abstract

Similar content being viewed by others

References

Yang X, Wu Y, Zhang Y et al (2020) Front Microbiol 11:241

Liu M, Dong H, Wang M et al (2020) J Genet 99:23

Zhang CY, You SP, Liu YD et al (2020) Biores. Technol. 305:123085

Zhou WT, Zhang WX, Cai YP (2020) Chem. Eng. J. 403:126272

Jiang YP, Cai JL, Pei JJ et al (2021). ACS Omega. https://doi.org/10.1021/acsomega.1c00370

Christopher LP, Yao B, Ji Y (2014). Front Energ Res. https://doi.org/10.3389/fenrg.2014.00012

Aracri E, Fillat A, Colom JF et al (2010) Biores Technol 101:8211–8216

Aza P, Salas FD, Molpeceres G et al (2021) Int J Mol Sci 22:1157

Li Q, Pei JJ, Zhao LG et al (2014) Appl Biochem Microbiol 50:140–147

Bezerra MA, Santelli RE, Oliveira EP et al (2008) Talanta 76:965–977

Amin M, Bhatti HN, Sadaf S, et al (2021) Cataly Lett 2

Bartley ML, Boeing WJ, Daniel D et al (2016) J Appl Phycol 28:15–24

Unuofin JO, Okoh AI, Nwodo UU (2019) J Environ Manage 231:222–231

Jegatheesan M, Eyini M (2015) Arab J Sci Eng 40:1809–1818

Diwaniyan S, Sharma KK, Kuhad RC (2012) J Basic Microbiol 52:397–407

Knapczyk-Stwora K, Nynca A, Ciereszko RE et al (2020) Theriogenology 153:102–111

Ffwa B, Yan Z, Xyza B et al (2020) J Chromatography A 1635:461765

Jeannot R, Sabik H, Sauvard E et al (2002) J Chromatogr A 974:143–159

Tsuda T, Takino A, Kojima M et al (1999) J Chromatography B 723:273–279

Zhang KW, Sai YE, Guang-Shui NA et al (2008) Chin J Analysis Lab 27:62–66

Wang H, Deng W, Shen M et al (2020) J Hazardous Mater 408:124775

Maryskova M, Linhartova L, Novotny V et al (2021). Environ Sci Pollut Research. https://doi.org/10.1007/s11356-021-12910-0

Li Q, Zhao DX, Liu SP et al (2014) J Nanjing Forestry Univ (Nat Sci Edtn) 38(3):93–97

Childs RE, Bardsley WG (1975) Biochem J 145:93–103

Bradford MM (1976) Anal Biochem 72:248–254

Burman JP, Plackett RL (1946) Biometals 33:305–325

Box G, Behnken DW (1960) Technometrics 2:455–475

Kececioglu D, Lamarre G (1978) Nucl Eng Des 50:149–162

El-Naggar EA (2019).

Kumari A, Mahapatra P, Banerjee R (2009) Braz Arch Biol Technol 52:1349–1356

Xia J, Wang Q, Luo Q et al (2019) Process Biochem 78:33–41

Vicente AI, Via-Gonzalez J, Santos-Moriano P et al (2016) J Mol Catal B Enzymatic 134:323–330

Yasmina M, Zhou S, Cusano AM et al (2014) J Biosci Bioeng 117(1):25–27

Danilo R, Chiara CM, Maurizio R et al (2010) FEMS Yeast Res 6:892–902

Bailey MJ, Adamitsch B, Rautio J et al (2007) Enzyme Microb Technol 41:484–491

Liang X, Hua DL, Zhao YX et al (2020) BioResources 15:9

Xie HF, Li Q, Wang MM et al (2013) J Microbiol Biotechnol 23(6):864–871

Hilgers RJ, Vincken JP, Gruppen H et al (2018) Acs Sust Chem Eng 6:2037–2046

D ‘Acunzo F, Galli C, Masci B (2010) Febs J 269:5330–5335

Wells A, Teria M, Eve T (2006) Biochem Soc Trans 34:304–308

Habimana P, Gao J, Mwizerwa JP et al (2021). ACS Omega. https://doi.org/10.1021/acsomega.0c05081

Zhao J, Zeng SQ, Xia Y et al (2018) J Biosci Bioeng 125(4):371–376

Xia TT, Feng M, Liu CL, et al. Eng Life Sci 1–8 (2021).

Qiu X, Wang Y, Xue Y et al (2019) Chem Eng J 391:123564

Gu Y, Xue P, Shi K (2020) J Porous Mater 27:73–82

Acknowledgements

This work was supported by the International Advanced Forestry Science and Technology Project Imported by State Forestry Administration (Grant No. 2011-4-15, 2010-4-19).

Author information

Authors and Affiliations

Contributions

Author contributions were as follows: Qi Li, Changsheng Chai, and Linguo Zhao conceived and designed the experiments; Qi Li performed all the experiments and analyzed the data; Yitong Du and Junli Cai helped to perform the experiments; Qi Li wrote the paper. All authors have read and approved the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Q., Chai, C., Du, Y. et al. Recombinant Laccase Production Optimization in Pichia pastoris by Response Surface Methodology and Its Application in the Biodegradation of Octyl Phenol and 4-Tert-Octylphenol. Catal Lett 152, 1086–1099 (2022). https://doi.org/10.1007/s10562-021-03682-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-021-03682-w