Abstract

Photocatalytic bactericidal activity of TiO2, and supported over HY, Hβ, HZSM-5 and SiO2–Al2O3 systems were investigated by taking Escherichia coli as a water pathogenic bacterial pollutant indicator. TiO2 of 0.75 g/L was the optimum concentration for higher bactericidal activity. Among HY, Hβ, HZSM-5 and SiO2–Al2O3 supports, Hβ supported system showed highest bacterial adsorption. This may be due to high surface area of Hβ compared to others and its hydrophobic nature of zeolite that attracts the organic bacterial pollutants than the binary SiO2–Al2O3. Different loading of TiO2, ranging from 2 to 15 wt.% supported on Hβ zeolite samples are evaluated for dark adsorption measurements and photocatalytic bactericidal activity studies. Increasing the TiO2 percentages onto zeolite support resulted decrease of bacterial adsorption. It is observed that 5 wt.% of TiO2/Hβ system exhibited high photocatalytic bactericidal activity compared to other catalysts. This higher bactericidal activity over 5 wt.% of TiO2/Hβ in comparison with TiO2 alone is due to the greater adsorption of bacteria and optimum dispersion of TiO2 on Hβ zeolite facilitating higher OH• radical formation and attack of Escherichia coli bacteria.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

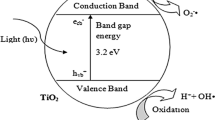

Application of photocatalysis as solution to the environmental problems has increased tremendously these days [1–3]. Presence of bacterial pathogens in wastewater and drinking water is one of the perennial problems. The disinfection of bacteria is a major challenge for environmentalists. Generally chlorine has been widely used for the treatment of water disinfection throughout the world. But chlorine when react with organic material will generate chloroorganic compounds which are highly carcinogenic [4, 5]. Titanium dioxide heterogeneous photocatalysis is found to be one of the technologies for disinfection of pathogenic bacteria present in drinking and wastewater systems. It is safe, nonhazardous and ecofriendly process, and does not produce any harmful products. Much research work was done in this area for photocatalytic removal of organic, inorganic and microbial pollutants [6, 7]. When TiO2 particles are exposed to UV irradiation there will be generation of electron hole pairs on metal oxide semiconductor. The valency band hole has a very positive reduction potential and is capable of oxidizing water, or hydroxide ions, to form hydroxyl radicals in water. Hydroxyl radicals are known to be powerful, indiscriminate oxidizing agents. Mechanism for the bactericidal action of TiO2 photocatalysis has been reported by Sunada et al. [8]. The combination of cell membrane damage and further oxidative attack of internal cellular components ultimately results in cell death [9, 10]. The photocatalytic efficiency of TiO2 is greatly influenced by crystal structure, particle size, surface area and porosity. One of the strategies to influence the photocatalytic efficiency is to increase the surface area of the catalyst. Thus forming TiO2 particles of high surface area, in thin film form will simplify the recovery of TiO2 from the treated water.

