Abstract

In the current study, the isomerization of geraniol over a natural sepiolite as a catalyst was investigated and optimized. Prior to application in the isomerization process, the physical and chemical properties of sepiolite were characterized using a battery of instrumental techniques, including XRD, nitrogen adsorption at 77 K, SEM, EDXRF, UV–Vis and FT-IR. Results indicated that geraniol isomerization is very complicated due to the large number of reactions taking place. The catalytic studies showed that the main reaction products were β-pinene, ocimenes, linalool, nerol, citrals, thunbergol and isocembrol; all chemical products with commercial applications. The quantity of each of these products depended on the temperature, catalyst content and reaction time employed in the isomerization process. During the current study, these parameters were varied in a step-wise approach over the ranges 80–150 °C (temperature), 5–15 wt% catalyst content and reaction time of 15–1440 min. As linalool is one of the most commercially important reaction products, the geraniol isomerization method was studied to identify conditions producing the highest selectivity for this compound. The most beneficial conditions for geraniol conversion and linalool formation were established as a temperature of 120 °C, catalyst content of 10 wt% and a reaction time of 3 h.

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Compounds of natural origin are becoming increasingly important in organic syntheses as they can be used as alternative, often cheaper and renewable raw materials. Although these compounds can be obtained from a range of sources, they are generally derived from plant material. The advantages of using compounds of natural origin includes their renewability and the possibility of obtaining them from waste vegetable material. The former is beneficial for the natural environment and fits directly into the concept of sustainable development, while the latter lowers their price. Naturally produced olefins are of particular interest as oxidation or isomerization reactions can be used to transform them into valuable compounds with multiple applications. Common examples of such compounds include limonene obtained from waste orange peel, α-pinene obtained from turpentine and S-carvone obtained from waste products of carraway cultivation (leaves and stems). In addition to their use in organic syntheses, they are also valuable compounds in the perfume, cosmetics (aroma and antioxidant additives) and food industries (flavors and aromas), as well as in medicine (treatment of lung, bladder or cancer). Thanks to their fragrance properties, an interesting application of these compounds is also aroma marketing, where they can be used to influence a customer’s decision to purchase a product [1].

Geraniol ((2E)-3,7-dimethyl-2,6-octadien-1-ol) is a popular ingredient in the composition of many cosmetics as its fragrance is fresh and resembles the smell of geranium flowers. Geraniol is found in essential oils derived from pelargonium (geranium), rose or lemongrass, as well as in a range of spice plants, vegetables and fruits (carrots, nutmeg, coriander, orange, blackberries and blueberries). Pure geraniol is a colorless and oily liquid, with natural antioxidant properties and anticancer activity [2]. However, it can also cause allergic reactions (geraniol is a weak allergen) [3] and undergoes autooxidation upon exposure to air to form the aldehydes geranial (citral A) and neral (citral B), which are also allergens [4]. Geraniol is characterized by a high chemical reactivity, with the presence of the double bonds and hydroxyl group meaning that it can be readily transformed through chemical reactions, facilitating its use as a raw material. As a result, it can be employed in the synthesis of some linear and cyclic compounds through dehydration, cyclization, isomerization, oxidation or C–C coupling reactions.

The isomerization of geraniol on heterogeneous catalysts is not widely described in the literature, but available data suggest a number of commercially relevant products can be formed under certain reaction conditions and with specific catalysts. Yu et al. [5] described FeCl2 × 6H2O catalyzed geraniol isomerization, where linalool and α-terpineol were formed as reaction products. Isomerization was achieved by dissolving geraniol and the catalyst in acetonitrile and using a reaction time of 4 h at room temperature.

Haese et al. [6] described the isomerization of a geraniol/nerol mixture (69.5% and 29.5%, respectively) to linalool (purity 98%). The reaction was carried out at 160 °C under a vacuum of 132–135 mbar, and with the addition of an oxodiperoxotungsten solution and a solution of 8-hydroxyquinoline in methanol. Studies were also conducted with pure geraniol, which gave the same results as those obtained for the geraniol/nerol mixture.

