Abstract

The ability of intact cells to perform chemical transformations has been periodically harnessed when technological, application, and market drivers have aligned. An example is the discovery of the therapeutic benefits of steroids and the realization that some cells could be used to perform selective oxidations that simplified existing multistep syntheses. The aim of the article is to provide some perspective on whole cell catalysis by first looking back at some approaches and successes such as steroid synthesis. Then, an attempt will be made to assess what productive applications lay ahead as well as the challenges that need to be addressed.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

While the race to land on the Moon was acquiring momentum, a revolution in large-scale industrial chemistry was also culminating. The operations of cracking and then reforming with platinum-based and other catalysts allowed for the increased demand for high octane motor fuel to be satiated while also providing streams of precursors for the growing chemical industry. Amongst the foundational US patents was US2944004 A, which was granted to Shell [1]. The term “platforming” was used throughout the patent to describe the use of platinum-containing catalysts and the derivative term “platformate” for the liquid product became a well known marketing tool for the improved octane and mileage automobile fuel. Indeed, “platformate” still generates interest amongst consumers as attested by the numerous postings and commentaries of Shell’s vintage 1960’s commercials on the internet (e.g. http://www.youtube.com/watch?v=s1iXmq9c4wE). This and other developments resulted in oil and gas supplanting coal as a feed stock and gave rise to what is now known as the “petrochemical industry.” This industry can, in turn, be described as one that adds considerable value to some “cracker” products with the aid of metal-based and other catalysts.

Roughly in parallel, leaps were made in harnessing cell-based, biological catalysts. For example, decades of new discovery in antibiotic molecules and subsequent derivatization had assembled a large arsenal of antibiotics by the time of Selma A. Waksman’s death in 1973. Other leaps in capability were made in that new target compounds were identified and the means were developed to employ the catalytic capability of cells in large-scale processes. This industry can be described as one that adds considerable value to some waste products or carbohydrate/salt mixtures with the aid of whole cell catalysts.

This introduction began with describing two productive, but largely isolated worlds. This helps to set the stage because the aim here is to describe how the two worlds may become more comingled in the future. This article will begin by introducing some background on biological catalysis. This will enable the brief examples of what can now be called traditional applications to be better understood as well as the later discussion of prospects and challenges. This article is not meant to be an exhaustive review. Rather, the intent is a general reader or even a specialist will pick up a few new things that adds to their understanding and perspective on cell-based catalytic processes.

1.1 Characteristics of Cellular Catalysts

This section will try to avoid a lot of biological terminology, which can frustrate some. Rather, some hopefully useful comparisons between heterogeneous catalysts and cellular catalysts will be made. Some basic quantitative constraints associated with cellular systems will also be provided.

1.1.1 The Good News

To lead on a positive, first the good news. The enzymes within cells have some attributes that are hard to match with synthetic alternatives, at least at first glance. The turnover frequency (TOF) of some enzymes can be as high as 106 s−1. Here, TOF refers to the number of molecules produced from reactant(s) per enzyme molecule per second in the absence of diffusional limitations. Carbonic anhydrase is an example of a fast enzyme with a turnover frequency of about 6 105 s−1. Ribulose-1,5-bisphosphate carboxylase/oxygenase (RuBisCO) is an exception to having a high turnover frequency attribute where it brings up the rear [2]. This enzyme catalyzes the fixation of CO2 to glucose in plants by the reaction

RuBisCO plods along with a turnover frequency of 3–10 s−1. As an aside, it is interesting that two reactions found in nature that use CO2 as a reactant differ so much in turnover frequency. In the case of RuBisCO, the shear abundance of the enzyme in the biosphere accounts for a sizable net rate of CO2 fixation (Scheme 1).

To underscore TOF ranges and differences, some example values from Boudart’s 1995 review [3] are shown in Table 1 along with the values I calculated for some enzymes. When comparing the TOF vaues, note that as Boudart points out, catalysis in the liquid phase considerably lowers the turnover frequency as compared to when catalysis occurs in the gas phase; hence, an enzyme achieving a value of 106 s−1 in water is quite impressive.

Enzymes can deliver high turnover to products at very low reactant concentrations. The classic Michaelis–Menten equation as shown below

gives the overall reaction rate (r) in terms of turnover frequency (k), total enzyme concentration (E T ), substrate (i.e. reactant, S) concentration, and dissociation constant (i.e. equilibrium constant K m for ES \(\rightleftarrows\leftarrow \to\) E + S). As also seen in Table 1, the concentration at which the maximal rate (kE T ) occurs is quite low and mM values or lower are the norm for K m . The ability to engineer both stereoselectivity and activity has continued to evolve [6].

1.1.2 The Less Good News

Turnover frequency is per active site. A metal-supported catalyst can contain many sites per total mass of catalyst thus providing a multiplier to the turnover frequency that can lead to a sizable global reaction rate. To make a comparison between biological and traditional catalysis, one gram of a laboratory-type cell suspension (i.e. cells plus water) contains about 3 10−4 g of cells on a dry weight basis. The cells, in turn, contain about 1.5 10−4 g of protein. An average protein has a molecular weight in the ball park of 50,000 g mol−1 leading to the total of one gram of cell suspension containing 1.8 1015 protein molecules. A bacterium has roughly 4,000 genes and if as a crude estimate, one half are expressed at 10 copies per gene, and most are enzymes as opposed to ribosomal or structural proteins, then there are ~1013 enzymatic active sites that can catalyze a particular reaction. In contrast, on the order of 1020 Pt surface sites can be found per gram when carbon is the support for an electrocatalyst [7].

While a Pt-containing surface site may not exactly correspond to an enzyme active site, no matter how one does the accounting, there will be a gap in the number of solid-supported and cell-based catalytic sites per total mass (or reaction volume) due to a combination of a number of dilution effects that arise in cellular systems. One effect has already been noted. Namely, an intact cell performs many reactions and functions, so any particular enzyme catalyst will be a small fraction of the total number within the cell. Cellular regulatory mechanisms control whether a particular enzyme is present or not and at what level. As will be noted later, these mechanisms can be tinkered with. Nonetheless, a functional cell will contain 1,000’s of different enzymes that all compete for the synthetic resources available to the cell.

Another diluting factor is the thermodynamic requirement for cellular life. Cells are designed to function in a dilute and high-molecular diversity situation. Quick turnover and specificity allows for many parallel reaction processes to be coordinated and performed that lead to replication and other facets of cellular life. Cellular membranes, walls, and stress systems allow for functionality over a range of physical conditions, but the ranges of temperature, water activity, and other physical variables over which functionality occurs are not wide. For example, the common bacterium Escherichia coli fares best at 37 °C. Raising the temperature to 42 °C can already start to decrease the growth rate and engage stress systems. The negative impact of the 5 degree shift suggests that in cellular systems, there is limited applicability of the rule of thumb: increasing the temperature by 10 °C will double the reaction rate.

The lower limit for water activity (product of water mole fraction and activity coefficient; a w = x w γ W ) tends to be around 0.90–0.95 for many bacteria [8]. The bacteria found in extreme environments (e.g. so-called halophiles) and some yeasts and fungi are hardier, but nonetheless ample a w is an omnipresent requirement. The lower limit of a W therefore limits the concentration of osmotically-active reactants and products that can be initially present or accumulated, respectively. In turn, the volumetric productivity (mol product/volume time) can be limiting.

Another diluting factor is the solubility of oxygen and the rate of mass transfer from the gas to liquid phase in a bioreactor. Oxygen has parts per million solubility and its mass transfer in standard lab (i.e. shake) cultivation can limit the cell concentration in aerobic cultures to a value of approximately 0.2–0.4 volume percent or an optical density of 9 for a 1 cm path length measurement at 550–650 nm. Improving aeration beyond that which occurs in a laboratory shake flask and also employing fed-batch cultivation can result in achieving 20 volume percent of cells.