Titania immobilization on different supports like glass matrix, optical fibers, pumice stone and stainless steel plate were studied extensively [11–14]. Unfortunately photocatalytic efficiency of immobilized TiO2 is often less than the suspended TiO2 particles [15]. The photocatalyst when it is attached to the adsorbent, there is chance to improve the photocatalytic efficiency since the problem of encounter between the substrate and the photoactive site is reduced from three-dimensional to a two dimensional diffusion problem. This led to the large number of attempts to anchor TiO2 on porous materials of large particle size of silica gel, activated carbon, clay, sand, and zeolites [16–21]. Zeolites are crystalline aluminosilicates with regular dimension structure, channels and cavities called micropores. Generally these will have surface area in the range of 400–600 m2/g and with pore volumes of >0.1 cm3/g which are common in conventional zeolites [22]. Our recent approaches on the various supports [12–15], TiO2 and zeolite system are [19–21] providing different leads in which photocatalytic water treatment studies are involved and inferring titania supported zeolite systems are most suitable one for efficient treatment of water pollutants. These studies have been attempted with a view to increase the adsorption of organic pollutants on the catalyst surface, there by increasing the photocatalytic degradation rate. Generally the zeolite materials exhibit several kinds of properties like high photochemical stability, thermal and chemical inertness, and also opaque to pass the UV–VIS radiations so that they will reach the guests located in intraparticle positions. The adsorbed molecules in the zeolite cavities are influenced by the interaction of the active sites in the pores of the zeolites and thus changes will be induced in the molecular properties of adsorbate. High concentration of the substrate in the proximity of the photosensitiser contributing to the success of the photocatalytic process [22]. The zeolites also facilitate electron transfer processes either as electron acceptor or electron donor. Especially, TiO2 supported zeolite system facilitates decrease of electron-hole pair recombination by the transfer of excited electron of TiO2 to the active acidic sites of the support. Thus, the two important factors are adsorption of pollutant over zeolite system and increase in OH• radical generation by the transfer of electrons to acidic sites of zeolite system that play major role in TiO2-zeolite photocatalytic bactericidal efficiency. In this study we have chosen zeolites of HY, Hβ and HZSM-5 that are having different surface areas along with variable SiO2/Al2O3 ratios, resulting different density of acidic sites [23]. Also a binary SiO2–Al2O3 support is chosen for comparison. The adsorption of bacterial pathogens usually transpire on the perimeter of TiO2-zeolite supported systems due to the limitation in the size of zeolite cavities/channels and the size of bacterial pathogen (usually more or less 1 μm) [24]. The Escherichia coli (E. coli) is a popular bacterial pollutant indicator in water as its presence indicates the water is polluted with good number of pathogenic bacteria and its complete absence concludes there is no pathogenic bacteria and hence it is used as treatment efficiency indicator substrate [25]. This work reports the role of zeolite supports and their adsorbent capabilities for pathogens that are having different surface area and density of acidic sites which are naturally possessed by zeolites in comparison with binary SiO2–Al2O3. The efficiency of Hβ zeolite in enhancing the photocatalytic disinfection of E. coli compared to TiO2 and other supported samples.

2 Experimental

2.1 Materials

Titanium dioxide (P-25, 80% anatase and 20% rutile specific area 50 m2/g) was from Degussa Corporation. SiO2–Al2O3 (SiO2/Al2O3 = 18) is from Aldrich chemical and is represented as SA hereafter. HY (SiO2/Al2O3 = 4.4) from Conteka, Sweden. HZSM-5 (SiO2/Al2O3 = 30) is from PQ Corporation, USA, Hβ (SiO2/Al2O3 = 20) is from National Chemical Laboratory (NCL), India. Ethanol and sodium chloride are from Ranbaxy, India of analytical grade quality. Escherichia coli broth and E. coli agar is from Sigma-Aldrich. E. coli bacteria were supplied by Microbial Type Culture Collection (MTCC), Institute of Microbial Technology (IMTECH), Chandigarh, India. Sterile distilled water was used in all experimental studies.

2.2 Preparation of Catalysts

The TiO2 supported over zeolites (HY, Hβ and HZSM-5) and binary SiO2–Al2O3 (SA) catalytic systems were prepared by mixing respective supports with TiO2 in an agate mortar using dry ethanol. The catalysts were dried overnight in a hot air oven at 393 K and finally calcined at 673 K for 6 h.

2.3 Preparation of E. coli Culture

The E. coli was inoculated into fresh sterilized autoclaved E. coli broth of 10 mL in a 50 mL capacity conical flask from stock agar slants and grown overnight at 37 °C by constant agitation (100 rpm) under aerobic conditions. The bacteria was subcultured from 50 to 500 mL flask having 250 mL broth and incubated aerobically (37 °C, 100 rpm) upto getting a maximum OD of 0.8 at 600 nm. At exponential growth phase bacterial cells were collected by centrifugation at 4,000 rpm (10 min, 4 °C) and the bacterial pellet was washed three times with saline water (0.9% NaCl solution) in order to remove the culture media components. Finally the resulted pellet was resuspended in sterile saline water and diluted to cell density of 10−7 colony forming units per mL (CFU/mL) using sterile saline water. This culture solution was stored at 4 °C and used for further experiments in the entire study. The colony forming unit counts per mL were done with serial dilution and spread plate method using E. coli agar medium.

