Abstract

We report the use of transition metal precursors impregnated into the pores of CPO-27(Co) metal–organic framework (MOF) crystals prior to pyrolysis as a straightforward strategy for tuning the properties of MOF-derived Co-based catalysts. By adding a Nb inorganic salt prior to pyrolysis hierarchical pores are formed in the resulting carbon and the Co accessible surface area is greatly increased leading to a strong enhancement of CO hydrogenation activity.

Graphic Abstract

Enhancing the activity of MOF-MS Co catalysts for syngas conversion by introducing Nb by impregnation into the pores of CPO-27(Co).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Metal–organic frameworks (MOFs) are a class of porous, coordination compounds in which metal cations (or nodes) are connected to organic linker molecules forming a three-dimensional network with potential cavities [1]. Liu et al. demonstrated in 2008 that MOFs can be used as templates for the synthesis of highly porous carbons via careful pyrolysis of the MOF crystals [2]. This strategy has been intensively used for the preparation of metal-loaded carbon catalysts in recent years [3,4,5,6]. The method presents three interesting features for the synthesis of heterogeneous catalysts, e.g. the inherent high tunability of MOFs, thus, of the properties of the resulting material; the high metal dispersion on the support; and finally, the entrapment of the metallic nanoparticles within the carbon support, which may slow down particle aggregation, a very common phenomenon in deactivation of solid catalysts during reaction conditions [7, 8].

A number of strategies of increasing complexity have been used in order to avoid full encapsulation such as creating hierarchical carbon structures [9] or promoting even more the growth of metal particles, in order to catalyse the formation of carbon nanotubes rather than a randomly interconnected porous network [10]. A prominent example of MOF-templated catalyst synthesis was reported by Santos et al., who studied the formation of a Fe/FexCy/C catalyst that exhibited higher stability than benchmark Fe catalysts in the conversion of syngas, a mixture of CO and H2 [11,12,13,14]. The influence of MOF hierarchical porosity and use of Na or S promoters, typically employed for Fe-catalysed Fischer–Tropsch synthesis (FTS), has been reported to profoundly impact their CO hydrogenation performance [15].

Contrary to the case of Fe, metal@carbon core–shell may be detrimental if the catalyst employed is Co, due to the fact that reaction is catalysed by the metallic Co0 surface, which may be covered by the aforementioned carbon matrix [16,17,18,19]. One recently developed strategy to overcome this problem consisted of using the pores of ZIF-67(Co) as a nanocast for a silica precursor, which after calcination, resulted in a highly loaded Co/SiO2 catalyst [20]. However, this method involved a hydrolysis and crystallization step of the silica precursor, and little control over the properties of the support itself. Thus, we explore the use of a simple impregnation step of a transition metal precursor into the pores of the MOF prior to pyrolysis. The use of transition metals loaded in the pores of a MOF to hierarchically structure the carbon matrix during pyrolysis has been studied [21]. Nevertheless, to the best of our knowledge, the use of such synthetic route for the preparation of Co catalysts for FTS has not been previously investigated.

Herein, we report the effects of introducing a Nb inorganic salt into the pores of CPO-27(Co) MOF crystals by incipient wetness impregnation prior to calcination. The introduction of Nb by using this strategy results in an increase of the available Co surface and the formation of mesopores in the carbon support, as schematically illustrated in Fig. 1a. A detailed explanation of the impact of Nb on the metal, support and the resulting catalytic properties in CO hydrogenation can be found in the following sections.

a Pyrolysis of Nb-loaded CPO-27(Co) results in higher porosity of the carbon matrix, as well as larger Co particles. b N2 physisorption isotherms at 77 K and c pore size distribution calculated by the Barrett-Joyner-Halenda (BJH) method (STSA carbon black as reference) of the Co@C (orange) and the NbOx-Co@C (purple) materials