Srivastava et al. [7] described the isomerization of geraniol using gamma-irradiation (source: 60Co). A solution of geraniol in methanol was irradiated with gamma rays, resulting in isomerization to nerol and linalool, although the maximum conversion of geraniol was only 30%.

Ramishvili et al. [8] and Tsitsishvili et al. [9] described the isomerization of geraniol over a range of micro- and micro-mesoporous BEA-type zeolites. Isomerization was carried out in a liquid phase (without any solvent), in an inert gas atmosphere (nitrogen, argon), at temperatures from 27 to 150 °C and for a reaction time of 1–2 h. With the catalysts studied, geraniol formed mainly terpene hydrocarbons with the general formula C10H16 (linalool and nerol), as well as alcohols: C14H24O ((2E, 6E)-6,11-dimethyl-2,6,10-dodecatrien-1-ol and C15H26O (trans, trans-farnesol—(2E, 6E)-3,7,11-trimethyl-2,6,10-dodecatrien-1-ol). The introduction of mesopores to microporous zeolites caused an increase in the acidity of the catalysts, which led to a corresponding increase in geraniol conversion to 99%. For catalysts with lower acidity and with a large amount of mesopores, the formation of trans-sesquiterpene alcohol isomers C14H24O and C15H26O from geraniol was higher [9]. The trans–trans farnesol formed from geraniol isomerization in the presence of the modified BEA catalysts was subsequently transformed into trans, trans, trans-geranylgeraniol. As a result of combining the first and the last carbon atom in the trans, trans, trans-geranylgeraniol molecule, the macrocyclic molecule thunbergol was formed (C20H34O), which was subsequently dehydrated to form thunbergene (C20H32). The conversion of geraniol reached 40%.

While these studies highlight many of the potential isomerization products that can be produced from geraniol, none of the applied catalysts appear capable to producing a broad range of products. The mineral “sepiolite” (also known as meerschaum) is a porous magnesium silicate with the formula Mg4[Si6O15(OH)]26H2O and a structure consisting of tetrahedral SiO4 groups, between which there are layers of magnesium atoms (Fig. 1). Sepiolite is characterized by a large surface area of about 300 m2/g, which has a large number of silanol groups (–Si–OH) acting as adsorption centers. Its particles have an average length of 1–2 μm, a width of 0.01 μm and contain open channels with dimensions of 3.6 Å × 10.6 Å. Sepiolite particles form loosely packed and porous aggregates. The mineral also has potential applications as a catalyst owing to its fine crystals with capillary habit [9]. The large surface area and porosity contribute to sepiolite exhibiting unusual adsorption (pesticides, toxic substances, dyes, Zn2+, Pb2+, NH4+, CrO4− and NO3−) and absorption properties [10, 11]. Importantly, sepiolite is readily available and cheap.