2.4 Photocatalytic Experimental Setup

The photocatalytic experimental setup was kept in laminar airflow hood after proper sterilization. It consists of a shaking unit with petriplates of capacity 50 mL, the catalyst and 25 mL of bacterial suspension was taken into each petriplate. The 250 W high-pressure mercury vapour bulb was provided as an illumination source from top, so that the radiation circumference will cover all the plates under study. An air-cooling fan was provided to reduce the temperature developed due to irradiation. The bacterial suspension with catalyst is kept under shaking at 50 rpm, for proper agitation at room temperature. The various combinate systems are TiO2 (2, 5, 10 and 15 wt.%) loaded Hβ and optimal TiO2 (5 wt.%) loaded HY, HZSM-5, SiO2–Al2O3 zeolite supported systems. Experiments for optimum catalyst amount required were carried out at room temperature and at pH of 6.5. All experiments were carried out for 280 min in dark and in UV light irradiation. Frequent samples of 0.1 mL was collected at 10 min interval time and inoculate into sterile 9 mL distilled water and was serially diluted and 0.1 mL of each dilution was inoculated into E. coli agar medium plates and spread the inoculum and kept for colony growth at 37 °C for 48 h. After 48 h duration the number of CFU/mL are noted.

2.5 Characterization of Catalysts

The BET-SA (Brunner Emmett Teller-Surface area) of TiO2, HY (4.4), HZSM-5 (30), Hβ (20) and SA (18) and TiO2 loaded supported systems were measured with Autochem-II 2920. The X-ray diffraction patterns of the fresh TiO2, Hβ and titania 2, 5, 10 and 15 wt.% supported on Hβ zeolite samples were obtained using Rigaku Miniflex diffractometer with Ni filtered Cu-Kα radiation in 2θ range 2–80°. Scanning Electron Microscopic (SEM) images were taken for bare TiO2, Hβ and 5 wt.% titania supported Hβ zeolite system, and also after 1 h dark period soaking in E. coli suspension and for the same after 1 h UV treatment using model JEOL-JSM 5600 at RUSKA lab, ANGRAU, Hyderabad, India. This facilitates to know the E. coli adsorption onto the catalyst TiO2, Hβ and TiO2 supported Hβ bactericidal activity interms of CFU/mL for comparision.

3 Results and Discussion

3.1 Escherichia coli Adsorption Studies

Escherichia coli adsorption studies were carried out initially for the selected zeolites of HY (4.4) HZSM-5 (30), Hβ (20) and over silica alumina SA (18) taking 0.75 g/L of catalyst support weight for all the preliminary studies. In case of HY and HZSM-5 zeolites it is observed that a maximum of 10% reduction in CFU/mL within 60 min and remains constant upto 280 min with continuous stirring in dark. In case of non zeolite silica alumina (SA) a maximum of only 6% reduction in CFU/mL is observed within 60 min and remains constant later. But, in case of Hβ zeolite a high amount of 20% reduction in CFU/mL of bacteria is observed within 60 min and remains constant upto 280 min (Fig. 1). This high amount of bacterial adsorption over Hβ is may be due to large surface area and fine dispersed silica alumina when compared with HY, HZSM-5 and silica alumina. (Fig. 1 and Table 1). As adsorption plays an important role in increasing the photocatalytic efficiency, further increase of TiO2 supported systems were carried with only Hβ zeolite support with different weight percent of TiO2 loadings. Thus E. coli adsorption studies were also carried for TiO2, Hβ and 2, 5, 10 and 15 weight percent of TiO2 loaded Hβ zeolite systems. In case of TiO2 samples no E. coli were adsorbed even after 280 min duration with continuous stirring in dark. On the other hand, with increasing percent content of titania, gradual decrease in adsorption of bacteria was observed, and there is no adsorption in case of 15 wt.% titania supported Hβ zeolite even after 120 min of the run (Fig. 2). This may be due to increase of titania content over zeolite that reduces the surface area of the catalyst system. The titania particles presumably might have covered most of the surface of zeolite and also aggregation of particles drastically decreases the surface area of zeolite for adsorption of bacteria and consequently the reduction of mechanical adsorption of bacteria that is observed. The increase in weight percent of TiO2 also causes aggregation of TiO2 particles which may lead to the decrease in the amount of photocatalytic active site distribution over zeolite surface. The increase in percent content of titania on zeolite is clearly observed in powder X-ray diffraction patterns as shown in Fig. 3c–f. The reflections appeared at 2θ of 25.4°, 37.8°, 48.0°, 53.9°, 55.0°, and 27.5°, 54.3°, 41.2°, 68.9° are representing anatase and rutile phases of titania (Fig. 3a) and the diffraction appeared at 5.4°, 22.4° and 27° are representing the phase of Hβ zeolite (Fig. 3b). From these pattern it is clearly observed that increase in percent content of titania there is an increase in peak intensities of reflections at 2θ = 25.4°, 48.0° and slight decrease in the reflections at 2θ = 5.4°, 22.4° in the Hβ zeolite phases (Fig. 3c–f). The SEM images for bare Fig. 4(a, b, c)1 and after 1 h dark period soaking Fig. 4(a, b, c)2 of TiO2, Hβ and 5 wt.% TiO2 loaded Hβ zeolite system in E. coli suspension were taken in order to observe the bacterial adsorption. The visual representation of the photographs shows that considerable adsorption of E. coli was there on bare Hβ and on 5 wt.% TiO2 loaded Hβ zeolite system, and no adsorption was observed on bare TiO2. From these visual photographs it is observed that Hβ zeolite is facilitating the considerable bacterial adsorption. Apart from these facts, the hydrophobic nature, regularly dispersed silica alumina with porous texture and high surface area of zeolites may be helping for attracting and adhering the superficially negative charged E. coli bacteria [26] thus obtaining more bacterial adsorption over Hβ zeolite.

