Abstract

This work investigates the long-term performance of Ba-Ni-hexaaluminate, BaNixAl12−xO19 as a catalyst in reforming of 1-methyl naphthalene and/or methane in a model-gas simulating that from a circulating fluidized bed (CFB) gasifier during 23–29 h in a lab scale set-up, as well as the tendency for coke formation, sintering and sulphur poisoning. 1-Methyl naphthalene is used as a tar model substance. The Ba-Ni-hexaaluminate induces a high conversion of both compounds in the temperatures investigated (850 and 950 °C) under sulphur-free conditions. In sulphur-containing gas, the methane conversion stops at 20 ppm H2S and the reforming of 1-MNP at 850 °C is slightly reduced at 100 ppm.

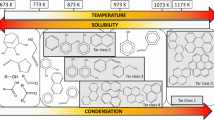

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Gasification of biomass is an attractive way of converting renewable carbon to energy or syngas, and one of the key obstacles to a successful development of technically advanced commercial-scale biomass gasification technologies is the formation of tars present in the produced raw gas.

Tars are a complex mixture of condensable hydrocarbons that may lead to fouling if the gasification gas becomes (over-) saturated. These fouling phenomena are not a problem as long as all the tars remain in the gas phase. But condensed tars may result in aerosol formation and in depositions, both inside the gasifier and in equipment coming in contact with tar contaminated product gas. This means that the base of the tar problematics is mainly depending on the composition and properties of the tar compounds formed and not necessarily on the amounts, as different tar components have different properties and the end usage applications may be more or less sensitive to different tars. Tars may be composed by single-ring to 5-ring aromatic compounds, but also as other oxygen containing hydrocarbons and complex polycyclic aromatic hydrocarbons (PAH:s) [1]. During gasification tars are being formed and reformed in a series of reactions. The so-called primary tars arise from the initial pyrolysis step and are strongly dependent on the fuel being gasified and may contain oxygenated hydrocarbons or substituted multifunctional phenols. In the following oxidation step under increased temperatures to about 500 °C the primary tars start to rearrange, forming gaseous products and a group of compounds called secondary tars with substances such as alkylated mono- or diaromatics. With a further increase of temperature (over 800 °C) and under influence of the reducing syngas the secondary tars start to decompose and recombine into so called tertiary tars which are mainly made up by aromatics and polynuclear aromatic hydrocarbons (PAH:s) such as benzene and naphthalene [2].

Tars are often defined differently by various research groups. The EU/IEA/US-DOE definition from 1998 [3] is that tars are all organic contaminants with a molecular weight larger than benzene, and this is also the definition being used in this work.

Some of the primary tar decomposition reactions that may occur in the gasification of woody biomass are [4]:

where CnHx represents tars and CnHy represents hydrocarbons with less C than tar.

The reforming reactions and partial oxidation lead to an enrichment of H2 and CO in the product gas of the gasifier. From them, steam reforming is largely used for the tar conversion [5].

One of the most used metal-containing catalysts for steam reforming contains nickel [6]. Nickel-based catalysts in various forms are generally considered to be very active for tar steam reforming, have a good robustness to a reduced expense. Nevertheless, factors like carbon deposition and sulfur poisoning still pose severe problems with these catalysts [7].

In steam reforming reactions carbon may be deposited on the surface of the catalyst and/or in its micropores [8]. This is assumed to be caused by disproportionation of CO, decomposition of hydrocarbons and/or by the dehydrogenation of adsorbed hydrocarbons. The formation of carbonaceous products, such as coke, in gasification of hydrocarbons specifically on nickel is fairly well understood. The assumption is that two types of carbons are being formed in the degrading reactions [9]; the monoatomic alpha-carbon and the heteroatomic beta-carbon. The beta-carbon is formed if there is an excess in the highly reactive alpha-carbon, or if the gasification process is slow. Formation of beta-carbons results in a coke build-up.

In this work we aim to study the possibility of incorporating the nickel in a crystal structure to decrease steam reforming complications with coking and poisoning. The catalytic tests are made in a prolonged timescale in order to get a better understating for their performance in a real application. The material in focus is hexaaluminate.