In addition to temperature, reaction engineers have pressure as a variable. The high-pressure synthesis of ammonia over a promoted iron catalyst is a classic example [9]. In such an application, the equilibrium conversion of the reaction is favorably influenced by increased pressure. Nominally, in a cellular application, increasing pressure can increase the equilibrium value of dissolved oxygen concentration and thus enhance the rate of mass transfer to the cell-containing liquid phase. Increased oxygen mass transfer, in turn, can support the respiration rate of a higher cell concentration. Interestingly, however, recent work has indicated that there may be not fully understood side effects associated with elevated pressure that can be either favorable or detrimental [10]. For example, higher pressure (5 bar) has been reported to enhance the production of a desired protein while lowering the amount of protein degrading enzymes with the result that a final higher product concentration was attained [11]. At very high pressures (>5 kbar), proteins can undergo unfolding as evident by alterations in the emission wavelength of tryptophan fluorescence or other characteristics [12]. Further investigation over a wide pressure range is merited especially given that so-called “omics” techniques are available that can inform on changes in the abundance of different proteins and enzymes.

1.2 Looking Back

Interestingly, it was nongrowing cells that proved to initiate waves of new pharmaceuticals that were difficult to synthesize. A variety of antibiotic molecules were found to be produced by fungi in response to some nutrients being depleted in the growth medium as the transition from growth to the stationary phase occurred. Thus, learning how to grow cells at large scale, using cheap raw materials, and achieving a reasonably high concentration of cells were all major accomplishments that had to be made before the actual production phase could commence.

Concerning antibiotic production, endogenous enzymes were initially used to produce the molecules [13]. That is, the cell contained the information and enzymes to execute a multistep synthesis leading to the final product. Later, so-called adjuncts or semi-synthetic derivatives were introduced [13]. Adjuncts are molecules that are added to the growth medium and then become incorporated as side chain functionalities, which present one route to antibiotic derivatives. Such derivatives can extend an antibiotic’s use from intravenous administration to oral, or they frustrate the evolving antibiotic defenses of the targeted pathogens.

Nongrowing cells were also used for steroid synthesis. In some initial approaches, cortisone synthesis used cholesterol as a raw material and necessitated many steps. An alternative animal bile-based process developed by Sarett and colleagues at Merck required 30 steps or more [14]. Later, researchers at the Upjohn Company found that starting with progesterone, a microbial-mediated oxygenation at C11 could be done with the result that 11 α-Hydroxyprogesterone could be produced at more than 90 % yield and this compound could be subsequently transformed to steroids [15]. Plants such as yams could provide a cheap source of progesterone [16]. Better yet, crystallization could be used to efficiently isolate the 11 α-Hydroxyprogesterone produced at high yield. Also, so-called “compound S” developed by Percy Julian, which was one short but tough to execute step away from the sought structure, could be converted by the fungi-based process [16]. Here, cells were used in what is termed a “biotransformation,” which entails some natives enzymes within intact cells help to perform a critical step within an overall sequence.

1.3 The Last Decade

More recently, growing cells have continued to be used to produce a growing list of molecules that are hard to synthesize. The genetic instructions that encode for what are often nonnative (i.e. so-called heterologous) proteins are inserted into the cell. Proteins such as insulin and human growth hormone are well established examples, where the former is produced in the bacterium E. coli.

The choice of the cell used is often based on whether the protein is glycosylated or not. Glycosylation is needed for functionality and not engaging the surveillance of the patient’s immune system [17]. Bacteria cannot perform such so-called post translational (i.e. after the amino acids are polymerized to protein) modifications. Therefore, cells that are more comparable to human cells in terms of biosynthetic and processing capability such as Chinese hamster ovary (CHO) cells are used in many processes that can now yield approximately 1 g of protein product per liter of culture [18–20].

Alternately, a yeast such as Pichia pastoris can be used where glycosylation can also occur [21]. Moreover, P. pastoris exports proteins, which provide opportunities for product isolation that avoid breaking open the cells and then trying to refine a mixture of many proteins and other biomolecules. Many process convert glycerol and methanol into products through a two stage process [22–25]. Glycerol is used to grow a mass of cells often via a fed-batch process where substantial cell concentration can be established. Thereafter, a methanol induction phase is done where methanol is provided, which triggers product synthesis through a promoter-related gene induction mechanism. The methanol also serves as a carbon and energy source that can support product synthesis. A recent example of using P. pastoris is the production of recombinant human serum albumin at a titer of 10 g/liter [24]. The product can be used to treat hypoalbuminemia and because it is free of blood-borne pathogens (e.g. viruses), such recombinant products could also be growth media constituents and thus leave the therapeutic category and enter the larger volume reagent market [26].

1.4 Looking Forward

The look-back above indicates that cell-based catalysis has been traditionally directed towards hard to synthesize molecules that also command a high price due to a singular property and low technical availability. For example, in the late 30 s and early 1940, different accounts suggest that cortisone was valued at 100–1,000 US$/gram. A more recent example of supply- and cost-driven cell-based synthesis is the path developed for producing the precursor to the antimalarial drug artemisinin [27].

Looking at more recent work, however, indicates an even more ambitious agenda for cell-based catalysis. A product class-centric approach will be used to describe these visions and the associated challenges. The categories to be further explored are (i) synthesis of alternative macromolecular products and (ii) renewable syntheses for the chemical process industry (CPI). For brevity, the reader is referred to other sources for (i) cells as waste-to-electrical energy transducers (e.g. [28, 29]) and (ii) using cells to produce flavors and fragrances that can be marketed as natural products (e.g. [30–32]).

1.5 Example of Alternative Macromolecules

As noted above, an explosion of the number of therapeutic proteins produced from bacterial, CHO, P. pastoris, and other cells has occurred. Virus-like particles have also been produced [33–35]. Along the way, exploration of biodegradable polymers has also occurred (e.g. [36]). Looking ahead, one sees now and can further envision that cells will be used to produce DNA-based drugs, tools for molecular medicine, and a source of DNA “parts” for DNA nanotechnology [37]. Looking over some issues with DNA vaccines will also provide some basics that apply to chemical manufacture via cells because replicating entities called plasmids are involved in vaccines as well as nearly all other applications.

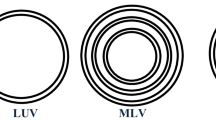

1.5.1 Plasmids: The Basis for DNA-Based Vaccines and DNA Parts

A plasmid is a circular molecule that is comprised of double stranded DNA. Plasmids are capable of replicating and thus remaining within cells over subsequent cellular division cycles. Plasmids exist in nature and these natural starting points have been extensively redesigned for use in biotechnology where, for example, a gene that encodes for a therapeutic protein is inserted into the plasmid DNA. The gene is “expressed” where the cell produces the protein encoded by the inserted gene. The copy number of a plasmid, which is how many plasmids stably persist per cell by replicating and then partitioning through division, is controlled by a negative feedback system [38]. One component involved serves as a starting primer for polymerization while another can bind to the primer thereby terminating the priming process.

DNA vaccines are also circular plasmids. They contain: (i) a gene that encodes one or more antigens, (ii) an antibiotic resistance gene that enables the selection of plasmid-bearing cells, and (iii) a bacterial origin of replication [39]. Here, an antigen, which is recognized by the immune system, is encoded as opposed to a therapeutic protein such as insulin. The antigen is not produced within the bacterial cell, because mammalian control systems (i.e. promoters) are used on the plasmid. Therefore the DNA vaccine is a hybrid molecule: it contains parts that work in bacterial cells (replication) and other parts that are active in mammalian cells (production of antigen).

