Abstract

Objective

To investigate the inhibiting effect of formic acid on acetone/butanol/ethanol (ABE) fermentation and explain the mechanism of the alleviation in the inhibiting effect under CaCO3 supplementation condition.

Results

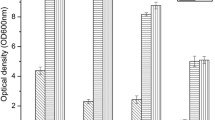

From the medium containing 50 g sugars l−1 and 0.5 g formic acid l−1, only 0.75 g ABE l−1 was produced when pH was adjusted by KOH and fermentation ended prematurely before the transformation from acidogenesis to solventogenesis. In contrast, 11.4 g ABE l−1 was produced when pH was adjusted by 4 g CaCO3 l−1. The beneficial effect can be ascribed to the buffering capacity of CaCO3. Comparative analysis results showed that the undissociated formic acid concentration and acid production coupled with ATP and NADH was affected by the pH buffering capacity of CaCO3. Four millimole undissociated formic acid was the threshold at which the transformation to solventogenesis occurred.

Conclusion

The inhibiting effect of formic acid on ABE fermentation can be alleviated by CaCO3 supplementation due to its buffering capacity.

Similar content being viewed by others

References

Baral NR, Li J, Jha AK (2014) Perspective and prospective of pretreatment of corn straw for butanol production. Appl Biochem Biotechnol 172:840–853

Calusinska M, Happe T, Joris B, Wilmotte A (2010) The surprising diversity of clostridial hydrogenases: a comparative genomic perspective. Microbiology 156:1575–1588

Cho DH, Shin S-J, Kim YH (2012) Effects of acetic and formic acid on ABE production by Clostridium acetobutylicum and Clostridium beijerinckii. Biotechnol Bioprocess Eng 17:270–275

Desai RP, Nielsen LK, Papoutsakis ET (1999) Stoichiometric modeling of Clostridium acetobutylicum fermentations with non-linear constraints. J Biotechnol 71:191–205

Ezeji T, Qureshi N, Blaschek HP (2007a) Butanol production from agricultural residues: impact of degradation products on Clostridium beijerinckii growth and butanol fermentation. Biotechnol Bioeng 97:1460–1469

Ezeji TC, Qureshi N, Blaschek HP (2007b) Bioproduction of butanol from biomass: from genes to bioreactors. Curr Opin Biotechnol 18:220–227

Gottwald M, Gottschalk G (1985) The internal pH of Clostridium acetobutylicum and its effect on the shift from acid to solvent formation. Arch Microbiol 143:42–46

Hendriks A, Zeeman G (2009) Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour Technol 100:10–18

Jang Y-S, Malaviya A, Cho C, Lee J, Lee SY (2012) Butanol production from renewable biomass by clostridia. Bioresour Technol 123:653–663

Jones DT, Woods DR (1986) Acetone–butanol fermentation revisited. Microbiol Rev 50:484

Jönsson LJ, Alriksson B, Nilvebrant N-O (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6:1

Liu C-G, Xue C, Lin Y-H, Bai F-W (2013) Redox potential control and applications in microaerobic and anaerobic fermentations. Biotechnol Adv 31:257–265

Maddox I, Steiner E, Hirsch S, Wessner S, Gutierrez N, Gapes J, Schuster K (2000) The cause of “acid crash” and “acidogenic fermentations” during the batch acetone–butanol–ethanol (ABE) fermentation process. J Mol Microb Biotechnol 2:95–100

Palmqvist E, Hahn-Hägerdal B (2000a) Fermentation of lignocellulosic hydrolysates. I: Inhibition and detoxification. Bioresour Technol 74:17–24

Palmqvist E, Hahn-Hägerdal B (2000b) Fermentation of lignocellulosic hydrolysates. II: Inhibitors and mechanisms of inhibition. Bioresour Technol 74:25–33

Qi G-X, Xiong L, Huang C, Chen X-F, Lin X-Q, Chen X-D (2015) Solvents production from a mixture of glucose and xylose by mixed fermentation of Clostridium acetobutylicum and Saccharomyces cerevisiae. Appl Biochem Biotechnol 177:996–1002

Qureshi N, Saha BC, Cotta MA (2007) Butanol production from wheat straw hydrolysate using Clostridium beijerinckii. Biotechnol Bioprocess Eng 30:419–427

Ren C, Gu Y, Hu S, Wu Y, Wang P, Yang Y, Yang C, Yang S, Jiang W (2010) Identification and inactivation of pleiotropic regulator CcpA to eliminate glucose repression of xylose utilization in Clostridium acetobutylicum. Metab Eng 12:446–454

Wang S, Zhang Y, Dong H, Mao S, Zhu Y, Wang R, Luan G, Li Y (2011) Formic acid triggers the “acid crash” of acetone/butanol/ethanol fermentation by Clostridium acetobutylicum. Appl Environ Microb 77:1674–1680

Acknowledgments

This work was supported by National Natural Science Foundation of China (51378486, 51508547, 21606229, 31600475), the Science and Technology Project of Huaian (HAS2015035), Natural Science Foundation of Guangdong Province, China (2016A030310124), the Science and Technology Planning Project of Guangdong Province, China (2016A010104009, 2016A010105016), Youth Innovation Promotion Association CAS (2015290).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qi, G., Xiong, L., Lin, X. et al. CaCO3 supplementation alleviates the inhibition of formic acid on acetone/butanol/ethanol fermentation by Clostridium acetobutylicum . Biotechnol Lett 39, 97–104 (2017). https://doi.org/10.1007/s10529-016-2231-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-016-2231-z