The general formula of hexaaluminates is M2O(M′O)-6Al2O3, where M or M′ stand for alkaline or alkaline-earth metal. The structure is lamellar and consists of layers of spinel blocks that are separated by a monolayer of oxides derived from either bulky alkaline cations or bulkier alkaline-earth ones [10]. By introducing transition metals into the hexaaluminate spinel blocks the structure gains well dispersed active sites that are less subjected to sintering, vaporization and carbon deposition [11]. Hexaaluminates have been used in various applications such as combustion, partial oxidation and steam- or dry-reforming reactions, either as catalysts or as support for catalysts [7, 9, 11, 12]. The dissociative adsorption of both hydrocarbons and sulphur on nickel catalysts has been found to be structure sensitive, but how does this apply on Ni-substituted hexaaluminates in biomass gasification? Does the dispersion of Ni in the material improve its coke resistance when acting as a steam reforming catalyst? And can it be assumed that the dispersion of the active metal in the electron deficient surroundings would reduce the disposition for coke formation and, it in the same manner, decrease sulfide formation? There are studies [13] made on coke and sulphur resistance in other, similar applications, suggesting a potential in metal-substituted hexaaluminates. Hepola [14] also reports on a temperature correlated reactivation on sulphur poisoned Ni-catalysts for hot gas cleaning. The activity returned when the H2S was removed and the reactivation rate increased with the temperature. How does this apply on sulphur deactivated hexaaluminates?

The formation of coke on reforming catalysts has shown to be highly dependent on the coordination and dispersion of the active sites in the catalyst as they affect the adsorption of hydrocarbons to the catalyst surface. If the hydrocarbons are strongly adsorbed, the carbon depositing reactions are more prone to occur and it has been suggested that it is the electron rich surfaces that adsorb more strongly. Well-dispersed and non-coordinated active sites have proven to better resist coke formation. Gardner et al. [13] made reforming studies on Ni-substituted hexaaluminates. Their results suggest that a lower state of coordination of the active Ni sites in the catalyst would result in less coke formation. Trimm [9] also demonstrated that by deactivating active sites by so called ensemble size control, the partially blocked sites would cause a catalyst more resistant to coking. In the BaNi-hexaaluminate catalyst, the barium ions in the lattice will influence the basicity of support and thus suppress the carbon deposition as acid sites are neutralized and steam adsorption enhanced [9].

Another property with high concern in biomass gasification is the thermal stability of the catalytic material. Hexaaluminates and related compounds are considered as highly suitable as high-temperature combustion catalyst due to their excellent thermal stability and decreased tendency for sintering [15]. By substituting nickel into the lattice of hexaaluminate the structure itself may serve to limit sintering of the active Ni species at the high temperatures used and thereby reducing carbon deposition [10]. When testing BaNiHA in partial oxidation of methane Chu reports that the spent catalyst has no loss of the surface nickel active species even after 100 h [8].

2 Experimental

The catalyst tested in this study consists of BaNi-hexaaluminate with Böhmite as a binder and the catalytic tests are all made in a lab-scale set-up at Linnaeus University. The tests are carried out either with CH4 or 1-methyl naphthalene (C10H7CH3) as the target for reforming. The bulk gas is a model gas resembling the permanent gases in CFBG product gas when gasifying woody biomass. The 1-methyl naphthalene (1-MNP) is a 95% solution, purchased from Sigma Aldrich, introduced by a syringe pump into a heated gas line.

The effect of H2S addition is examined and the long-term activity related to eventual coke formation. The composition of the gas produced in the tests is determined in an on-line analysis setup. The catalysts used are characterized before and after tests.

2.1 Conversion and Yields

The conversion degree (X) of the aromatic hydrocarbon is defined as:

The carbon balance for the performed reforming test on 1-MNP and CH4 are calculated in Table 1.

2.2 Preparation of Catalysts

BaNi-hexaaluminate is synthesized as a BaNi0.5Al10.5O19 according to a co-precipitation method previously described [16] by standard ProAnalysi quality chemicals purchased from Fisher Scientific. To prepare the catalyst material, the calcined and milled BaNiHA is mixed as slurry with Böhmite (Disperal 20 from Sasol) to a 90:10-relation (w:w). The slurry is then dried and calcined at 1200 °C for 7 h and finally crushed and sieved. The particle size on the catalysts used in the tests is 0.5–0.7 mm diameter. Prior to the test the catalyst is reduced within the reactor set-up at 950 °C for 2 h in 5% H2 in N2.