In order to produce a DNA vaccine, bacteria are first grown at large scale. Using the bacteria-based control system (i.e. “bacterial origin of replication”) that regulates plasmid replication allows for bacterial cell growth and simultaneous synthesis of the plasmid. The isolated plasmid DNA is then injected into the vaccine recipient. The antigen gene’s promoter, which is the molecular “starter” for gene expression to produce antigen, is designed to be active in the recipient’s cells, but it is not expressed in bacteria during plasmid production. Upon injection, transient antigen production occurs until the plasmid DNA is degraded.

For producing DNA parts, a mammalian-type promoter is not a relevant plasmid component. However, producing plasmid DNA in quantity through bacterial growth would still be first done. Thereafter, one means of processing would entail enzymatically excising the target DNA from the isolated plasmid by using sites that were designed into the plasmid.

1.5.2 Challenges for Cellular Production of DNA-Based Drugs and Parts

For vaccines, the challenges can be divided into two categories: (i) biological efficacy and (ii) efficient production. Concerning the former, DNA vaccines were first tested in patients with HIV infection [40] followed by testing as preventive vaccines for HIV [41]. In early trials, the immune responses to DNA vaccines were found to be less than expected in humans. In contrast, early vaccines and administration protocols showed good efficacy in animals. More recently, delivery via gene guns (US Military) and electroporation have been found to significantly increase antibody response compared to when naked DNA is injected. For example, clinical trial NCT00859729 addresses the treatment of prostate cancer and entails testing the efficacy of a DNA vaccine administered intradermally in combination with electroporation (http://clinicaltrials.gov/ct2/show/NCT00859729). Improving efficacy will be a challenge to pursue for the foreseeable future.

The designer of cellular-catalysts and molecules can have a direct impact on the second category, efficient production, which impacts DNA drug and parts applications. Impact to date, however, may be less than possible because this category may also be less appreciated. This follows from most of the prior experience with the biotechnological use of plasmids has involved recombinant protein production. In this now well established application, one can summarize the overall reaction process as

The β-lactamase shown above is produced by a gene on the plasmid in addition to the recombinant protein, which is encoded by another gene on the plasmid. The β-lactamase enzyme degrades antibiotics such as ampicillin. Thus, only plasmid-containing cells can survive in a growth medium containing ampicillin. To insure that all cells in a culture are productive in that they contain plasmid, antibiotic “selection” is used to isolate and maintain plasmid-containing cells.

Producing recombinant proteins has been extensively optimized. Currently, 20 % or more of the protein produced by a cell can be accounted for by the desired protein product. Thus, it is easy to simply adopt the existing plasmids and host cells used for recombinant protein production as the starting point for DNA production. One can just swap the recombinant protein gene for that of one or more antigens or DNA “parts.”

However, when only plasmid DNA is sought, basic mass and energy balances indicate that the problem may actually be much different than recombinant protein production. A DNA precursor has about three-times the mass of an amino acid. The energy required per bond during DNA polymerization is about one-third of that needed for protein synthesis [42]. Thus, when combined, the energy cost per mass is about one-tenth less for DNA polymerization than for protein polymerization. Additionally, as opposed to producing an antibiotic resistance marker protein (e.g. β-lactamase), which can comprise up to 18 % of cellular protein [43], alternate antibiotic-free selections are available that do not entail “energetically expensive” protein synthesis [44]. Moreover, such antibiotic-free methods are more in line with FDA recommendations [45].

This suggests that the molecular control mechanisms in the plasmid-host cell combination that restrain plasmid replication can be relaxed unlike the case for recombinant protein production where such deregulation could “crash” the cell due to an overwhelming redirection of precursor and energetic resources away from essential cellular functions. Prior research has elucidated how plasmid replication is controlled and what mutations (i.e. alterations to origin of replication) can be used [38]. Thus, rather than optimizing around the established recombinant protein systems, prior work could be applied in conjunction with modern “omics” methods to develop high productive DNA-producing cells. Indeed, some recent work shows that when antibiotic-free selection was used, the bacterium E. coli could tolerate partially deregulated plasmid synthesis in that the growth rate was not impacted [46]. Moreover, instead of 100’s of plasmids per cell, plasmid copy numbers of 3,000–15,000 were measured [46].

Looking even further ahead, designing a whole cell-based process could have a significant physiochemical limitation as opposed to exclusively being related to reactant and energy availabilities. The interior of E. coli contains 1,000’s of different proteins, 4.6 106 or more base pairs of chromosomal DNA, other macromolecules, and now potentially 1,000’s of extra plasmids. As depicted in Fig. 1, it has shown that plasmid clustering occurs thus implying that some spatial organization can exist even for plasmids that are present at 10–100 copies per cell [47]. Crowding, which is a different process than metabolic engineers are used to (precursors, energy, and redox cofactors), could prove to ultimately limit how much plasmid DNA that can be produced when the copy number is 105 per cell or higher. For example, ribosomal assembly and function could be impeded through a crowding effect.

Microscope-acquired images of plasmid-containing E. coli. Different colors result from different fluorescent dyes being associated with different cellular structures. Green area depicts a cluster of plasmid molecules. Blue corresponds to chromosomal DNA. Therefore, shown are plasmid + membrane (J), chromosomal DNA (K), and all three overlayed (L). Clusters of plasmids within cells growing on rich medium can be observed in J and K. Reproduced from [47] with permission. Image copyright note: Copyright (2001) National Academy of Sciences, U.S.A

1.6 Renewable Syntheses for the CPI

While economics and demand for a new and unmatched property of a molecule have historically driven the development of cell-based processes, the vision of a chemical industry based on using renewable carbohydrates from biomass as the starting point drives much current research. Another driver is the interest of using advances on the biological side as an impetus for rethinking or inventing nonbiological catalysts and processes. Here, the “handoff” from a biological process may be further transformed by a revamped conventional catalytic process. However, the new nature of the chemical constituents present in the “handoff” product mixture can drive new problems in selectivity and deactivation that have to be solved for the nonbiological catalyst.

As even more natural gas and condensables become available from fractured shale formations, a migration from bioenergy research may further increase the volume of ongoing research in biorenewable chemicals. Also, because some bioenergy research entails engineering cells to produce long chain fatty acids, the prospect for upgrading such molecules to chemical products as opposed to fuel molecules results in an intersection between and biorenewable energy and chemical research.

The commercial interest in keeping pace with and potentially adopting the research product, in turn, is driven by the renewable aspect as well as other strategic issues. The export of US-produced natural gas as well as other liquefied components has caused some concern within some quarters of the US CPI (see PRESS REPORTS & COMPANY STATEMENTS). Indeed, the tight propane market during the winter of 2014 demonstrates how fulfilling obligated export contracts during a period of increased spot demand can perturb the market place. The ability to domestically produce small to mid-sized precursors or chemicals on a sustainable basis could mitigate the impact of exports on raw material supplies and costs. From another commercial perspective, substantial growth occurred in the CPI when new molecules and materials such as nylon appeared in the market. An infusion of new bifunctional molecules that could be transformed or polymerized into new products with enhanced or new properties could result in a new wave of innovation and growth. Harnessing cellular catalysis alone or in combination with new developments in nonbiological catalysis could lead to such an infusion.