2 Experimental Section

2.1 Materials Synthesis

2.1.1 CPO-27(Co) Crystals

For the synthesis of CPO-27 (Co) crystals a previously reported procedure was used [22]. In brief, cobalt nitrate hexahydrate (5.943 g, 20.4 mmol, 99 + %, Acros Organics) and 2,5-dihydroxyterephthalic acid (1.205 g, 6.08 mmol, 98%, Sigma-Aldrich) were introduced into 400 mL of a 1:1:1 v/v/v mixture of N,N-dimethylformamide (99.8% anhydrous, Sigma-Aldrich), ethanol (98%, VWR International) and deionized water within a 1 L sealed Schott bottle. The bottle was heated at 383 K for 24 h in an oven, then, the solution allowed to cool down to room temperature naturally. The supernatant liquid was removed by decantation and 200 mL of fresh ethanol introduced, in order to exchange the solvent within the pores. The ethanol was replaced after 4 h for other 200 mL of ethanol. After 8 h, the solid was recovered by centrifugation (3000 rpm, 5 min) and dried at 333 K in air for 16 h. Activation of the MOF prior to Nb impregnation consisted of drying under dynamic vacuum (p < 0.1 bar) at 423 K for 1 h of the framework.

2.1.2 Incipient Wetness Impregnation (IWI)

Impregnation of the evacuated materials was done by adding the necessary amount ammonium niobium oxalate (ANO, Companhia Brasileira de Metalurgia e Mineração) in ultrapure water (Metrohm Lab filtration station, 18.2 MΩ cm, 25 °C) dropwise under constant stirring of the powder in vacuum, attaining a Nb:Co atomic ratio of 0.0157.

2.1.3 Pyrolysis

Calcination of the MOF materials was done in a fixed-bed tubular quartz reactor were ca. 250 mg were placed, under a N2 (Linde, 99.9998%) flow of 50 mL min−1 at 333 K for 1 h, then at 773 K for 4 h, by using a ramp of 5 K min−1 to heat up the reactors. No specific passivation method was used after naturally cooling down to room temperature.

2.2 Materials Characterization

X-ray diffraction (XRD) patterns were obtained by a Bruker-AXS D2 Phaser powder X-ray diffractometer using Co Kα1,2 with λ = 1.79026 Å, operated at 30 kV, the sample holder rotated at 15 rot min−1. Measurements were carried out between 5 and 70 2θ° using a step size of 0.05 2θ step−1 and a scan speed of 1 s/step. Simulated CPO-27(Co) pattern was obtained from the previously resolved structure in Ref. [23] (cif file, Mercury 3.7© software (Co Kα1,2 λ = 1.79026 Å, FHWM = 0.2)). In the case of the Co@C materials, XRD was measured in the 30–60 2θ° range with the same parameters and instrument described above.

CO2adsorption/desorption isotherms at 195 K was determined on an AutoSorb I (Quantachrome) instrument. The materials were previously degassed in vacuum (p < 10−5 mbar) at 473 K for 16 h prior to the sorption measurements. BET area and pore volumes were calculated according to the consistency criteria established by Rouquerol et al. [24]. Pore size distributions were obtained by using non-local density functional theory (NLDFT) method (assuming CO2 at 195 K on Carbon Slit pores in MicroActive®, Micromeritics, version 4.06).

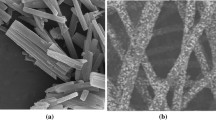

Scanning electron microscopy (SEM) images of the CPO-27(Co) crystals were obtained by depositing the powder sample of carbon tape (no sputtered Au or Pt was added). The images were recorded with a PhenomPro™ scanning electron microscope equipped with a back-scattering detector (BSD), a CsB filament and operated at 5 kV and a × 2800 magnification.

N2adsorption/desorption isotherm measurements at 77 K were carried out in a Micromeritics Tristar 3000 apparatus, calculation of BET, the interval between p/p0 = 0.05–0.3, and the desorption BJH method, along with the t-plot method for the calculation of external/internal surface area ratio. Samples were pretreated at 473 K under a N2 flow of 10 mL min−1 for 16 h prior to the adsorption measurements. The hysteresis loop in (a) reveals the presence of uniform mesopores as well as micropores (H-type I, according to IUPAC), while (b) only shows the presence of ill-defined micropore systems (H-type II), and a cavitation step during desorption at p/p0 = 0.5.

