Abstract

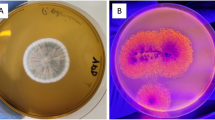

The present study aims to produce a mycelium-bound lipase of the fungus Rhizopus oryzae CCT3759 by submerged fermentation in order to be applied as biocatalyst in the hydrolysis of different vegetable oils. Optimal cultivation conditions have been achieved in a medium containing olive oil as inducer for 72 h of fermentation, thus obtaining 30.5 g/L of dry biomass concentration and hydrolytic activity of 389.1 U/g, which corresponds to a total lipase activity around of 12,000 U/L. Maximum hydrolytic activity was observed at pH 6.0 and 40 °C. Kinetic parameters concerning apparent Michaelis–Menten constant (Km = 50.5 mM) and maximum reaction rate (Vmax = 815.4 µmol/g min) have been determined in olive oil emulsion hydrolysis. Thermal stability tests revealed that the enzyme retained 75% of its initial activity after 4 h at 50 °C, whose thermal inactivation constant (Kd) and half-life (t1/2) was 0.073 h−1 and 9.4 h, respectively. The effect of biocatalyst concentration, expressed as activity units—U (200 and 400 U), on the hydrolysis of vegetable oils was investigated under fixed conditions: oil/buffer mass ratio of 25% (m/m), 100 mM buffer sodium phosphate pH 6.0, 40 °C and the mechanical stirring frequency of 600 rpm. As expected, increasing the initial activity from 200 to 400 U leads to higher values of initial reaction rates and hydrolysis percentage. However, initial reaction rate values were similar for six different vegetable oils due to the high accessibility of the lipase to the substrate under such experimental conditions. A complete hydrolysis of olive, cottonseed, sunflower and canola oils has been achieved after 26–30 h of reaction using 400 U of activity. These results suggest a promising application of the produced biocatalyst in the production of free fatty acids, an important class of compounds for oleochemical industries.

Graphic Abstract

Similar content being viewed by others

References

https://www.statista.com/statistics/263933/production-of-vegetable-oils-worldwide-since-2000/

Cavalcante FTT, Neto FS, Falcão IRA et al (2020) Opportunities for improving biodiesel production via lipase catalysis. Fuel 288:119577

Costa MJ, Silva MRL, Ferreira EEA et al (2020) Enzymatic biodiesel production by hydroesterification using waste cooking oil as feedstock. Chem Eng Process 157:108131

Zhong L, Feng Y, Wang G et al (2020) Production and use of immobilized lipases in/on nanomaterials: a review from the waste to biodiesel production. Int J Biol Macromol 152:207–222

Zhou GX, Chen GY, Yan BB (2015) Two-step biocatalytic process using lipase and whole cell catalysts for biodiesel production from unrefined jatropha oil. Biotechnol Lett 37:1959–1963

Jadhav JV, Anbu P, Yadav S et al (2019) Sunflower acid oil-based production of rhamnolipid using Pseudomonas aeruginosa and its application in liquid detergents. J Surfactants Detergent 22:463–476

Sena HH, Sanches MA, Rocha DFS, et al (2018) Production of biosurfactants by soil fungi isolated from the Amazon forest. Int J Microbiol, Article ID 5684261

Silva RCFS, Almeida DG, Meira HM et al (2017) Production and characterization of a new biosurfactant from Pseudomonas cepacia grown in low-cost fermentative medium and its application in the oil industry. Biocatal Agric Biotechnol 12:206–215

Reis WSM, Ferreira RDM, Pereira EB (2020) Immobilization of commercial lipase onto different supports: characterization and application in esterification reaction. Int J Eng Res Sci 6:15–24

Sá AGA, Meneses AC, Araújo PHH et al (2017) A review on enzymatic synthesis of aromatic esters used as flavor ingredients for food, cosmetics and pharmaceuticals industries. Trends Food Sci Technol 69:95–105

Alang MB, Ndikontar MK, Sani YM et al (2018) Synthesis and characterisation of a biolubricant from Cameroon palm kernel seed oil using a locally produced base catalyst from plantain peelings. Green Sustain Chem 8:275–287

Lage FAP, Bassi JJ, Corradini MCC et al (2016) Preparation of a biocatalyst via physical adsorption of lipase from Thermomyces lanuginosus on hydrophobic support to catalyze biolubricant synthesis by esterification reaction in a solvent-free system. Enzyme Microb Technol 84:56–67

Bassi JJ, Todero LM, Lage FAP et al (2016) Interfacial activation of lipases on hydrophobic support and application in the synthesis of a lubricant ester. Int J Biol Macromol 92:900–909

Fernandes KV, Papadaki A, da Silva JAC et al (2018) Enzymatic esterification of palm fatty-acid distillate for the production of polyol esters with biolubricant properties. Ind Crops Prod 116:90–96

