Abstract

There is an ongoing debate on elucidating the actual role of Fe impurities in alkaline water electrolysis, acting either as reactivity mediators or as co-catalysts through synergistic interaction with the main catalyst material. This perspective summarizes the most prominent oxygen evolution reaction (OER) mechanisms mostly for Ni-based oxides as model transition metal catalysts and highlights the effect of Fe incorporation on the catalyst surface in the form of impurities originating from the electrolyte or co-precipitated in the catalyst lattice, in modulating the OER reaction kinetics, mechanism and stability.

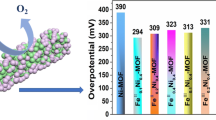

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

We live in an era where chemical energy conversion via electrocatalytic processes has gained a considerable interest due to the huge negative impact of fossil fuels on the environment. The direct electrochemical conversion of chemical bonds of reactants/precursors into usable fuels like hydrogen, methanol, ethanol and other carbonaceous fuels, by harvesting natural energy sources like wind and most importantly solar and the storage of excess energy into batteries and supercapacitors has opened new and exciting pathways during the last few decades in the field of energy economy. All this effort arises from the realization that if nature can so elegantly photosynthesize fuels, why not use similar principles to imitate nature. Thus, a realistic candidate for storing solar energy in the form of chemical bonds and their subsequent harvesting, would be hydrogen.

Water electrolysis, is consequently frequently considered as a clean and scalable technology for harvesting hydrogen via small or large scale electrolyzers, which are all part of the modern ‘hydrogen economy’ infrastructure. However, even though water electrolysis has been studied for over 200 years, the complexity of all the processes taking place at the 3-phase solid/liquid/gas boundaries on the anode and the cathode still hides many challenges, especially for the anode part where the very energy demanding oxygen evolution reaction (OER) takes place. Amongst the most challenging issues, is the necessity for advanced materials of high activity and most prominently stability for both acidic and alkaline conditions. This is where Pourbaix diagrams play a crucial role by supplying thermodynamic information on how certain catalysts might behave upon pH and potential changes.

As such, for acidic conditions Ir- and Ru-based oxides and their respective alloys are primarily used, while in alkaline conditions one can find the more traditional Ni-based oxides like Raney-Nickel already dating back to the 1930s and a variety of alloys like Ni/Co, Ni/Mn, Ni/Mo, Ni/Zn and Ni/Fe, with the latter having the highest activity. In this perspective we will give an overview of how in particular Fe incorporation in the catalyst lattice or catalyst surface changes the structural properties, surface conductivity, catalytic activity and stability of Ni-based OER catalysts. Relevant to all this is the effect of Fe impurities inherently present in KOH, which is the electrolyte of choice for alkaline electrolyzers. Even extremely low Fe amounts in the order of μg/L in the electrolyte is enough to have a dramatic impact on catalyst performance, thus making it imperative to understand this very important unusual phenomena as well as suggests that is necessary to clarify how electrolyte additions can enhance reaction kinetics.

2 General Aspects of Water Oxidation

To acquire hydrogen by electrolysis, i.e. the electrocatalytic splitting of water into its constituents, hydrogen and oxygen, energy is required, which will provide the necessary electrons to drive the 2 half-reactions involved in the overall water splitting reaction:

2.1 Reaction Mechanism of OER in Alkaline Media

Oxygen evolution reaction (OER) is a 4-electron process which takes place at the anode, in an electrolysis cell (2, 3). Compared to HER, the OER process has more sluggish kinetics, where M represents surface active sites of the catalysts and M–OOH, M–O and M–OH are the adsorption intermediates of each reaction step. Generally, the mechanism of OER is believed to proceed in initial step by H2O deprotonation in acidic electrolytes or OH− electroadsorption in alkaline electrolytes, both resulting in M-OH formation, followed by the other three steps including oxidizing M-OH into M–O, M–O into M–OOH and finally M-OOH into O2 (4–8).

Cathode reaction:

Anode reaction:

Proposed OER mechanism under alkaline conditions

Alternatively, a more sluggish 2-electron pathway involving peroxide formation [1, 2].

2.2 Basic Thermodynamics

Water electrolysis, is an endergonic reaction that requires a theoretical amount of ΔG0 = + 237 kJ mol−1 of electrical energy (Gibbs free energy of the reaction) to be applied at standard conditions for 1 mol of water to split into hydrogen and oxygen. At the same conditions, the molar enthalpy change of the reaction ΔH0, which is the heat formation of one mole of water, is 286 kJ mol−1. Using Eq. (9) and substituting the number of electrons participating in the reaction with 2 and the Faraday’s constant with 96,485 C/mol the reversible electrolysis cell voltage of 1.229 V at standard conditions (STP) can be calculated, which is the minimum potential required to split water. However, Eq. (10) gives the total energy requirement for the reaction to proceed, both the free energy term (ΔG0) and entropic (TΔS0), with the latter term having a value of 49 kJ mol−1.

Thus, the total energy requirement is 286 kJ mol−1, which translates into a potential of 1.481 V, called the thermoneutral potential of the reaction, which is the potential above which the reaction proceeds as exothermic, while in the potential range 1.229–1.481 V (between reversible and thermoneutral voltage) the reaction proceeds as endothermic [3]. In reality however, electrolyzers emit heat due to operation voltages between 1.8 and 2.2 V, not only to acquire higher hydrogen yields but also to overcome losses related to the reaction (sluggish kinetics, poor mass transport of reactants and products) and ohmic resistances of the cell connections and ions in solution, also called activation, concentration and resistance overpotentials respectively.

2.3 Catalyst Evaluation

In order to evaluate catalyst performance for the OER certain electrochemical and spectroscopic techniques are used to acquire information on the activity, stability and faradaic efficiency. It is well established that, linear sweep voltammetry (LSV) and/or cyclic voltammetry (CV) are utilized for kinetic analysis, including diagnostics of redox chemistry. Also, Faradaic efficiency is typically evaluated by comparing total mass of products using Faraday’s law with the measured mass of produced gas. However, only recently experimental setups are built that can quantify stability via in-situ measured dissolution rate.

2.3.1 Catalyst Dissolution

Measuring the amount of dissolved catalyst during OER is a very important metric for catalyst evaluation. Therefore, there are two different pathways to measure catalyst dissolution either ex-situ (post mortem) or in-situ analysis of the dissolution products in the electrolyte used. In the latter case, importantly transient analysis of dissolution rates can be performed by combining traditional electrochemistry with Induced Coupled Plasma (ICP) spectrometry, which has proved to be a very powerful tool for the determination of catalyst deterioration [4], or by other techniques, like electrochemical Quartz Crystal Microbalance (eQCM) which can also detect extremely low catalyst mass changes in the order of ng s−1.