H2-chemisorption was measured on a Micromeritics ASAP 2020 C using ca. 100 mg of sample. The catalysts were reduced in pure H2 prior to the measurement. The pristine samples were reduced for 2 h (5 K min−1) at 623 K. After reduction, the samples were evacuated, cooled to 423 K and analyzed at that temperature. The metallic surface area and average particle diameter were calculated assuming a cobalt cross-sectional area of 0.0662 nm2, an H/Co stoichiometry of 1 and spherical cobalt particles. See main text (Fig. 2f) for uptake isotherms of Co@C and NbOx-Co@C.

a HAADF micrographs and b–d TEM–EDX maps of NbOx-Co@C catalysts (C, green; Co, dark blue; Nb, light blue; O, red) and pyrolysis. e Particle size distribution with the average (and standard deviation in brackets) values and f H2-uptake isotherms of the Co@C (orange) and NbOx-Co@C (purple) materials obtained after pyrolysis (metallic surface area values next to each isotherm)

Thermogravimetrical analysis (TGA) was performed using a TGA Q50 equipment (TA Instruments, USA). Typically, ca. 20 mg of sample were placed in a platinum crucible under 40 cm3 min−1 air flow and heated until 1073 K (15 K min−1), 40 cm3 min−1 N2 flow was used as reference.

X-ray photoelectron spectroscopy (XPS) data were acquired on a Thermo Scientific K-Alpha spectrometer using a Al Kα (hν = 1486.6 eV) monochromatic small-spot X-ray source. Charging effects were corrected by using the adventitious carbon C1s (sp3) peak as reference for all samples at a binding energy (BE) of 284.8 eV. Analysis of the XPS spectra was done with CasaXPS, in which Shirley background was removed and the peaks assigned. Gaussian peaks were assumed for the fitting of the spectra (BE, full width at half maximum—FWHM; peak shape, peak asymmetry and number of species), which was performed with Fiytk© software, version 0.8.6. Levenberg–Marquardt fit.

Raman spectroscopy was carried out with a Renishaw InVia™ microscope equipped with a CCD detector, a 532 nm laser and a 1200 lines/mm grating. The samples were deposited on a quartz cover and measured with a laser output power of 0.24 mW (i.e., 1.12 × 10−5 W cm−2), 50 × objective, 10 accumulations with an integration time of 10 s. Savitzky-Golay filter was applied over a smooth window of 9, with a square polynomial order.

High-temperature XRD experiments were carried out in a Bruker D8 diffractometer in Bragg–Brentano geometry, equipped with a high-temperature cell, a Co Kα,β (λ = 1.79026 Ǻ) source and a LYNXEYE detector. Samples were introduced in the flat Si holder and flushed with a He flow of 20 mL·min−1 for 10 min. Then, diffractograms were recorded with 0.041° step−1 and 1 s step−1 measurement time during a temperature program starting at 298 to 773 K, with a heating ramp of 2 K min−1.

Scanning Transmission Electron Microscopy-High Angle Annular Dark Field (STEM-HAADF) images and energy dispersive X-ray spectroscopy (EDX) analysis were obtained with an FEI Talos F200X transmission electron microscope, operated at 200 kV and equipped with a high-brightness field emission gun (X-FEG) and a Super-X G2 EDX detector. More than 150 particles were measured to obtain a particle size distribution. Bright field images were recorded on a FEI Tecnai 12 Icor TEM operating at 120 kV. Samples were prepared by drop-casting a colloidal solution on a carbon-coated TEM grid, which were left to dry in air.

2.3 Catalytic Testing

The evaluation of the catalytic performance was performed using a quartz glass plug-flow reactor, loaded with ca. 20 mg catalyst (sieve fraction: 38–150 μm) diluted with ca. 200 mg of SiC. The catalysts were reduced in situ at 623 K (5 K min−1, 2 h) in Ar:H2 = 2.0 v/v flow (GHSV = 190,000 h−1). After reduction, the reactor temperature was changed to 493 K (5 K min−1) and once the temperature was reached the atmosphere was changed to synthesis gas (H2:CO = 2.0 v/v, GHSV = 28,000 h−1, 1 bar). The reaction was carried out for 100 h for each catalyst. Analysis of C1 to C18 products was done with an online gas chromatograph (Varian 430 GC, CP sil-5 column).