2.3 Set-Up of Reactor

Activity tests were carried out in a laboratory-scale, down flow, fixed-bed reactor (Fig. 1). The reactor compartment is made up by a stainless high temperature steel tube construction with a length of 300 mm and id 25 mm. The bed consists of 15 ml catalyst placed in the middle of the reactor resting on a calcinated α-alumina bed (T-162 from Almatis, calcinated at 1200 °C, 7 h) of 1–2 mm diameter grains. The reactor is also filled with this α-alumina on top of the catalyst bed to reduce the void.

The desired composition of permanent gases is prepared by mixing pure gases/generated steam by means of a system of mass flow controllers from Bronkhorst. All gases are instrumental quality from AGA gas. The gas feed consists of steam, N2, CO, CO2, H2, CH4 and H2S in various concentrations with a total GHSV of 2500 h−1 based on the active catalyst. In the test with 1-methyl naphthalene a syringe pump (CMA/100) is adding the tar model substance into the heated gas line and in these experiments no CH4 is added. The catalytic reactor is placed inside of a transparent tube furnace (Thermcraft, TTL-1.5-0-12-1B) in a vertical set-up. A thermocouple is placed inside the catalyst bed. The composition of the resulting gas is analyzed. Also, a gas by-pass may be led past the reactor in order to measure the composition of the unaffected gas as a control point.

The conditions for the catalytic experiments are presented in Table 2. Eight different conditions are tested, with and without 1-MNP, with and without H2S and each at 850 and 950 °C. The sulfur recovery test is run with CH4 at 950 °C.

2.4 On-Line Gas Analysis

The components in the produced gas are analyzed on-line by means of GC-FID for the hydrocarbons and by micro-GC (TCD) for CO/CO2/H2/CH4. A FTIR-instrument is also used for on-line control analysis of permanent gases. The GC-FID is a Varian CP3800 equipped with heated gas-sample distribution line, an on-line injector and a CP-SIL CB8 capillary column. The micro-GC is a Varian CP4900 with a TCD detector and a Poraplot Q column for the determination of CO/CO2 and a Molsieve 5A PLOT column for H2. The FTIR-instrument is a Gasmet DX4000 equipped with a heated sample line.

2.5 Characterization

The total metal content was analyzed by means of Atomic Absorption Spectroscopy. Measurements were performed by a Perkin-Elmer AAnalyst 400 Atomic Absorption Spectrometer with the following detection limits: Ba 0.5 ppm, Al 1 ppm and Ni 0.14 ppm.

Thermal analysis was carried out by a Netzsch STA 409PC. The heating rate used was 15 °C min−1, and the samples were heated in air from ambient temperature to 1000 °C.

X-ray powder diffraction was performed using a PANalytical X’Pert diffractometer equipped with a copper anode (λmean = 0.15418 nm) and a fast X’Celerator detector. Wide-angle diffractogram was collected over 2θ range from 5 to 70° with a step size of 0.07° and counting time 50 s. X’Pert HighScore Plus software with standard database was used for phase identification.

Scanning electron microscopy (SEM) coupled with energy dispersive spectrometry (EDS) was performed by using an EP EVO 50 Series Instrument (EVO ZEISS) equipped with an INCA X-act Penta FET® Precision EDS microanalysis and INCA Microanalysis Suite Software (Oxford Instruments Analytical) to provide images of the spatial variation of elements in a sample. The accelerating voltage was 20 kV and the spectra were collected in duration of 60 s.

Micro-Raman spectra were in situ recorded during SEM/EDS analysis by a Renishaw Raman Invia spectrometer configured with a Leica DMLM microscope using Ar+ laser source (λ = 514.5 nm, Pout = 30 mW considering the decrease in power due to the plasma filter). In each measurement, the laser power was set by 10% of the source and the signal was accumulated by four individual spectra with an acquisition time of 10 s.

N2 adsorption–desorption isotherms were measured at − 196 °C using a Micromeritics ASAP 2020 instrument. Before measurement, the catalysts were preconditioned via two steps at 150 °C for 30 min under a pressure of 30 μmHg and then 250 °C for 30 min. The specific surface area (SBET) was calculated using the Brunauer–Emmett–Teller (BET) multiple-point method in the relative pressure range p/po from 0.05 to 0.3, while the pore volume was calculated at p/p0 = 0.99.