3.2 Effect of Amount of TiO2

Figure 5 illustrates the survival number of E. coli CFU/mL with change of titania catalyst concentration from 0.1 to 1.5 g/L under UV irradiation with time. In dark experiment there is no change in number of CFU/mL. In control run (photolysis) UV irradiation showed considerable bactericidal activity and complete removal of bacteria was achieved after long period ca. 280 min. With increasing the titania concentration, the bactericidal activity is increased and at concentration of 0.75 g/L removal of 99% bacteria is observed within 40 min. Further increase in concentration to 0.75 g/L resulted a decrease in removal of bacteria and this may be due to increase of turbidity in solution which will reduce the penetration of UV irradiation and thus producing less number of OH• radicals in solution, that eventually leads to the decrease in bactericidal activity. Increase in catalyst amount would result in the deactivation of activated molecules due to collision with the ground state molecules and also aggregation of TiO2 will lower the effective surface area of the catalyst [7, 19]. From this it is concluded that TiO2 of 0.75 g/L is optimum for initial number of 107 CFU/mL bacterial concentrations. Similarly, experiments with different titania loadings of 2–15 wt.% supported over Hβ zeolite were carried out taking the total amount of catalyst as 0.75 g/L to nullify the turbidity effects.

3.3 Effect of TiO2 Loading on Hβ Zeolite for Photocatalytic Disinfection

Photocatalytic experiments were performed further with the high adsorbent support i.e. Hβ zeolite and with different percent TiO2 loaded Hβ zeolite systems to understand the effect of TiO2 loading on the supported system and to optimize the amount of TiO2 loading for maximum amount of E. coli removal. The observations depicted in Fig. 6 reveals that the bactericidal activity is higher with 5 wt.% TiO2 loading, in which 99 % removal of bacteria was obtained within 20 min. In case of 2 wt.% loading the bactericidal activity is less compared to 5 wt.% and it is due to insufficient number of titania dispersion over zeolite surface to get the sufficient amount of OH• radicals. Similarly for more than 5 wt.% of titania there is decrease in activity and this is due to over crowding of titania and in turn formation of agglomerates on zeolite surface which results a decrease in effective surface area of the catalyst. In view of this the excited titania particles may not be close to the zeolite surface and hence its conduction band electrons are not delocalised over zeolite [17–19, 22]. As a result there could be more electron hole recombination giving low degradation rate. Bactericidal activity with Hβ is slightly more when compared with photolysis. Furthermore, during UV radiation photolysis effect occurs over zeolite and there is adsorption of some bacteria, which also reduces the amount of bacteria in free liquid suspension resulting decrease in number of CFU/mL. The slight increase and decreasing tendency in bactericidal activity is attributed due to release of adsorbed bacteria into solution with increase in time. This could be explained due to the mechanical adsorption and desorption of bacteria on the Hβ zeolite. It is found that a titania loading of 5 wt.% supported on Hβ zeolite is more active towards bacterial killing compared to other catalyst systems used. It is also observed from visual photographs of SEM taken for Hβ zeolite alone Fig. 4(b)3 and 5 wt.% supported on Hβ zeolite Fig. 4(c)3 after 1 h UV exposure in E. coli suspension, that the adjacent photocatalytic oxidation/reduction of E. coli by TiO2 is responsible for complete removal of E. coli in case of 5 wt.% supported on Hβ zeolite system. Similarly in case of Hβ zeolite alone still bacterial markings were observed even after 1 h UV treatment no photocatalytic oxidation/reduction of bacteria takes place revealing as there is no TiO2 loading on Hβ usually there is no complete removal of E. coli. These interpretations also supporting the results obtained interms of CFU/mL in Fig. 6, where 99% bacterial removal was observed within 20 min for 5 wt.% TiO2 supported Hβ zeolite system whereas more than 250 min time was taken for completion in case of Hβ alone.

3.4 Comparison of Bactericidal Activity of TiO2 and Hβ Supported Photocatalysts

