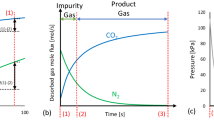

Based on the analysis of Dual Piston Pressure Swing Adsorption (DP-PSA) technology, in which only one adsorber is used, the possibility of a significant reduction in energy costs for gas mixture separation is been demonstrated. A mathematical model of a DP-PSA system for the separation of gas mixtures is described. Using this mathematical model, optimization of parameters of the DP-PSA system was carried out to produce oxygen from air. The concentration of production oxygen was chosen as the objective function. The optimized parameters were the phase shift angle of piston movement and the ratio of volumes displaced by the pistons. The optimum phase of piston movement in the cylinder filled with air is 51° ahead of the phase of piston movement in the cylinder filled with production oxygen. In this case, the concentration of oxygen at the outlet from the unit reaches 94.7 %. The optimal ratio of volumes displaced by the pistons turned out to be 1.0. The wave approach was used to analyze and calculate the periodic adsorption processes, as well as simulate DP-PSA systems.

Similar content being viewed by others

References

Pat. 4.354,854 USA. IPC B01D 53/04. “Enhanced gas separation by selective adsorption,” G. E. Keller and C. Y. A. Kuo (1982).

M. B. Kravchenko, “Wave approach to modeling pressure swing adsorption”, Tekhnicheskie Gazy, No. 5, 35–41 (2013).

M. B. Kravchenko, “Wave adsorption. Analytical description and analysis of processes”, Tekhnicheskie Gazy, No. 5, 49–59 (2011).

M. B. Kravchenko, “Wave adsorption. Effect of adsorbent grain size on pressure swing adsorption”, Kholodil’naya Tekhnika i Tekhnologiya, No. 3, 63–74 (2012).

M. B. Kravchenko, Wave Adsorption [in Russian], Lap. Lambert Academic Publishing, Saarbruecken (2014).

M. B. Kravchenko, “Wave mathematical model to describe gas chromatography,” Refrigeration Engineering and Technology, 53, No. 6, 24–34 (2017).

D. M. Ruthven, S. Farooq, and K. S. Knaebel, Pressure Swing Adsorption, VCH Publishers Inc., New York (1994).

M. Masoud and J. S. Ehsan, “Comparison of low pressure swing adsorption processes for air separation using Zeolite 5a and Zeolite 13x,” Petroleum & Coal, 55, No. 3, 216–225 (2013).

R. Arvind, S. Farooq, and D. M. Ruthven, “Analysis of a piston PSA process for air separation,” Chem. Eng. Sci., 57, No. 3, 419–433 (2002).

K. Singh and J. Jones, “Numerical simulation of air separation by piston-driven pressure swing adsorption,” Chem. Eng. Sci., 52, No. 18, 3133–3145 (1997).

S. Farooq, C. Thaeron, and D. M. Ruthven, “Numerical simulation of a parallel-passage piston-driven PSA unit,” Sep. Purif. Technol., 13, 181–193 (1998).

L. T. Biegler, L. Jiang, and V. G. Fox, “Recent advances in simulation and optimal design of pressure swing adsorption systems,” Sep. Purif. Technol., 33, 1–39 (2005).

W. Dang, D. Friedrich, and S. Brandani, “Characterisation of an automated Dual Piston Pressure Swing Adsorption (DPPSA) system,” Energy Proced., 37, 57–64 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 55, No. 4, pp. 20–24, April, 2019.

Rights and permissions

About this article

Cite this article

Kravchenko, M.B., Lavrenchenko, G.K. Effective Use of DP-PSA Gas Separation Technology. Chem Petrol Eng 55, 298–305 (2019). https://doi.org/10.1007/s10556-019-00618-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-019-00618-5