3 Results and Discussion

For this study, CPO-27(Co) needle-like crystals of ca. 20 µm length were prepared as described in previously reported literature [22]. Phase purity, crystallinity, morphology and porosity were confirmed by X-ray diffraction (XRD), scanning electron microscopy (SEM) and CO2 adsorption isotherms at 195 K (Sects. 1–4 of the Electronic Supplementary Information, ESI). Thereafter, the material was degassed and impregnated with an aqueous solution of ammonium niobium (V) oxalate (ANO), attaining a Nb:Co atomic ratio of 0.0157 (see ESI for details). After drying, the material was pyrolyzed in a fixed-bed reactor (773 K, ramp 5 K min−1, 4 h, 50 mL min−1 N2 flow) to obtain NbOx-Co@C composites by MOF degradation.

The presence of Nb species in the pores of CPO-27(Co) resulted in the formation of mesopores in the carbon matrix, in contrast to pristine CPO-27(Co), as demonstrated by N2 physisorption at 77 K (Fig. 1b). Co@C showed an isotherm type II (ill-defined micropores) and the BJH pore size distribution revealed the presence of 3–4 nm mesopores in the carbon matrix (Fig. 1c). In contrast, the NbOx-Co@C composite exhibited the presence of large mesopores (20–35 nm) with ca. 4 nm pores still being present, as evidenced by the isotherm type I and the pore size distribution.

BET apparent surface area of the resulting NbOx-Co@C material was 428 m2 g−1, in contrast to the non-promoted CPO-27(Co) pyrolyzed MOF, with BET surface area of 235 m2 g−1 (see Sect. 5 in the SI for details). This observation indicates that impregnation with NbOx-precursor solution leads to the formation of larger pores throughout the carbon network. Consequently, the total pore volume of the materials was found to be 0.89 and 0.21 cm3 g−1 for the NbOx-Co@C and Co@C materials, corroborating the presence of a much higher internal pore space in the case of the Nb-promoted system.

In order to study the location of Nb after pyrolysis, TEM–EDX maps of the obtained NbOx-Co@C (Fig. 2a–d) show that Nb is in close vicinity to the Co inside the C matrix. Thus, not only the porosity of the carbon supports was affected, but also the growth of the metal clusters was affected by the inclusion of ANO into the honeycomb structure of CPO-27(Co). Particle surface average diameters (d32) of both materials obtained from TEM (Fig. 2e) show a larger average size and broader size distribution for NbOx-Co@C (ca. 25 nm) compared to Co@C (ca. 11 nm), indicating that the Nb precursor has a strong effect on the growth of Co nanoparticles during pyrolysis.

Although the porosity and particle size were affected, we sought to verify if the metal nanoparticle were more accessible after pyrolysis of the Nb impregnated MOF. Indeed, the increase in porosity was critical for the accessibility to the entrapped Co nanoparticles as shown by H2 chemisorption experiments (Fig. 2d). Despite exhibiting a higher average particle size, the promoted material possesses more than four times accessible Co0 sites compared to the Co@C material, confirming our hypothesis. Additionally, TGA under air flow was used to estimate the final cobalt content of the pyrolysed materials, resulting in ~ 50 wt % for both materials (Fig. S5). Surprisingly, the increase in porosity did not result in a higher degree of oxidation of the Co particles, which are typically oxidized to CoxOy in air. X-ray diffraction of the obtained materials (Fig. S6) shows the presence of only one peak dominating the diffractogram at 51°, which corresponds to a metallic Co fcc lattice. However, it cannot be excluded that the exposed cobalt was oxidized and the fraction of the oxide was too low and/or amorphous to be detected by XRD.

XPS analysis of the NbOx-Co@C catalyst in Sect. S7 of the Supporting Information showed the presence of both Co and CoxOy species. Specifically, the Co 2p XPS peaks in Fig. S8 fitted at 802.7, 796.4, 785.6 and 780.4 eV were assigned to CoO, while the Co 2p XPS peak at 792.6 eV corresponds to Co3O4 [25]. Significant presence of reduced Co0 was confirmed by the peak at 778.2 eV, and the presence of the LMM Auger emission peak [26,27,28]. In addition, the XPS peaks at 209.6 and 206.9 eV, corresponding to Nb 3d3/2 and 3d5/2 lines, respectively, indicated that the promotor is present as niobium (V) oxide (Fig. S9) [29].