The process of geraniol isomerization can generate many different types of products including dehydration products (β-pinene, ocimenes), isomerization products (linalool and nerol), oxidation products (geranial and neral), and cyclization products (thunbergol). β-pinene (C10H16) occurs in many plants and its fragrance resembles the scent of pine. This compound has applications in medicine as an anti-inflammatory, a bronchodilator, an expectorant and an antiseptic, as well as application as an anti-cancer drug in traditional Chinese medicine [12,13,14,15,16]. Ocimene isomers (C10H16; α-, β- and allo-ocimene) are found in a variety of plants, including marigold and lavender oils. Due to the sweet herbal fragrance, these compounds are mainly used in the perfumery, although they also exhibit antifungal properties [17]. Linalool (C10H18O) is an unsaturated aliphatic alcohol that belongs to the terpene group. This compound is produced by over 200 species of plants, mainly from the Lauraceae families (laurel, cinnamon, rosewood), Lamiaceae (mint, aromatic herbs), Rutaceae (citrus fruit), as well as birch and some fungal species. Studies have shown that linalool reduces the activity of 100 genes that are activated in stressful situations. Linalool is mainly used as a fragrance in cosmetics (soaps, hygiene products, detergents and balms), but also has potential use as an insecticide (against fleas and cockroaches) and mosquito repellent [18]. Nerol (C10H18O) has a rose aroma and is found in essential oils such as neroli (bitter orange) and bergamot. Neroli oil is widely used in the treatment of acute and chronic inflammation, reducing pain sensitivity and symptoms of menopause, as well as an aromatherapeutic agent to reduce stress and improve the endocrine system. The active compounds contained in this oil have an anticonvulsant effect (treatment of epileptic seizures) and microbiological activity toward bacteria, fungi and yeast, leading to application as an auxiliary in the treatment of bacterial skin infections. Neroli oil is used in cosmetics to promote regeneration of skin cells, improve elasticity, help maintain serum levels and reduce the appearance of wrinkles, stretch marks and scars. Its soothing and calming properties have led to use in the treatment of stress-induced dermatological diseases [19,20,21,22,23,24]. Citral (C10H16O) is an organic chemical compound from the aldehyde group, which is characterized by an intense aroma of lemon. This compound has two geometrical isomers; trans (citral a) and cis (citral b). Citral is a component of many essential oils, including lemon, lemon myrtle (90–95%), in the oil of mountain pepper (70–85%), in lemongrass (65–85%), lemon verbena (30–35%), melissa and orange. Citral is used as a fragrance in the perfume industry and as a flavor enhancer in the food industry. It also has antibacterial properties and has been used in the treatment of cancer [25,26,27]. Thunbergol, also known as isocembrol, is a monocyclic diterpene alcohol that has been used in the treatment of cancer [28] and may also have neuroprotective properties [29].

The aim of the current study was to investigate the catalytic activity of sepiolite and characterize the products formed from sepiolite-catalyzed geraniol isomerization. Prior to use, the sepiolite material was subjected to a detailed physicochemical characterization. The geraniol isomerization process chosen for studying sepiolite catalysis is poorly described in the scientific literature due to its high degree of complexity (large number of reactions can occur in the system). The studies conducted examined the influence of temperature, catalyst content and reaction time on the geraniol isomerization process. The tests were carried out under atmospheric pressure, in an atmosphere of air and without the use of a solvent, which is a beneficial alternative to the geraniol isomerization methods described previously. The selectivity for linalool was used as the main parameter for choosing the most beneficial conditions for geraniol isomerization.

2 Experimental

2.1 Materials

Sepiolite catalyst was purchased from Sepifeed (Spain) and geraniol (99 wt%) was purchased from Acros Organics (United States). In addition, the following chromatographic standards (templates) were used during quantitative analyzes by gas chromatography mass spectrometry (GC–MS): citronellol (95%, Sigma Aldrich), citral (95%, Sigma Aldrich), ocimene (90%, Sigma Aldrich), beta-pinene (95%, Fluka), linallol (97%, Acros organics), farnesol (96% Acros organics), nerol (97%, Acros organics), myrcene (technical grade, Sigma Aldrich), geranylgeraniol (85%, Sigma Aldrich), and geraniol (99%, Acros Organics).

2.2 Characterization of Sepiolite Catalyst

X-ray diffraction (XRD) was performed using Empyrean X-ray diffractometer with a Cu Kα radiation source (Malvern Panalytical, UK). Samples were analyzed in the range 5–30° with step size of 0.02°. The specific surface area (SSA), total pore volume (TPV) and micropore volume (MV) were measured by nitrogen adsorption at 77 K using a QUADRASORB evoTM Gas Sorption Surface Area and Pore Size Analyzer (Quantachrome Instruments, USA). Prior to analysis, sepiolite samples were degassed at 250 °C for 20 h under N2. Scanning electron microscopy (SEM) was performed with an ultra-high resolution field emission SEM (Hitachi UHR FE-SEM SU8020, Tokyo, Japan) equipped with the secondary electron detector. Elemental analysis was performed using energy dispersive X-ray fluorescence (EDXRF) spectrometer Epsilon3 (Malvern Panalytical, UK). The structure of sepiolite was characterized by UV–Vis (SPECORD M40) analysis in the wavelength range 200–600 nm. In addition, FT-IR spectra were made (Thermo Nicolet 380 apparatus) in the range of wavenumbers from 400 to 4000 cm−1.