From Fig. 6 it is clearly indicated that 5 wt.% TiO2/Hβ zeolite system demonstrates highest bactericidal activity than TiO2 alone and TiO2 loaded Hβ zeolite catalysts. This observation leads to state that the dispersion of TiO2 over Hβ zeolite is playing major role. In 2 wt.% TiO2/Hβ system the amount of titania concentration is very less and hence less in dispersion which resulted less in bactericidal activity. Similarly increasing concentration of more than 5 wt.% of TiO2 makes over crowding of TiO2 particles on zeolite surface due to which excited particles may not be close to the zeolite surface and hence its conduction band electrons are not delocalised over zeolite. When compared to 5 wt.% TiO2/Hβ system the activity is less for TiO2 suspension and this may be due to high surface area of zeolite host material which will attract the charged bacterial cells and form mechanical immobilization thus allowing mass transfer of bacteria from surrounding solution to charged surfaces of the zeolite which will facilitate or enhances the possibility of attack of photogenerated active species on bacteria [22]. The optimum fine dispersion of TiO2 on Hβ zeolite avoids both the particle–particle aggregation and light scattering by TiO2, and it is found to be 5 wt.% TiO2/Hβ zeolite system as the optimum one in this present investigation compared to the other TiO2 loading systems. The titania loading on Hβ is crucial and the highest activity over 5 wt.% TiO2 is presumably due to more number of active sites that generate OH• which attacks the adjacent adsorbed bacterial cells. These OH• radicals oxidize the bacterial cell walls and cell membrane and finally cell lysis take place by release of inner cell contents that contains toxins like endotoxin etc. The released endotoxins may also be adsorbed in the micropores of the zeolite, where oxidation takes place by the photocatalyst. The SEM photographs taken for TiO2, Hβ and 5 wt.% titania supported Hβ Fig. 4(a, b, c)1 and after 1 h dark period soaking in E. coli suspension Fig. 4(a, b, c)2 clearly indicate the adsorption of the E. coli bacteria. The same samples after 1 h UV treatment in E. coli suspension Fig. 4(a, b, c)3 supporting the viewpoint of E. coli degradation. The inspection of the images Fig. 4(a, b, c)2 are indicating that there was no adsorption of E. coli on titania Fig. 4(a)2, whereas considerable adsorption of E. coli over Hβ and 5 wt.% titania supported Hβ zeolite system is seen Fig. 4(b, c)2. The images taken after 1 h UV treatment Fig. 4(a, b, c)3 shows that complete removal of E. coli on 5 wt.% titania loaded Hβ zeolite system Fig. 4(c)3 compared to Hβ alone Fig. 4(b)3 where slight marking of E. coli observed and the TiO2 surface Fig. 4(a)3 looks as it is a fresh one as there is no adsorption on it. These results are inferring that the zeolite particles are having capability for bacterial adsorption and thus increasing the availability of bacteria to the adjacent photocatalytic action of TiO2 especially more on 5 wt.% titania supported Hβ zeolite system. These observations from SEM photographs also supporting the data obtained in terms of CFU/mL (Fig. 7) where 99 % bacterial removal was observed in 20 min in case of 5 wt.% titania supported Hβ zeolite system and for the same percent removal in TiO2 suspension it has taken 60 min. Other supports HY, HZSM-5 and SiO2-Al2O3 loaded with the optimum TiO2 (5 wt.%) were compared with the 5 wt.% titania supported Hβ zeolite system for photocatalytic bactericidal activity carried out for 10 min. Table 1 shows that SiO2–Al2O3 showed less adsorption (6% bacterial (CFU/mL) removal) in dark than all other supports. So, naturally it showed less photocatalytic bactericidal activity of 20% bacterial (CFU/mL) removal with 5 wt.% TiO2/SiO2–Al2O3 than all other supported photocatalytic systems. When compared with HY, HZSM-5 even though binary SiO2–Al2O3 has little high surface area but the regular arrangement and fine distribution of silica alumina is due to difference in SiO2/Al2O3 ratio of HY, HZSM-5 and it may be the reason for considerable low adsorption (6%) over SiO2–Al2O3 than over HY, HZSM-5 (10 and 12% respectively) [23]. With 5 wt.% TiO2/Hβ zeolite system a high 40 % removal of bacteria (CFU/mL) within 10 min of the photocatalytic experiments compared to a low percent 28, 25 and 20 removals with 5 wt.% TiO2/HY, 5 wt.% TiO2/HZSM-5 and 5 wt.% TiO2/SiO2–Al2O3 catalysts respectively. TiO2 alone showed the lowest percent removal of 18 when compared to all other TiO2 supported systems. Thus overall high efficiency with 5 wt.% TiO2/Hβ zeolite system is may be due to the cumulative effect of high surface area of Hβ, optimal dispersion of TiO2. The transfer of excited electrons to the adjacent acidic sites over the surface of zeolite is due to prevention of electron hole pairs that occurs resulting the generation of high amount of OH• radicals and moderate acidic strength of Hβ compared to HY and HZSM-5 [23] supports. These supported photocatalytic systems also may completely oxidize the organic cell contents like endotoxins released into the aqueous suspensions by pooling over or into the pores of zeolite systems [25, 26]. Thus, the 5 wt.% TiO2/Hβ zeolite system is the efficient catalytic system to complete the removal of bacteria (CFU/mL) in aqueous suspensions within 20 min of UV exposure compared with the TiO2, and TiO2 supported HY, HZSM-5 and SiO2–Al2O3 systems (Fig. 8).