All this information described above can be converted into performance metrics and be depicted into a single chart called spider graph which allows the simultaneous comparison of different catalysts under identical conditions. These metrics can be diverse depending on the experimental techniques that are used and can be used to categorize catalysts according to their stability and activity. To do so, we have chosen 6 different metrics (with EJ=10 mA cm−2geo and EOER, onset influencing activity while ΔJLSV%, nCP,2h%, nFaradaic and ΔcorCP,2 h influencing stability) and 5 different hypothetical model catalysts (Fig. 1a–e), each one favoring activity, stability or both (Fig. 1e: ideal case). The values of each marker for these model catalysts were chosen carefully to represent each category of catalysts [4].

Spider plots of different catalyst performance metrics for efficient catalyst comparison under similar conditions. Reprinted (adapted) with permission from [4]. Copyright (2020) American Chemical Society

3 Sate of the Art Catalysts

Already starting from late 60s and early 70s [5], there have been substantial interest in water electrolysis and a wide variety of catalyst classes have been investigated over the years.

3.1 Precious Metal Oxides

Noble metal-based catalysts are known to be some of the most active catalysts for both alkaline and acidic water electrolysis [6] already since the 60s, with Damjanovic et al being one of the first to study OER kinetics on Pt, Ir and Rh-based catalysts [7]. Since then many studies have dealt with the effect of crystal structure [8,9,10], alloying and/or doping [11] of Ir and Ru which are the most promising OER catalysts in acidic conditions, with the purpose of identifying those conditions that can merge together two different properties of these materials, that is, the superior catalytic activity of Ru-based oxides with the superior stability of Ir-based oxides. Both those metal oxides have a rutile crystal structure, where Ru and Ir are located in the center of an octahedral site with oxygen in the corners, with each octahedron connecting to each other through sharing the corners. IrO2 is known to have far better catalytic activity in the amorphous state compared to its crystalline counterparts, although rutile-IrO2 shows considerably better stability. Comparatively, RuO2 although the most active OER catalyst known today, seriously lacks stability, since as Cherevko et al. [12] have demonstrated, RuO2 is unstable and heavily dissolved during OER under high anodic polarization conditions, compared to IrO2. According to the proposed mechanism for the observed catalyst dissolution, RuO2 at high anodic polarization acquires the Ru4+ oxidation state (Ru4+)O2 and subsequently transforms into the hydrous compound RuO2(OH)2 which under deprotonation leads to the formation of a high oxidation state (Ru8+)O4 [13,14,15] which is readily soluble in the solution.

3.2 Transition Metal Oxides and hydroxides

Ni- and Co-based materials have been used for many decades as OER catalysts due to their superior catalytic activity and stability in alkaline conditions, their environmental friendliness, low cost and material abundance. From a synthesis point of view both types of catalysts can be realized in nanosized powders which is crucial for high electrocatalytic surface area and improved reaction efficiency. The structures of such catalysts are typically, spinel, perovskites and layered double hydroxides, where the OER overpotential at 10 mA/cm2 is typically in the range of 200–400 mV depending on the type of catalyst and the catalyst support.

Perovskites have the general formula ABX3 and ABO3 for the equivalent oxides, where A is alkaline- and/or rare-earth metal of larger size than B which is a transition metal and is centered in an octahedron of oxygen atoms surrounding it, thus completing the structure of the perovskite. The conductivity of a perovskite is mostly due to an overlap in the d-orbital of the transition cation B and the p-orbital of the oxygen anions and the available d-electrons [16], which Matsumoto et al. connected in a study on a La1−xSrxFe1−yCoyO3 system for the OER, to the activity of the catalyst, due to the d-band distribution and the higher oxidation state of the Co ion. The mixed oxidation state of 3+ and 4+ of some perovskites depend on the oxidation state of cation A and has been linked [2] to their high catalytic activity for the OER.

Spinel-type oxides have a more complex structure than perovskites with two cation sites surrounded by oxygen atoms in an octahedral and tetrahedral orientation. Typical catalysts from this group of materials are Co3O4, Fe3O4, Ni-doped Co3O4 or NiCo2O4 and many more. These materials typically have high conductivities due to high carrier mobilities, like Li-doped Co3O4 and NiCo2O4 which both have higher conductivities and activities compared to Co3O4. Doping of such catalysts with various metals can readily alter the structural and electrocatalytic properties of these materials. What was universal, independently from lattice type, was that impurities affected catalytic performance drastically.

4 Effect of Impurities on Electrocatalysis

The susceptibility of electrocatalytic reactions to the presence of even the slightest amount of impurity traces in the reaction medium, electrochemical vessels [17] or at the catalyst itself has been known for many decades. Their sizable effect on the reaction mechanism, selectivity, catalyst stability and activity, by masking/blocking or otherwise altering the active sites for the relevant reaction is well documented.

Kwon et al. showed by using a combination of online HPLC and in situ FTIR that the addition of bismuth on a carbon supported platinum electrode (catalyst denoted as Pt-Bi) is capable of oxidizing glycerol to dihydroxyacetone with 100% selectivity, by blocking the primary alcohol oxidation pathway [18].

Pumera et al. showed that trace amounts of Fe within remnant metallic nanoparticle impurities of Co and Mo nanoparticles in MWCNT are able to catalyze peroxide reduction [19], while Ullman et al. [20] reported the effect of Co(II) on the apparent water splitting activity of Co(III)4O4 molecular cubanes, which is only triggered by the formation of the well-known Co-OEC (oxygen evolving complex) cobaltate catalyst during synthesis [21]. Bockris investigated the effect of trace amounts of Pt on the ORR and OER activity of a NaxWO3 crystal, which increased up to 4 orders of magnitude as Pt was introduced and it approached the activity of pure Pt at 400 ppm of Pt in the crystal. The specific activity on a bronze crystal was 103 times that of bulk Pt due to a spillover effect of adsorbed intermediates from Pt on the bronze giving rise to the enhanced catalytic activity [22].

Likewise, during the oxygen reduction reaction (ORR) on Pt catalyst surfaces, the Pt sites can be readily covered by various anions, like CN−, F−, Cl−, Br− and I− [23,24,25,26] present in the electrolyte or in the catalyst synthesis medium, with Cl− anions being commonly known for their presence in reference electrodes like the calomel (Hg/Hg2Cl2) and Ag/AgCl and are capable of blocking Pt active sites thus hindering the reaction. These anions can be released in the electrolyte due to a concentration gradient near the reference electrode surface which can enhance the escape of such anions from the electrode compartment into the electrolyte in the course of prolonged use. In the case of CN− anions, those can have a positive effect on the ORR activity of Pt in H2SO4 and H3PO4 by blocking the strongly adsorbing sulfates and phosphates anions from the electrolyte which otherwise inhibit ORR activity.