1.6.1 Developing Cellular Catalytic Routes

The bacterium E. coli and the yeast Saccharomyces cerevisiae are the most common cells used for prototype development. Both are well characterized and alterable at the genetic level. Yeast also tend to have more innate tolerance to when its metabolism is redirected towards chemical synthesis. The minimum a w of most yeasts is also less than that of E. coli. The yeast vs E. coli comparison of robustness logically follows from the niches they occupy in nature. E. coli lives in the temperature-controlled and nutrient-rich environment provided in the human gut while yeasts are commonly found associated with high sugar concentration fruits.

There are a large number of routes that aspire towards the biological synthesis of commodity or moderate volume specialty chemicals. When developing a cellular catalyst for chemical synthesis, some key steps and considerations also tend to always emerge. Thus, as opposed to surveying all efforts aimed at different target molecules, an example will instead be covered that illustrates many of the basic issues and steps that arise. Moreover, a successful process will likely be one where more than one value-added product can be made. That is, a platform is developed and different products radiate from the platform. Such a strategy can better contend with fluctuations in different market sectors, add to scale, and leverage some common resources and technologies. The synthesis of triacetic acid lactone (TAL; C6H6O3 see Scheme 2) is of keen interest and provides an illustration of the biological issues and also leveraging.

TAL is now produced by heating dehydroacetic acid in acid based on chemistry that was established some time ago [48]. Isolation entails either extraction or crystallization in cold water. A number of products can be made from TAL including resorcinol, a component of resins and adhesives, and sorbic acid, which is a food preservative and antimicrobial. Obtaining a product such as sorbic acid could be realized by a combination of biological production of TAL and subsequent conversion of the TAL via metal (Pd)-supported and Amberlyst™ catalysts [49]. The molar yield of sorbic acid from TAL through a multistep sequence of catalytic reactions was reported to be 64 % and further optimization is likely to occur [49].

A first step towards something like a TAL platform is to conceive a biological reaction pathway. Due to its renewable nature, glucose is typically used as the initial starting point. Thus, some pathway already present in the cell will have to be “hijacked” where a glucose-derived metabolite is siphoned off to produce the target compound. Sometimes an enzyme is found in nature in another cell that can catalyze this chemistry. Regarding, TAL the enzyme 2-pyrone synthase (2-PS) is found in Gerbera hybrida (Gerbera is a genus of ornamental plants of the sunflower family). The enzyme in plants normally participates in polyketide synthesis, which may contribute to the plant’s pathogen resistance. The reactants used are acetylCoA and malonlyCoA according to Scheme 2 where SCoA denotes a thioester is formed between the carbon compound and coenzymeA.

In a bacterium such as E. coli, acetylCoA and malonylCoA are common metabolites. AcetylCoA is yielded from glucose in a process where glycolysis first yields pyruvate and then the pyruvate is oxidized to form acetylCoA. It is acetylCoA that enters the Krebs cycle for oxidation and consequently energy production for the cell. MalonylCoA is, in turn, produced from acetlyCoA via the reaction

The above reaction is a first step in fatty acid synthesis, where these acids ultimately constitute the phospholipids that comprise cellular membranes. Thus, through the use of genetic engineering (e.g. using plasmids as described earlier) 2-PS can be introduced into either E. coli or yeast to produce TAL.

A reader with a systems perspective may anticipate that the next major issue that arises after determining if there is a reaction route is how will synthesis of TAL, which diverts acetylCoA and malonylCoA away from some rather important functions, alter energy production and membrane integrity. Excessive diversion could result in slow growing cells or those with compromised membranes. Thus, if TAL production is proportional to cell mass concentration in a reactor, the metabolic drain that slows cell mass accumulation plus a W requirements could conspire to result in low temporal productivity and product concentration. Thus, metabolic engineers try to achieve what is called “pathway balancing” where upstream precursor supply is increased through eliminating nonessential uses or through enzyme amplification such that an acceptable growth rate is achieved while product formation occurs. Alternately, a two-step process can be developed somewhat akin to antibiotic or steroid production. First cells are grown to a high concentration. Thereafter, the new enzymes added through genetic engineering are induced to result in a production phase.

Another way to develop a reaction route is to alter an enzyme found in nature such that it catalyzes a different overall reaction. Thereafter, the enzyme is introduced into cell usually via plasmid-based cloning. Regarding TAL synthesis, the 2-PS and mutated enzyme approaches has been explored and compared in E. coli and yeast using similar fed-batch reactor protocols [50]. The enzymes 6-methylsalycilic acid synthase (6-MSAS; from Penicllium patulum) and fatty acid synthase B (FAS-B; from Brevibacterium ammoniagenes) were subjected to mutagenesis where amino acids in the active site region were changed.

The best combination proved to be yeast hosting a version of 6-MSAS that had one amino acid replaced (i.e. “single mutant”) [50]. Under fed-batch conditions, a titer of 1.8 g TAL/l was achieved with a yield from glucose equal to 6 mol TAL/100 mol glucose. In addition to the yeast possessing an active enzyme, the reactor operation was also key a factor in gaining a titer greater than 1 g/l. The presence of an enzyme within a cell is controlled by a binding-based, operator-promoter system. The operator and promoter are binding sites that precede a gene. The operator is akin to an on–off switch and it is adjacent to the gene. Through the binding of other molecules to the operator site, the access to the gene can either be blocked or open. If the gene is “open” at the operator level, then the promoter is where converting the gene’s information to a functional enzyme molecule begins. Transcription of the gene through the synthesis of messenger RNA via RNA polymerase is initiated here. Promoters of different strengths and interactions with other signals exist, which differentiates how avidly they bind and thus compete for RNA polymerase. Different promoters can be used to control the level of expression of foreign genes within cells. In the case of producing TAL with yeast harboring a mutated 6-MSAS, maintaining low glucose concentration through a feedback-based control system was essential to ensuring that the promoter used was not “shut down” and thus 6-MSAS was expressed at a significant level within the yeast cells.

The nature of the mutated 6-MSAS provides a reminder of another problem that can arise. This problem is known as “cofactor” balancing or cycling. In cells, oxidation and reduction reactions require an intermediary electron carrier. In energy-yielding oxidations, nicotinamide adenine dinucleotide is the electron carrier. An example is ethanol oxidation to acetaldehyde followed by oxidation of the reduced form of nicotinamide adenine dinucleotide (NADH) back to the oxidized form (NAD+)

Electrons are transacted as hydrides (H−) and NADH carries the electrons to a subsequent oxidant. As the scheme above implies, a fixed amount of cofactor cycles between redox states such that the total nicotinamide adenine dinucleotide pool is fixed as the sum of NAD+ and NADH. Oxidation of NADH to NAD+ is done through a series of membrane-associated electron carriers that bear quinone functionalities or are heme-containing proteins. To maintain biosynthetic oxidations/reductions distinct from energetic reactions, a phosphorylated form (NADP+, NADPH) is instead used as the electron carrier in biosynthetic reactions.

If a synthesis draws excessively upon any of the cofactors (NAD+, NADH, NADP+ or NADPH), then as is the case for excessive metabolite withdrawal, cellular proliferation and thus kinetics and productivity can be compromised. The mutated 6-MSAS had a “reductase” activity suppressed leading to a change in selectivity towards TAL synthesis as opposed to 6-methylsalicylic acid. In other cases where net NAD+ or NADH use occurs in a synthesis, problems can arise if cofactor cycles are overly taxed by product synthesis.