Svar S, Kv R (2018) Vegetable oils as bio-lubricants. J Biotechnol Bioeng 5:1091

Akil E, Pereira AS, El-Bacha T et al (2020) Efficient production of bioactive structured lipids by fast acidolysis catalyzed by Yarrowia lipolytica lipase, free and immobilized in chitosan-alginate beads, in solvent-free medium. Int J Biol Macromol 163:910–918

Moreira DKT, Gandra RLP, Zuin JC et al (2020) Synthesis and characterization of structured lipid rich in behenic acid by enzymatic interesterification. Food Bioprod Process 122:303–310

Paula AV, Nunes GFM, Castro HF et al (2015) Synthesis of structured lipids by enzymatic interesterification of milkfat and soybean oil in a basket-type stirred tank reactor. Ind Eng Chem Res 54:1731–1737

Anand A, Weatherley LR (2018) The performance of microbial lipase immobilized onto polyolefin supports for hydrolysis of high oleate sunflower oil. Process Biochem 68:100–107

Istyami AN, Soerawidjaja TH, Prakoso T (2018) Mass balances and thermodynamics study of thermal triglyceride hydrolysis. MATEC Web Conf 156:1–5

Zarli A (2019) Oleochemicals: all time players of green chemistry. In: Studies in surface science and catalysis, pp 77–95

Ferreira MM, Oliveira GF, Basso RC et al (2019) Optimization of free fatty acid production by enzymatic hydrolysis of vegetable oils using a non-commercial lipase from Geotrichum candidum. Bioprocess Biosyst Eng 42:1647–1659

Nitbani FO, Tjitda PJP, Nurohmah BA et al (2020) Preparation of fatty acid and monoglyceride from vegetable oil. J Oleo Sci 69:277–295

Byreddy AR, Rao NM, Barrow CJ et al (2017) Tween 80 influences the production of intracellular lipase by Schizochytrium S31 in a stirred tank reactor. Process Biochem 53:30–35

Gonçalves MCP, Kieckbusch TG, Perna RF et al (2019) Trends on enzyme immobilization researches based on bibliometric analysis. Process Biochem 76:95–110

Rios NS, Pinheiro BB, Pinheiro MP et al (2018) Biotechnological potential of lipases from Pseudomonas: sources, properties and applications. Process Biochem 75:99–120

Rodrigues RC, Virgen-Ortíz JJ, Santos JCS et al (2019) Immobilization of lipases on hydrophobic supports: immobilization mechanism, advantages, problems, and solutions. Biotechnol Adv 37:746–770

Navvabi A, Razzaghi M, Fernandes P et al (2018) Novel lipases discovery specifically from marine organisms for industrial production and practical applications. Process Biochem 70:61–70

Rios NS, Morais EG, Santos WG et al (2019) Further stabilization of lipase from Pseudomonas fluorescens immobilized on octyl coated nanoparticles via chemical modification with bifunctional agents. Int J Biol Macromol 141:313–324

Javed S, Azeem F, Hussain S et al (2018) Bacterial lipases: a review on purification and characterization. Prog Biophys Mol Biol 132:23–34

Kumar R, Goomber S, Kaur J (2019) Engineering lipases for temperature adaptation: structure function correlation. Biochim Biophys Acta 1867:140261

Bharathi D, Rajalakshmi G (2019) Microbial lipases: an overview of screening, production and purification. Biocatal Agric Biotechnol 22:101368

Geoffry K, Achur RN (2018) Screening and production of lipase from fungal organisms. Biocatal Agric Biotechnol 14:241–253

Kapoor M, Gupta MN (2012) Lipase promiscuity and its biochemical applications. Process Biochem 47:555–569

de Castro FF, Pinheiro ABP, Nassur CB et al (2017) Mycelium-bound lipase from a locally isolated strain of Aspergillus westerdijkiae. Biocatal Agric Biotechnol 10:321–328

Lima RT, Sato PM, Pereira RM et al (2017) Mycelium-bound lipase production of immobilized whole cell from a wild-type Penicilium citrinum strain. Int J Eng Res Sci 3:1–9

Marotti BS, Cortez DV, Gonçalves DB et al (2017) Screening of species from Penicillium producing cell bound lipases to be applied in the vegetable oil hydrolysis. Quim Nova 40:427–435

Hermansyah H, Andikoputro MI, Alatas A (2019) Production of lipase enzyme from Rhizopus oryzae by solid state fermentation and submerged fermentation using wheat bran as substrate. In: AIP Conference Proceedings, p. 020013

Jiao L, Zhou Q, Su Z et al (2018) High-level extracellular production of Rhizopus oryzae lipase in Pichia pastoris via a strategy combining optimization of gene-copy number with co-expression of ERAD-related proteins. Protein Expr Purif 147:1–12