Inadvertently doping sp2 carbon nanomaterials like the well-known ‘metal-free’ graphite-based ORR catalysts, with Fe, Co, Ni, Mn, Mo, V and Cr impurities coming from the synthesis medium, can have a great impact on their activity as well [27,28,29,30,31,32,33,34,35,36]. Masa et al. showed that trace Fe metal impurities in supposedly metal-free nitrogen doped carbon-based catalysts for the ORR, were mostly responsible for their remarkable activity [37]. In related studies, a manganese oxide catalyst supported on graphene derived from graphite containing trace iron impurities was shown to exhibit superior ORR and OER activity compared to a similar catalyst supported on Fe impurity-free graphene [38]. Meanwhile, when entrapped inside carbon nanotubes (CNTs), residues of transition metals used as catalysts for CVD growth of the CNTs have been demonstrated to markedly influence the electrocatalytic properties of the CNTs [39, 40].

Finally, Corrigan [41] was the first to investigate the promotional effect of Fe impurities from as low as 0.01 wt% up to a 1:1 Ni:Fe ratio on the (OER) activity of Ni-oxide films (Fig. 2) and suggested his work as a future reference for catalyst design, although neglected up until early 2010s’.

Effect of 1 ppm Fe impurities in 25wt% KOH on a Nickel oxide thin film catalyst. Reprinted (adapted) with permission from [41]. Copyright (2020) IOP Publishing

4.1 Effect of Fe on Transition Metal OER Electrocatalysts

Typically alloying of Ni- and Co-based oxides readily increases their activity due to surface area, conductivity enhancement, and electronic structure related phenomena affecting the OH− adsorption bond strength on the catalyst surface. Bockris et al. [42] and Trassati [43] explained the high performance of Ni oxides in terms of surface Lewis acidity and changing of the M-OH bond strength (Sabatier principle) with the addition of a second cation in the oxide’s lattice, while Li et al. [44], hypothesized that an enhanced Ni–O covalency and thus greater oxyl character, due to the presence Fe3+ results in a more active catalyst. Two different studies by Görlin et al. [45] (Fig. 3) and Bell et al. [46] report a change in the local environment of Ni in the Ni–Fe catalysts upon Fe addition, which affects not only the oxidation state of Ni but also its activity.

a XAS-derived structural motifs prevalent during OER catalysis at high and intermediate Ni-content. At high Ni-content the dominating host is the layered γ-NiOOH (a “NiO2” phase) with octahedrally coordinated edge-sharing Ni4+. In the presence of Fe there is a mixture of edge- and corner sharing octahedra.76,90,91 Above 4% Fe, the dominant host is the Ni(OH)2 with Ni2+. b Simplified scheme of the electrochemical water splitting cycle with metal oxidation rate constant, kM,OX, and the catalytic OER rate constant, kOER. Reprinted (adapted) with permission from [45]. Copyright (2020) American Chemical Society

On the other hand Friebel [47] reported a change in the Fe–O bond length in a NiFeOxHy catalyst compared to the same bond length in a FeOxHy catalyst, also reporting a lower overpotential for the Fe–O sites compared to the Ni–O ones (Fig. 4). Although both authors see no change in the oxidation state of Fe (Fe3+), Bard [48] reported an Fe3+ to Fe4+ change using a surface-interrogation scanning electrochemical microscope. As a result, whether the addition of Fe alters the bond length of Fe–O, Ni–O or Ni–O–Fe remains still unclear.

Theoretical OER overpotentials at Ni and Fe surface sites for impure and doped γ-NiOOH and γ-FeOOH model structures. a Proposed OER pathway with intermediates HO*, O* and HOO*, illustrated using the example of the on-top site at a substituted Fe surface atom in γ-NiOOH(011̅2). The binding energies of these species are used to estimate the OER overpotential. b OER activity volcano showing the overpotential as a function of Gibbs free energies of the reaction intermediates. Computed overpotentials are shown for the OER at Ni–Ni bridge and Fe on-top sites located in pure γ-NiOOH (011̅2) and in γ-NiOOH(011̅2) with Fe surface and subsurface doping, at a Ni on-top site in pure γ-NiOOH(011̅2), and at Fe–Fe bridge sites in pure and Ni-doped γ-FeOOH(010) (25% Ni in bulk unit cell). Reprinted (adapted) with permission from [47]. Copyright (2020) American Chemical Society

4.2 Transition Metal Layered-Type Double Hydroxide (LDH) Catalysts

The main attribute of this type of catalysts is their high surface area due to their mesoporous hierarchical 3D structure, thus they are the most promising type of catalyst materials for alkaline water electrolysis. The structure of LDHs (in the forms of metal hydroxides and oxyhydroxides) comprises of stacked layers with protons (H+) and water molecules and alkali cations (Na+ and K+) intercalated in between the layers and the transition metals forming an octahedron with oxygen anions on each corner of the octahedron, which further interconnect with each other through edge sharing, thus forming 2D structures, with Ni and Co typically present in the center of the octahedrons. Depending on the distance between the layers, β- or γ-type NiOOH is formed, with the β-type being the most active for OER electrocatalysis.

Their activity is based on the Ni3+ or mixed valence Ni3+ and Ni4+ nature of the NiOOH structure. There are four nickel oxide phases before OER starts [49] and transformation of the Ni(OH)2 phase to the NiOOH phase via the transition (11) has been known to be the principle mechanism of catalyst activation before OER starts [50, 51], as shown in the Bode diagram in Fig. 5.

The main mechanism for Ni- based catalyst activation during OER can be divided into a few steps: (1) spontaneous formation of a hydrous α-Ni(OH)2 upon immersion in alkaline electrolyte (2) ageing of the hydroxide layer to a β-Ni(OH)2,, (3) transformation of the α- and β-hydroxides respectively to γ-NiΟOH and β-NiOOH below 450 mV versus Hg/HgO (4) and finally β-NiOOH can be further oxidized to γ-NiΟOH when the potential is higher than 600 mV versus Hg/HgO [46, 52,53,54,55,56,57,58,59].

However, Yeo et al. [59] used in situ Raman spectroscopy to identify the composition of the active phase on the surface of nickel electrodes and concluded that a different phase other than γ-NiΟOH was formed upon further oxidation of β-NiOOH, which was responsible for the high activity of the catalyst, thus once more determination of the active sites was inconclusive.

Even though the pioneering work of Corrigan [41] on the influence of Fe impurities on the activity of Ni(OH)2/NiOOH was known from the 80s, there had been no systematic study on the actual role of Fe impurities on the activity and probably on the stability of OER catalysts in alkaline environment until the early 2010s’. Trotochaud et al. [60], were among the first to identify the promotional effect of Fe impurities on oxygen electrocatalysis in alkaline electrolytes. Interestingly the authors showed, that both β- and γ-NiOOH phases are poor electrocatalysts for the OER in Fe-free electrolyte with overpotentials higher than 500 mV at 10 mA/cm2. In this work, the authors focused on the effect of incidental Fe impurities in the electrolyte on the catalyst performance and concluded that the incorporation of Fe on NiOOH is responsible for the catalyst activation, thus showcasing that previous knowledge on the mechanism of Ni-based OER catalysts was compromised by Fe impurities.