High resolution transmission electron microscopy (HRTEM) characterization was carried out by a TEM/STEM FEI TECNAI F20 microscope, equipped with an EDS analyzer. Powder catalysts were suspended in ethanol under ultrasounds for 20 min. The suspension was subsequently deposited on a Cu grid with lacey quanti-foil carbon film and dried at 100 °C before doing the measurement. Fast Fourier Transformation (FFT) was applied to determine the interplanar spacing of the crystals. Particle size distribution was processed considering around 150 particles in three different zones for each sample.

Temperature programmed reduction by Hydrogen (H2-TPR) was performed in an AutoChem II (Chemisorption analyzer, Micromeritics). The catalyst was firstly pre-conditioned at 150 °C under 30 mL min−1 of He for 30 min. After cooling to 40 °C in He, the carrier gas was switched to 5% H2/Ar (v/v) at 30 mL min−1. When the baseline was stable, the temperature was elevated to 900 °C with a ramp of 10 °C min−1, while the amount of H2 consumed was measured by means of a thermal conductivity detector (TCD).

3 Results and Discussion

3.1 Catalyst Characterization

AAS analysis shows that the composition of the prepared Ba-Ni-substituted hexaaluminate is BaNi0.5Al10.5O19.

XRD analysis in Fig. S1 shows diffraction patterns of the as-prepared Ba-Ni-hexaaluminate and after mixing with Boehmite, respectively. The as-synthesized sample contains the β-Al2O3 phase (mainly type I), in which Ni and Ba are substituted into the spinel framework [13, 17, 18] and the BaAl2O4 side-phase [17]. After mixing with the boehmite binder (10 wt%), the BaAl2O4 reflections disappear, like in our previous work [16] (90 wt% boehmite binder). However, the α-Al2O3 and θ-Al2O3 phases previously identified are absent, as the boehmite concentration is lower. NiO reflections are not observed, which may be related to the inclusion of Ni2+ into the spinel block [19].

The as prepared NiBaHA shows low surface area and pore volume, Table 1, which are characteristic of these types of materials [20] [21]. N2 adsorption/desorption isotherms are related to macroporous or non-porous materials with interparticle pores [22]. The dilution of the NiBaHA with 10 wt% binder leads to a slight decrease in surface area of the calcined sample, but to an increase in total pore volume, this may be related to some contribution of the α-Al2O3 expected to be developed by calcination of boehmite at 1200 °C, though it was not observed by XRD. H2-TPR profiles of the catalyst exhibited one very weak peak at ca. 670 °C and one main peak located at high temperature (higher than 950 °C). The former is related to a small amount of segregated NiO, not observable by XRD, while the latter may be attributed to Ni2+, which is strongly incorporated into the support [22].

To investigate the morphology of the support as well as the particle size and distribution of Ni0 in the catalyst at the beginning of the reaction, the Ni sample (actual catalyst) was reduced under similar conditions as before catalytic tests and characterized by SEM and HRTEM (Fig. 2). It should be remarked that it was not possible to detect the reflections of the reforming active phase Ni0 in the diffraction pattern due to the overlapping of the Ni0 with BHA peaks. SAED analyses confirmed the formation of Ni0 particles. The images show irregular particles with anisotropic planar crystallites due to the layered structure of hexaaluminate (Fig. 2a, c). A quite homogeneous distribution of Ni0 particles is identified at higher magnifications (Fig. 2b, d). From HAADF images a particle size distribution between 10 to 60 nm is measured, with an average size of 33 ± 11 nm (Fig. 3d).

Roussière et al. [23] has proposed a mechanism for the reduction of Ni2+ in hexaaluminates. A Ni2+ cation that is substituted in the hexaaluminate structure migrates from the mirror-plane to the grain surface where it is reduced. Metallic nanoparticles of nickel migrate to edges and steps close to surface-defect sites of the hexaaluminate grains where the Ni0 can be regarded as nucleation centers for growing Ni-particles. This mechanism is believed to start over and over.