1.6.2 Perspective and Challenges Concerning Cell-Based Routes to Commodity Chemicals

A 6 % yield on glucose may not sound impressive to one experienced in heterogeneous catalysis. On the other hand, titers in the 10 g/lit range sound pretty good to a cell engineer considering zero was the starting point for a molecule like TAL not too long ago. As long as growing cells are used, the yield on glucose will always be less than 100 %. For a bacterium like E. coli that has not been engineered, the carbon budget from glucose is roughly 50 % of the carbon mass goes to biomass and 50 % is accounted for by metabolic by-products such as CO2 and acetate. A yield of 6 mol TAL/100 mol glucose also represents 6 % of the carbon mass in glucose being directed to TAL. Overall, if growing cells are used the carbon budget will be tight. Some of the 50 % that goes to metabolic by-products such as CO2 and acetate can be diverted, but energy production is coupled to CO2 production; hence, a lower bound constraint exists on what can be diverted before not meeting energetic demands for biosynthesis and maintenance become problematic.

Of the 50 % that goes to cell mass formation, some can be potentially redirected if the cell is “stripped down” by removing genes/proteins that are nonessential under process conditions. An example is the genome reduction of Bacillus subtilis 168, where 20 percent of the chromosomal DNA was removed, which was equivalent to eliminating 87,400 base pairs of DNA. The genome-reduced strain exhibited increased production of a plasmid-encoded cellulase product [51]. Overall, in the near future g/l titers will remain the goal that is aspired to. The cost of separations and raw materials versus product value will be the major discriminators of feasibility.

Based on conventional chemical engineering, one would expect that modeling the outcome ahead of time would enable the screening of process alternatives as well as “cell design.” The predictive capability is improving. Linear programming or other network analysis methods can suggest what the yield horizon may be for a set of cell-wide stoichiometric, energetic, and growth constraints. Typically, the new enzyme(s) associated with the reaction path are introduced into a cell and shake-flask scale experiments are performed to see how the yield and productivity compare to the theoretical. Thereafter, problems with toxicity and yield are trouble shooted through different trials of reducing or amplifying different enzyme within the cell via metabolic engineering.

Along with yield horizon prediction, the optimal reaction rates to establish within the network of cellular reactions can now be predicted. Thus, the particular rates that are either elevated or reduced provide suggestions on how to modify the host “chassis” to optimally produce a product. Altering promoters, structural genes or other regulatory features within the cell can increase or decrease the abundance of a metabolic enzyme along the lines prescribed by the computed optimal solution. This leads to simple “knockouts” where an enzyme activity is removed to effect a redirection of precursors towards a desired product such as folic acid [52]. Alternately, more recently and at a larger scale, the manipulation of the abundance 17 different gene products was identified from network analysis as potentially being able to improve precursor and cofactor supplies for TAL synthesis [53]. In yeast possessing a 2-PS activity, the investigators reported a titer and yield from glucose of 2.2 g TAL/l and 0.13 g TAL/g glucose. When converted and compared to the prior TAL work [50], the yield is about tripled to from 0.06 to 0.19 mol TAL/mol glucose [53].

Network analyses will continue to evolve and expand. One issue will be the redundancy of biological networks and the resulting prospect for alternate optima or clonal solutions. For example, multiple reactions within a cell produce NADPH, which in turn, provides reducing power for biosynthesis akin to the use of hydrogen in a chemical plant. There are numerous linear combinations of these NADPH-producing reactions that can provide a particular value of total NADPH production. Thus, there may be more than one distribution of “tweaked” intracellular reaction rates that optimally or nearly optimally support a synthesis. A basic example is the alternate optima that can arise in E. coli when the enzyme pyruvate kinase is knocked out [54, 55] and clonal solutions which differ from the optimal by only a small amount [56]. Small error bounds on what are considered to be measured inputs to models can also alter the number of reaction rate solutions, which is indicative of plasticity [57].

A less esoteric issue is the growth medium that is used in studies that are conducted to demonstrate initial feasibility and then later, improvements in titer and yield. A bacterium like E. coli can grow extremely well (doubling time about 20 min) on rich medium containing macromolecule precursors such as amino acids. E. coli can also grow reasonable well (doubling time ~1 h) on so-called minimal medium that contains only glucose and salts. From the economic and simplicity point of view, the minimalist E. coli would seem quite appealing. However, there can be a tendency to use complex medium at least initially in E. coli studies. The thought is the preformed precursors may afford some growth support to the initial cell construct, which will likely show some synthesis but also require revision to mitigate pathway imbalances or other problems that are amenable to further optimization.

This may be true, but growth in complex medium at the bench scale can also have some downsides that could skew results. For example, in so-called LB medium not supplemented with glucose, an experimenter may be unaware that the buffering capacity of the medium is typically exceeded due to the extensive deamination of the numerous amino acids that are used as energy sources [58]. As the pH becomes alkaline, stress from the product synthesis could be compounded thereby affecting the yield and other measurements. Supplementing LB medium with glucose tends to result in the opposite. There can be extensive acetate formation through overflow metabolism thereby lowering the pH while also adversely impacting carbon redirection into product.

Another negative feedback effect can occur that “piggy backs” on to the growth reduction that arises from basic or acid pH excursions, acetate accumulation, or from other sources. The number of plasmids within a cell, where the plasmids endow a cell with the ability to produce, for example, 2-PS, can increase as the growth slows [46, 59–61]. This occurs because the plasmids replicate while cell growth provides volume-increasing dilution of the intracellular constituents. When the so-called cytoplasmic dilution decreases due to growth reduction, the intracellular abundance of entities such as plasmid can increase. (Early and more recent examples of cytoplasmic dilution calculations and data can be found in [61, 62].) The more plasmids per cell, the more 2-PS genes per cell that can be processed into TAL-producing enzyme. If the plasmid also happens to be selected for by antibiotic resistance, then referring back to the DNA vaccine section suggests that there is also excessive and taxing protein synthesis associated with producing more 2-PS and the associated TAL product. Thus, the innate metabolism of the cell in a common medium can compound with the toxicity or stress associated with heterologous gene expression to slow or cease production.

Alternately, if the produced molecule exerts a toxic effect on the cell, growth may decrease. Decreased cytoplasmic dilution will raise the intracellular concentration of many molecules including the chemical product if export to the extracellular space is slow. A spiral can thus occur where slowed growth leads to slower growth and accentuated toxicity and possibly plasmid burden effects. This points to the other major challenge past a W : stability in the face of a time-dependent rate of chemical production and accumulation within the system.

Yeast often fares better in product synthesis than E. coli (e.g. [50]) and yeast workers tend to use a more complex medium in experimentation. Extracts that contain methionine and cysteine, which are sulfur-containing amino acids, are frequently used to grow engineered cells. A variation is a medium that does not contain added amino acids, but rather one that provides an ammonium salt and a number of vitamins. The alternative is commonly known as “yeast nitrogen base without amino acids.” This additive contains the sulfur-containing molecules such as biotin (C10H16N2O3S) and thiamine hydrochloride (C12H18Cl2N4OS). Thus, if subsequent reactions are done using metal-based catalysts, the isolation procedures and solvent choices made should insure that the transfer of potential catalyst poisons such as sulfur-containing compounds does not occur down the line.

While not as news making as engineering cells to accomplish the total synthesis of cortisone [63], new media may have to be developed or revamped for economic and processing reasons. While knowledge will be gained and demonstrations provided, the complete reliance on the use of laboratory medium may result in optimization of the chemical-producing cell around the wrong drivers. When the cell is later used in a bulk biomass-derived medium, new toxicities or imbalances may emerge. Additionally, poisons to downstream catalysis may emerge.

For example, considerable quantities of the corn processing byproduct, corn steep water (liquor), are produced and sold to animal feeding, fermentation, and other industries. If using this traditional source of industrial fermentation media is considered as a feedstock for a cell-based chemical industry, the impact of SO2 content and prior fermentation of sugars by residential lactobacilli [64] on upstream and downstream steps may have to be considered. Moreover, while containing g/l levels of glucose [64], other sugars are present that E. coli cannot naturally metabolize whereas yeast can show more versatility. Likewise, the alternative of breaking down lignocellulosic biomass yields glucose and xylose as well as potential inhibitors. [65–67] Thus, the ground that lies in between actual feedstocks and basic laboratory medium needs to be investigated.