We recently showed that Fe impurities in the electrolyte at concentrations as low as 40 μg/L have a huge impact not only on the activity but also on the stability of the Ni-Co3O4 catalyst used [61]. Activity was enhanced both after catalyst activation by cycling between 0.7 and 1.6VRHE at 50 mV/s and after a prolonged electrolysis stress test at 10 mA/cm2 for 2 h (Figs. 6, 7a).

Activity comparison of the Ni–Co3O4 catalyst between 1.2 and 1.7 VRHE at 5 mV s−1 scan rate in Fe-contaminated (black) and Fe-free (red) 1 M KOH. Reprinted (adapted) with permission from [47]. Copyright (2020) American Chemical Society

Chronopotentiometry stress test profiles of the Ni–Co3O4 catalyst with and without Fe in solution at 10 mA cm−2 for 2 h. ICP-OES transient analysis of the corrosion products of the Ni–Co3O4 catalyst in (b) 1 M KOH Fe-contaminated and (c) Fe-free KOH solution. The Fe content of the KOH solution was monitored Reprinted (adapted) with permission from [61]. Copyright (2020) American Chemical Society

Most interestingly, ICP-OES analysis revealed an Fe uptake on the catalyst during prolonged electrolysis and negligible Ni and Co dissolution (Fig. 7b), compared to the same catalyst treated in purified electrolyte where the amount of Ni and Co dissolved after the same 2 h stress test was substantially higher (Fig. 7c). Our data suggest that Fe is only loosely incorporated on the catalyst surface and not in the bulk and is swiftly removed when polarization ends (not shown here).

Corrigan in his work on a Ni(OH)2/NiOOH catalyst, correlated the remarkable activity of the catalyst towards oxygen evolution on the presence of Fe impurities in the electrolyte and cautioned that future investigations should avoid such pitfalls. In his work, Corrigan tried to explain the resulting boost in activity evidenced by the immense drop of the Tafel slope from 70 to 20–25 mV/dec for the Fe doped Ni catalyst on the amount of Fe in the electrolyte and a change of the rate determining step from the discharge of hydroxide ions with an expected Tafel slope of a 120 mV/dec to the recombination of oxygen radicals, with a 15 mV/dec slope. This could be one plausible explanation, if the Fe sites present on the catalyst surface could provide more favorable sites for adsorption of the radical intermediates. In another explanation by Corrigan, he linked the observed activity boost to a conductivity enhancement of the catalyst through the incorporation of Fe sites. His explanation was based on findings by Lu et al. [56] who had previously suggested that the low conductivity of Ni oxides can affect the overpotential for oxygen evolution due to so called barrier layer effects [62].

Although NiFe-based oxides are well known to be the most active non-platinum group catalysts for the OER [63, 64], not until the effect of Fe was recognized, most work on Ni catalysts for the OER was focused on correlating catalyst structure to activity and investigating the effect of alloying and/or doping Ni oxides with other metal cations, with Fe being the most prominent [65,66,67,68,69,70,71,72]. However, direct mediation of Fe present in the electrolyte on electrolytic reactions is something that has always been neglected. Boetcher et al. were among the first to identify the promotional effect of Fe impurities on oxygen electrocatalysis in alkaline electrolytes and thus introduced a purification methodology for removal of Fe residues from the electrolyte, in order to compare the intrinsic activities of various catalysts without the inadvertent contribution of Fe. In their work, [60] activity increase after cycling in sub-OER potentials was typically linked to catalyst ageing and the phase transformation of α-Ni(OH)2 to β-Ni(OH)2 which up until then had led to the conclusion that the OER activity of β-NiOOH was higher compared to that of γ-NiOOH. However, as indicated by Trotochaud et al. and Klaus et al., [72, 73] the increase in OER activity for the Ni(OH)2/NiOOH catalyst was linked to inherent presence of Fe impurities in the commercial KOH electrolyte. However, the significant activity improvement could not be explained only in terms of conductivity enhancement arising from the incorporation of Fe impurities on the catalyst surface. Thus, the authors concluded that the Fe sites must be the active sites of the reaction.

Additionally, the effect of Co was investigated in order to clarify the reaction mechanism on those ternary alloys. Apparently, alloying Ni with Co enhances activity only by a factor of two compared to CoOxHy catalysts. However, a two to three orders of magnitude greater activity is observed when Fe is co-deposited or even just spiked in the solution, also showing that Ni-base oxides have a higher affinity towards Fe incorporation compared to Co-based oxides [74, 75].

Likewise, Li et al., [76] and Zhou et al. [77] performed calculations for a Ni1-xFexOOH and NiOOH OER catalyst respectively to clarify the role of Fe and Ni species. The former concluded that the Fe centers served as the active sites for the reaction, while the latter calculated the Pourbaix diagram of Ni electrodes and showed that under reaction conditions exist several metastable NiOxHy phases while at the same time Fe doping enhances the stability of oxy-hydroxo species (Fig. 8). Therefore, based on their calculations, the authors concluded that when a N-based catalyst is immersed in water, both water molecules and Fe ions intercalate into the bulk of the electrode, causing the layered structure to exfoliate and subsequently further adsorb on the inner layers. Thus, higher and lower oxidation state Fe and Ni ions respectively emerge through the proton transfer between Fe and NiOOH, with these newly formed Ni ions being more active than the initial material.

Pourbaix diagrams with and without Fe doping calculated by HSE06. Doping reduces the formation energies of Ni–O compounds and stabilizes the electrodes under reaction conditions. Figures on the right show the configurations of most stable undoped and Fe-doped nickel (oxy)hydroxide compounds from high potential to low potential. Reprinted (adapted) with permission from [77]. Copyright (2020) American Chemical Society

In a similar work from the group of Nocera [44], the observed Fe3+ were responsible for the formation of formal Ni4+ which can be directly correlated to the enhanced activity of the Fe doped Ni oxide system studied and thus they were considered as the active sites, while Chen et. al [78] could not find sufficient evidence from Mossbauer spectroscopy that the resulted Fe4+ sites produced during OER were enough to be considered as the active sites.

In a different approach Xiao et al. [79], used DFT calculations to determine the mechanism for OER, including the kinetics of O–O coupling on pure and Fe-doped NiOOH catalysts. The authors reported the formation of an active O radical species and the subsequent O–O coupling, thus showcasing that pure NiOOH is a poor OER catalyst because of its inability to produce the O radical, in contrast to the Ni:Fe catalyst which due to the synergy between Ni and Fe, the high spin Fe4+ can stabilize the O radical by an exchange interaction, while Ni4+ catalyzes the O–O coupling. This synergy is key for driving the reaction.