Comparative inactivation of E. coli (CFU/mL) at 0.75 g/L catalyst of different TiO2 loaded Hβ zeolite supported system. (◯) with only UV; (●) TiO2 without UV; (▼) TiO2 with UV; (•) Hβ without UV; (□) Hβ with UV and (Δ) 2, (▽) 5, (○) 10 and (◊) 15 wt% titania loaded Hβ zeolite supported system under UV illumination

4 Conclusions

The present investigation concludes that adsorption property of TiO2 supported on Hβ zeolite enhances the rate of photocatalytic bacterial killing of E. coli. The E. coli bacteria are adsorbed more onto the titania supported Hβ zeolite, and they are completely detoxified by photocatalytic reaction. Furthermore, 5 wt.% TiO2 loading over Hβ is sufficient to get higher bactericidal activity. It is observed that high surface area, moderate acidic strength and surface charges of Hβ zeolite system are may be the reasons for high mechanical adsorption of negative surface charged bacterial cells when compared to other selected supports and thus enhancing the bactericidal activity by concentrating bacterial cells for availability of photocatalytic activity of TiO2 generating OH• radicals. The scanning electron microscopic studies are also supporting the bacterial adsorption onto Hβ zeolite and bacterial cell oxidation by adjacent TiO2. The colony forming unit count reveals that for complete removal of bacteria TiO2 requires 40 min duration whereas Hβ supported titania requires only 20 min. Since supported Hβ system contains less amount of TiO2 it reduces the investment cost too. Hence the TiO2 supported on Hβ zeolite systems have good potential in complete removal of bacteria resulting detoxification of water.