3.2 Catalytic Tests

To investigate any formation of carbon and the sintering phenomena during steam reforming, two studies were made in a lab-scale set-up under controlled experimental conditions. Gas compositions were set to be similar to actual CFBG conditions according to permanent gases and as a carbon source in the steam reforming reaction either methane or 1-methyl naphthalene (1-MNP) was used. A 15 cm3 of catalyst was used and the GSVH was 5700 h−1 based on the active catalyst. The different experiments were carried out in model gas under conditions shown in Table 2. The temperatures tested were 850 °C and 950 °C and the time span was in the order of 23–29 h with a sampling stop during night. A blank test of the thermal decomposition of 1-MNP on α-Al2O3 has been made in a previous study [16] where a CFBG model gas on α-Al2O3 at 950 °C under non-sulphur conditions with a SV of 2500 h−1 has shown a 10% thermal conversion at 800 °C and a 60% thermal conversion of 1-MNP at 950 °C. In the prevailing SV this would be equivalent to approximately 10% thermal conversion of 1-MNP. With this in mind there is also a small extent of thermal degradation causing the conversion.

The effect of sulphur on CH4 and 1-MNP reforming was investigated performing overnight tests with a stepwise increasing H2S concentration up to 100 ppm during day one, running with 100 ppm overnight. Then, if the conversion was unaffected after approximately 23 h, the H2S concentration was stepwise increased to 300 ppm in order to stress the catalyst (Table 3).

- Exp 1:

Reforming of CH4 at 850 °C

- Exp 2:

Reforming of CH4 at 950 °C

- Exp 3:

Reforming of CH4 with H2S at 850 °C

- Exp 4:

Reforming of CH4 with H2S at 950 °C

- Exp 5:

Reforming of 1-MNP at 850 °C

- Exp 6:

Reforming of 1-MNP at 950 °C

- Exp 7:

Reforming of 1-MNP with H2S at 850 °C

- Exp 8:

Reforming of 1-MNP with H2S at 950 °C

- Exp 9:

Recovery test. Reforming of CH4 ± H2S at 950 °C

3.2.1 Carbon Formation and Sintering

During reforming at 950 °C (experiments 2 and 6) both CH4 and 1-MNP show a total conversion even after 28 h of time-on-stream, Figs. 3 and 4b. In the reforming of 1-MNP, the tests also show a complete reforming of all the 1-MNP intermediates.

In the experiments at 850 °C the reforming of 1-MNP, exp 5, has an average of 96.6% conversion and shows no tendency to decrease during the 29 h experiment. However, the complete conversion of 1-MNP derived products is decreasing; resulting in minor concentrations of partially cracked substances in the outlet stream, such as benzene and substituted benzenes.

The resulting gas composition for the CH4-reforming at 850 °C run for 28 h, exp 1, is shown in Fig. 4a, with a linear fitting plotted for both CH4 and reaction products. The concentrations are measured in moist gas. The conversion decreases from 100 to 90% after an overnight run (totally 28 h). Moreover there is an increased amount of CO and a simultaneous decrease of H2 and CO2 as would be expected according to the equilibrium, although the sensitivity of the measurements is not sufficient for this to be confirmed by a calculation. The decreased conversion at 850 °C after 15 h is believed to be an effect of sintering of nickel particles as active phase on the catalyst surface. This is not shown at 950 °C (Fig. 4b) as the reaction rate is increasing. The statement is both supported by the results from reforming of methane with H2S, as the surface nickel is deactivated by sulphur resulting in an interrupted conversion reaction and by the results from characterization of the spent catalyst.

The characterization of the spent catalysts by XRD revealed that the Ni-Ba-hexaaluminate structure is not modified after the different reaction conditions due to their high thermal stability (Figs. S1 and S2). Indeed, the catalysts were calcined at a temperature widely overcoming the reaction temperature. However, the reforming causes a slight decrease in surface area, with the exception of the one tested for CH4 reforming at 850 °C.

HRTEM images confirm that Ni particles sintered during reforming using either CH4 or 1-MNP as feedstock, although there are no Ni0 reflections identified in the diffraction patterns in Fig. 2, like for the reduced sample it was not possible to distinguish Ni0 reflections in the XRD due to the overlapping with BHA reflections. However, SAED confirmed its presence of Ni0. In the reforming of CH4 at 950 °C (Fig. 5), the sintering of Ni particles results in a wide particle size distribution up to 190 nm with an average value of 90 ± 53 nm (Fig. 5a, b), while after 1-MNP reforming, the particles are distributed up to 100 nm with a medium size of 46 ± 20 nm (Fig. 5c, d).