Another facet of raw material and chemical complexity management that could be explored is under investigation by some in the bioenergy research arena. Schemes are being considered to recycle the carbohydrate and other nutritive portions of each cell mass “crop” back into the process in order to improve the overall conversion of input materials or to lower the input of new material [68, 69]. Note, however, that the food-to-energy criticism of bioethanol is mitigated somewhat by the direction of waste grain and yeast crops to the animal feed market. Indeed, yeast has been fed to livestock for many years and the comparison with feeding with grains such as soy beans has been reported to be favorable [70]. With any recycle system there is a purge. However, with some cell mass partially refined and recycled, the amount of the analogous credit back to the food chain may be less. Another dimension is whether it would be acceptable to put intact genetically modified organisms into the food chain through animal feeding.

2 Discussion and Conclusions

This article has attempted to provide some current information on the issues and progress associated with cell-based catalysis. The vehicle used was concrete examples of a new product as well as new directions for some old and established products. A look back was also done in an attempt to add to the perspective. Also, some of what worked before could be adopted in some fashion again. For the nonbiologist, the presentation of some basic issues such as a W and cofactor cycling may add to the understanding of what challenges need to be surmounted to improve the operational and yield characteristics of processes based on cell-based catalysts.

In the near future, one can expect to see more reports on being able to achieve 1–10 g/l titers of products like TAL. In some cases where the toxicity and osmo activity are both low, higher titers will be obtained. Further increasing concentrations or volumetric productivities will likely rely on hybrid integrated processes where product synthesis and removal concurrently occur. Alternately, akin to the antibiotic and steroid predecessors, a growth stage to high cell concentration followed by biotransformation will be necessary.

Rather than making an array of different molecules in a distributed fashion, the economy of scale will likely favor platform hubs with different combinations of biological and nonbiological catalysis leading to a radiating slate of specialty or near commodity products. Should significant inroads be made, the impact on how agriculture and forestry by-products are used could be such that new media products will be developed. The development of new bifunctional molecules would especially be exciting as these would lead to the genesis of new chemical products.

In the case of any technology, there are threats that accompany the opportunities. Four can be immediately recognized. First, separation technologies and associated costs may not make the newly envisioned cell-based processes viable. Secondly, the metal-based and other catalysts used for upgrading may not be able to contend with impurities. Presently, the first cannot be answered until titer limits are found whereas we are now in a phase of growing titers. The second does not seem insurmountable as there appears to be ample opportunities to reformulate growth media and much work on exploring upgrading catalysts is underway [71].

Thirdly, an abundance of cheap hydrocarbons from fractured shale formations and other sources will derail the economics of renewable chemicals despite impressive titers. Targeting medium size carbon compounds for cell-based processes may not overlap with products derived from the precursors found in wet gas. Additionally, the intent to export liquefied products, which function as precursors in some conventional chemical syntheses, has already been demonstrated while extensive interest exists to expand exports. Thus, raw material costs may still face uncertainty despite greater abundance due to competing demands and variable price points in different global markets.

Finally, the earlier discussion of the carbon budget for a “plain vanilla” E. coli may have prompted the reader to wonder why the whole cell needs to be used. It would seem that a lot of carbon is invested in cell mass that supports the synthesis of a lot of things, where only a small subset actually leads to the molecular product of interest. Thus, a conceivable threat is the question and position

“Why use cells at all? Eliminate them from the picture. Maybe using their parts could be more economical and sensible.”

One answer is we would still have to grow cells and then isolate the enzymes. For an N step synthesis and for M products, the combinatorics can quickly become impressive. Moreover, the intracellular environment does provide some “perks” for enzymes such as protection against oxidants and the rebuilding of enzymes that have expired. Some enzymes are also challenging to immobilize in active form. Therefore, from a more macro standpoint, the prevailing assumptions now are (i) glucose can potentially be cheap, (ii) an intact cell provides multi-step synthetic and catalytic capabilities, and (iii) capturing CO2 through biomass formation as the glucose source provides a societal benefit that may be financially recognizable by lessened negative impact from climate change or the reduced use of finite nonrenewable resources. Thus, many view building a multifunctional, mini chemical factory (cell) from glucose as a net value-adding proposition.

In the long run, however, it may be more pragmatic to not consider using cell parts as a threat. Rather, an evolutionary process will unfold that will lead to a range of solutions and their combinations. Using intact cells will enable forward movement. As we learn more, we will likely become better at eliminating nonessential parts akin to the cellulase example noted earlier [51]. An initial start is the collection of E. coli where each member has a single gene removed [72]. Methods have since been developed that can be directed towards the larger goal of genome-scale editing. The new methods include so-called “clustered regularly interspaced short palindromic repeats” (CRISPR) technology [73], multiplex automated genome engineering [74], and yeast oligo-mediated genome engineering [75]. The prospect of acellular synthesis can be viewed as the other end of the spectrum that will exist. A starting point is the virus-like particles and other large molecules of interest have been reported to be made from cellular components [76, 77]. Another application has been proposed where only a handful of enzymes and 2-ketoisovaleric acid are used to produce small fuel molecules [78]. The acid is derived from a fermentation; hence, both ends of the spectrum, intact and cell-free catalysts, are used in this application.

References

R.W.M. J, Preparation of component for premium grade motor gasoline, in, Google Patents, 1960

Ishikawa C, Hatanaka T, Misoo S, Miyake C, Fukayama H (2011) Functional incorporation of sorghum small subunit increases the catalytic turnover rate of Rubisco in transgenic rice. Plant Physiol 156(3):1603–1611

Boudart M (1995) Turnover Rates in Heterogeneous Catalysis. Chem Rev 95:661–666

Singh R, Wiseman B, Deemagarn T, Jha V, Switala J, Loewen PC (2008) Comparative study of catalase-peroxidases (KatGs). Arch Biochem Biophys 471:207–214

Ren X, Lindskog S (1992) Buffer dependence of CO2 hydration catalyzed by human carbonic anhydrase I. Biochim Biophys Acta 1120:81–86

Reetz MT (2011) Laboratory evolution of stereoselective enzymes: a prolific source of catalysts for asymmetric reactions. Angewandte Chemie (International ed. in English) 50:138–174

Punyawudho K, Blom DA, Van Zee JW, Monnier JR (2010) Comparison of different methods for determination of Pt surface site concentrations for supported Pt electrocatalysts. Electrochim Acta 55:5349–5356

Mugnier J, Jung G (1985) Survival of bacteria and fungi in relation to water activity and the solvent properties of water in biopolymer gels. Appl Environ Microbiol 50:108–114

Schlögl R (2008) Ammonia Synthesis. In: Handbook of heterogeneous catalysis. Wiley, New York

Lopes M, Belo I, Mota M (2014) Over-pressurized bioreactors: application to microbial cell cultures. Biotechnol Prog 30:767–775

Lopes M, Oliveira C, Domingues L, Mota M, Belo I (2014) Enhanced heterologous protein production in Pichia pastoris under increased air pressure. Biotechnol Progr 30:1040–1047

Silva JL, Weber G (1993) Pressure stability of proteins. Annu Rev Phys Chem 44:89–113

Elander RP (2003) Industrial production of beta-lactam antibiotics. Appl Microbiol Biotechnol 61:385–392

Hirschmann R (1992) The cortisone era: aspects of its impact. Some contributions of the Merck Laboratories, Steroids 57:579–592