Diaz-Moralles investigated the doping effect of other metals on a NiMOOH catalysts with M=Fe, Cr and Mn having a positive effect while Co, Cu and Zn on the contrary had a deleterious effect, which also comes into contrast with previous studies which showed that Co actually has a positive effect [80]. Their DFT calculations revealed that in the cases of Fe and Mn, those metals are expected to be the active sites responsible for the OER activity enhancement in contrast to Cr which although has a positive effect on activity upon doping the NiOOH catalyst, it does not act as the active site, but Ni does instead.

To further investigate the effect of Fe on transition metal-based alloy oxide catalysts [81, 82] the group of Boetcher used MOxHy catalysts with certain Fe amount spiked into the solution and eliminating the effects of Fe impurities in the electrolyte, conductivity and confounding surface area (Fig. 9). It was firstly shown that when Ni or Co are added to Fe-free CoOxHy and NiOxHy catalysts respectively they have only a small effect on activity due to conductivity enhancement, compared to the more impactful Fe spiking, suggesting a small synergistic effect between Ni and Co. When Fe is spiked it is not incorporated into the catalyst bulk but most probably only on the catalyst defects and edges as indicated by the more negative oxidation peak shift compared to a catalyst where Fe was co-deposited, although in both cases the activity was similar. However, as data suggested the affinity of Fe incorporation on the Ni-based catalysts compared to the Co-ones was the contributing factor for the superior activity of the former.

Activity analysis (a) as a function of overpotential, b at η = 350 mV, and c at η = 450 mV. The catalysts are synthesized by electrodeposition as (oxy)hydroxides on Au (closed symbols) and Pt (open symbols) microbalance electrodes and measured in triplicate for those on Au. (Some error bars are smaller than the symbols.) Compositions listed in (b) and (c) are ordered based on the atomic number of the host/primary cation. The fit lines and shading in (a) were added to make trends clear. The dotted lines in (b) and (c) are to guide the eye. Film masses were 8–12 μg cm−2 for all films except the thin FeOxHy, which was 0.5 to 1.0 μg cm−2. Reprinted (adapted) with permission from [81]. Copyright (2020) American Chemical Society

Finally, Markovic et al. in a similar manner to the previous work, tried to identify the active sites on different MOxHy (M=Ni, Co, Fe, Cu, Ti, Mn, Cr and V) catalysts in Fe-free and Fe-containing electrolytes, suggesting that Fe plays the role of the surface active sites for the reaction, but not in a static/stable state that it has been for long thought to be, but otherwise in a more dynamic/meta-stable state. The number of these sites is dependent on the balancing of the dissolution and redeposition rates of Fe on the host MOxHy material and the affinity of the host metal M to strongly interact with Fe, when Fe is either co-deposited on the MOxHy catalysts or simply spiked in the electrolyte [83].

From all the single metal MOxHy catalysts investigated, NiOxHy shows the highest affinity to attract Fe, followed by Co, Fe, Mn, Cr, V and Ti. In Fe-free 0.1 M KOH catalytic activity follows the order: FeOxHy > CoOxHy > NiOxHy, with stability having the exact opposite trend FeOxHy < CoOxHy < NiOxHy. However, when 0.1 ppm of Fe was spiked in the solution which resulted in a certain amount of Fe to be deposited on the catalyst surface, the activity trend gets reversed but once again the stability of the now Fe containing catalysts remains the same as in the non-Fe containing solution: Fe-FeOxHy < Fe-CoOxHy < Fe-NiOxHy. By doping the NiOxHy catalyst with other 3d transition metals the authors were able to further tune the adsorption energy of Fe on the catalysts and further improve catalytic activity.

Interestingly, CuOxHy has even higher Fe adsorption energy than Ni suggesting that CuOxHy could potentially be a better candidate for an OER catalyst, however its high dissolution rate prevents its potential practical use. Thus, doping Ni with Cu proved to consolidate the individual properties of NiOxHy and CuOxHy, that is, high stability, high Fe adsorption energy and in the end superior catalytic activity than any other M-doped NiOxHy studied by the authors. These findings suggest actually that the saturation coverage of Fe on a given MOxHy catalyst, could be a more relevant activity descriptor than the M–O adsorption energy (Sabatier principle).

5 Summary

To sum up, we have shown that the intrinsic activity in the case of Ni-based oxide catalysts, by the accidental or on-purpose addition of Fe impurities in the electrolyte can be orders of magnitude higher compared to Fe-free electrolyte/catalysts. One can only wonder how such trace amounts of impurities can have such a significant effect on the activity and stability of certain types of catalysts. In many cases, even the slightest amount of metal impurities in the electrolyte or in the bulk of the catalyst may not only greatly boost but also plummet a catalyst’s performance, only to conclude that perhaps impurities really run the reaction in many cases, with the ‘catalysts’ just playing the role of a vessel carrying those impurities or otherwise catalysts in such cases.

That means, in order to run proper electrochemical experiments, we need to eliminate all those factors that can lead to false conclusions, but more importantly it opens new avenues of research into understanding the nature of interaction between electrode and impurities/ions at the interface. Afterall, proper electrochemistry really relies on clean experiments which however is sometimes unfortunately neglected, not on purpose but because in many cases we cannot know. Unless thoroughly investigated, the effect of parameters often presumed to be inconsequential, such as trace amounts of certain metals present in the electrolyte or the inclusion of certain metal precursors during catalyst preparation, as well as residues from cell cleaning, ought not to be assumed to be passive.

A characteristic example is the effect of Fe on Ni-based catalysts. Even though the OER activity of such catalysts is apparently higher compared to Co-based oxides, the intrinsic activity of the former decreases significantly upon removal of Fe impurities from the electrolyte leading to a lot lower OER activity than that of Co oxides. Just a trace of Fe can significantly lower the OER reaction overpotential, while at the same time cyclic voltammetry shows a significant positive shift in oxidation and reduction potentials of Ni species present in the catalyst, which change with increasing amount of Fe.

The precise role of Fe impurities has long been debated with conflicting explanations. The prevailing theories are that incorporation of Fe on the catalyst surface (very improbable to affect the bulk too) enhances the conductivity of NiOOH, or that a new dual metal active site Ni-FeOOH is formed, for which an electronic effect is responsible for the remarkable activity enhancement. More recently, it was also proposed that Fe impurities are the active sites themselves and the underlying catalyst only plays the role of a conducting medium. Another possibility could be the formation of an extremely thin layer of Fe in the outer Helmholtz plane which enhances charge transfer by facilitating electron tunneling towards the catalyst, since it has also been shown that the addition of other elements other than Fe in the electrolyte can have a similar effect. All this is still however not understood and to a great extent speculative, which means that a proper understanding of phenomena as complex as these could potentially have a huge impact on future design of catalysts and experimental setups.

