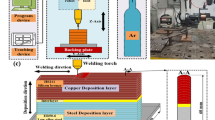

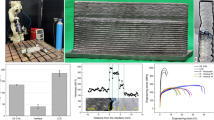

New technology and equipment developed from the results of research work are created for producing bimetallic wire. A feature of the new technology is production of bimetallic wire by passing a steel core through molten metal. This method of obtaining bimetallic wire is called “freezing” in publications, since the external appearance of the wire obtained is similar to a form crystallized metal. Results are provided for comprehensive studies, and recommendations are aimed at increasing the level of adhesion between a coating and a core by application a thin underlayer of non-ferrous metal (copper, brass, tin, etc.) to the core surface. Use of a rotating metal brush is proposed for coating formation, i.e., a flexible tool cladding (FTC) method.

Similar content being viewed by others

References

A. M. Yampol’skii, Copper and Nickel Plating [in Russian], Mashinostronenie, Moscow (1977).

D. A. Kharlov, V. I. Kadoshnikov, and M. V. Androsenko, “Effect of a surface layer on physicochemical and operating properties of machine components and assemblies,” Actual Problems of Contemporary Science, Proc. Internat. Sci.-Pract. Conf. (2014).

V. I. Kadoshnikov, K. N. Vdovin, and E. V. Kulikova, “Model for forming a skin coating on the surface of a core with passage through melt,” Vestn. Magntogorsk Gos. Univ, im. G. I. Nosova, No. 4(8), 10–14 (2004).

V. I. Kadoshnikov, K. N. Vdovin, and E. V. Kulikova, Design of a New Method for Preparing Steel-Copper Composite [in Russian], GOU VPO MGTU, Magnitogorsk (2006).

L. S. Belevskii, V. I. Kadoshnikov, R. R. Ismagilov, et al., “Improving the performance of metallic components by frictional plating,” Steel in Translation, 41, No. 2, 175–178 (2011).

Y. A. Pozhidaev and V. I. Kadoshnikov, “Damping-system design on the basis of electrochemical modules,” Russian Engineering Research, 32, No. 5–6, 478–481 (2012).

S. P. Nefedyev, R. R. Dema, S. A. Nefedyeva, and A. V. Yaroslavtsev, “Microstructure of cast iron after plasma bleaching,” J. Chemical Technology and Metallurgy, 50, No. 2, 213–216 (2015).

N. S. Tyuteryakov, R. R. Dema, and S. P. Nefedyev, “Simulation and calculation of temperature distribution in roll fittings’ guides in contact with the rolled strip,” Procedia Engineering, 150, 667–673 (2016).

A. N. Emelyushin, E. V. Petrochenko, and S. P. Nefed’ev, “Investigation of the structure and impact-abrasive wear resistance of coatings of the Fe–C–Cr–Mn–Si system, additionally alloyed with nitrogen,” Welding International, 27, No. 2, 150–153 (2013).

V. I. Kadoshnikov, V. P. Antsupov, R. R. Dema, and A. V. Antsupov, “Expansion of production possibilities of the cladding method with a flexible tool,” Vestn. Mashinostroeniya, No. 10, 64–66 (2003).

S. I. Platov, R. R. Dema, and A. V. Zotov, “Model for forming the thickness of a clad layer on components of a friction pair for production equipment,” Vestn. MGTU im. Nosova, No. 1, 69–72 (2013).

V. I. Kadoshnikov, E. V. Kulikova, M. V. Androsenko, et al., “Increasing the useful life of metallurgical equipment by applying coatings on contact surfaces,” Young Engineers–Basis of Scientific and Technical Progress, Proc. Int. Sci.-Tech. Conf. (2015).

Work was carried out with financial support of the RF Ministry of Education and Science for project No. 11.2054.2017/PCh within the scope of a state assignment for 2017–2019 (Number for publication: 11.2054.2017/4.6).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 55, No. 1, pp. 44–48, Januar, 2019.

Rights and permissions

About this article

Cite this article

Kadoshnikov, V.I., Kulikova, E.V., Dema, R.R. et al. Manufacturing Technology Improvement of Technology and Equipment for Preparing Steel-Copper Wire. Chem Petrol Eng 55, 76–83 (2019). https://doi.org/10.1007/s10556-019-00585-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-019-00585-x