After reforming of 1-MNP at 850 °C, amorphous and graphite-like carbonaceous deposited on the catalyst surface are identified by micro-Raman with bands at 1352 and 1588 cm−1 (Fig. 6). It should be noted that, despite the long time on stream, graphite was not identified by XRD (Fig. S2), unlike in dry reforming of CH4 with CO2 reported by Gardner et al. [24]. This can be explained by relatively high steam content in the model gas mixture. The S/C-ratio for the experiments is 2.7.

Hence, the sintering of the Ni surface active phase could explain the decrease in the surface area commented above and the loss of activity in the CH4 reforming at 850 °C. While for the reforming of 1-MNP at 850 °C carbon deposition also contributed to the deactivation observed in converting 1-MNP derived degradation products.

3.2.2 Sulphur Deactivation

In the CH4 reforming activity tests, the catalytic activity is severely affected by the addition of H2S, both at 850 and 950 °C. Figure 7 shows how the reforming of CH4 at 950 °C is reduced in sulphur containing gas, even at a concentration as low as 20 ppm. After 1 h on stream an addition of 20 ppm H2S starts and it continues for 1 h. During this time the catalyst activity goes down to zero. After H2S-shut off it takes about 30 min for the catalyst to regain activity to 95% conversion. The second addition of 20 ppm H2S continues for about 1 h and the recovery this time is prolonged. Even after 3 h the catalyst is not recovered to more than about 75% of the original activity. At 850 °C the effect is even more severe (not shown here).

In presence of H2S, XRD diffraction patterns, as expected, are not modified (Figs. S1 and S2) and HRTEM images evidence that Ni sintering also occurs (Fig. 8). This sintering is accompanied by a decrease in the SBET, although it seems that the growing of particles was to some extent limited. For instance, the particle size distribution for the Ni-M-S-950 is in the 10–90 nm range, with an average size of 40 ± 18 nm (Fig. 8d). The sulphur poisoning of Ni particles is evidenced by the correlation between EDS–STEM elemental maps of Ni and S (Fig. 8c). On the other hand, no carbonaceous deposits were identified like in the tests without H2S.

From these results, it could be stated that, as is well-known, NiS is formed during the tests by dissociative chemisorption of H2S [25, 26]. The formation of an amorphous NiS is reversible [27], and thus the catalyst recovers the activity as the sulphur is turned off. Namely, the high operation temperatures and the H2 in the reaction mixture shifts the equilibrium toward the reactant, forming again the active Ni0 sites 28 [28,29,30]. Sintering may explain the not complete recovery of the activity at longer time-on-stream [31].

Additionally, a sulphur-recovery test is performed for CH4 reforming at 950 °C, where 20 ppm H2S is injected for 1 h and then turned off, repeatedly (Fig. 9). The other conditions are the same as for experiment 4. These tests are run for three days, stopped overnight and the catalyst recovers in a low-flow N2 stream at 100 °C. The plot is for the actual accumulated time on stream. The activity results show that there is indeed a catalyst recovery, although not complete, 1 h after exposure to H2S. Repeating the exposure will still imply that the catalyst regains activity; after standing over-night in a low flow of N2 at 100 °C the catalyst is recovered to 95%. This is shown as the starting conversion for day 2 in Fig. 9. The behaviour may be related to sintering as above explained. At the first H2S-shutoff day 2 the catalyst reactivates almost completely within 1 h. The second time there has been sintering enough to form larger particles on the catalyst making it adsorb more sulphur resulting in a prolonged reactivation time.

Active site coordination has been stated to affect the adsorption of sulfur compounds on nickel. It has been reported that a critical ensemble of four nickel atoms was necessary for H2S to dissociatively adsorb and form bulk nickel sulphide [32, 33]. Alstrup and Andersen [34] found that the surface grid of sulphur being adsorbed did not coincide with the surface grid of the nickel metal atoms. Instead, in high coverages, the surface can be best described as containing nickel sulphides with islands of free nickel metal sites. Assuming that these islands of active sites are supernumerary to the substrate the activity would still remain.

