Abstract

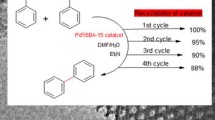

Mesoporous SBA-15 was modified with organic functional groups by co-condensation method. The functionalized mesoporous silica can be loaded with palladium and the resulting material used as a catalyst for the Suzuki–Miyaura coupling reactions. Highly dispersed and uniform palladium nanoparticles could be detected using transmission electron microscopy. The Pd-SBA-15 nanocomposite with controlled molar ratio of amino groups to palladium exhibits an excellent catalytic activity and low Pd leaching for the Suzuki–Miyaura coupling reaction. The catalyst can also be reused at least six recycles in air with only a minor loss of activity.

Graphical Abstract

Mesoporous SBA-15 was modified with organic functional groups by co-condensation method. The functionalized mesoporous silica can be loaded with palladium and the resulting material used as a catalyst for the Suzuki–Miyaura coupling reactions. Highly dispersed and uniform palladium nanoparticles could be detected using transmission electron microscopy. The Pd-SBA-15 nanocomposite with controlled molar ratio of amino groups to palladium exhibits an excellent catalytic activity and low Pd leaching for the Suzuki–Miyaura coupling reaction. The catalyst can also be reused at least six recycles in air with only a minor loss of activity.

Similar content being viewed by others

References

Martin R, Buchwald SL (2008) Acc Chem Res 41:1461

Littke AF, Fu GC (2002) Angew Chem Int Ed 41:4176

Yin LX, Liebscher J (2007) Chem Rev 107:133

Zhang R, Ding W, Tu B, Zhao D (2007) Chem Mater 19:4379

Pan X, Fan Z, Chen W, Ding Y, Luo H, Bao X (2007) Nat Mater 6:507

Castillejos E, Debouttiere P-J, Roiban L, Solhy A, Martinez V, Kihn Y, Ersen O, Philippot K, Chaudret B, Serp P (2009) Angew Chem Int Ed 48:2529

Serp P, Castillejos E (2010) ChemCatChem 2:41

Wu CD, Hu A, Zhang L, Lin WB (2005) J Am Chem Soc 127:8940

Mitsudome T, Nose K, Mori K, Mizugaki T, Ebitani K, Jitsukawa K, Kaneda K (2007) Angew Chem Int Ed 46:3288

Mandal S, Roy D, Chaudhari RV, Sastry M (2004) Chem Mater 16:3714

Vos DED, Dams M, Sels BF, Jacobs PA (2002) Chem Rev 102:3615

Webb JD, MacQuarrie S, McEleney K, Crudden CM (2007) J Catal 252:97

Zhi J, Song D, Li Z, Lei X, Hu A (2011) Chem Commun 47:10707

Hea C, Zhanga F, Yueb L, Shanga X, Chena J, Hao Z (2012) Appl Catal B 111–112:46

Huang J, Yin J, Chai W, Liang C, Shen J, Zhang F (2012) New J Chem 36:1378

Morèrea J, Tenorioa MJ, Torralvob MJ, Pandoa C, Renuncioa JAR, Cabãnasa A, Super J (2011) Fluids 56:213

Gu J-L, Shi J-L, You G-J, Xiong L-M, Qian S-X, Hua Z-L, Chen H-R (2005) Adv Mater 17:557

Hao X-Y, Zhang Y-Q, Wang J-W, Zhou W, Zhang C, Liu S (2006) Microporous and Mesoporous Materials 88:38

Crooks RM, Zhao M, Sun L, Chechik V, Yeung LK (2001) Acc Chem Res 34:181

Zhao SF, Zhou RX, Zheng XM (2004) J Mol Catal A: Chem 211:139

Zhou J, Zhou R, Mo L, Zhao S, Zheng X (2002) J Mol Catal A: Chem 178:289

Wang X, Chan JCC, Tseng Y-H, Cheng S (2006) Micro Meso Mater 95:57

Zhu H, Lee B, Dai S, Overbury SH (2003) Langmuir 19:3974

Levasseur B, Ebrahim AM, Bandosz TJ (2012) Langmuir 28:5703

Li C, Zhang Q, Wang Y, Wan H (2008) Catal Lett 120:126

Zhao D, Sun J, Li Q, Stucky GD (2000) Chem Mater 12:275

Zhao D, Feng J, Huo Q, Melosh N, Frederickson GH, Chmelka BF, Stucky GD (1998) Science 279:548

Mahata N, Vishwanathan V (2000) J Catal 196:262

Ali SH, Goodwin JG (1998) J Catal 176:3

Panpranot J, Pattamakomsan K, Goodwin JG, Praserthdam P (2004) Catal Commun 5:583

Anderson JR (1975) Structure of metallic catalysts. Academic, London

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquerol J, Siemieniewska T (1985) Pure Appl Chem 57:603

Nohair B, MacQuarrie S, Crudden CM, Kaliaguine S (2008) J Phys Chem C 112:6065

Zheng Z, Li H, Liu T, Cao R (2010) J Catal 270:268

Acknowledgments

This work was supported by the Fundamental Research Funds for the Central Universities, China. (Grant No. zyz2012057), Natural Science Foundation of Gan Su Province (Grant No. 0803RJZA008), China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, G., Wang, P. & Wei, X. Palladium Supported on Functionalized Mesoporous Silica as an Efficient Catalyst for Suzuki–Miyaura Coupling Reaction. Catal Lett 143, 1188–1194 (2013). https://doi.org/10.1007/s10562-013-1054-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-013-1054-y