2.3 Isomerization of Geraniol

Geraniol isomerization in the presence of the sepiolite catalyst was carried out in a glass reactor (25 cm3) equipped with a reflux condenser and a magnetic stirrer with a heating function. The studied parameters were changed in the following ranges: temperature 80–150 °C, catalyst content 5–15 wt%, and reaction time from 15 min to 24 h. For both qualitative and quantitative analyses, the post-reaction mixture was centrifuged (350 rpm for 3 min), followed by dissolving an aliquot of the post-reaction solution in acetone in a 1:3 wt ratio (0.2 g of post-reaction solution in 0.6 g of acetone). Qualitative chemical analyses were performed using a GC–MS system comprised of a ThermoQuest Trace 2000 GC fitted with a Agilent J&W DB-5 column (30 m × 0.25 mm × 0.5 µm film thickness) and equipped with a Voyager Finnigan mass spectrometer. The carrier gas was helium at a constant flow of 1 mL/min. Samples (0.5 µL) were injected in split mode at 200 °C. The oven was held at 50 °C (2.5 min), then increased by 10 °C/min to 300 °C and held for 4 min. The transfer line temperature was 200 °C. The MS was operated at 70 eV in full scan mode (10–500 m/z) with the ion source at 200 °C and the quadrupole at 200 °C.

Quantitative analyses were performed with a Thermo Electron FOCUS GC equipped with a flame ionization detector (FID) detector and a Thermo Fisher Scientific TRACE TR-FAME column (cyanopropylphenyl, 30 m × 0.25 mm × 0.25 µm). The carrier gas was helium at a constant flow of 0.7 mL/min. Samples (0.5 µL) were injected in split mode at 200 °C. The oven was held at 60 °C (7 min), then increased by 15 °C/min to 240 °C and held for 2 min. The FID was maintained at 250 °C. Two methods were used to quantitatively determine the reaction products in post-reaction mixtures: (i) an external standard method using commercially available chemical standards, and (ii) an internal standardization method. In the external standard method, 8-point calibration curves for each compound were made within a concentration range of 0–33 wt%. The mass balances for the syntheses allowed the conversion of geraniol and the selectivities of the different products to be calculated. The method employed for calculating these main functions of the process is as follows:

3 Results and Discussion

3.1 Characterization of Sepiolite Catalyst

Characteristic reflections for sepiolite have previously been reported to arise from the planes (1 1 0), (0 4 0) and (4 0 0) at 2θ = 7.46, 19.72 and 26.64°, respectively [30], and were observed in the XRD spectra generated in the current study (Fig. 2). The basal spacing of sepiolite (interlayer distance) calculated from the position of (1 1 0) was equal to 1.18 nm.

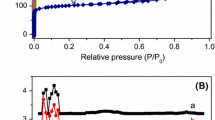

The N2 adsorption–desorption isotherm exhibited type II/IV isotherms with hysteresis loops type H3 without adsorption limit at relative pressures close to 1. The H3 hysteresis indicates the presence of slit-shaped mesopores. The SSA was equal to 105 m2/g, the TPV for pores lower than 180 nm was equal to 0.266 cm3/g, and the MV calculated on the basis of a t-plot was approximately 0.007 cm3/g. Such a low MV value can be neglected and it can be concluded that all the pores were mesopores. Sepiolite grains with different particle sizes were observed in SEM images (Fig. 3a). A detailed analysis showed that the grains were comprised of fibers and that the grains frequently had filamentous borders (Fig. 3b). Bundle-like filamentous–fibrous aggregates were also observed.

The results of elemental analysis are listed in Table 1. Two characteristic peaks at wavelengths of around 230 nm and 260 nm can be observed on the UV–Vis spectrum of sepiolite (Fig. 4). The peak at 230 nm corresponds to the Mg–O–Mg groups in sepiolite, while the peak at 260 nm corresponds to the presence of Mg–O–Si groups [31].