Finally, we have presented different transition metal-based catalyst activation mechanisms, where catalyst activity and more precisely catalyst active sites have been classified in terms of catalyst support, catalyst surface conductivity, mixed valence oxidation state of the catalyst material, differences in M–O bond length and strength and in terms of impurities. In the latter case, Fe has been the predominant metal impurity with a significant influence on the catalytic properties. All the above lead to the conclusion that understanding which are the OER active sites of transition metal-based catalysts and the actual effect of Fe impurities are still poorly explained.

6 Perspective

Water electrolysis and in particular OER can be very challenging due to sluggish kinetics and the multi-step/multiple intermediates involved in comparison to the hydrogen evolution reaction (HER) which is a much faster process. However, catalyst materials and undoubtedly factors such as catalyst stability/dissolution also play a crucial role on the reaction efficiency. Water electrolysis has proved to be a very impactful reaction in the energy era of our time especially after the realization that oxygen evolution reaction catalysts are of the outmost importance not only for water oxidation but also for metal-air and regenerative fuel cells related processes. As such an OER catalyst of high performance can serve in a multitude of purposes.

As far as the OER is concerned, two types of catalysts have been used for many decades. Ir- and Ni-based oxides are the most common materials of high activity and stability for acidic and alkaline environment respectively. The large cost and low abundance of Ir-based catalysts and common corrosion problems prevalent in PEM electrolyzers compared to their Ni counterparts used in alkaline water electrolysis, make the latter more favorable as water oxidation catalysts for the long term.

However, one needs to realize that the choice of the proper catalyst requires thorough investigation of the preparation method, catalyst structure/morphology, catalyst conductivity, the effect of catalyst support, the electrolyte effect and most importantly the effect of impurities and/or dopants in the electrolyte, and the catalyst material itself. Catalyst intrinsic conductivity in particular is a very important material property that greatly impacts apparent activity, however, this can be boosted via dopants in the material, or by supporting the catalyst on carbon-based supports or noble metals, which in the former case also greatly increases the catalyst surface area typically by introducing micro-porosity into the catalyst, another important key factor for reactivity.

From this point of view, there are still many aspects that need to be thoroughly investigated before scaling-up and commercializing water electrolysis can be realized at a cost-effective level. At first, a complete understanding of how morphology and structure of catalysts affect activity and stability is key to designing new materials with controllable size, shape and morphology which can affect reaction selectivity. In the case of OER, during the last few decades there has been a swift change towards nanomaterials due to their favorable size which leads to extremely high available surface to catalyze the reaction. However, even those efforts lack a proper understanding of how for example nanoparticle shape and surface area affect the exposed active sites.

One of the most important aspects of electrochemistry still remains the full understanding of a reaction’s mechanism, which is of outmost importance in order not only to enhance the reaction rates by diminishing reaction barriers but also to avoid unwanted side effects and side-products like hydrogen peroxide. Even though the theoretical background on OER mechanism is immense, going back to fundamental understanding of certain processes can still help bridging this knowledge with the catalyst morphology and electrochemical conditions. Such a broad knowledge of all these processes is necessary not only to improve activity but also stability, which is far more important, since an active but unstable catalyst, typical example for the OER is RuO2, is unimportant. A catalyst that can sacrifice some activity for the sake of stability is far more desirable. For this reason, novel materials, such Ni-borides and phosphides have only recently shown very promising catalytic properties. Ni-phosphides in particular, due to leaching of phosphorus during water electrolysis become considerably more active, most likely due to surface area enhancement, a very interesting path to investigate.

Another important aspect, that still needs to be understood is reactions kinetics and mass transport of reactants and products not only in laboratory conditions and half-cell reactions but also in commercial systems under realistic conditions, where more complex phenomena related to catalyst loading and bubble formation and removal are relevant to be investigated.

References

Krasil’shchikov AN (1963) Intermediate stages in the anodic evolution of oxygen. Zh Fiz Khim 37(531):531–537

Matsumoto Y, Sato E (1986) Electrocatalytic properties of transition metal oxides for oxygen evolution reaction. Mater Chem Phys 14(5):397–426

Bockris JOM (1975) On methods for the large-scale production of hydrogen from water. In: Veziroğlu TN (ed) Hydrogen energy: part A. Springer, Boston, pp 371–403

Spanos I, Auer AA, Neugebauer S et al (2017) Standardized benchmarking of water splitting catalysts in a combined electrochemical flow cell/inductively coupled plasma–optical emission spectrometry (ICP-OES) setup. ACS Catal 7(6):3768–3778

Nuttall LJ, Fickett AP, Titterington WA (1975) Hydrogen generation by solid polymer electrolyte water electrolysis. In: Veziroğlu TN (ed) Hydrogen energy: part A. Springer, Boston, pp 441–455

Trasatti S (1980) Electrocatalysis by oxides — Attempt at a unifying approach. J Electroanal Chem Interfacial Electrochem 111(1):125–131

Damjanovic A, Dey A, Bockris JOM (1966) Electrode kinetics of oxygen evolution and dissolution on Rh, Ir, and Pt-Rh alloy electrodes. J Electrochem Soc 113(7):739

Pfeifer V, Jones TE, Velasco Vélez JJ et al (2016) The electronic structure of iridium and its oxides. Surf Interface Anal 48(5):261–273

Reier T, Teschner D, Lunkenbein T et al (2014) Electrocatalytic oxygen evolution on iridium oxide: uncovering catalyst-substrate interactions and active iridium oxide species. J Electrochem Soc 161(9):F876–F882

Pfeifer V, Jones TE, Velasco Vélez JJ et al (2017) In situ observation of reactive oxygen species forming on oxygen-evolving iridium surfaces. Chem Sci 8(3):2143–2149

Kasian O, Geiger S, Stock P et al (2016) On the origin of the improved ruthenium stability in RuO2–IrO2 mixed oxides. J Electrochem Soc 163(11):F3099–F3104

Cherevko S, Geiger S, Kasian O et al (2016) Oxygen and hydrogen evolution reactions on Ru, RuO2, Ir, and IrO2 thin film electrodes in acidic and alkaline electrolytes: a comparative study on activity and stability. Catal Today 262:170–180

Danilovic N, Subbaraman R, Chang KC et al (2014) Activity-stability trends for the oxygen evolution reaction on monometallic oxides in acidic environments. J Phys Chem Lett 5(14):2474–2478

Kötz R, Lewerenz HJ, Stucki S (1983) XPS studies of oxygen evolution on Ru and RuO2 anodes. J Electrochem Soc 130(4):825–829

Kötz R, Neff H, Stucki S (1984) Anodic iridium oxide films: XPS-studies of oxidation state changes and. J Electrochem Soc 131(1):72–77

Goodenough JB (1971) Metallic oxides. Prog Solid State Chem 5:145–399

Mayrhofer KJJ, Wiberg GKH, Arenz M (2008) Impact of glass corrosion on the electrocatalysis on Pt electrodes in alkaline electrolyte. J Electrochem Soc 155(1):P1