Peterson DH, Murray HC, Eppstein SH, Reineke LM, Weintraub A, Meister PD, Leigh HM (1952) Microbiological Transformations of Steroids. 1. Introduction of Oxygen at Carbon-11 of Progesterone. J Am Chem Soc 74:5933–5936

Stille DR (2009) Percy Lavon Julian : pioneering chemist, Compass Point Books. Minn, Minneapolis

Shade K-T, Anthony R (2013) Antibody Glycosylation and Inflammation. Antibodies 2:392–414

McCracken NA, Kowle R, Ouyang A (2014) Control of galactosylated glycoforms distribution in cell culture system. Biotechnol Prog 30:547–553

Yang WC, Lu J, Kwiatkowski C, Yuan H, Kshirsagar R, Ryll T, Huang Y-M (2014) Perfusion seed cultures improve biopharmaceutical fed-batch production capacity and product quality. Biotechnol Prog 30:616–625

Rouiller Y, Périlleux A, Vesin M-N, Stettler M, Jordan M, Broly H (2014) Modulation of mAb quality attributes using microliter scale fed-batch cultures. Biotechnol Prog 30:571–583

Bretthauer RK, Castellino FJ (1999) Glycosylation of Pichia pastoris-derived proteins. Biotechnol Appl Biochem 30(Pt 3):193–200

Anasontzis GE, Salazar M (2014) Penã, O. Spadiut, H. Brumer, L. Olsson, Effects of temperature and glycerol and methanol-feeding profiles on the production of recombinant galactose oxidase in Pichia pastoris. Biotechnol Prog 30:728–735

Goldfeld M, Christensen J, Pollard D, Gibson ER, Olesberg JT, Koerperick EJ, Lanz K, Small GW, Arnold MA, Evans CE (2014) Advanced near-infrared monitor for stable real-time measurement and control of Pichia pastoris bioprocesses. Biotechnol Prog 30:749–759

Mallem M, Warburton S, Li F, Shandil I, Nylen A, Kim S, Jiang Y, Meehl M, d’Anjou M, Stadheim TA, Choi B-K (2014) Maximizing recombinant human serum albumin production in a Muts Pichia pastoris strain. Biotechnol Progr. doi:10.1002/btpr.1990

Unrean P (2014) Pathway analysis of Pichia pastoris to elucidate methanol metabolism and its regulation for production of recombinant proteins. Biotechnol Prog 30:28–37

Zhu J, Wooh JW, Hou JJ, Hughes BS, Gray PP, Munro TP (2012) Recombinant human albumin supports single cell cloning of CHO cells in chemically defined media. Biotechnol Prog 28:887–891

Paddon CJ, Keasling JD (2014) Semi-synthetic artemisinin: a model for the use of synthetic biology in pharmaceutical development. Nat Rev Microbiol 12:355–367

Malvankar NS, Lovley DR (2014) Microbial nanowires for bioenergy applications. Curr Opin Biotechnol 27:88–95

Mathuriya AS, Yakhmi JV (2014) Microbial fuel cells—applications for generation of electrical power and beyond. Crit Rev Microbiol 6:1–17

Philippe RN, De Mey M, Anderson J, Ajikumar PK (2014) Biotechnological production of natural zero-calorie sweeteners. Curr Opin Biotechnol 26:155–161

Hagedorn S, Kaphammer B (1994) Microbial biocatalysis in the generation of flavor and fragrance chemicals. Annu Rev Microbiol 48:773–800

Deshmukh Y, Khare P, Patra DD, Nadaf AB (2014) HS-SPME-GC-FID method for detection and quantification of Bacillus cereus ATCC 10702 mediated 2-acetyl-1-pyrroline. Biotechnol Progr. doi:10.1002/btpr.1989

Kee GS, Jin J, Balasundaram B, Bracewell DG, Pujar NS, Titchener-Hooker NJ (2010) Exploiting the intracellular compartmentalization characteristics of the S. cerevisiae host cell for enhancing primary purification of lipid-envelope virus-like particles. Biotechnol Prog 26:26–33

Saccardo P, Rodriguez-Carmona E, Villaverde A, Ferrer-Miralles N (2014) Effect of the DnaK chaperone on the conformational quality of JCV VP1 virus-like particles produced in Escherichia coli. Biotechnol Prog 30:744–748

Yin S, Sun S, Yang S, Shang Y, Cai X, Liu X (2010) Self-assembly of virus-like particles of porcine circovirus type 2 capsid protein expressed from Escherichia coli. Virology journal 7:166

Mozejko J, Ciesielski S (2014) Pulsed feeding strategy is more favorable to medium-chain-length polyhydroxyalkanoates production from waste rapeseed oil. Biotechnol Progr 30:1243–1246

Zhang C, Mao C (2008) DNA Nanotechnology: bacteria as factories. Nat Nano 3:707–708

Tomizawa J, Som T (1984) Control of ColE1 plasmid replication: enhancement of binding of RNA I to the primer transcript by the Rom protein. Cell 38:871–878

Herweijer H, Wolff JA (2003) Progress and prospects: naked DNA gene transfer and therapy. Gene Ther 10:453–458

MacGregor RR, Boyer JD, Ugen KE, Lacy KE, Gluckman SJ, Bagarazzi ML, Chattergoon MA, Baine Y, Higgins TJ, Ciccarelli RB, Coney LR, Ginsberg RS, Weiner DB (1998) First human trial of a DNA-based vaccine for treatment of human immunodeficiency virus type 1 infection: safety and host response. J Infect Dis 178:92–100

Boyer JD, Cohen AD, Vogt S, Schumann K, Nath B, Ahn L, Lacy K, Bagarazzi ML, Higgins TJ, Baine Y, Ciccarelli RB, Ginsberg RS, MacGregor RR, Weiner DB (2000) Vaccination of seronegative volunteers with a human immunodeficiency virus type 1 env/rev DNA vaccine induces antigen-specific proliferation and lymphocyte production of beta-chemokines. J Infect Dis 181:476–483

I.J. Neidhardt FC, Schaechter M (1990) Physiology of the bacterial cell: a molecular approach. Sinauer Associates, Sunderland

Rozkov A, Avignone-Rossa CA, Ertl PF, Jones P, O’Kennedy RD, Smith JJ, Dale JW, Bushell ME (2004) Characterization of the metabolic burden on Escherichia coli DH1 cells imposed by the presence of a plasmid containing a gene therapy sequence. Biotechnol Bioeng 88:909–915

Luke J, Carnes AE, Hodgson CP, Williams JA (2009) Improved antibiotic-free DNA vaccine vectors utilizing a novel RNA based plasmid selection system. Vaccine 27:6454–6459

Williams JA, Carnes AE, Hodgson CP (2009) Plasmid DNA vaccine vector design: impact on efficacy, safety and upstream production. Biotechnol Adv 27:353–370

Trivedi RN, Akhtar P, Meade J, Bartlow P, Ataai MM, Khan SA, Domach MM (2014) High-level production of plasmid DNA by E. coli DH5α/sacB by Introducing inc Mutations. Appl Environ Microbiol. doi:10.1128/AEM.02445-14

Pogliano J, Ho TQ, Zhong Z, Helinski DR (2001) Multicopy plasmids are clustered and localized in Escherichia coli. Proc Natl Acad Sci USA 98:4486–4491

Collie JN (1891) LVI.-The lactone of triacetic acid. Journal of the Chemical Society, Transactions 59:607–617

Chia M, Schwartz TJ, Shanks BH, Dumesic JA (2012) Triacetic acid lactone as a potential biorenewable platform chemical. Green Chem 14:1850–1853