In order to further study the structure of the carbon support, both XPS and Raman spectroscopies were used. On the one hand, the XPS peaks at 284.1, 285.8 and 288.8 eV were assigned to C sp2, C–O and C=O species (i.e. acid and –OH groups) on the carbon surface, respectively (Fig. S10). On the other hand, Raman spectra of the pyrolyzed materials (irrespective of the promoter) showed the typical D and G bands (at 1365 and 1595 cm−1, respectively, with an I(D)/I(G) =0.82), as well as the absence of the second 2D’ band at 2400–2700 cm−1, indicating a disordered nanocrystalline graphitic matrix with high content of amorphous sp2 hybridized carbon (Fig. S11) [30, 31]. In addition to those Raman bands, a number of peaks at 198, 480, 522, 618 and 687 cm−1 corresponding to Co3O4 appeared for both the pristine and the Nb-loaded Co@C samples [32]. This was in line with the TEM–EDX map in Figs. 2d, that shows an O signal around the Co particles, suggesting that the entrapped Co species consist of bulk metallic Co0 crystallites surrounded by a thin layer of CoOx oxides.

To study the evolution of Co crystals formed during pyrolysis, in situ XRD analysis of both materials was carried out. The materials were heated up to 773 K (5 K min−1) under He flow, then the temperature kept constant for 10 h. In both cases (Fig. 3), a peak at 2θ = 51.3°, corresponding to a Co fcc lattice, developed with increasing temperature and time after decomposition of CPO-27 (Co) at 553 K. It can be clearly seen that, while in the case of the Nb-loaded material the lattice starts growing right after decomposition of the framework, pristine CPO-27 does not show significant growth of Co before 400 min of calcination at 773 K, pointing to a strong role of niobium oxide during the pyrolysis (Figs. S12 and S13). Evolution of crystallite size with time of the Nb-promoted MOF shows that fcc Co crystallites reach an average size of ca. 25 nm, after 4 h at 773 K, whereas in the case of pristine CPO-27(Co), the size is limited to ca. 11 nm after the same calcination time. This difference is Co nanoparticle size is further corroborated by TEM imaging of the obtained materials (Figs. S14 and S15). A number of research groups have suggested that other transition metals, such as Cu2+, may act as nucleation points for the metal particles, as well as oxygen scavengers that facilitate CO2 extraction of the linkers leading to a faster decomposition [21]. At this moment, the exact mechanism by which Nb acts on the growth of the metallic Co nanoparticles and the carbon framework remains elusive.

Evolution of fcc Co lattice calculated via the Scherrer equation for the pristine CPO-27(Co) (orange) and loaded with Nb (purple). *t0= 2 h in the graph indicates that fcc Co appeared after ca. 200 min of pyrolysis. The dashed line at 4 h indicates the size obtained for the Co@C materials later used for catalysis

As mentioned earlier, Co-based catalysts are used for the synthesis of long-chain hydrocarbons by the FTS reaction, that are later cracked into shorter fractions within the range of diesel [33, 34]. Apart from a critical influence of the Co particle size [35, 36], transition metal oxides (such as Nb2O5 or TiO2) and noble metals (e.g. Pt, Re, Ru) have been added to the system in order to tune activity, selectivity and stability of the catalyst [37]. Thus, we sought to study the catalytic performance of the Co-based materials. As shown in Fig. 4 and Table 1, the impact of the transition metal promotor was critical in the ability of Co to catalyse the formation of hydrocarbons. The Nb-promoted Co-based FTS catalyst showed a substantially higher activity throughout the experiment compared to the non-promoted Co@C catalyst (Fig. 4). The differences in activity could be ascribed to the larger exposed Co0 surface in the NbOx-Co@C material, as shown by H2-chemisorption and the similar initial turn-over-frequencies (TOF) of both materials.