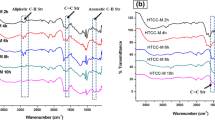

In the FTIR spectrum, the most characteristic bands for sepiolite are the 642 and 682 cm−1 bands, which occur in octahedral phyllosilicates and are associated with the spotting vibrations that occur in the –OH groups (Fig. 5). The next identifying band for this mineral is the band 1200 cm−1, which originates from vibrations caused by Si–O bonds. Bands at 1016 and 460 cm−1 are responsible for the oscillations of Si–O–Si bonds. The 437 cm−1 band is derived from octahedral–tetrahedral bonds, while the 690 and 637 cm−1 bands correspond to Mg–OH vibrations. The bands in the 4000–3000 cm−1 range are responsible for the vibrations of the Mg–OH group [32].

3.2 Influence of Temperature on Geraniol Isomerization

The influence of temperature on sepiolite catalyzed geraniol isomerization was studied over the range of 80–150 °C. The fixed parameters of the geraniol isomerization temperature studies included a catalyst concentration of 10 wt% and a reaction time of 3 h. Figure 6 presents a summary of the influence of temperature on the conversion of geraniol and the selectivities of the different reaction products.

A considerable increase in the degree of geraniol conversion was observed with increasing temperature of the isomerization process. The highest increase in the conversion of geraniol was observed in the temperature range 100–120 °C, where an almost threefold increase from about 29 mol% to about 97 mol% was observed. While the highest temperature tested (150 °C) led to an almost 100% conversion of geraniol, the selectivity of transformation to linalool amounted only to about 6 mol%. Considerably higher values of selectivity for this compound were obtained at lower temperatures in the range 110–130 °C, with the highest value of approximately 19 mol% observed at 120 °C. As the temperature of the reaction system is increased, a slight increase in the selectivity values of most other geraniol isomerization products is also observed, including β-pinene (from 0 to 2 mol%), the ocimenes (from 0 to 7 mol%), nerol (from 0 to 2 mol%), and citral (from 1 to 2 mol%).

A significant increase in selectivity is only observed for isocembrol and thunbergol [isocembrol from 0 to 44 mol% (at the temperature of 90 °C) and thunbergol form 0 to 51 mol% (at the temperature of 150 °C)]. The dominant product is thunbergol, which exhibited selectivities at the highest temperatures corresponding to 2–5 times higher than isocembrol. For example, at 150 °C thunbergol is formed with a selectivity of approximately 51 mol%. Only at a temperature of 90 °C was a significantly greater selectivity for isocembrol observed relative to thunbergol (almost 10 times higher). At this temperature the selectivity of geraniol transformation to isocembrol was about 43 mol%, while thunbergol was 4 mol%. This is probably related to the greater stability of the isocembrol molecule at lower temperatures. The increase in temperature appears to cause the isomerization of isocembrol to thunbergol, which the current study indicates is much more stable at elevated temperatures. On the basis of the results from the temperature studies, the scheme of reactions presented on Fig. 7 is proposed for geraniol isomerization process over sepiolite catalyst.

As the temperature was increased from 80 to 150 °C, the combined total selectivity for the other geraniol transformation products that were not individually determined by the GC–MS analyses decreased from 96 to 22 mol%. At lower temperatures these products probably include myrcene, limonene, trans, trans-farnesol, and trans, trans, trans-geranylgeraniol, while at higher temperatures mainly oligomeric compounds are formed [8, 9].

As linalool is the geraniol isomerization product with the greatest number of applications (and therefore potential commercial value), this product was used as the basis for selecting temperature to be used in conducting further studies into the geraniol isomerization process over sepiolite catalyst. A temperature of 120 °C was selected as this represented the highest selectivity (19 mol%) observed for linalool in the temperature studies.

3.3 Influence of Sepiolite Catalyst Content on Geraniol Isomerization

The influence of sepiolite catalyst content on geraniol isomerization was studied over the range 2.5–15 wt%. The fixed parameters of the catalyst content studies included a temperature of 120 °C and a reaction time of 3 h. The results are summarized in Fig. 8, which shows that an increase in the content of sepiolite from 2.5 to 10 wt% leads to an increase in the level of geraniol conversion from 58 to 88 mol%.