The reforming activity of 1-MNP with H2S at 850 °C is shown in Fig. 10. The conversion of 1-MNP is reduced to 60% conversion at 850 °C after 5 h on stream in 100 ppm H2S. At 950 °C it remains at 100% throughout the experiment, even at increasing concentrations of H2S up to 300 ppm during day 2 (not shown here).

But, unlike 1-MNP, the reforming ability for benzene is affected by the presence of sulfur. Figure 11 shows how the cracking products from 1-MNP also degrades in a sulphur containing model gas. As can be seen the degradation of 1-MNP is total up to 300 ppm H2S in the inlet gas, but there is a minor part of benzene remaining as 60 ppm H2S is introduced. And as the concentration of H2S increases, the ability to crack benzenes decrease.

The different behavior in reforming of methane compared to 1-MNP suggests that there are different mechanisms involved in their decomposing reactions on the catalyst surface in the steam reforming reaction. At increasing sulphur load the product gas from decomposing of 1-MNP contains increasing amounts of benzene. Previous work has also shown a significant change of product distribution on Ni catalysts after being poisoned by sulphur [26, 33, 34]. This is likely due to the difference in C-H bond dissociation energy in these hydrocarbons. For example, the molecular bond dissociation energies for RH → R + H for some hydrocarbons are: Benzene (113 kcal/mol) > CH4 (105 kcal/mol) > C2H6 (101 kcal/mol) > C3H8 (98 kcal/mol) [35], which would be in reverse order of their reforming activity.

The increased reversibility of adsorbed sulphur with increasing temperature has been shown on Ni-catalysts by Hepola [14]. A high temperature during regeneration, as well as a reducing atmosphere, is assumed to have a positive effect because of the high heat of chemisorption for H2S.

Characterization of the spent catalysts was also performed and data are summarized in Figs. 8 and 12, confirming that surface NiS formation, sintering and carbon deposition are the three deactivation phenomena, which depend on the SR temperature. The efficiency of the catalyst at 950 °C in reforming the 1-MNP into permanent gasification gases is affected by the formation of NiS on the surface as identified by HRTEM of the spent catalyst (Fig. 12). While at 850 °C, besides the S-poisoning the formation of carbon that covers both the support and the nickel particles takes place, as identified by micro-Raman and HRTEM (Fig. 12). This can also contribute to the deactivation, like in the tests without H2S.

4 Conclusion

BaNi-substituted hexaaluminate, BaNi0.5Al10.5O19, obtained by a co-precipitation route in aqueous media, has been tested as a steam reforming catalyst in the degradation of methane and of methyl-naphthalene in a gasifier model gas. Long term lab-scale tests were run at 850 or 950 °C in a gasification model-gas, in the presence or absence of sulphur. It has been shown that the conversion of methane at 850 and 950 °C is very high in a sulphur free atmosphere and with no carbon formation. At 850 °C the conversion decreases from 100 to 90% after the first day of tests, due to sintering. A minor sintering effect may be also seen at 950 °C but the full activity remains. The methane reforming on BaNiHA is very sensitive to sulphur poisoning. But in a recovery test the catalyst reactivates in the steam reforming of methane when sulphur is removed from the gas flow, indicating a reversible but not complete recovery. The recovery behavior after sulphur poisoning proposes that the metal sulphides are unstable amorphous NiS and that the catalyst can be recovered.

The degradation of 1-MNP is complete at 950 °C, even in high concentrations of H2S (up to 300 ppm), which indicates different reaction mechanisms paths compared to those of methane reforming. At 850 °C the 1-MNP conversion is slightly reduced to 96% of conversion at 2nd day and minor amounts of benzene can also be detected in the product gas. A slight coke build-up may be seen in the 1-MNP reforming test with sulfur at 850 °C, but not at 950 °C. The complete degradation of 1-MNP to permanent gases at 850 °C is also negatively impacted by sulphur containing gas resulting in increasing amounts of benzene and substituted benzenes, and this effect increase as the H2S in the model gas increases. Sintering of the catalyst in the steam reforming of 1-MNP with H2S is reduced to some extent and no carbonaceous deposits are detected in these experiments.

Thus, we can conclude that there are promising properties in BaNiHA as a catalyst for tar reforming in biomass gasification gas, but that the presence of sulphur in the process gas decreases the ability to reform smaller hydrocarbons such as benzene and methane even though the deactivation seems to be reversible.