The product distribution was similar for both materials at TOS = 100 h (Fig. S16), despite the reported promotional effect of NbOx for C5+ formation. This could be due to the low Nb loading or the unknown crystallinity of NbOx, two features that can have a strong influence [38, 39]. As mentioned before, the carbon surface exhibited acid groups (–COO and –OH), which might as well affect the selectivity of the materials [40] TEM images of the catalysts after 100 h of reaction (Figs. S17 and S18) showed Co particle growth for both materials, with the largest growth in surface average diameter for the NbOx-Co@C catalyst from 25 to 34 nm compared to 11 to 12 nm for Co@C. Both materials showed bimodal particle size distributions with smaller particles within the 5–20 nm range, most likely still entrapped in the carbon matrix, and the formation of agglomerates of 20–50 nm diameters. These agglomerates are present in the NbOx-Co@C catalyst to a larger extent, suggesting that particle sintering may be the reason for the activity decrease in CO hydrogenation.

4 Conclusions

We have described how by simply impregnating a particular Metal-MOF material, namely CPO-27(Co), with a Nb precursor solution, the properties of the resulting MOF-derived Co@C material can be tuned. Although the exact mechanism remains elusive, we have demonstrated how Nb can strongly influence the porosity of the obtained carbon matrix, thus, availability of entrapped metallic nanoparticles, rendering this composite a potential catalyst for hydrogenation reactions. Despite an initial loss of activity, hydrocarbon productivity from syngas of the NbOx-Co@C material showed appreciable stability for at least 100 h of operation. Thus, we can conclude that active and stable Co-FTS catalysts can be prepared by this strategy, combining the use of transition metal promoters and metal–organic framework mediated synthesis. Moreover, we believe that this method represents an interesting alternative for the introduction of promoters in close proximity of the active, nanoparticulate phase. These findings could guide the way for the synthesis of hierarchically structured, efficient MOF-derived catalyst materials for various chemical reactions.

References

Zhou H-C, Long JR, Yaghi OM (2012) Introduction to metal–organic frameworks. Chem Rev 112(2):673–674

Liu B, Shioyama H, Akita T, Xu Q (2008) Metal–organic framework as a template for porous carbon synthesis. J Am Chem Soc 130(16):5390–5391

Zhong W, Liu H, Bai C, Liao S, Li Y (2015) Base-free oxidation of alcohols to esters at room temperature and atmospheric conditions using nanoscale co-based catalysts. ACS Catal 5(3):1850–1856

Aijaz A, Masa J, Rösler C, Xia W, Weide P, Botz AJR, Fischer RA, Schuhmann W, Muhler M (2016) Co@Co3O4 encapsulated in carbon nanotube-grafted nitrogen-doped carbon polyhedra as an advanced bifunctional oxygen electrode. Angew Chem Int Ed 55(12):4087–4091

Yang J, Zhang F, Lu H, Hong X, Jiang H, Wu Y, Li Y (2015) Hollow Zn/Co ZIF particles derived from core-shell ZIF-67@ZIF-8 as selective catalyst for the semi-hydrogenation of acetylene. Angew Chem Int Ed 54(37):10889–10893

Hu H, Guan B, Xia B, Lou XW (2015) Designed formation of Co3O4/NiCo2O4 double-shelled nanocages with enhanced pseudocapacitive and electrocatalytic properties. J Am Chem Soc 137(16):5590–5595

Shen K, Chen X, Chen J, Li Y (2016) Development of MOF-derived carbon-based nanomaterials for efficient catalysis. ACS Catal 6(9):5887–5903

Bartholomew CH (2001) Mechanisms of catalyst deactivation. Appl Catal A 212(1):17–60

Xia W, Zou R, An L, Xia D, Guo S (2015) A metal-organic framework route to in situ encapsulation of Co@Co3O4@C core@bishell nanoparticles into a highly ordered porous carbon matrix for oxygen reduction. Energy Environ Sci 8(2):568–576

Xia BY, Yan Y, Li N, Wu HB, Lou XW, Wang X (2016) A metal–organic framework-derived bifunctional oxygen electrocatalyst. Nat Energy 1(1):15006–15014

Santos VP, Wezendonk TA, Jaén JJD, Dugulan AI, Nasalevich MA, Islam H-U, Chojecki A, Sartipi S, Sun X, Hakeem AA, Koeken ACJ, Ruitenbeek M, Davidian T, Meima GR, Sankar G, Kapteijn F, Makkee M, Gascon J (2015) Metal organic framework-mediated synthesis of highly active and stable Fischer–Tropsch catalysts. Nat Commun 6(6):6451–6459