Interestingly, a further increase in the content of the catalyst to 12.5 and 15 wt% causes a slight decrease in level of geraniol conversion to 69 mol%. It is suggested that this decrease is caused by clogging of the catalyst pores by isomerization products that form during the process. The clogging of the catalyst pores by these products would result in the remaining geraniol particles having reduced access to them, leading to a corresponding reduction in the number of reactions associated with geraniol transformation.

The highest degree of linalool selectivity (19 mol%) was achieved at a catalyst content of 10 wt%. Under the tested conditions, a number of other low molecular weight products were also formed with low levels of selectivity (e.g. β-pinene, ocimenes or nerol). In contrast, high selectivity levels were observed for isocembrol and thunbergol, although thunbergol was always formed with approximately twice the selectivity as isocembrol. The selectivity of these two compounds decreased from 28 and 46 mol% at a catalyst content of 2.5 wt% to 9 mol% and 17 mol% at an increased catalyst content of 15 wt%. At the same time, the combined total selectivity of the other transformation products that were not individually determined by the GC–MS analyses increased from 15 to 56 mol% as the catalyst content increased from 2.5 to 15 wt%. It suggested that these additional, non-target products are oligomeric compounds, the amount of which may increase as the number of active catalyst centers increases.

Continuing to use maximum linalool production as the target outcome for an optimized sepiolite catalyzed geraniol isomerization method, the most beneficial catalyst content was identified as 10 wt%. Together with a temperature of 120 °C, this catalyst content was selected for use in the next stage of the method development process.

3.4 Influence of Reaction Time on Geraniol Isomerization

The influence of the reaction time on sepiolite catalyzed geraniol isomerization was studied over the range 15 min to 24 h. The fixed parameters of the geraniol isomerization reaction time studies included a temperature of 120 °C and a catalyst content of 10 wt%. The results are summarized in Fig. 9, which shows that lengthening the reaction time generally leads to a corresponding increase in geraniol conversion.

The results show that a reaction time of 4 h is sufficient to achieve a total conversion of geraniol into products. However, the selectivity of geraniol conversion to linalool reaches the highest level (19 mol%) after a reaction time of 3 h (19 mol%). Isocembrol and thunbergol again dominate among other reaction products, irrespective of the reaction time, where thunbergol is formed with a twofold higher selectivity. The combined total selectivity of the other transformation products that were not individually determined by the GC–MS analyses decreases from 98 to 37 mol% with an increase in the reaction time from 15 min to 24 h. For the longest reaction times, these transformation products are suggested to form mainly from oligomerization reactions.

4 Conclusions

The geraniol isomerization process is a complex process where many parallel and follow-up reactions take place, and which produces a broad range of reaction products. The method for isomerization of geraniol using sepiolite catalyst developed in this study was optimized for the production of linalool. Linalool is one of the most commercially important products from geraniol isomerization and is formed in our method with the highest selectivity relative to other low molecular weight products. At the same time, high selectivities also occur for the cyclization products isocembrol and thunbergol, with thunbergol typically being formed with a twofold higher selectivity than isocembrol. These two compounds have value due to their applications in medicine and are therefore of significant interest as products of this process. Importantly, all of the other identified geraniol transformation products obtainable from this process have commercial applications. The proposed sepiolite catalyzed geraniol isomerization method has the advantage that it is carried out without the use of a solvent. Furthermore, it is possible to achieve a geraniol conversion level of 100 mol% when implementing the optimized conditions described herein. The use of sepiolite also seems to be beneficial from an ecological perspective as it is a readily available porous material of natural origin. Similarly, geraniol can be obtained readily from a variety of natural sources.

In the future, new directions of research on the process of geraniol isomerization could investigate the use of other porous materials of natural origin, e.g. clinoptilolite, vermiculite or halloysite. The use of these materials, especially clinoptilolite, which is a natural zeolite with a strictly defined structure, may facilitate increasing the selectivity specifically towards one of the products, e.g. linalool or thunbergol and isocembrol. Other directions for future research on this process could include increasing the pressure (pressure process using an autoclave with a Teflon liner) and identifying an optimal solvent. Mathematical process optimization, using a rotatable-uniform design for example, could be also be helpful in providing a more accurate description of this process.