Xie D, Shao Z, Achkar J, Zha W, Frost JW, Zhao H (2006) Microbial synthesis of triacetic acid lactone. Biotechnol Bioeng 93:727–736

Toya Y, Hirasawa T, Morimoto T, Masuda K, Kageyama Y, Ozaki K, Ogasawara N, Shimizu H (2014) 13 C-metabolic flux analysis in heterologous cellulase production by Bacillus subtilis genome-reduced strain. J Biotechnol 179:42–49

Zhu T, Pan Z, Domagalski N, Koepsel R, Ataai MM, Domach MM (2005) Engineering of Bacillus subtilis for enhanced total synthesis of folic acid. Appl Environ Microbiol 71:7122–7129

Cardenas J, Da Silva NA (2014) Metabolic engineering of Saccharomyces cerevisiae for the production of triacetic acid lactone. Metab Eng 25:194–203

Lee S, Phalakornkule C, Domach MM, Grossmann IE (2000) Recursive MILP model for finding all the alternate optima in LP models for metabolic networks. Comput Chem Eng 24:711–716

Ghosh S, Zhu T, Grossmann IE, Ataai MM, Domach MM (2005) Closing the loop between feasible flux scenario identification for construct evaluation and resolution of realized fluxes via NMR. Comput Chem Eng 29:459–466

Ghosh S, Grossmann IE, Ataai MM, Domach MM (2006) A three-level problem-centric strategy for selecting NMR precursor labeling and analytes. Metab Eng 8:491–507

Meade J, Khan S, Ataai M, Domach M (2012) Use of flux pre-analysis to enable (1)(3)C tracer studies in pyruvate kinase-deficient Escherichia coli. Biotechnol J 7:449–460

Sezonov G, Joseleau-Petit D, D’Ari R (2007) Escherichia coli physiology in Luria-Bertani broth. J Bacteriol 189:8746–8749

Prather KJ, Sagar S, Murphy J, Chartrain M (2003) Industrial scale production of plasmid DNA for vaccine and gene therapy: plasmid design, production, and purification. Enzyme and Microbial Technology 33:865–883

Carnes AE (2005) Fermentation Design for the Manufacture of Therapeutic Plasmid DNA. BioProcess International 3:2–7

Cunningham DS, Liu Z, Domagalski N, Koepsel RR, Ataai MM, Domach MM (2009) Pyruvate kinase-deficient Escherichia coli exhibits increased plasmid copy number and cyclic AMP levels. J Bacteriol 191:3041–3049

Yagil G, Yagil E (1971) On the relation between effector concentration and the rate of induced enzyme synthesis. Biophys J 11:11–27

Szczebara FM, Chandelier C, Villeret C, Masurel A, Bourot S, Duport C, Blanchard S, Groisillier A, Testet E, Costaglioli P, Cauet G, Degryse E, Balbuena D, Winter J, Achstetter T, Spagnoli R, Pompon D, Dumas B (2003) Total biosynthesis of hydrocortisone from a simple carbon source in yeast. Nat Biotechnol 21:143–149

Hull SR, Yang BY, Venzke D, Kulhavy K, Montgomery R (1996) Composition of Corn Steep Water during Steeping. J Agric Food Chem 44:1857–1863

Wang L, Tang P, Fan X, Yuan Q (2013) Effect of selected aldehydes found in the corncob hemicellulose hydrolysate on the growth and xylitol fermentation of Candida tropicalis. Biotechnol Prog 29:1181–1189

Lu Y, Warner R, Sedlak M, Ho N, Mosier NS (2009) Comparison of glucose/xylose cofermentation of poplar hydrolysates processed by different pretreatment technologies. Biotechnol Prog 25:349–356

Zhou H, Lan T, Dien BS, Hector RE, Zhu JY (2014) Comparisons of five Saccharomyces cerevisiae strains for ethanol production from SPORL-pretreated lodgepole pine. Biotechnol Progr 30:1076–1083

Gowtham YK, Miller KP, Hodge DB, Henson JM, Harcum SW (2014) Novel two-stage fermentation process for bioethanol production using Saccharomyces pastorianus. Biotechnol Prog 30:300–310

Severa G, Kumar G, Cooney MJ (2014) Corecovery of lipids and fermentable sugars from Rhodosporidium toruloides using ionic liquid cosolvents: application of recycle to batch fermentation. Biotechnol Progr 30:1239–1242

Grieve DG (1979) Feed intake and growth of cattle fed liquid brewer’s yeast. Canadian J Anim Sci 59:89–94

Jacoby M (2012) Teaming up for biobased chemicals. Chem Eng News 90:37–38

Baba T, Ara T, Hasegawa M, Takai Y, Okumura Y, Baba M, Datsenko KA, Tomita M, Wanner BL, Mori H (2006) Construction of Escherichia coli K-12 in-frame, single-gene knockout mutants: the Keio collection. Mol Syst Biol. doi:10.1038/msb4100050

DiCarlo JE, Norville JE, Mali P, Rios X, Aach J, Church GM (2013) Genome engineering in Saccharomyces cerevisiae using CRISPR-Cas systems. Nucl Acids Res 41:4336–4343

Wang HH, Isaacs FJ, Carr PA, Sun ZZ, Xu G, Forest CR, Church GM (2009) Programming cells by multiplex genome engineering and accelerated evolution. Nature 460:894–898

DiCarlo JE, Conley AJ, Penttilä M, Jäntti J, Wang HH, Church GM (2013) Yeast Oligo-Mediated Genome Engineering (YOGE). ACS Synthetic Biology 2:741–749

Smith MT, Varner CT, Bush DB, Bundy BC (2012) The incorporation of the A2 protein to produce novel Qbeta virus-like particles using cell-free protein synthesis. Biotechnol Prog 28:549–555

Basu D, Castellano JM, Thomas N, Mishra RK (2013) Cell-free protein synthesis and purification of human dopamine D2 receptor long isoform. Biotechnol Prog 29:601–608

Grimaldi J, Collins CH, Belfort G (2014) Toward cell-free biofuel production: stable immobilization of oligomeric enzymes. Biotechnol Prog 30:324–331

Press Reports & Company Statements

DOW CHEMICAL CEO: “RUSHING TO SELL NATURAL GAS TO EUROPE AND ASIA RISKS DAMAGE TO THE U.S. ECONOMY” file:///C:/Users/md0q/Desktop/Whole%20Cell%20Article/DOW%20NG%20folder/Dow%20Chemical%20CEO%20%20%E2%80%9CRushing%20to%20sell%20natural%20gas%20to%20Europe%20and%20Asia%20risks%20damage%20to%20the%20U.S.%20economy%E2%80%9D%20%20%20America’s%20Energy%20Advantage.htm

Dow Statement on U.S. Department of Energy LNG Export Decision file:///C:/Users/md0q/Desktop/Whole%20Cell%20Article/DOW%20NG%20folder/Dow%20Statement%20on%20U.S.%20Department%20of%20Energy%20LNG%20Export%20Decision%20News%20-%20News%20Center%20-%20The%20Dow%20Chemical%20Company.htm

Acknowledgments

This work was supported, in part, by NSF Grant CBET-0967932. The results reported here represent the efforts and conclusions of the authors and not those of the supporting entities. The author would like to thank Professor Brent Shanks and his colleagues for sharing their thoughts on this subject and thus positively adding to scope discussed. The author and his colleagues at Carnegie Mellon would like to also recognize the continuing positive influence of their friend and teacher of catalysis, Professor Edmond Ko.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Domach, M.M. Perspectives and Prospects for Whole Cell Catalysis. Catal Lett 145, 346–359 (2015). https://doi.org/10.1007/s10562-014-1389-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-014-1389-z