Fukuda H, Kondo A, Tamalampudi S (2009) Bioenergy: sustainable fuels from biomass by yeast and fungal whole-cell biocatalysts. Biochem Eng J 44:1–12

Yu X, Xu Y, Xiao R (2016) Lipases from the genus Rhizopus : characteristics, expression, protein engineering and application. Prog Lipid Res 64:57–68

Zavarise JP, Pinotti LM (2020) Advances in biochemical characterization of microbial lipases: a review. Res Soc Dev 9:1–22

Pereira DG, Kilikian BV (2001) Effect of yeast extract on growth kinetics of Monascus purpureus. Appl Biochem Biotechnol 91–93:311–316

Wang D, Zhu Z, Wang X et al (2015) Improving mycelium-bound lipase production by aggregating Rhizopus chinensis on a draft tube in a modified stirred tank fermentor. Process Biochem 50:2019–2028

Giakoumis EG (2018) Analysis of 22 vegetable oil’s physico-chemical properties and fatty acid composition on a statistical basis, and correlation with the degree of unsaturation. Renew Energy 126:403–419

Rooney D, Weatherley LR (2001) The effect of reaction conditions upon lipase catalysed hydrolysis of high oleate sunflower oil in a stirred liquid-liquid reactor. Process Biochem 36:947–953

Cortez DV, de Castro HF, Andrade GSS (2017) Potential catalytic of mycelium-bound lipase of filamentous fungi in biotransformation processes. Quím Nova 40:85–96

Hama S, Tamalampudi S, Fukumizu T et al (2006) Lipase localization in Rhizopus oryzae cells immobilized within biomass support particles for use as whole-cell biocatalysts in biodiesel-fuel production. J Biosci Bioeng 101:328–333

Wang D, Xu Y, Shan T (2008) Effects of oils and oil-related substrates on the synthetic activity of membrane-bound lipase from Rhizopus chinensis and optimization of the lipase fermentation media. Biochem Eng J 41:30–37

Matsumoto T, Takahashi S, Kaieda M et al (2001) Yeast whole-cell biocatalyst constructed by intracellular overproduction of Rhizopus oryzae lipase is applicable to biodiesel fuel production. Appl Microbiol Biotechnol 57:515–520

Matsumoto T, Takahashi S, Ueda M et al (2002) Preparation of high activity yeast whole cell bioctalysts by optimization of intracellular production of recombinant Rhizopus oryzae lipase. J Mol Catal B Enzym 17:143–149

Athalye S, Sharma-Shivappa R, Peretti S et al (2013) Producing biodiesel from cottonseed oil using Rhizopus oryzae ATCC # 34612 whole cell biocatalysts: culture media and cultivation period optimization. Energy Sustain Dev 17:331–336

Andrade GSS, Carvalho AKF, Romero CM et al (2014) Mucor circinelloides whole-cells as a biocatalyst for the production of ethyl esters based on babassu oil. Bioprocess Biosyst Eng 37:2539–2548

Lima RT, Alves AM, Paula AV et al (2019) Mycelium-bound lipase from Penicillium citrinum as biocatalyst for the hydrolysis of vegetable oils. Biocatal Agric Biotechnol 22:101410

Essamri M, Deyris V, Comeau L (1998) Optimization of lipase production by Rhizopus oryzae and study on the stability of lipase activity in organic solvents. J Biotechnol 60:97–103

Razak CNA, Musani R, Basri M, Salleh AB (1999) Characterization of membrane-bound lipase from a thermophilic Rhizopus oryzae isolated from palm oil mill effluent. J Am Oil Chem Soc 76:171–174

Braz CA, Carvalho AKF, Bento HBS et al (2020) Production of value-added microbial metabolites: oleaginous fungus as a tool for valorization of dairy by-products. BioEnergy Res 13:963–973

Acknowledgements

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – Brasil (CAPES) – Finance Code 001. W.S.M.R. thanks CAPES for the student fellowship. A.A.M. thanks Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq – Brazil) for the research fellowship (Process 310633/2020-6).

Author information

Authors and Affiliations

Contributions

Willian S. M. Reis and Alexandre B. Matias carried out the experimental work. Willian S. M. Reis, Adriano A. Mendes and Ernandes B. Pereira carried out the final editing of the manuscript and the writing of the article. Adriano A. Mendes, Ernandes B. Pereira and Heizir F. de Castro were responsible for conceptualization, supervision and funding acquisition. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Heizir F. de Castro—in memorian.

Rights and permissions

About this article

Cite this article

Reis, W.S.M., Matias, A.B., Mendes, A.A. et al. Production and Characterization of Whole-Cell Rhizopus oryzae CCT3759 to be Applied as Biocatalyst in Vegetable Oils Hydrolysis. Catal Lett 152, 1–11 (2022). https://doi.org/10.1007/s10562-021-03622-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-021-03622-8