Kwon Y, Birdja Y, Spanos I et al (2012) Highly selective electro-oxidation of glycerol to dihydroxyacetone on platinum in the presence of bismuth. ACS Catal 2(5):759–764

Pumera M, Iwai H (2009) Metallic impurities within residual catalyst metallic nanoparticles are in some cases responsible for “electrocatalytic” effect of carbon nanotubes. Chem Asian J 4(4):554–560

Ullman AM, Liu Y, Huynh M et al (2014) Water oxidation catalysis by Co(II) impurities in Co(III)4O4 cubanes. J Am Chem Soc 136(50):17681–17688

Surendranath Y, Lutterman DA, Liu Y et al (2012) Nucleation, growth, and repair of a cobalt-based oxygen evolving catalyst. J Am Chem Soc 134(14):6326–6336

Bockris JOM, McHardy J (1973) Electrocatalysis of oxygen reduction by sodium tungsten bronze. J Electrochem Soc 120(1):61

Shin S, Kim J, Park S et al (2019) Changes in the oxidation state of Pt single-atom catalysts upon removal of chloride ligands and their effect for electrochemical reactions. Chem Commun 55(45):6389–6392

Schmidt TJ, Paulus UA, Gasteiger HA et al (2001) The oxygen reduction reaction on a Pt/carbon fuel cell catalyst in the presence of chloride anions. J Electroanal Chem 508(1):41–47

Strmcnik D, Escudero-Escribano M, Kodama K et al (2010) Enhanced electrocatalysis of the oxygen reduction reaction based on patterning of platinum surfaces with cyanide. Nat Chem 2(10):880–885

Katsounaros I, Schneider WB, Meier JC et al (2013) The impact of spectator species on the interaction of H2O2 with platinum – implications for the oxygen reduction reaction pathways. Phys Chem Chem Phys 15(21):8058–8068

Calle-Vallejo F, Koper MTM (2013) Theoretical considerations on the electroreduction of CO to C2 species on Cu(100) electrodes. Angew Chem Int Ed 52(28):7282–7285

Hatsukade T, Kuhl KP, Cave ER et al (2014) Insights into the electrocatalytic reduction of CO2 on metallic silver surfaces. Phys Chem Chem Phys 16(27):13814–13819

Hori Y, Wakebe H, Tsukamoto T et al (1994) Electrocatalytic process of CO selectivity in electrochemical reduction of CO2 at metal electrodes in aqueous media. Electrochim Acta 39(11):1833–1839

Kedzierzawski P, Augustynski J (1994) Poisoning and activation of the gold cathode during electroreduction of CO 2. J Electrochem Soc 141(5):L58–L60

Kostecki R, Augustynski J (1994) Electrochemical reduction of CO2 at an activated silver electrode. Berichte der Bunsengesellschaft für physikalische Chemie 98(12):1510–1515

Kuhl KP, Cave ER, Abram DN et al (2012) New insights into the electrochemical reduction of carbon dioxide on metallic copper surfaces. Energy Environ Sci 5(5):7050–7059

Montoya JH, Peterson AA, Nørskov JK (2013) Insights into C-C coupling in CO2 electroreduction on copper Eeectrodes. ChemCatChem 5(3):737–742

Nie X, Esopi MR, Janik MJ et al (2013) Selectivity of CO2 Reduction on copper electrodes: the role of the kinetics of elementary steps. Angew Chem Int Ed 52(9):2459–2462

Peterson AA, Nørskov JK (2012) Activity descriptors for CO2 electroreduction to methane on transition-metal catalysts. J Phys Chem Lett 3(2):251–258

Sreekanth N, Phani KL (2014) Selective reduction of CO2 to formate through bicarbonate reduction on metal electrodes: new insights gained from SG/TC mode of SECM. Chem Commun 50(76):11143–11146

Masa J, Zhao A, Xia W et al (2013) Trace metal residues promote the activity of supposedly metal-free nitrogen-modified carbon catalysts for the oxygen reduction reaction. Electrochem Commun 34:113–116

Morales DM, Masa J, Andronescu C et al (2017) Promotional effect of Fe impurities in graphene precursors on the activity of MnOX/graphene electrocatalysts for the oxygen evolution and oxygen reduction reactions. ChemElectroChem 4(11):2835–2841

Deng J, Ren P, Deng D et al (2014) Highly active and durable non-precious-metal catalysts encapsulated in carbon nanotubes for hydrogen evolution reaction. Energy Environ Sci 7(6):1919–1923

Banks CE, Crossley A, Salter C, Compton RG et al (2006) Carbon nanotubes contain metal impurities which are responsible for the “electrocatalysis” seen at some nanotube-modified electrodes. Angew Chem Int Ed 45(16):2533–2537

Corrigan DA (1987) The catalysis of the oxygen evolution reaction by iron impurities in thin film nickel oxide electrodes. J Electrochem Soc 134(2):377–384

Bockris JOM, Otagawa T (1984) The electrocatalysis of oxygen evolution on perovskites. J Electrochem Soc 131(2):290–302

Trasatti S (1984) Electrocatalysis in the anodic evolution of oxygen and chlorine. Electrochim Acta 29(11):1503–1512

Li N, Bediako DK, Hadt RG et al (2017) Influence of iron doping on tetravalent nickel content in catalytic oxygen evolving films. Proc Natl Acad Sci 114(7):1486

Görlin M, Chernev P, Ferreira de Araújo J et al (2016) Oxygen evolution reaction dynamics, faradaic charge efficiency, and the active metal redox states of Ni–Fe oxide water splitting electrocatalysts. J Am Chem Soc. 138(17):5603–5614

Louie MW, Bell AT (2013) An investigation of thin-film Ni–Fe oxide catalysts for the electrochemical evolution of oxygen. J Am Chem Soc 135(33):12329–12337

Friebel D, Louie MW, Bajdich M et al (2015) Identification of highly active Fe sites in (Ni, Fe)OOH for electrocatalytic water splitting. J Am Chem Soc 137(3):1305–1313

Ahn HS, Bard AJ (2016) Surface interrogation scanning electrochemical microscopy of Ni1–xFexOOH (0 < x < 0.27) oxygen evolving catalyst: kinetics of the “fast” iron sites. J Am Chem Soc 138(1):313–318

Bode H, Dehmelt K, Witte J (1966) Zur kenntnis der nickelhydroxidelektrode—I.Über das nickel (II)-hydroxidhydrat. Electrochim Acta 11(8):1079–1087

Kostecki R, McLarnon F (1997) Electrochemical and in situ Raman spectroscopic characterization of Nickel Hydroxide Electrodes: I. Pure Nickel Hydroxide. J Electrochem Soc 144(2):485–493

Merrill MD, Dougherty RC (2008) Metal oxide catalysts for the evolution of O2 from H2O. J Phys Chem C 112(10):3655–3666