References

Retajczyk M, Wróblewska A (2019) Catalysts 9:1

Chen W, Viljoen AM (2010) S Afr J Bot 76:643

Polish Pharmaceutical Society (2014) Pharmacopoeia Poland X. Office of registration of medical products, medical devices and biocidal products, Warsaw

Hagvall L, Bäcktorp C, Svensson S, Nyman G, Börje A, Karlberg AT (2007) Chem Res Toxicol 20(5):807

Yu W, Wen M, Yang L, Liu ZL (2002) Chin Chem Lett 13:495

Haese F, Ebel K, Burkart K, Unverricht S, Munster P (2006) US Patent 7126033

Srivastava P, Wagh RS, Naik DG (2010) Radiochemistry 52:561

Ramishvili T, Tsitsishvili V, Ivanova I, Bukia T, Kurtsikidze G, Kokiashvili N (2018) Int J Rec Sci Res 9:25454

Tsitsishvili V, Ramishvili T, Ivanova I, Dobryakova I, Bukia T, Kokiashvili N (2008) Bull Georg Natl Acad Sci 12:62

Majdan M, Sabah E, Bujacka M (2008) Przem Chem 87:1

Yun Y, Shengli Q, Zhan Z, Wu X (2011) Mater Res Bull 46:1593

Russo E (2011) Br J Pharmacol 163:1344

Nissen L, Zatta A, Stefanini I, Grandi S, Sgorbati B, Biavati B (2010) Fitoterapia 8:413

Pinheiro MA, Magalhães RM, Torres DM (2015) Pharmacogn Mag 11:123

Wróblewska A, Miądlicki P, Sreńscek-Nazzal J, Sadłowski M, Koren ZC, Michalkiewicz B (2018) Microporous Mesoporous Mater 258:72

Hayatifar M, Marchetti F, Pampaloni G (2012) Catal Today 192:177

Zviely M (2013) Perf Flav 38:42

Phillips CA, Gkatzionis K, Laird K, Score J (2012) Nat Prod Commun 7:103

Trevelyan J, Booth B (1998) Unconventional medicine. Medical Publisher, Warsaw

Romer M (2009) Aromatheraphy. Lexicon of medical plants (MedPharm, Wroclaw, Poland

MC. Lapare, Aromatherapy—essential oils that relieve pain (Club for you, Warsaw, 2005)

Brud WS, Konopacka I (1995) Fragrant pharmacy—the secrets of aromatherapy. COMES Publishing Agency, Warsaw

Lis-Balchin M (1997) J R Soc Promo Health 117:324

Boskabady MH, Shafei MN, Saberi Z (2011) J Basic Med Sci 14:295

Lawless J (2002) The Illustrated Encyclopedia of Essential Oils (Harper Collins Paperbacks, 2002)

Onawunmi GO (1989) Lett Appl Microbiol 9:105

Kuwahara Y, Suzuki H, Matsumoto K, Wada Y (1983) Appl Entomol Zool 18:30

Lima EJ, Alves RG, Elia GM, Anunciação TA, Silva VR, Santos LS, Soares MB, Cardozo NM, Costa EV, Silva FM, Koolen HH, Bezerra DP (2018) Molecules 23:2974

Ma CJ, Sung SH, Kim YC (2010) Nat Prod Res 24:562

Nikolica MS, Petrovica R, Veljovica D, Cosovicb V, Stankovicc N, Djonlagica (2017) Eur Polym J 97:198

Zhang M, Gao M, Chenab J, Yu Y (2015) RSC Adv 5:25959

Alkan M, Tekin G, Namli H (2005) Microporous Mesoporous Mater 84:75

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors claim no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Fajdek-Bieda, A., Wróblewska, A., Miądlicki, P. et al. Influence of Technological Parameters on the Isomerization of Geraniol Using Sepiolite. Catal Lett 150, 901–911 (2020). https://doi.org/10.1007/s10562-019-02987-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-02987-1