References

Li C, Suzuki K (2009) Renew Sust Energ Rev 13:594

Molino A, Chianese S, Musmarra D (2016) J Energy Chem 25:10

Maniatis K, Beenackers AACM (2000) Biomass Bioenergy 18:1

Font Palma C (2013) Appl Energy 111:129

Kusar H, Brandin J, Hulteberg C (2017) A review of thermo-chemical conversion of biomass into biofuels-focusing on gas cleaning and up-grading process steps. http://lup.lub.lu.se/record/600980e1-9305-4858-aa11

Chan FL (2014) Renew Sust Energ Rev 38:428

Cavattoni T, Garbarino G (2017) Rend Fis Acc Lincei 28(Suppl 1):69. https://doi.org/10.1007/s12210-017-0609-z

Chu W, Yang W, Lin L (2002) Appl Catal A Gen 235:39

Machida M, Teshima T, Eguchi K, Arai H (1991) Chem Lett 134:231

Trimm D (1999) Catal Today 49:3

Artizzu-Duart P, Millet JM, Guilhaume N, Garbowskia E, Primeta M (2000) Catal Today 59:163

Majocchi L, Groppi G, Cristiani C, Forzatti P, Basini L, Guarinoni A (2000) Catal Lett 65:49

Gardner T, Shekhawat D, Berry D, Smith M, Salazar M, Kugler E (2007) Appl Catal A Gen 323:1

Hepola J, Simell P (1997) Appl Catal B Environ 14:305

Mashida M, Sato A, Kijima T, Inoue H, Eguchi K, Arai H (1995) Catal Today 26:239

Parsland C, Larsson A, Benito P, Fornasari G, Brandin J (2015) Fuel Process Technol 140:1

Zhang Y, Wang X, Zhuc Y, Zhang T (2013) Appl Catal B Environ 129:382

Mishra D, Anand S, Panda RK, Das RP (2002) Mater Lett 56:873

Gardner T, Spivey J, Kugler E, Campos A, Hissam J, Roy A (2010) Phys Chem C 114:7888

Santiago M, Pérez-Ramírez J (2007) Environ Sci Technol 41:1704

Lietti L, Cristiani C, Groppi G, Forzatti P (2000) Catal Today 59:191

Thommes M, Kaneko K, Neimark A, Olivier J, Rodriguez-Reinoso F, Rouquerol J, Sing K (2015) Pure Appl Chem 87:1051

Roussière T, Schelkle K, Titlbach S, Wasserschaff G, Milanov A, Cox G, Schwab E, Deutschmann O, Schulz L, Jentys A, Lercher J, Schunk S (2014) ChemCatChem 6:1438

Gardner T, Spivey J, Kugler J, Pakhare D (2013) Appl Catal A Gen 455:129

Wentrcek PW, McCarty JG, Ablow CM (1980) J Catal 61(232):241

Argyle M, Bartholomew C (2015) Catalysts 5:145

Bartholomew C (2001) Appl Catal A Gen 212:17

Koningen J, Sjöström K (1998) Ind Eng Chem Res 37(2):341–346

Srinakruang J, Sato K, Vitidsant T, Fujimoto K (2006) Fuel 85(2419):2426

Hernandez AD, Kaisalo N, Simell P, Scarsella M (2019) Appl Catal B 258:117977

Hepola J (2000) Sulfur transformations in catalytic hot-gas cleaning of gasification gas. VTT Publ 1:5

Basile F, Albertazzi S, Barbera D, Benito P, Einvall J, Brandin J, Fornasari G, Trifirò F, Vaccari A (2011) Biomass Bioenergy 35:116

Alstrup I, Andersen N (1987) J Catal 104:466

Bartholomew C, Agrawal P (1982) Adv Catal 31:136

Blanksby S, Ellison G (2003) Acc Chem Res 36:255–263

Acknowledgements

Open access funding provided by Linnaeus University. M Almström, Mechanical Engineering, Linnaeus University, Sweden is gratefully acknowledged for assisting in the construction of the reactor.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Parsland, C., Ho, P.H., Benito, P. et al. Ba-Ni-Hexaaluminate as a New Catalyst in the Steam Reforming of 1-Methyl Naphthalene and Methane. Catal Lett 150, 1605–1617 (2020). https://doi.org/10.1007/s10562-019-03042-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-03042-9