Wezendonk TA, Santos VP, Nasalevich MA, Warringa QSE, Dugulan AI, Chojecki A, Koeken ACJ, Ruitenbeek M, Meima G, Islam H-U, Sankar G, Makkee M, Kapteijn F, Gascon J (2016) Elucidating the nature of Fe species during pyrolysis of the Fe-BTC MOF into highly active and stable Fischer–Tropsch catalysts. ACS Catal 6(5):3236–3247

An B, Cheng K, Wang C, Wang Y, Lin W (2016) Pyrolysis of metal-organic frameworks to Fe3O4@Fe5C2 core-shell nanoparticles for Fischer–Tropsch synthesis. ACS Catal 6(6):3610–3618

Wezendonk TA, Sun X, Dugulan AI, van Hoof AJF, Hensen EJM, Kapteijn F, Gascon J (2018) Controlled formation of iron carbides and their performance in Fischer–Tropsch synthesis. J Catal 362:106–117

Oschatz M, Krause S, Krans NA, Hernández Mejía C, Kaskel S, de Jong KP (2017) Influence of precursor porosity on sodium and sulfur promoted iron/carbon Fischer–Tropsch catalysts derived from metal–organic frameworks. Chem Commun 53(73):10204–10207

Chen Y-Z, Zhang R, Jiao L, Jiang H-L (2018) Metal–organic framework-derived porous materials for catalysis. Coord Chem Rev 362:1–23

Zhang C, Guo X, Yuan Q, Zhang R, Chang Q, Li K, Xiao B, Liu S, Ma C, Liu X, Xu Y, Wen X, Yang Y, Li Y (2018) Ethyne-reducing metal–organic frameworks to control fabrications of core/shell nanoparticles as catalysts. ACS Catal 8(8):7120–7130

Jagadeesh RV, Murugesan K, Alshammari AS, Neumann H, Pohl M-M, Radnik J, Beller M (2017) MOF-derived cobalt nanoparticles catalyze a general synthesis of amines. Science 358(6361):326

Qiu B, Yang C, Guo W, Xu Y, Liang Z, Ma D, Zou R (2017) Highly dispersed Co-based Fischer–Tropsch synthesis catalysts from metal–organic frameworks. J Mater Chem A 5(17):8081–8086

Sun X, Suarez AIO, Meijerink M, van Deelen T, Ould-Chikh S, Zečević J, de Jong KP, Kapteijn F, Gascon J (2017) Manufacture of highly loaded silica-supported cobalt Fischer–Tropsch catalysts from a metal organic framework. Nat Commun 8(1):1680–1688

Sun J-K, Xu Q (2014) From metal–organic framework to carbon: toward controlled hierarchical pore structures via a double-template approach. Chem Commun 50(88):13502–13505

Caskey SR, Wong-Foy AG, Matzger AJ (2008) Dramatic tuning of carbon dioxide uptake via metal substitution in a coordination polymer with cylindrical pores. J Am Chem Soc 130(33):10870–10871

Dietzel PDC, Panella B, Hirscher M, Blom R, Fjellvag H (2006) Hydrogen adsorption in a nickel based coordination polymer with open metal sites in the cylindrical cavities of the desolvated framework. Chem Commun 9:959–961

Llewellyn P, Maurin G, Rouquerol J (2014) Adsorption by metal-organic frameworks. Adsorption by powders and porous solids, 2nd edn. Academic Press, Oxford, pp 565–610

Zafeiratos S, Dintzer T, Teschner D, Blume R, Hävecker M, Knop-Gericke A, Schlögl R (2010) Methanol oxidation over model cobalt catalysts: influence of the cobalt oxidation state on the reactivity. J Catal 269(2):309–317

Biesinger MC, Payne BP, Grosvenor AP, Lau LWM, Gerson AR, Smart RSC (2011) Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Cr, Mn, Fe, Co and Ni. Appl Surf Sci 257(7):2717–2730