Godwin IJ, Lyons MEG (2013) Short communication. Electrochem Commun 32:39–42

Oliva P, Leonardi J, Laurent JF et al (1982) Review of the structure and the electrochemistry of nickel hydroxides and oxy-hydroxides. J Power Sour 8(2):229–255

Desilvestro J, Corrigan DA, Weaver MJ (1988) Characterization of redox states of nickel hydroxide film electrodes by in situ surface Raman spectroscopy. J Electrochem Soc 135(4):885–892

Michael EG, Lyons MPB (2008) The oxygen evolution reaction on passive oxide covered transition metal electrodes in aqueous alkaline solution Part 1-Nickel. Int J Electrochem Sci 3:1386–1424

Lu PWT, Srinivasan S (1978) Electrochemical-ellipsometric studies of oxide film formed on nickel during oxygen evolution. J Electrochem Soc 125(9):1416–1422

Cappadonia M, Divisek J, von der Heyden T et al (1994) Oxygen evolution at nickel anodes in concentrated alkaline solution. Electrochim Acta 39(11):1559–1564

Wehrens-Dijksma M, Notten PHL (2006) Electrochemical Quartz Microbalance characterization of Ni(OH)2-based thin film electrodes. Electrochim Acta 51(18):3609–3621

Yeo BS, Bell AT (2012) In situ Raman study of nickel oxide and gold-supported nickel oxide catalysts for the electrochemical evolution of oxygen. J Phys Chem C 116(15):8394–8400

Trotochaud L, Young SL, Ranney JK et al (2014) Nickel–iron oxyhydroxide oxygen-evolution electrocatalysts: the role of intentional and incidental iron incorporation. J Am Chem Soc 136(18):6744–6753

Spanos I, Tesch MF, Yu M et al (2019) Facile protocol for alkaline electrolyte purification and its influence on a Ni–Co oxide catalyst for the oxygen evolution reaction. ACS Catal 9(9):8165–8170

Meyer RE (1960) Cathodic processes on passive zirconium. J Electrochem Soc 107(10):847

Corrigan DA (1989) Hydrogen generator having a low oxygen overpotential electrode. US Patent 4,882,024

Corrigan DA, Bendert RM (1989) Effect of coprecipitated metal ions on the electrochemistry of nickel hydroxide thin films: cyclic voltammetry in 1M KOH. J Electrochem Soc 136(3):723–728

Singh RN, Pandey JP, Anitha KL (1993) Preparation of electrodeposited thin films of nickel-iron alloys on mild steel for alkaline water electrolysis. Part I: studies on oxygen evolution. Int J Hydrogen Energy 18(6):467–473

Hu C-C, Wu Y-R (2003) Bipolar performance of the electroplated iron–nickel deposits for water electrolysis. Mater Chem Phys 82(3):588–596

Li X, Walsh FC, Pletcher D (2011) Nickel based electrocatalysts for oxygen evolution in high current density, alkaline water electrolysers. Phys Chemy Chem Phys 13(3):1162–1167

Landon J, Demeter E, İnoğlu N et al (2012) Spectroscopic characterization of mixed Fe–Ni oxide electrocatalysts for the oxygen evolution reaction in alkaline electrolytes. ACS Catal 2(8):1793–1801

Miller EL, Rocheleau RE (1997) Electrochemical behavior of reactively sputtered iron-doped nickel oxide. J Electrochem Soc 144(9):3072–3077

Gong M, Li Y, Wang H et al (2013) An advanced Ni–Fe layered double hydroxide electrocatalyst for water oxidation. J Am Chem Soc 135(23):8452–8455

McCrory CCL, Jung S, Peters JC et al (2013) Benchmarking heterogeneous electrocatalysts for the oxygen evolution reaction. J Am Chem Soc 135(45):16977–16987

Trotochaud L, Ranney JK, Williams KN et al (2012) Solution-cast metal oxide thin film electrocatalysts for oxygen evolution. J Am Chem Soc 134(41):17253–17261

Klaus S, Cai Y, Louie MW et al (2015) Effects of Fe electrolyte impurities on Ni(OH)2/NiOOH structure and oxygen evolution activity. J Phys Chem C 119(13):7243–7254

Stevens MB, Trang CDM, Enman LJ et al (2017) Reactive Fe-sites in Ni/Fe (Oxy)hydroxide are responsible for exceptional oxygen electrocatalysis activity. J Am Chem Soc 139(33):11361–11364

Zhang T, Nellist MR, Enman LJ et al (2019) Modes of Fe incorporation in Co–Fe (Oxy)hydroxide oxygen evolution electrocatalysts. Chemsuschem 12(9):2015–2021

Li Y-F, Selloni A (2014) Mechanism and activity of water oxidation on selected surfaces of pure and Fe-doped NiOx. ACS Catal 4(4):1148–1153

Zhou Y, López N (2020) The role of Fe species on NiOOH in oxygen evolution reactions. ACS Catal 10(11):6254–6261

Chen JY, Dang L, Liang H et al (2015) Operando analysis of NiFe and Fe oxyhydroxide electrocatalysts for water oxidation: detection of Fe4+ by Mössbauer spectroscopy. J Am Chem Soc 137(48):15090–15093

Xiao H, Shin H, Goddard WA (2018) Synergy between Fe and Ni in the optimal performance of (Ni, Fe)OOH catalysts for the oxygen evolution reaction. Proc Natl Acad Sci 115(23):5872

Diaz-Morales O, Ledezma-Yanez I, Koper MTM et al (2015) Guidelines for the rational design of Ni-based double hydroxide electrocatalysts for the oxygen evolution reaction. ACS Catal 5(9):5380–5387

Burke MS, Zou S, Enman LJ et al (2015) Revised oxygen evolution reaction activity trends for first-row transition-metal (oxy)hydroxides in alkaline media. J Phys Chem Lett 6(18):3737–3742

Stevens MB, Enman LJ, Korkus EH et al (2019) Ternary Ni-Co-Fe oxyhydroxide oxygen evolution catalysts: Intrinsic activity trends, electrical conductivity, and electronic band structure. Nano Res 12(9):2288–2295

Chung DY, Lopes PP, Martins PFBD et al (2020) Dynamic stability of active sites in hydr(oxy)oxides for the oxygen evolution reaction. Nat Energy 5(3):222–230

Acknowledgements

The authors would like to acknowledge Max Planck Society and the MAXNET Energy consortium for the financial support.

Funding

Open Access funding enabled and organized by Projekt DEAL..

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Spanos, I., Masa, J., Zeradjanin, A. et al. The Effect of Iron Impurities on Transition Metal Catalysts for the Oxygen Evolution Reaction in Alkaline Environment: Activity Mediators or Active Sites?. Catal Lett 151, 1843–1856 (2021). https://doi.org/10.1007/s10562-020-03478-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-020-03478-4