References

Yogo K, Ishikawa M (2000) Catal Surv Japan 4:83

Blake DM, Maness PC, Huang Z, Wolfrum EJ, Huang J, Jacoby WA (1999) Sep Purif Methods 28:1

Ljubas D (2005) Energy 30:1699

Dunlop PSM, Byrne JA, Manga N, Eggins BR (2002) J Photochem Photobiol A: Chem 148:355

Kool HJ, Kreijl CF, Hrubec J (1985) In water chlorination: chemistry, environmental impact and health effects. Lewis publishers, Inc., Chelsia, MI

Fujishima A, Rao TN, Tryk DA (2000) J Photochem Photobiol C: Photochem Rev 1:1

Rinco´n AG, Pulgarin C (2005) Catal Today 101:331 and references therein

Sunada K, Watanabe T, Hashimoto K (2003) J Photochem Photobiol A: Chem 156:227

Haung Z, Maness PC, Blake DM, Wolfrum EJ, Smolinski SL, Jacoby WA (2000) J Photochem Photobiol A: Chem 130:163

Maness PC, Smolinski S, Blake DM, Huang Z, Wolfrum EJ, Jacoby WA (1999) Appl Environ Microbiol 65:4094

Xu Y, Zheng W, Liu W (1999) J Photochem Photobiol A: Chem 122:57

Rachel A, Subrahmanyam M, Boule P (2002) Appl Catal B: Environ 37:301

Subba Rao KV, Rachel A, Subrahmanyam M, Boule P (2003) Appl Catal B: Environ 46:77

Noorjahan M, Pratap Reddy M, Durga Kumari V, Lavédrine B, Boule P, Subrahmanyam M (2003) J Photochem Photobiol A: Chem 156:179

Subba Rao KV, Subrahmanyam M, Boule P (2004) Appl Catal B: Environ 49:239

Matos J, Laine J, Hermann JM (1998) Appl Catal B: Environ 18:281

Kasahara T, Inumaru K, Yamanaka S (2004) Micropor Mesopor Mater 76:123

Ding H, Sun H, Shan Y (2005) J Photochem Photobiol A: Chem 169:101

Durga Kumari V, Subrahmanyam M, Subba Rao KV, Ratnamala A, Noorjahan M, Tanaka K (2002) Appl Catal A: Gen 234:155

Noorjahan M, Durga Kumari V, Subrahmanyam M, Boule P (2004) Appl Catal B: Environ 47:209

Noorjahan M, Durga Kumari V, Subrahmanyam M, Panda L (2004) Appl Catal B: Environ 57:289

Corma A, Garcia H (2004) Chem Commun 13:1443

Čejka J, Bekkum HV, Corma A, Schüth F (2007) Studies in surface science and catalysis 168: Introduction to zeolite science and practice, 3rd revised edn, Elsevier, Oxford OX2 8DP, UK

Sakaguchi K, Matsui M, Mizukami F (2005) Appl Microbiol Biotechnol 67:306

Baker KH, Herson DS (1999) Water Environ Res 71:530

Noda Y, Kanemasa Y (1984) Physiol Chem Phys Med NMR 16:264

Makowski A, Wardas W (2001) Curr Top Biophy 25:19

Lu ZX, Zhou L, Zhang ZL, Shi WL, Xie ZX, Xie HY, Pong DW, Shen P (2003) Langmuir 19:8765

Acknowledgments

One of the authors M. P. R acknowledges CSIR-New Delhi for the award of senior research fellowship. The authors thank Dr. P. N. Sarma, Biochemical and Environmental Engineering Center (BEEC) for his support by extending his lab facilities. The authors also thank Dr. Naga Malleswari, RUSKA Lab, ANGRAU, Hyderabad, India for providing SEM analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pratap Reddy, M., Phil, H.H. & Subrahmanyam, M. Photocatalytic Disinfection of Escherichia coli over Titanium (IV) Oxide Supported on Hβ Zeolite. Catal Lett 123, 56–64 (2008). https://doi.org/10.1007/s10562-008-9393-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-008-9393-9