Chuang TJ, Brundle CR, Rice DW (1976) Interpretation of the X-ray photoemission spectra of cobalt oxides and cobalt oxide surfaces. Surf Sci 59(2):413–429

Dai E, Xu J, Qiu J, Liu S, Chen P, Liu Y (2017) Co@Carbon and Co3O4@Carbon nanocomposites derived from a single MOF for supercapacitors. Sci Rep 7(1):12588

Hu ZP, Li YP, Ji MR, Wu JX (1989) The interaction of oxygen with niobium studied by XPS and UPS. Solid State Commun 71(10):849–852

Tuinstra F, Koenig JL (1970) Raman spectrum of graphite. J Chem Phys 53(3):1126–1130. https://doi.org/10.1063/1.1674108

Ferrari AC (2007) Raman spectroscopy of graphene and graphite: disorder, electron–phonon coupling, doping and nonadiabatic effects. Solid State Commun 143(1):47–57

Li Y, Qiu W, Qin F, Fang H, Hadjiev VG, Litvinov D, Bao J (2016) Identification of cobalt oxides with Raman scattering and Fourier transform infrared spectroscopy. J Phys Chem C 120(8):4511–4516

Iglesia E (1997) Design, synthesis, and use of cobalt-based Fischer–Tropsch synthesis catalysts. Appl Catal A 161(1):59–78

Khodakov AY, Chu W, Fongarland P (2007) Advances in the development of novel cobalt Fischer–Tropsch catalysts for synthesis of long-chain hydrocarbons and clean fuels. Chem Rev 107(5):1692–1744

Bezemer GL, Bitter JH, Kuipers HPCE, Oosterbeek H, Holewijn JE, Xu X, Kapteijn F, van Dillen AJ, de Jong KP (2006) Cobalt particle size effects in the Fischer–Tropsch reaction studied with carbon nanofiber supported catalysts. J Am Chem Soc 128(12):3956–3964

Munnik P, de Jongh PE, de Jong KP (2014) Control and impact of the nanoscale distribution of supported cobalt particles used in Fischer–Tropsch catalysis. J Am Chem Soc 136(20):7333–7340

Morales F, Weckhuysen BM (2006) Promotion effects in Co-based Fischer–Tropsch catalysis. In: Spivey JJ, Dooley KM (eds) Catalysis. The Royal Society of Chemistry, London, pp 1–40

den Otter JH, Nijveld SR, de Jong KP (2016) Synergistic promotion of Co/SiO2 Fischer–Tropsch catalysts by niobia and platinum. ACS Catal 6(3):1616–1623

Mendes FMT, Perez CAC, Noronha FB, Schmal M (2005) TPSR of CO hydrogenation on Co/Nb2O5/Al2O3 catalysts. Catal Today 101(1):45–50

Fu T, Li Z (2015) Review of recent development in Co-based catalysts supported on carbon materials for Fischer–Tropsch synthesis. Chem Eng Sci 135:3–20

Acknowledgements

This project has received funding from the European Union’s Horizon 2020 research and innovation program under the Marie Sklodowska-Curie Grant Agreement No. 641887 (DEFNET). Companhia Brasileira de Metalurgia e Mineração (CBMM) is thanked for financial support of this research. KPdJ acknowledges the European Research Council, EU FP7 ERC Advanced Grant no. 338846. P. Vervoorts (TU München, Germany) is gratefully acknowledged for measuring CO2 adsorption. We are thankful to W. S. Lamme (Utrecht University, UU) for measuring TEM–EDX of the materials; D. Wezendonk and M. Versluijs-Helder (UU) for the in situ XRD measurements and J. L. Weber (UU) for help with the thermogravimetry analysis. We are thankful to Dr. F. E. Oropeza-Palacio, Dr. J. P. Hofmann and Prof. E. J. Hensen (all from TU Eindhoven) for measuring XPS of the promoted sample.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Rivera-Torrente, M., Hernández Mejía, C., Hartman, T. et al. Impact of Niobium in the Metal–Organic Framework-Mediated Synthesis of Co-Based Catalysts for Synthesis Gas Conversion. Catal Lett 149, 3279–3286 (2019). https://doi.org/10.1007/s10562-019-02899-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-02899-0