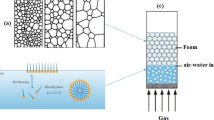

It is noted that with traditional foam casting under pressure technology the casting mold chamber formed during injection of molten polymer material (PM) is only partly filled with the mixture of melt and gas-former, but total filling of the chamber occurs during melt foaming. In this stage, the pressure of the forming gas governs the magnitude of the internal pressure in the casting mold. It is demonstrated that due to the relatively low pressure and bubble formation during mold filling it is impossible to obtain a component with a high quality surface. In order to avoid this disadvantage, the following are developed: “breathing” casting molds; a method using a gas counterpressure in the mold; special coatings for forming the casting mold surface, reducing temperature oscillation and smoothing of the component microrelief of a component made of PM; a Variotherm method, based on controlling mold temperature.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 10, pp. 45–47, October, 2008.

Rights and permissions

About this article

Cite this article

Ivanov, S.P., Abakacheva, E.M., Boev, E.V. et al. Methods of improving the quality of foam casting components. Chem Petrol Eng 44, 604–607 (2008). https://doi.org/10.1007/s10556-008-9106-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-008-9106-7